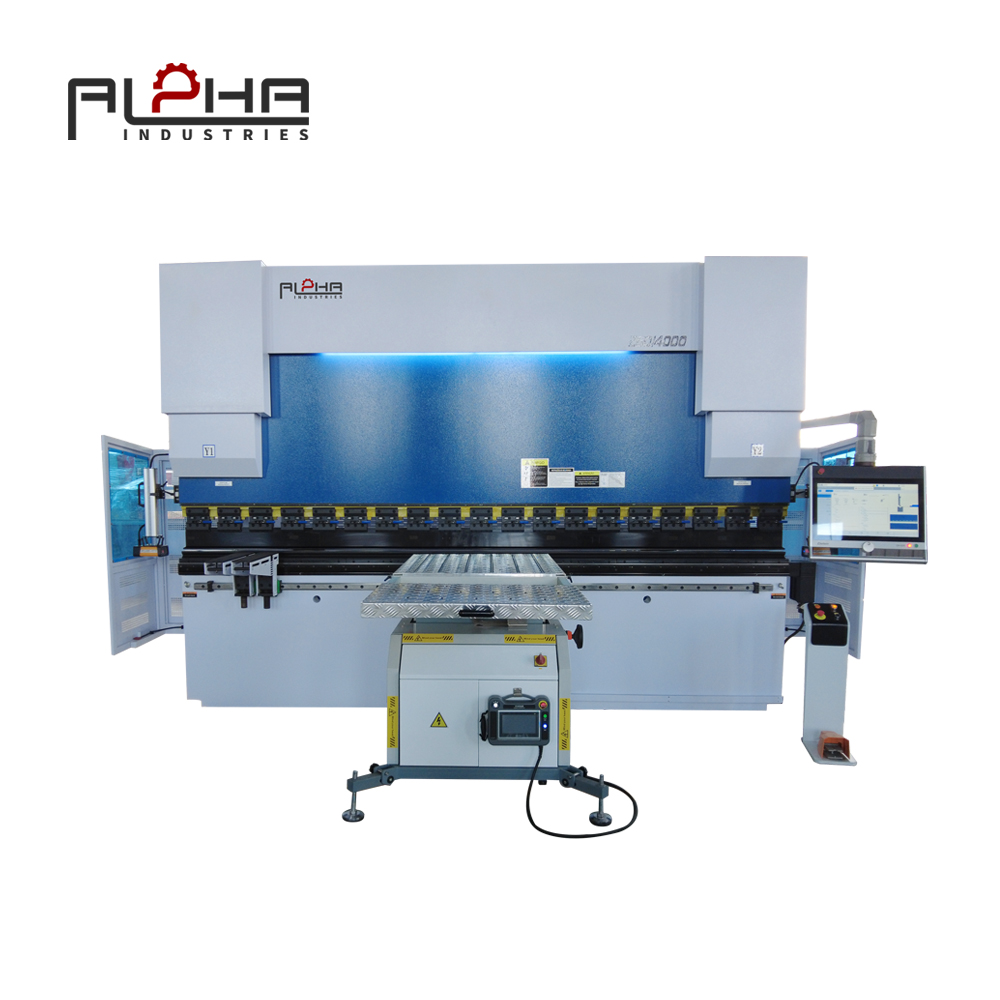

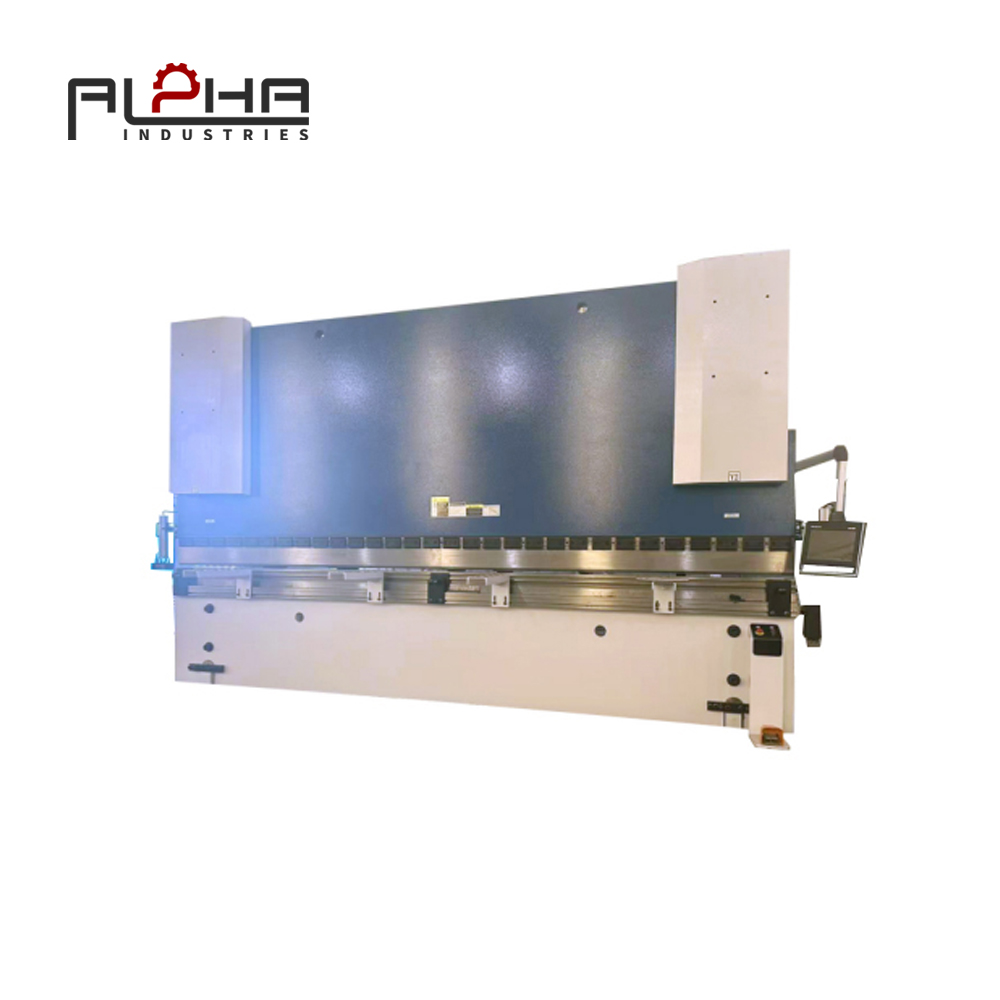

Press Brake 8+1 Axis Backgauge System for Advanced Bending Accuracy

In high-end sheet metal fabrication, positioning accuracy is just as critical as bending force. As part geometry becomes more complex and tolerances become tighter, traditional backgauge systems are no longer sufficient. A press brake 8+1 axis backgauge system provides the flexibility and precision required for modern bending applications.

At Alpha, we design press brakes equipped with advanced multi-axis backgauge systems to support complex parts, high-mix production, and demanding accuracy requirements.

What Is a Press Brake 8+1 Axis Backgauge System?

A press brake 8+1 axis backgauge system consists of eight independently controlled positioning axes combined with one auxiliary axis. These axes work together to control finger movement, depth positioning, vertical adjustment, lateral alignment, and synchronization with the bending sequence.

This configuration enables precise positioning for complex workpieces, including box-shaped parts, stepped bends, and asymmetric components.

Why Multi-Axis Backgauge Control Is Essential in Modern Bending

As bending programs grow more complex, backgauge limitations directly affect productivity and quality. Without sufficient axis control:

-

Manual repositioning increases setup time

-

Positioning errors accumulate across multiple bends

-

Part consistency becomes difficult to maintain

A press brake multi-axis backgauge system eliminates these issues by enabling automated, repeatable positioning throughout the entire bending cycle.

