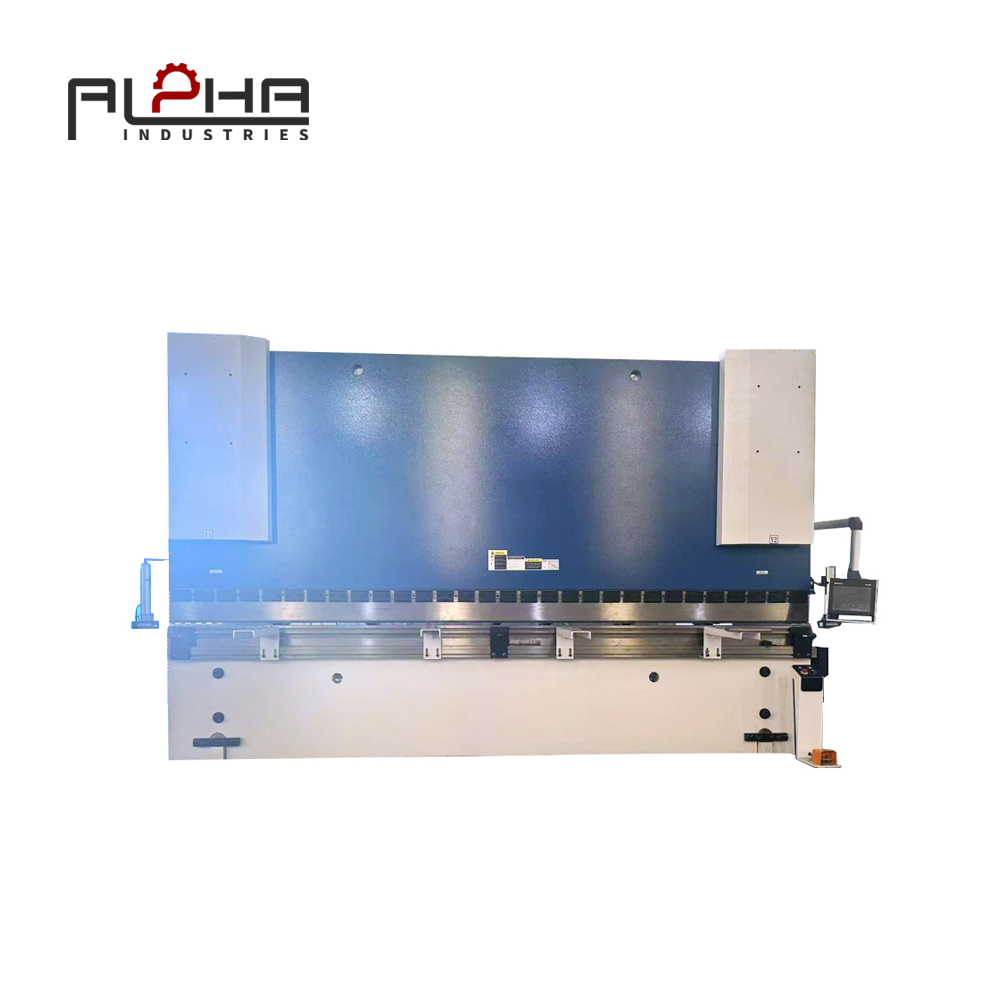

In modern sheet metal fabrication, the press brake is one of the most critical machines. Whether producing electrical cabinets, elevator parts, automotive components, or industrial enclosures, bending quality directly determines the final product performance.

Among all performance indicators of a press brake, accuracy and repeatability are the most important. These two factors define whether a bending machine can deliver consistent results day after day.

