Reliable Performance in Long-Part Turning

When machining long components like shafts or rollers, tool deflection and part vibration are common issues. ALPHA’s flat bed CNC lathe addresses these with a wide-bed structure, advanced damping characteristics, and precision control, ensuring consistent roundness and surface quality.

Extended Z-Axis Travel and Tailstock Support

The long Z-axis travel range allows uninterrupted turning without repositioning the part. ALPHA machines include programmable tailstock options that automatically follow the tool carriage, improving support and reducing manual setup.

Reinforced Bed Casting and Drive System

To prevent thermal distortion and maintain long-term geometric stability, the bed is thermally balanced and vibration-resistant. The axis drive system features precision ball screws, powerful servo motors, and backlash compensation—ensuring micron-level repeatability across the full machining range.

Tooling System Adapted for Rough and Finish Cuts

The turret system is optimized to handle both roughing and finishing tools. Heavy-duty boring bars and threading tools can be used without chatter, while finer inserts can complete high-tolerance finishes in a single setup.

Customization and Industry Integration

Customers can configure:

-

Bed length and swing over bed

-

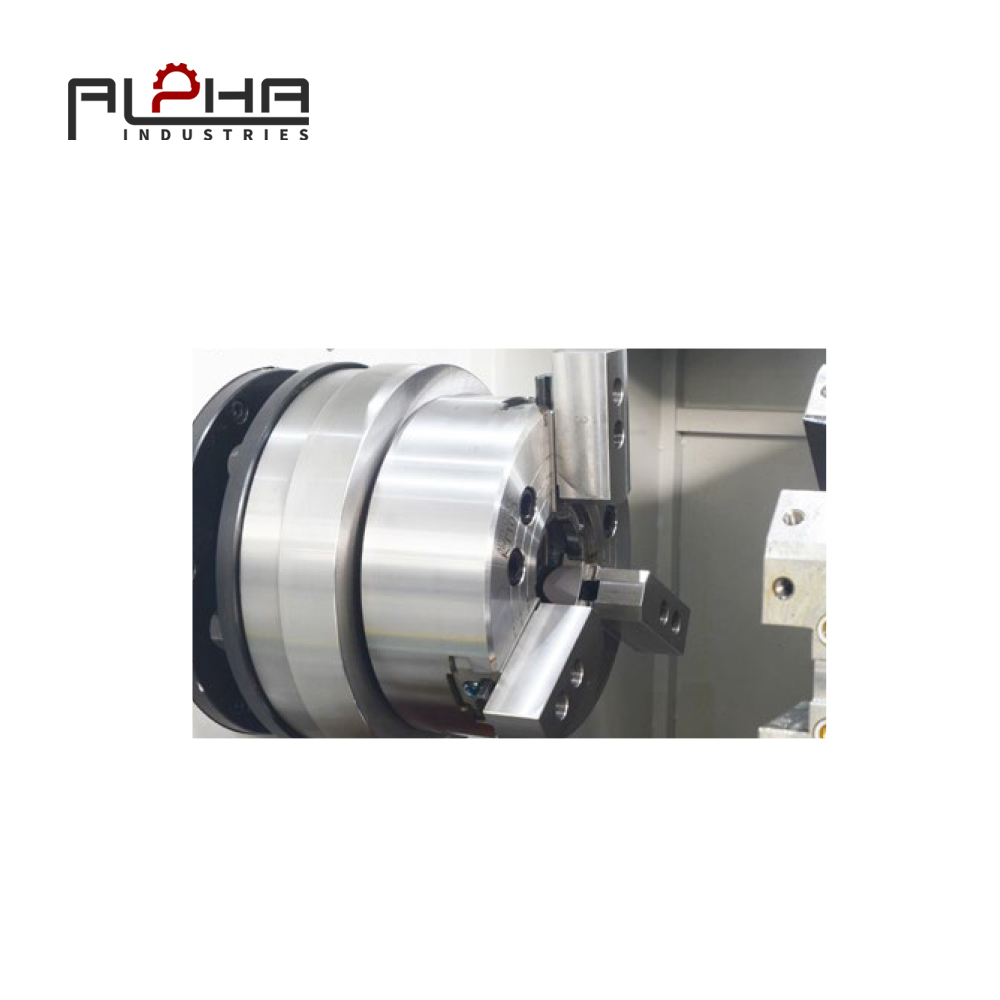

Spindle bore diameter

-

Chuck type and tailstock stroke

-

Hydraulic system and lubrication package

-

CNC controller type (based on regional preference)

These machines are commonly used in:

-

Oil & gas pipe threading

-

Steel roller finishing

-

Electric motor shaft production

-

Mining and mechanical component repairs

Frequently Asked Questions (People Also Ask)

What makes a flat bed lathe suitable for shaft machining?

Its long travel, wide guideways, and strong tailstock ensure minimal bending and high axial precision in shaft work.

Can a flat bed CNC lathe perform both threading and boring?

Yes. With appropriate tooling and control parameters, both operations can be integrated in a single cycle.

Is vibration a concern with long shafts on flat beds?

Not with proper setup. ALPHA machines include damped guideways and support options like steady rests to reduce vibration.

What spindle bore sizes are available?

Various configurations from standard to large bore are available to accommodate thick shafts or pipe feed-through.

How accurate are these machines in mass production?

With servo positioning and compensation features, ALPHA flat bed lathes maintain consistent tolerances over large batches.