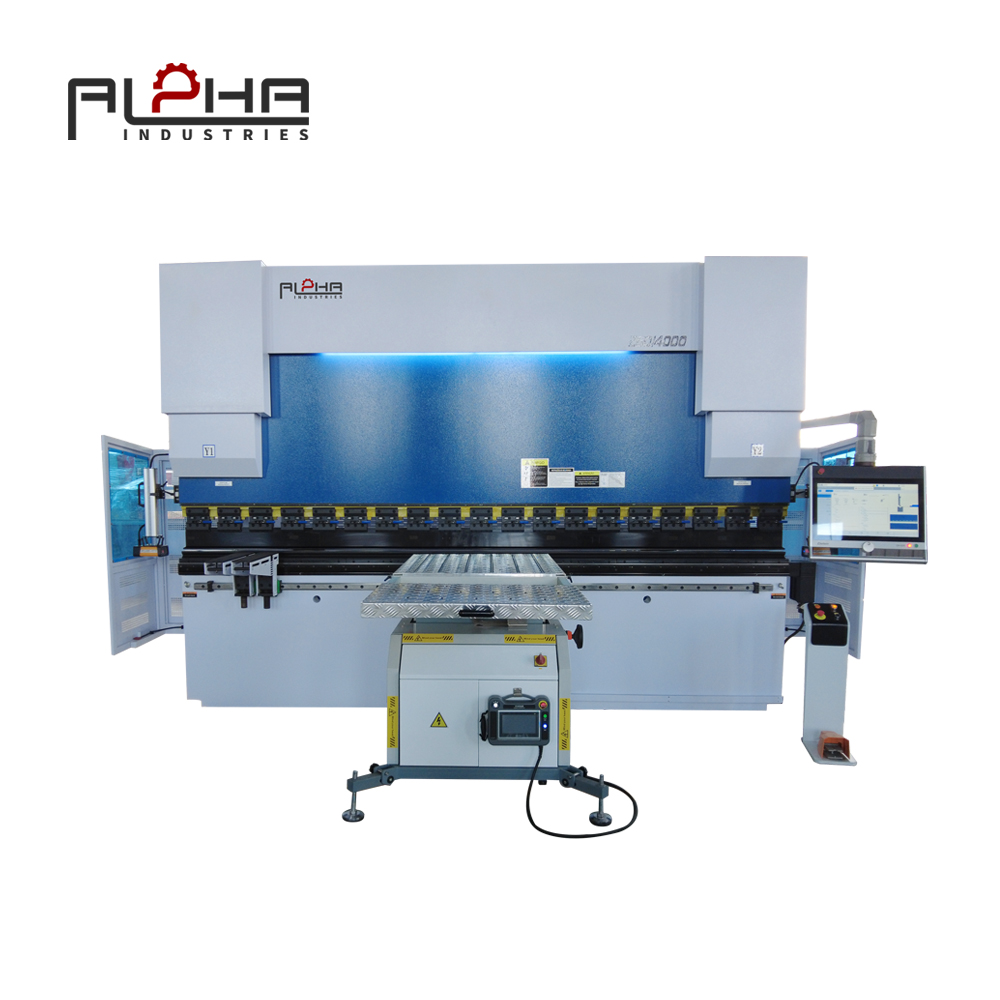

CNC Press Brake – Mastering Precision Bending Accuracy

A CNC Press Brake is not only a bending machine; it’s the core technology that defines the dimensional precision of modern sheet metal fabrication. For industries that demand exact geometry — such as aerospace, automotive, and energy — bending accuracy determines the overall quality and structural integrity of the final product.

At ALPHA, our CNC Press Brake systems are engineered with advanced motion control, adaptive compensation, and real-time hydraulic synchronization to achieve micron-level repeatability and accuracy in every bend.

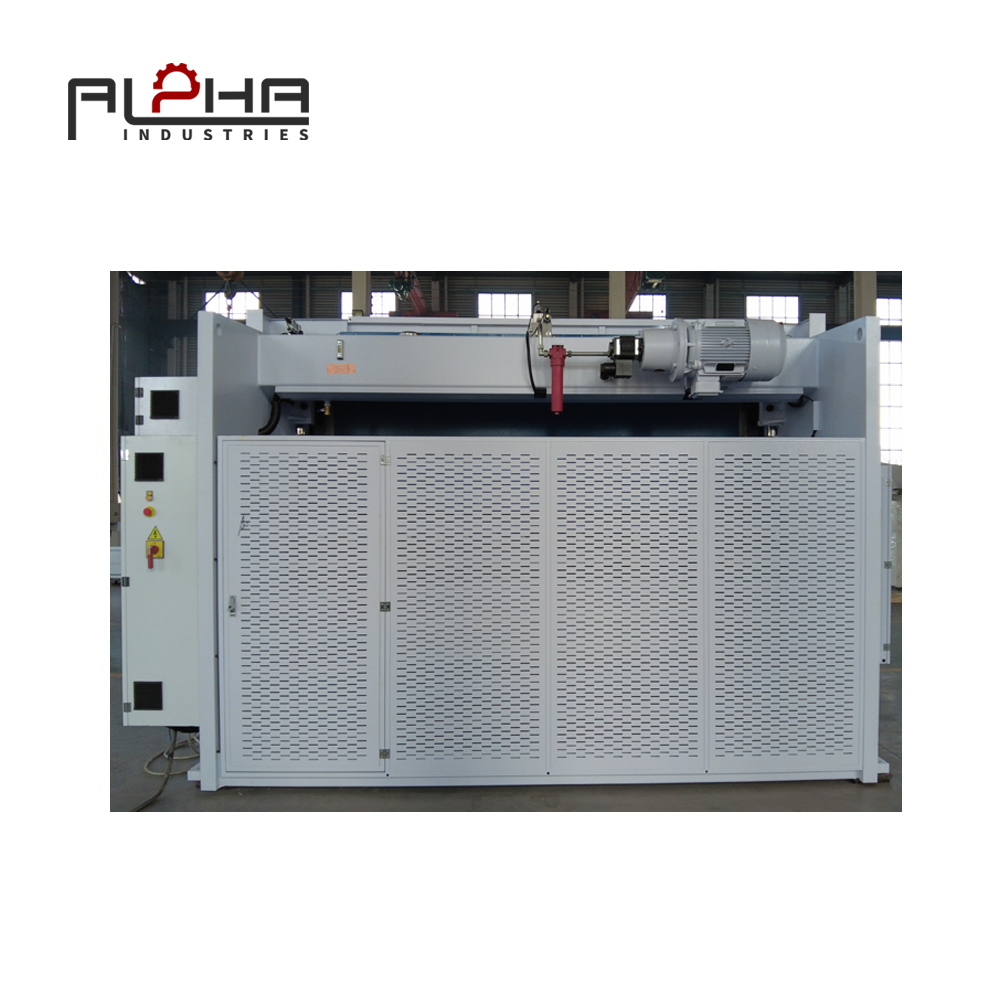

The Role of Frame Rigidity in Bending Precision

The foundation of any high-performance press brake is its machine frame. ALPHA designs each CNC Press Brake using finite element analysis (FEA) to optimize structural rigidity.

-

The monoblock welded steel frame minimizes deflection even under full tonnage load.

-

Stress-relieved casting ensures long-term dimensional stability.

-

Linear deformation between the upper and lower beams is kept below 0.02 mm.

This rigid mechanical base provides the stability necessary for precision bending across the full working length of the machine.

Servo-Hydraulic Synchronization for Real-Time Bending Control

The key to achieving perfect bending angles lies in synchronization accuracy. ALPHA’s CNC Press Brake integrates a servo-hydraulic system where each cylinder’s position is constantly monitored by high-resolution linear scales.

-

Closed-loop control: The controller adjusts ram movement within milliseconds.

-

High-speed response valves: Maintain consistent pressure during bending.

-

Real-time feedback: Ensures both sides of the ram remain parallel at all times.

This advanced servo-hydraulic synchronization results in consistent bending angles and eliminates human error caused by manual adjustments.