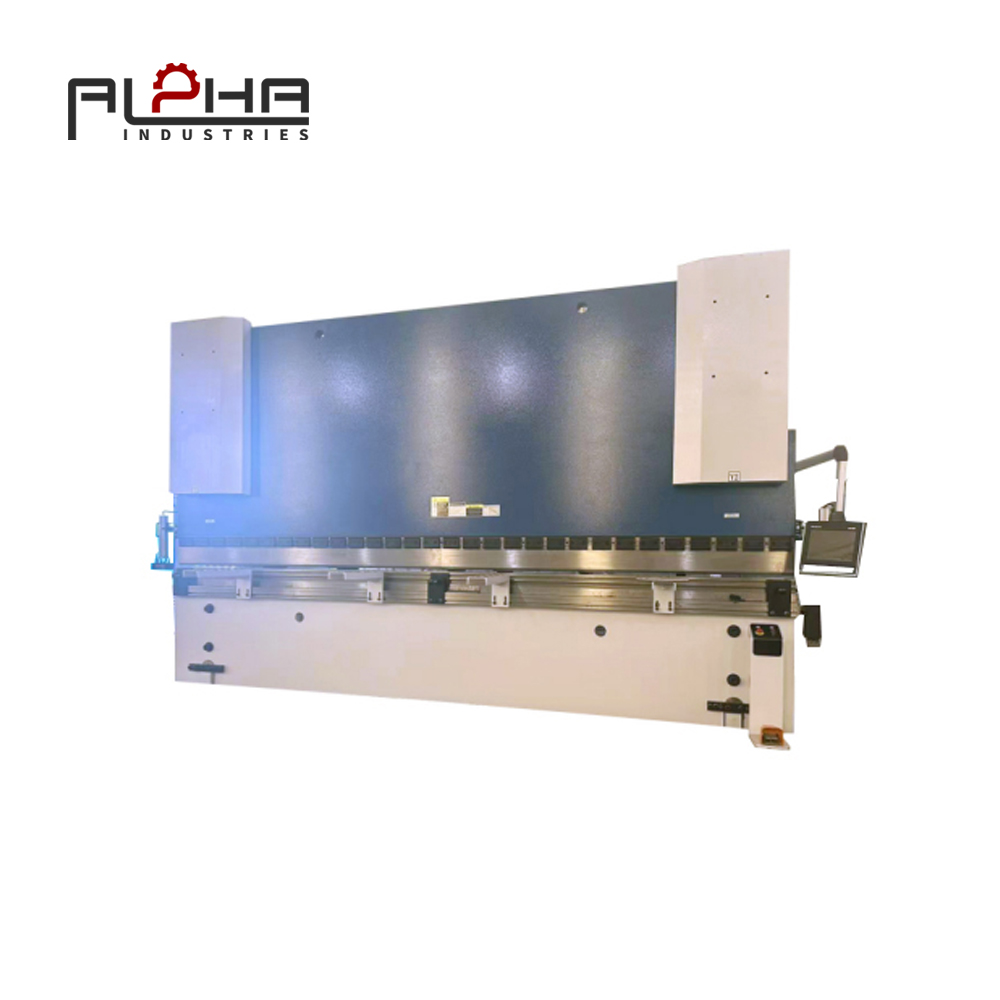

At Alpha, we focus on designing and manufacturing professional press brake solutions that guarantee high-precision and stable bending performance for global customers.

Why Accuracy Is the Core of Press Brake Performance

A press brake is not only a machine that bends metal. It is a precision forming system. Every bending process involves multiple technical elements:

-

Ram positioning

-

Back gauge movement

-

Tool alignment

-

Material properties

-

Machine frame rigidity

If any of these elements are unstable, the final bending angle will deviate, leading to quality problems.

For manufacturers, inaccurate bending means:

-

Rework

-

Scrap

-

Assembly difficulties

-

Higher production cost

-

Lower customer satisfaction

Therefore, ensuring press brake accuracy is the foundation of efficient production.

What Determines Press Brake Accuracy

Many users believe that bending precision only depends on the CNC system. In reality, accuracy is the result of a combination of mechanical, hydraulic, and control factors.