Key Axes Functions in an 8+1 Axis Backgauge System

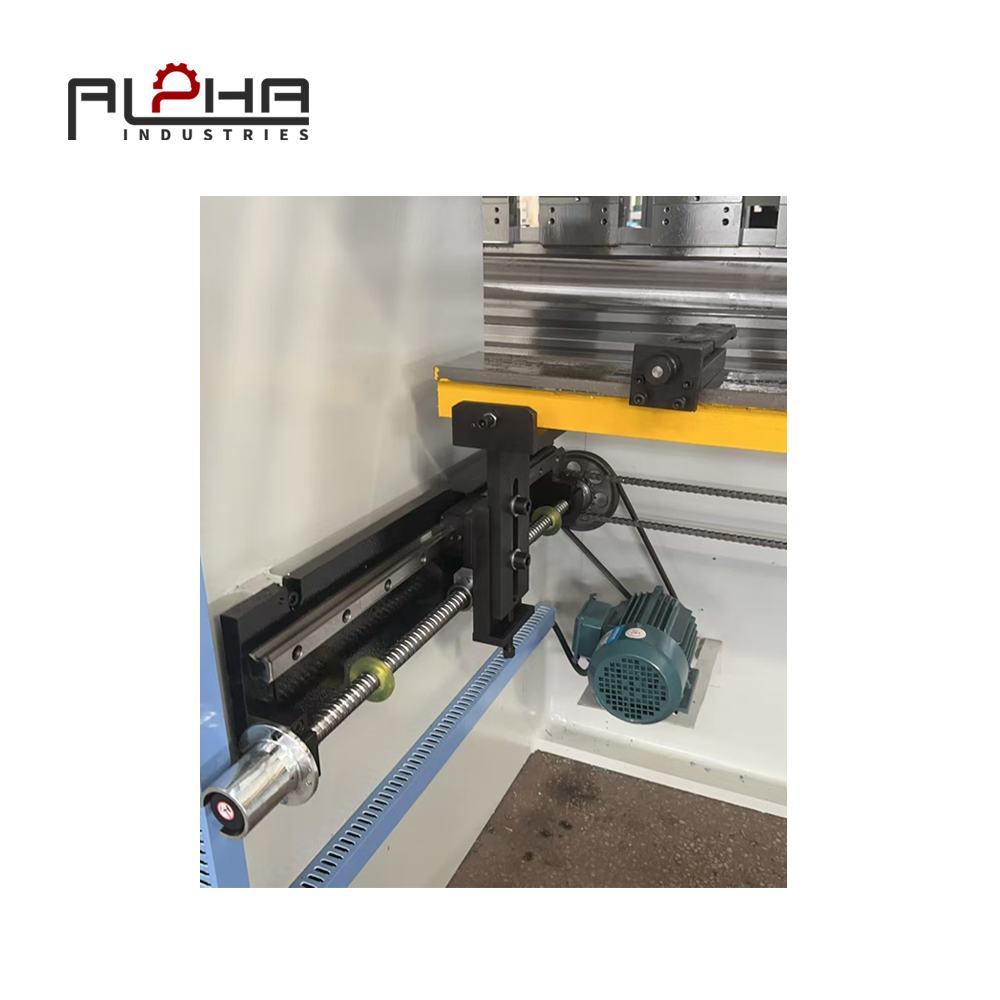

X and X′ Axes – Depth Positioning

Independent control of left and right X axes ensures accurate depth positioning, even for tapered or asymmetric parts.

R and Z Axes – Vertical and Lateral Adjustment

R-axis movement allows vertical finger positioning, while Z-axis control adjusts lateral spacing. This combination supports a wide range of part geometries.

