Hydraulic Synchronization System in Press Brake for Ultra-Precision Metal Bending

In modern sheet metal fabrication, press brake bending accuracy is primarily determined by the hydraulic synchronization system. As the core control mechanism of ram movement, the synchronization system directly affects bending angle consistency, repeatability, and long-term machine stability.

At Alpha, we design industrial press brakes with high-response hydraulic synchronization technology to guarantee micron-level parallelism and consistent bending quality across long workpiece lengths.

This article provides a deep technical analysis of hydraulic synchronization in press brake machines, explaining how it enhances precision, load balancing, and structural reliability in heavy-duty bending operations.

What Is a Hydraulic Synchronization System in a Press Brake?

A hydraulic synchronization system is the mechanism that ensures both sides of the press brake ram move perfectly in parallel during bending. It consists of:

-

Dual hydraulic cylinders

-

High-response proportional valves

-

Precision linear scales or displacement sensors

-

Closed-loop control unit

-

Pressure feedback and flow compensation modules

Its main function is to prevent ram twisting, angular deviation, and uneven force distribution, especially when bending long or thick metal sheets.

Why Hydraulic Synchronization Determines Press Brake Accuracy

Ram Parallelism Control

If the left and right hydraulic cylinders are not synchronized, the ram will tilt, causing:

-

Inconsistent bend angles

-

Uneven material stress

-

Premature tool wear

With hydraulic synchronization, the parallelism error is controlled within ±0.01 mm/m, ensuring uniform bending along the full working length.

Precision in Long Workpiece Bending

For press brakes above 3–6 meters, mechanical synchronization is insufficient. Hydraulic synchronization compensates in real time for:

-

Oil temperature fluctuation

-

Load imbalance

-

Elastic deformation of the frame

This is critical for industries requiring high straightness such as elevator panels, enclosures, and shipbuilding components.

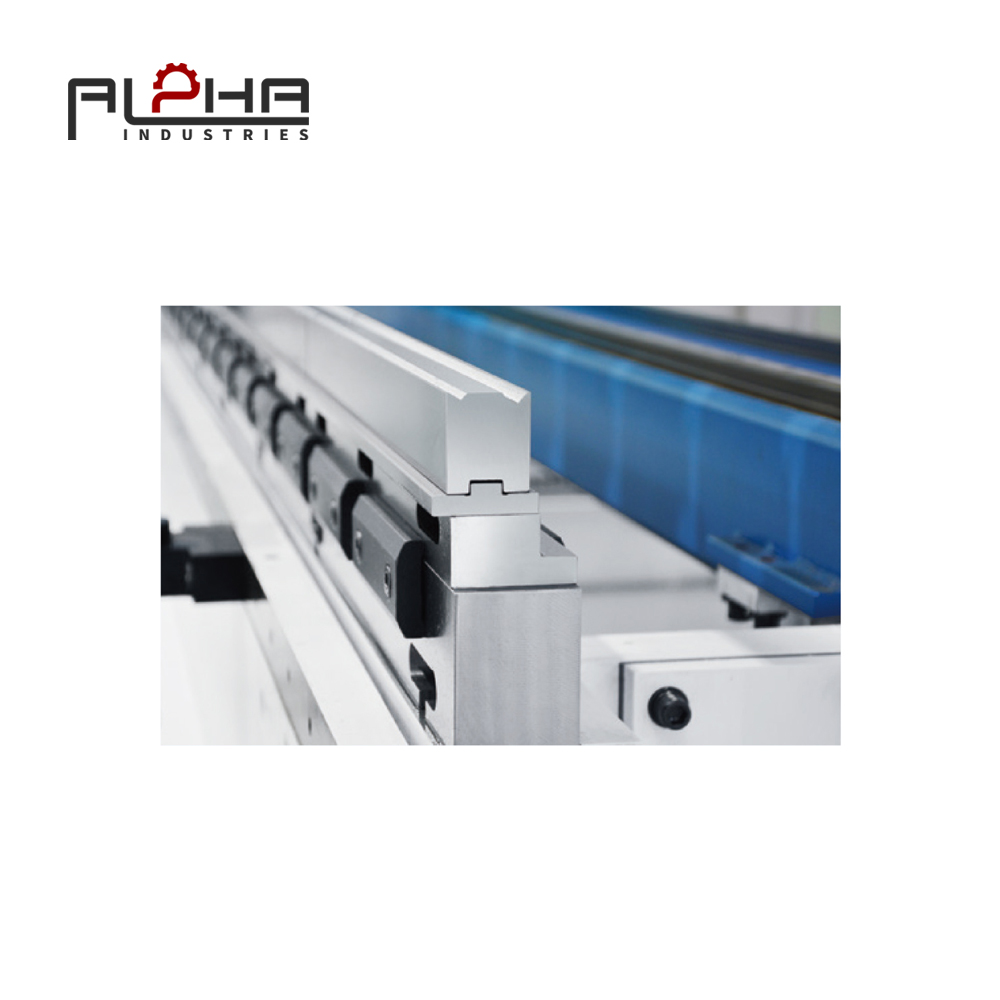

Structural Design of Alpha Hydraulic Synchronization Press Brake

Dual Independent Cylinder Architecture

Alpha press brakes use two fully independent hydraulic cylinders, each controlled by a proportional servo valve. The advantage is:

-

Independent oil flow adjustment

-

Instant deviation compensation

-

Stable force distribution under eccentric loads

High-Rigidity Frame for Synchronization Stability

Synchronization accuracy also depends on machine stiffness. Alpha adopts:

-

Q345B welded steel frames

-

Full stress relief heat treatment

-

Finite element structural optimization

This prevents frame distortion from affecting hydraulic accuracy.

Closed-Loop Control Technology in Hydraulic Press Brakes

Alpha hydraulic press brakes operate under a fully closed-loop electro-hydraulic control system:

-

Linear scale monitors real-time ram position

-

Sensor sends displacement data to controller

-

Controller adjusts proportional valves instantly

-

Hydraulic output is corrected within milliseconds

This enables:

-

High repeatability

-

Fast response at high bending speeds

-

Stable performance during continuous production shifts

Load Compensation and Anti-Eccentric Bending Technology

In real production, sheets are rarely centered. Eccentric loading can cause:

-

Cylinder pressure imbalance

-

Ram torsion

-

Angle deviation across the workpiece

Alpha press brakes use:

-

Active load detection

-

Automatic pressure redistribution

-

Dynamic ram torsion correction

This ensures accurate bending even under unbalanced load conditions, which is essential in cabinet manufacturing and structural steel components.

Hydraulic Oil Control and Thermal Stability

Hydraulic performance is highly sensitive to oil temperature and purity. Alpha integrates:

-

Multi-stage oil filtration system

-

Automatic temperature compensation

-

Independent oil cooling circulation

-

Pressure fluctuation damping modules

This keeps the system:

-

Thermally stable

-

Free from micro-pollutant blockage

-

Consistent in long-hour operation

As a result, the bending angle deviation over a full production shift remains under ±0.3°.

Synchronization System vs Mechanical Synchronization in Press Brakes

| Feature | Hydraulic Synchronization | Mechanical Synchronization |

|---|---|---|

| Accuracy | Ultra-high | Medium |

| Load compensation | Automatic | Limited |

| Long machine support | Excellent | Restricted |

| Maintenance | Low | High |

| Real-time correction | Yes | No |

For modern industrial press brake applications, hydraulic synchronization is now the mainstream solution.

Application Industries Requiring High Synchronization Accuracy

Hydraulic synchronized press brakes are essential in:

-

Elevator sheet metal systems

-

Electrical enclosure fabrication

-

Automotive body structure

-

Aerospace aluminum components

-

Steel structure and bridge supports

In these industries, angle uniformity across long bending lengths directly determines assembly precision and product appearance quality.

How Alpha Ensures Synchronization Precision in Every Press Brake

Each Alpha press brake undergoes:

-

Hydraulic cylinder alignment calibration

-

Linear scale parallelism verification

-

Proportional valve flow consistency testing

-

Full-load eccentric bending simulation

-

48–72 hour continuous synchronization stability test

Only machines that meet industrial-grade synchronization tolerance are released for shipment.

FAQ

Q1: What system controls the accuracy of a hydraulic press brake?

The hydraulic synchronization system combined with linear scale feedback controls the real-time accuracy of the ram.

Q2: Why is synchronization important in long press brakes?

It prevents ram twisting and angle deviation, ensuring uniform bends across large sheet widths.

Q3: Can hydraulic synchronization compensate for eccentric loading?

Yes. Advanced hydraulic press brakes automatically redistribute pressure and correct ram deviation during off-center bending.

Q4: Does hydraulic synchronization reduce tool wear?

Yes. Balanced loading minimizes die edge stress and punch misalignment, significantly extending tool life.

-

View our Vertical Machining Center for Precision Milling

-

Explore our Industrial Lathe Machines for Shaft Turning

-

Discover our Heavy-Duty Hydraulic Guillotine Shear

-

Browse the full range of Metal Processing Machinery by Alpha