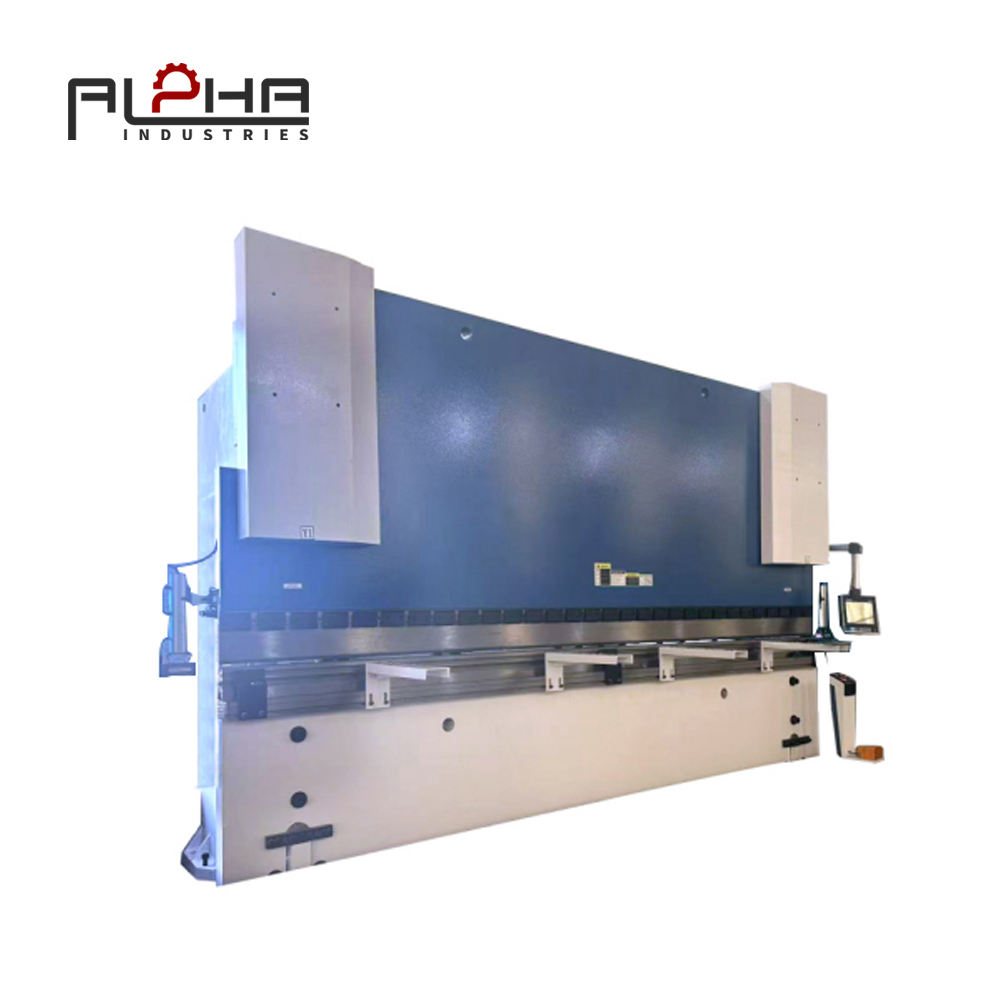

1. Machine Frame Rigidity

The structural rigidity of a press brake is the basis of accuracy. During bending, the machine frame bears extremely high force.

If the frame is not strong enough, it will cause:

-

Deformation

-

Uneven pressure distribution

-

Angle inconsistency

Alpha press brakes are built with heavy-duty welded frames and stress-relief treatment to ensure long-term stability.

2. Hydraulic System Stability

In hydraulic press brakes, the ram movement is driven by hydraulic cylinders. Any pressure fluctuation directly affects bending results.

A high-quality hydraulic system must provide:

-

Smooth pressure output

-

Fast response

-

Stable synchronization

-

Accurate positioning

Alpha adopts premium hydraulic components and advanced proportional valve control to maintain consistent bending force.

3. CNC Control Precision

Modern CNC press brakes rely on intelligent control systems to manage:

-

Bending depth

-

Angle calculation

-

Back gauge position

-

Tool compensation

A powerful CNC system allows operators to easily achieve complex and precise bending operations.

Alpha integrates user-friendly CNC controllers that support:

-

Automatic angle programming

-

Multi-step bending

-

Real-time compensation

-

Database management

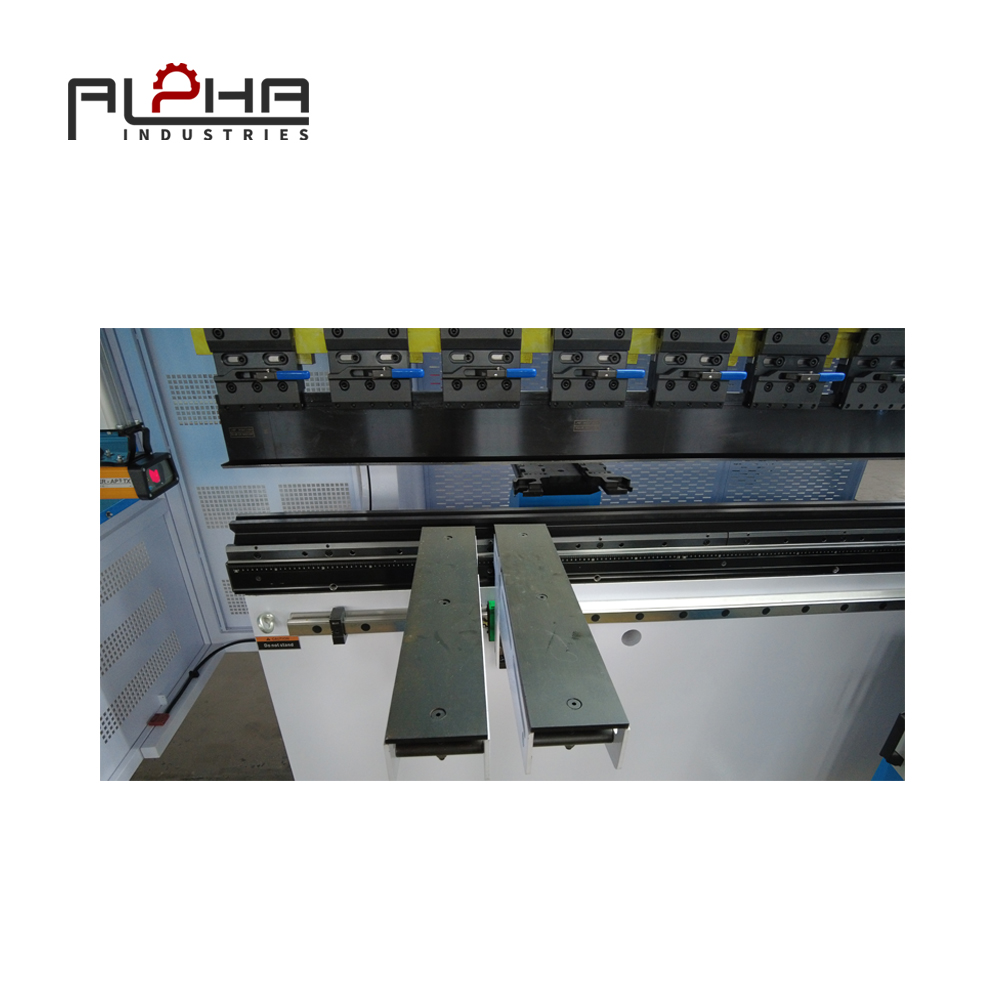

4. Back Gauge Accuracy

The back gauge determines the bending position of the sheet metal. Even a small positioning error will result in dimensional deviation.

High-precision back gauge systems require:

-

Servo motor drive

-

Linear guide rails

-

Ball screw transmission

-

Stable mechanical structure

Alpha press brakes are equipped with accurate and reliable back gauge systems to ensure repeatable positioning.

5. Press Brake Tooling Quality

Even the best machine cannot produce accurate bends with poor tooling.

High-quality press brake tooling must have:

-

Precise dimensions

-

Proper hardness

-

Good wear resistance

-

Correct die opening

Alpha provides professional tooling solutions matched perfectly with our press brakes.

Repeatability – The Real Test of a Press Brake

Accuracy is important, but repeatability is even more critical in mass production.

Repeatability means:

👉 The machine can produce the same bending result consistently, not just once.

In daily production, a press brake must handle:

-

Different operators

-

Long working hours

-

Various materials

-

Changing temperatures

Only a well-designed and stable machine can maintain the same accuracy under all these conditions.

Alpha press brakes are engineered specifically for high repeatability in real factory environments.

Common Problems Affecting Bending Accuracy

In practical use, many factors can reduce precision:

-

Tool wear

-

Incorrect die selection

-

Unstable material thickness

-

Improper parameter settings

-

Poor machine maintenance

Understanding these issues helps users avoid quality risks.

How to Improve Press Brake Accuracy

To achieve the best bending results, users should focus on:

-

Selecting the right press brake model

-

Using proper tooling

-

Performing regular calibration

-

Maintaining hydraulic stability

-

Training operators correctly

Alpha provides complete technical support to help customers optimize every step of the bending process.

Industries That Require High-Precision Press Brakes

Accurate press brakes are essential in many fields:

-

Electrical cabinets

-

Elevator manufacturing

-

Automotive parts

-

Kitchen equipment

-

Construction machinery

-

Aerospace components

In these industries, even small bending errors can cause serious assembly problems.

Why Choose Alpha Press Brakes

Alpha press brakes are designed with precision and reliability as top priorities.

Our machines feature:

-

Heavy-duty machine frame

-

Advanced CNC control

-

High-quality hydraulic system

-

Accurate back gauge

-

Professional tooling options

-

Stable long-term performance

Every Alpha press brake is built to help customers achieve perfect bending results.

FAQ

Q1: What is press brake accuracy?

Press brake accuracy refers to the ability of the machine to bend sheet metal to the exact programmed angle and dimension.

Q2: Why is repeatability important in a press brake?

Because mass production requires the same bending result every time. Good repeatability ensures consistent product quality.

Q3: What affects press brake bending precision most?

Machine rigidity, hydraulic stability, CNC control, tooling quality, and back gauge accuracy.

Q4: Can tooling influence bending results?

Yes. Incorrect or worn tooling is one of the main reasons for poor bending accuracy.

Q5: How to maintain press brake precision?

Through regular maintenance, calibration, proper operation, and using high-quality tools.

Q6: Are Alpha press brakes suitable for high-precision industries?

Yes. Alpha press brakes are designed specifically for industries requiring strict bending tolerance.

Conclusion

In sheet metal fabrication, a press brake is far more than a simple bending machine. Its true value lies in the ability to deliver:

-

High accuracy

-

Excellent repeatability

-

Stable performance

-

Long-term reliability

Only when these factors are perfectly combined can manufacturers achieve efficient and profitable production.

Alpha is committed to providing professional press brake solutions that help customers reach the highest level of bending quality.

If you are looking for a reliable and high-precision press brake for your production line, Alpha is ready to support you.

Learn more about our professional solutions:

👉 [Contact Us – Alpha]