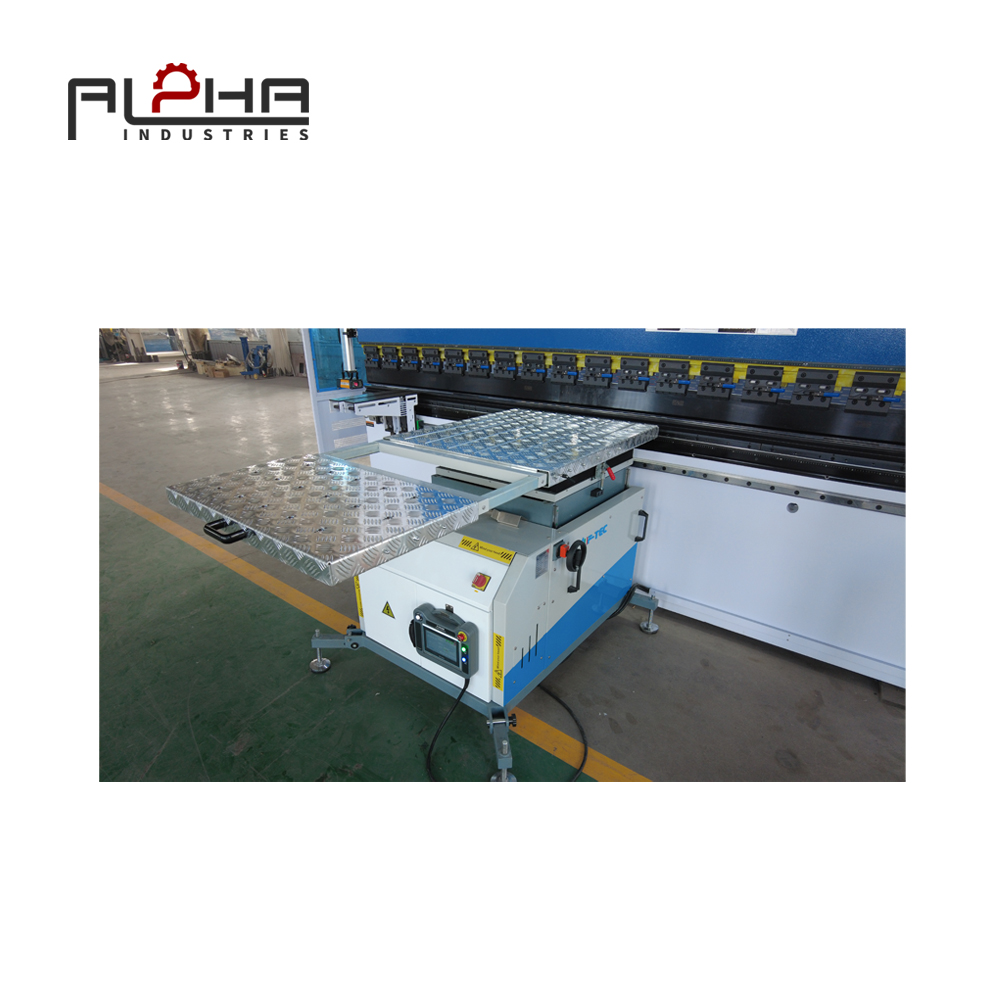

Additional Axes – Flexible Part Support

The remaining axes enable finger tilting, rotation, and auxiliary positioning, allowing seamless handling of complex bends and return flanges.

Technical Advantages of Alpha Press Brake 8+1 Axis Backgauge Systems

Alpha integrates backgauge systems as an essential part of the press brake structure and CNC logic.

Technical highlights include:

-

High-precision servo drive systems

-

Rigid backgauge beam construction

-

Full CNC synchronization with bending programs

-

Automatic axis positioning for each bend step

These features ensure stable operation and long-term positioning accuracy.

How 8+1 Axis Backgauge Systems Improve Productivity

With an advanced press brake backgauge system:

-

Setup time is significantly reduced

-

Complex parts can be bent in fewer steps

-

Operator dependency is minimized

-

Repeat orders achieve consistent quality

This makes 8+1 axis backgauge systems ideal for both batch production and flexible job-shop environments.

Application Scenarios for 8+1 Axis Backgauge Press Brakes

Multi-axis backgauge systems are widely used in:

-

Electrical enclosures and control cabinets

-

Elevator and architectural metal components

-

Automotive and transportation parts

-

Custom sheet metal fabrication workshops

For manufacturers producing complex or high-precision components, an 8+1 axis backgauge is a decisive advantage.

FAQ

What is the difference between a standard backgauge and an 8+1 axis backgauge?

A standard backgauge typically controls only depth and lateral position. An 8+1 axis system adds multiple controlled movements, enabling complex positioning without manual adjustment.

Is an 8+1 axis backgauge necessary for all bending applications?

Not for simple parts. However, for complex geometries, box bending, or frequent changeovers, a multi-axis backgauge greatly improves efficiency and accuracy.

Can the backgauge axes be fully programmed through CNC?

Yes. Alpha press brakes allow full CNC programming and automatic coordination of all backgauge axes during the bending process.

Why Choose Alpha Press Brakes With 8+1 Axis Backgauge Systems?

Alpha focuses on intelligent motion control, structural rigidity, and practical production efficiency. Our 8+1 axis backgauge systems are designed to deliver precision, flexibility, and reliability in real-world manufacturing environments.

Choosing Alpha means:

-

Greater bending flexibility

-

Higher positioning accuracy

-

Reduced setup and labor costs

-

Consistent quality across complex parts

Learn more about Alpha press brake solutions:

For technical consultation or quotations, please visit: