Overview of CNC Lathe Flat Type

A CNC Lathe Flat Type is designed for robust and accurate turning of metal workpieces, featuring a horizontal flat bed layout that provides superior rigidity and support for heavy components. Unlike slant bed lathes, the flat bed configuration offers enhanced structural stability, particularly suitable for large-diameter parts, steel shafts, and heavy mechanical components.

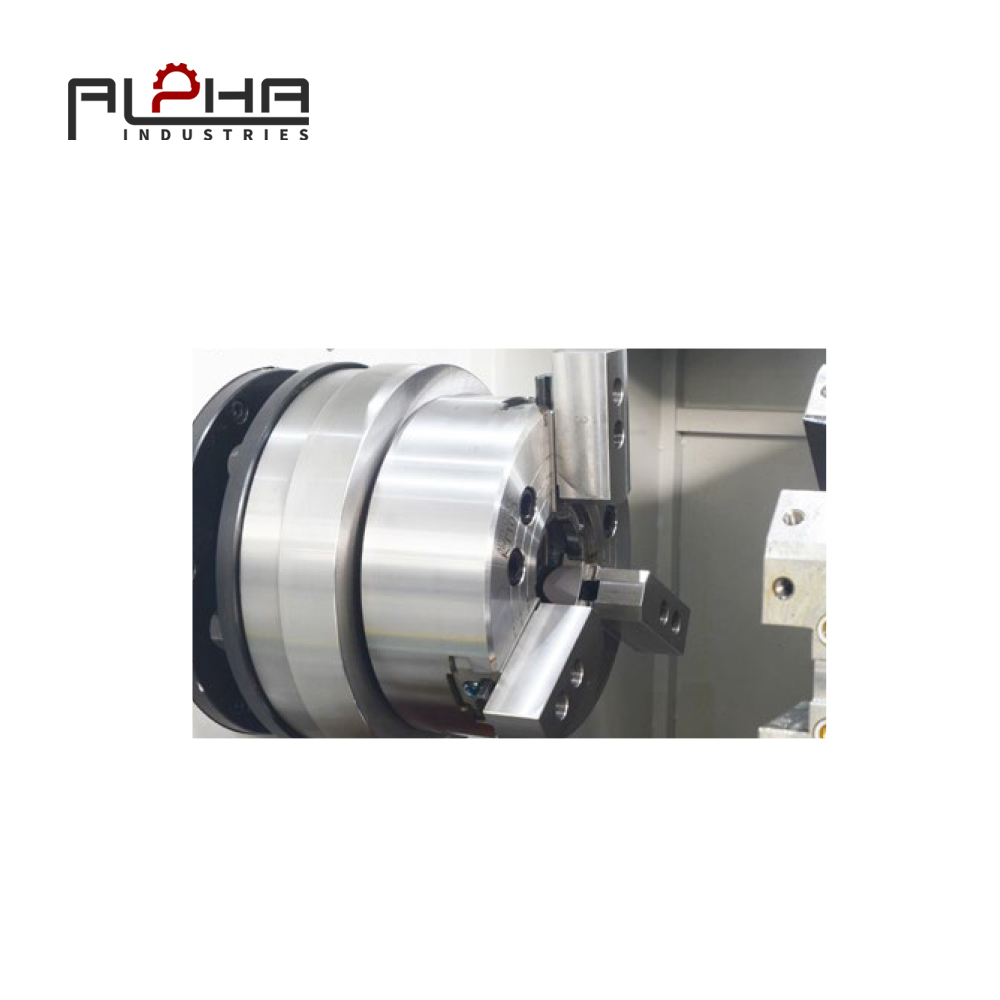

Alpha’s CNC Lathe Flat series integrates advanced spindle systems, reinforced casting design, and precision feed drives to deliver long-term accuracy and reduced vibration during high-load cutting.

Why Bed Structure Matters in Flat Type CNC Lathe

The machine bed is the foundation of any CNC lathe — it determines rigidity, vibration resistance, and overall machining quality.

In flat-type configurations, the bed carries the entire weight of the carriage, tailstock, and workpiece, making its structure critical for maintaining geometric precision.

A weak or poorly designed bed can cause:

-

Spindle misalignment under load

-

Vibration-induced tool wear

-

Deviation in roundness and surface roughness

That’s why Alpha engineers focused on FEM (Finite Element Method) analysis to optimize the flat bed’s mechanical stiffness and heat dissipation.

Alpha’s High-Rigidity Bed Design

(1) One-Piece Casting

The bed of Alpha CNC Lathe Flat is cast from high-grade Meehanite iron (HT300) in a single-piece structure. This eliminates joint deformation and ensures consistent rigidity throughout the machine’s lifetime.

(2) Box-Type Rib Reinforcement

The internal structure adopts a box-type rib layout, strategically placed under the carriage rail section. This absorbs vibration energy generated during heavy-duty turning and prevents bed distortion.

(3) Wide Guide Rail Design

The ultra-wide slideways are induction-hardened and precision ground, providing smoother motion for the carriage and tool post, ensuring consistent feed accuracy under full load.

(4) Stress-Relief Heat Treatment

Before machining, each bed undergoes two-stage aging treatment to eliminate internal stresses caused by casting and rough machining, guaranteeing long-term dimensional stability.

Performance Benefits of Alpha CNC Lathe Flat

Superior Machining Accuracy

The rigid base prevents deformation even during deep cutting, ensuring turning accuracy up to ±0.002 mm.

Extended Tool Life

Stable structure minimizes vibration, reducing insert wear and improving cutting edge retention.

High Stability Under Heavy Load

With a low gravity center and wide-span bedway, the machine supports continuous cutting of large steel parts up to 1000 mm diameter.

Reduced Maintenance

The one-piece casting and hardened rail design minimize alignment adjustments and mechanical wear over years of operation.

Comparison: Flat vs. Slant Bed CNC Lathe

| Feature | Flat Bed CNC Lathe | Slant Bed CNC Lathe |

|---|---|---|

| Rigidity | High (for heavy-duty cutting) | Moderate |

| Cutting Load Capacity | Excellent | Good |

| Chip Flow | Manual or conveyor-assisted | Gravity-assisted |

| Maintenance | Easy access | Compact but complex |

| Cost Efficiency | Lower investment | Higher precision cost |

For operators focusing on large workpieces, strong cutting forces, and long-term durability, the flat bed CNC lathe remains the best industrial choice.

Application Industries

Alpha CNC Lathe Flat type is widely adopted in:

-

Automotive Shaft Manufacturing

-

Oil and Gas Equipment Components

-

Railway Axles and Couplers

-

Heavy Machinery Parts

-

Shipbuilding Components

Its ability to maintain high rigidity and precision under tough cutting conditions makes it ideal for mass production and continuous operation environments.

Maintenance Recommendations

To maintain long-term accuracy and bed rigidity:

-

Clean slideways daily and apply protective oil film.

-

Check leveling bolts monthly to avoid torsional deformation.

-

Perform realignment every 12 months using laser calibration tools.

-

Replace coolant regularly to prevent rust and bed corrosion.

Why Choose Alpha CNC Lathe Flat

-

Heavy-duty, precision-ground bed with long life cycle

-

Enhanced vibration absorption for stable cutting

-

Customizable chuck and spindle configurations

-

Integrated chip removal and coolant filtration

-

Reliable global support and spare parts supply

Alpha’s engineering philosophy: Build machines that last longer, cut stronger, and run smarter.

FAQ

Q1: What is a CNC Lathe Flat type machine?

A1: It’s a flat-bed CNC lathe designed for heavy-duty metal turning with high rigidity and accuracy, ideal for large-diameter parts.

Q2: How does a rigid bed improve machining quality?

A2: A stronger bed structure absorbs vibration and maintains alignment, ensuring precise cutting results over long production cycles.

Q3: What materials can be processed on a CNC Lathe Flat?

A3: Steel, stainless steel, cast iron, aluminum, and other non-ferrous materials.

Q4: What are the advantages of Alpha’s CNC Lathe Flat?

A4: One-piece casting, FEM-optimized rigidity, wide guide rails, and customizable automation solutions.

Call to Action

Boost your production accuracy with Alpha’s CNC Lathe Flat Type.

Experience unmatched rigidity, precision, and durability in every cut.

Visit https://alpha-cnc.com to learn more.