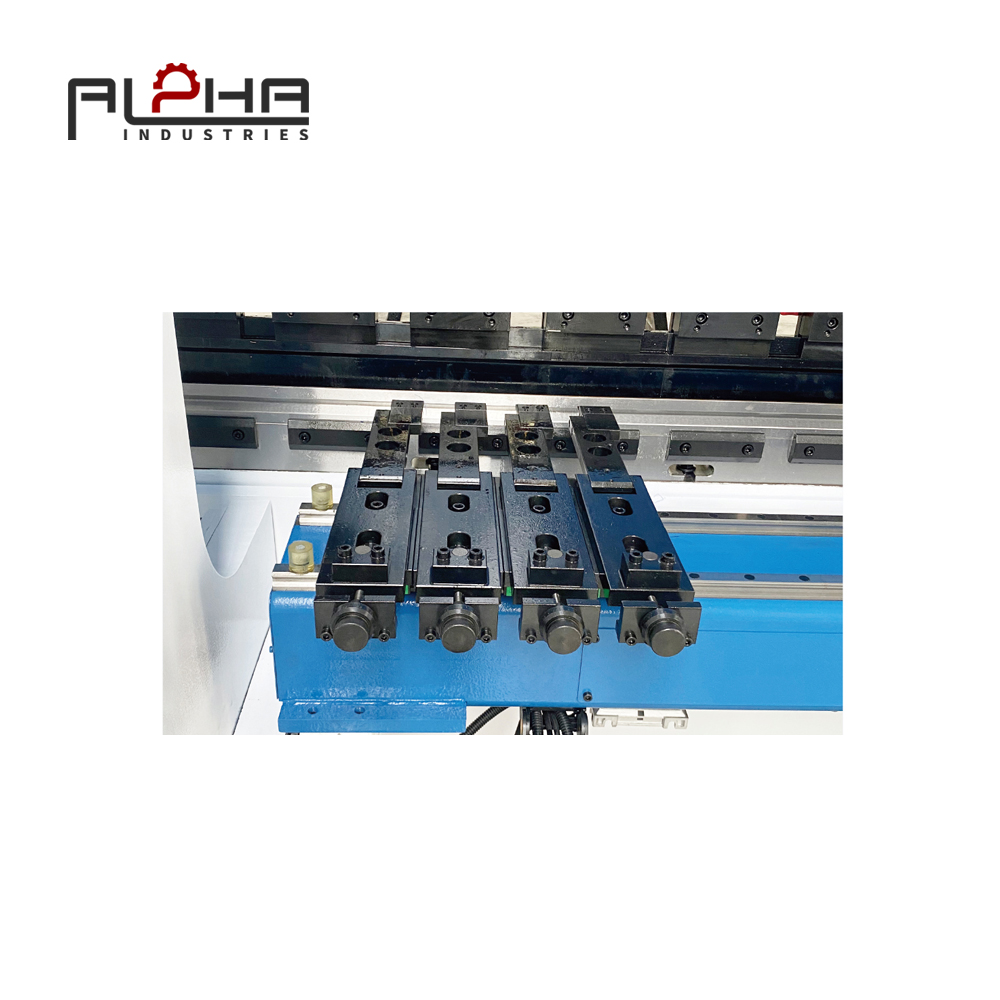

Intelligent CNC System and Angle Compensation Technology

Equipped with modern CNC controllers such as Delem DA-66T, ESA S660W, or Cybelec ModEva, ALPHA’s CNC Press Brake allows intelligent angle programming and automatic compensation.

Features include:

-

Automatic calculation of bending sequence and backgauge positioning.

-

Real-time spring-back compensation through precision sensors.

-

Adaptive hydraulic crowning system to maintain uniform bending pressure.

This ensures that every bend is produced with consistent accuracy, even when material thickness or hardness varies.

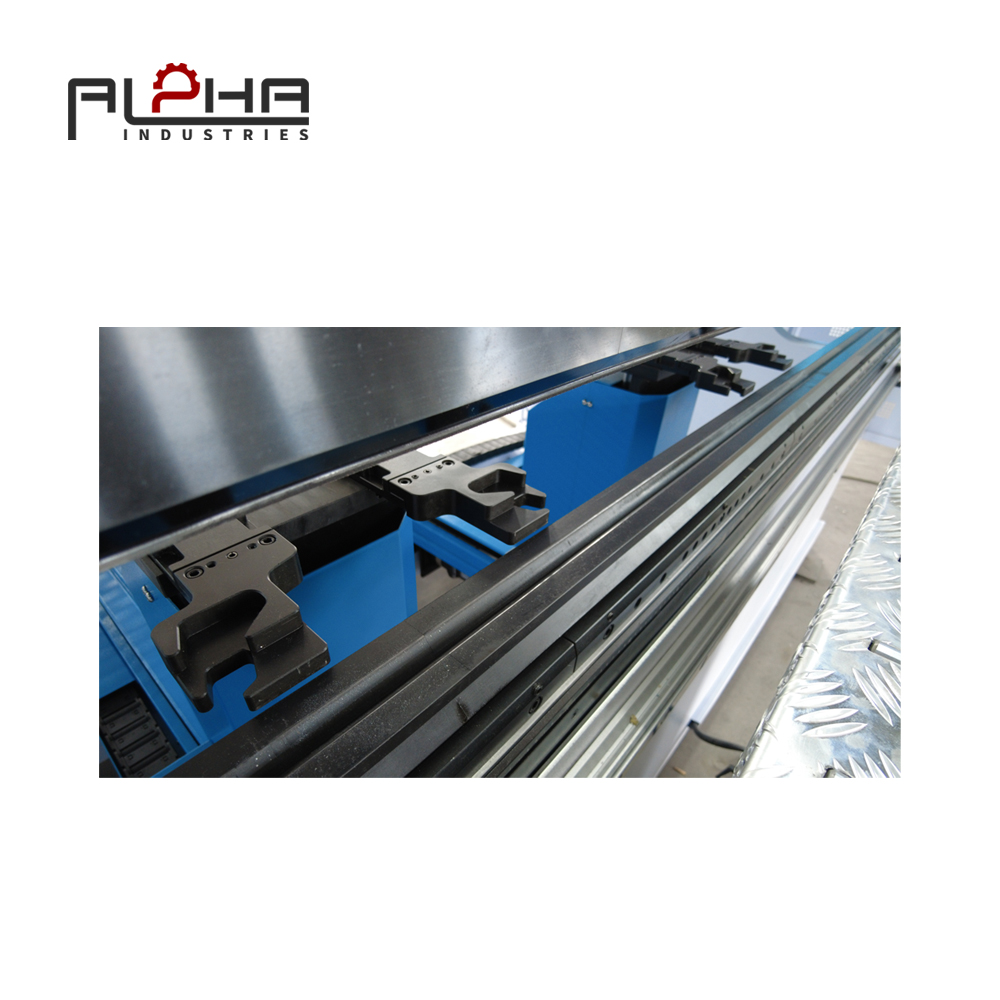

Backgauge System – The Heart of Repeatability

The backgauge determines how precisely a sheet is positioned before bending. ALPHA utilizes multi-axis CNC backgauge systems (X, R, Z1, Z2 axes) with high-speed ball screws and linear guides.

-

Positional accuracy: ±0.01 mm.

-

Servo-driven for smooth, fast operation.

-

Modular design allows expansion for complex multi-step bending operations.

This guarantees repeatability across batch production and reduces setup time dramatically.

Adaptive Crowning – Eliminating Deflection Errors

Deflection naturally occurs when bending long sheets, causing angle deviation in the center section. ALPHA’s CNC Press Brake integrates adaptive crowning, a real-time compensation mechanism that automatically adjusts the lower beam curvature during bending.

The result:

-

Perfectly straight bends along the entire sheet.

-

Uniform angles from edge to center.

-

Reduced rework and scrap rates.

This adaptive control improves product consistency and ensures flawless part geometry.

Energy Efficiency and Environmental Performance

ALPHA’s CNC Press Brake combines performance with sustainability.

-

Hybrid servo drive system minimizes oil consumption and energy use by up to 60%.

-

Low-noise operation enhances workplace comfort.

-

Automatic standby function reduces idle-time power loss.

The result is a machine that’s not only precise but also environmentally responsible.

Applications Across Industrial Sectors

The high accuracy of ALPHA’s CNC Press Brake makes it indispensable in various manufacturing fields:

-

Aerospace: Thin aluminum panel bending with ultra-high repeatability.

-

Automotive: Precision chassis and bracket forming.

-

HVAC & Construction: Duct, enclosure, and frame fabrication.

-

Energy: Heavy-gauge steel components for wind and solar systems.

Each industry benefits from consistent accuracy, minimal setup time, and extended machine life.

Operator-Friendly Interface and Smart Functions

ALPHA emphasizes operator efficiency with touchscreen CNC interfaces, graphical 2D/3D simulation, and auto-sequencing functions.

Operators can visualize bending processes, reduce setup errors, and maintain productivity even with complex multi-step operations.

Quality Assurance and Global Standards

Every CNC Press Brake from ALPHA undergoes rigorous inspection:

-

Laser calibration for ram parallelism.

-

Finite element stress testing for frame strength.

-

ISO 9001 and CE certification compliance for global safety and quality.

Our machines are tested to perform reliably for years under continuous industrial workloads.

Why Choose ALPHA CNC Press Brake

-

Over 20 years of manufacturing experience in sheet metal machinery.

-

Customizable tonnage, bending length, and axis configuration.

-

Comprehensive after-sales support, training, and technical assistance.

-

Global service network and spare parts availability.

Choosing ALPHA means investing in a precision-engineered system that guarantees consistent quality and long-term value.

Frequently Asked Questions

Q1: How does CNC Press Brake achieve consistent bending accuracy?

A1: Through servo-hydraulic synchronization, adaptive crowning, and high-resolution position sensors, ensuring micron-level control of ram movement.

Q2: What is the main advantage of a CNC Press Brake over a conventional hydraulic press brake?

A2: CNC systems automate angle correction, backgauge positioning, and compensation, greatly improving precision, repeatability, and productivity.

Q3: How often should a CNC Press Brake be recalibrated?

A3: Depending on usage intensity, calibration is typically performed every 6–12 months using laser measurement systems.

Q4: Can CNC Press Brake handle different materials and thicknesses?

A4: Yes, the CNC control automatically adjusts bending parameters for various materials including stainless steel, aluminum, and mild steel.

Call to Action :

Experience Unmatched Bending Precision. Contact ALPHA today to customize your CNC Press Brake solution.