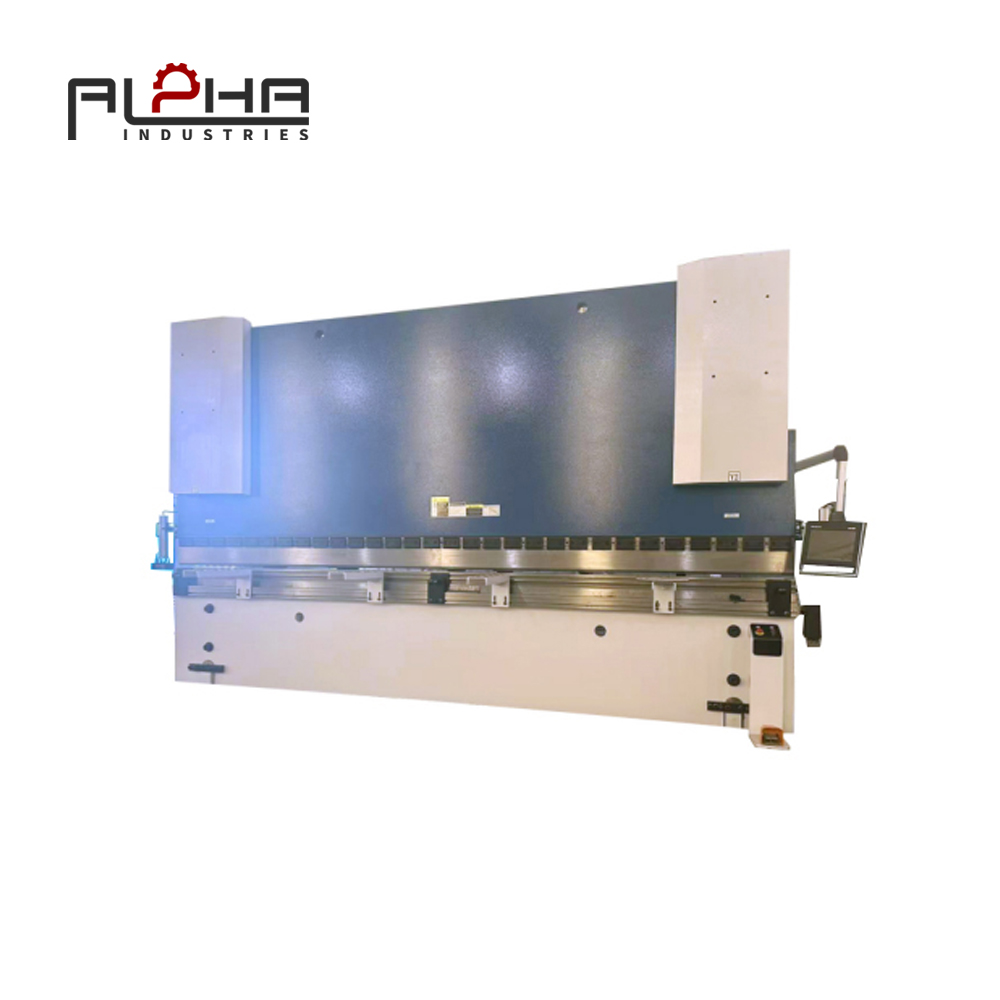

Press Brake Performance Depends on Hydraulic System Stability

In modern sheet metal fabrication, a press brake is no longer judged solely by tonnage capacity or CNC control sophistication. Hydraulic system stability has become a defining factor that directly determines bending accuracy, repeatability, and long-term production reliability.

An unstable hydraulic system leads to pressure fluctuation, inconsistent ram movement, and unpredictable bending results. For manufacturers targeting tight tolerances and batch consistency, hydraulic stability is not optional—it is fundamental.

At Alpha, press brake hydraulic systems are engineered with stability as a core design objective, ensuring reliable bending performance under continuous industrial operation.

Why Hydraulic Stability Matters in Press Brake Bending

During a bending cycle, the press brake hydraulic system controls:

-

Ram movement speed

-

Applied bending force

-

Pressure holding during dwell time

-

Return stroke smoothness

Any fluctuation in hydraulic pressure or flow directly affects the bending angle. Even minor instability can cause measurable angle deviation, especially in precision sheet metal forming.

A stable hydraulic system ensures:

-

Smooth and synchronized ram movement

-

Accurate pressure control throughout the stroke

-

Consistent bending angles across batches

-

Predictable machine behavior over long production runs

Common Hydraulic Instability Issues in Press Brakes

Without proper engineering, press brake hydraulic systems may suffer from:

-

Pressure fluctuation during bending

-

Inconsistent approach and bending speed

-

Oil temperature rise causing viscosity change

-

Delayed pressure response during dwell

These issues often result in angle inconsistency, increased adjustment time, and reduced productivity.

Key Engineering Factors Behind a Stable Press Brake Hydraulic System

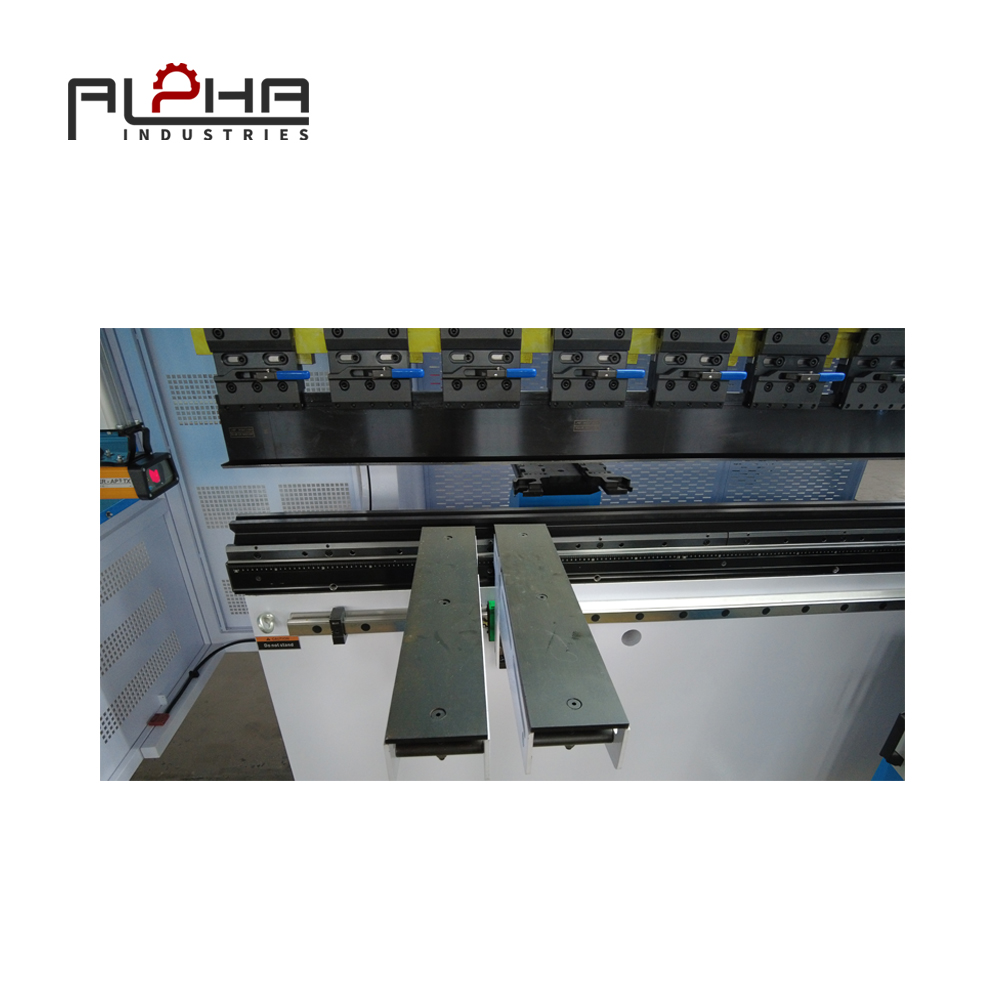

High-Precision Hydraulic Valve Control

The hydraulic valve system governs pressure and flow accuracy. Alpha press brakes utilize precision-grade proportional or servo valves to ensure smooth pressure transitions and accurate force control during bending.

This allows the press brake to maintain stable pressure even during complex multi-step bending operations.

Optimized Hydraulic Circuit Design

Hydraulic circuit layout directly impacts system responsiveness and stability. Alpha engineers optimize oil flow paths to reduce pressure loss, minimize turbulence, and ensure uniform response across the entire bending stroke.

Balanced circuit design also improves synchronization between left and right cylinders.

Oil Temperature Control and Thermal Stability

Hydraulic oil temperature affects viscosity and system response. Excessive temperature fluctuation leads to unstable pressure output.

Alpha press brakes integrate effective oil cooling and temperature management solutions to maintain consistent hydraulic performance during long production shifts.

Hydraulic System Stability and Bending Accuracy

A stable hydraulic system directly improves press brake bending accuracy by:

-

Maintaining constant bending force

-

Preventing ram speed variation

-

Ensuring consistent dwell pressure

-

Reducing angle deviation between parts

This is especially critical for stainless steel, high-strength materials, and long-length sheet metal bending.

Impact on Repeatability and Batch Production

In batch production, repeatability is more important than single-part accuracy. Hydraulic stability ensures that every bending cycle behaves identically, regardless of production duration or operator changes.

With a stable hydraulic system, press brakes deliver:

-

Consistent angles across large batches

-

Reduced need for frequent recalibration

-

Lower scrap rates

-

Improved overall equipment efficiency

CNC Control Integration with Hydraulic Systems

In modern CNC press brakes, the hydraulic system works in close coordination with the control unit. Parameters such as pressure, speed, and dwell time are dynamically managed based on bending programs.

Alpha press brakes integrate hydraulic stability with CNC logic, enabling fast job changes while preserving bending accuracy.

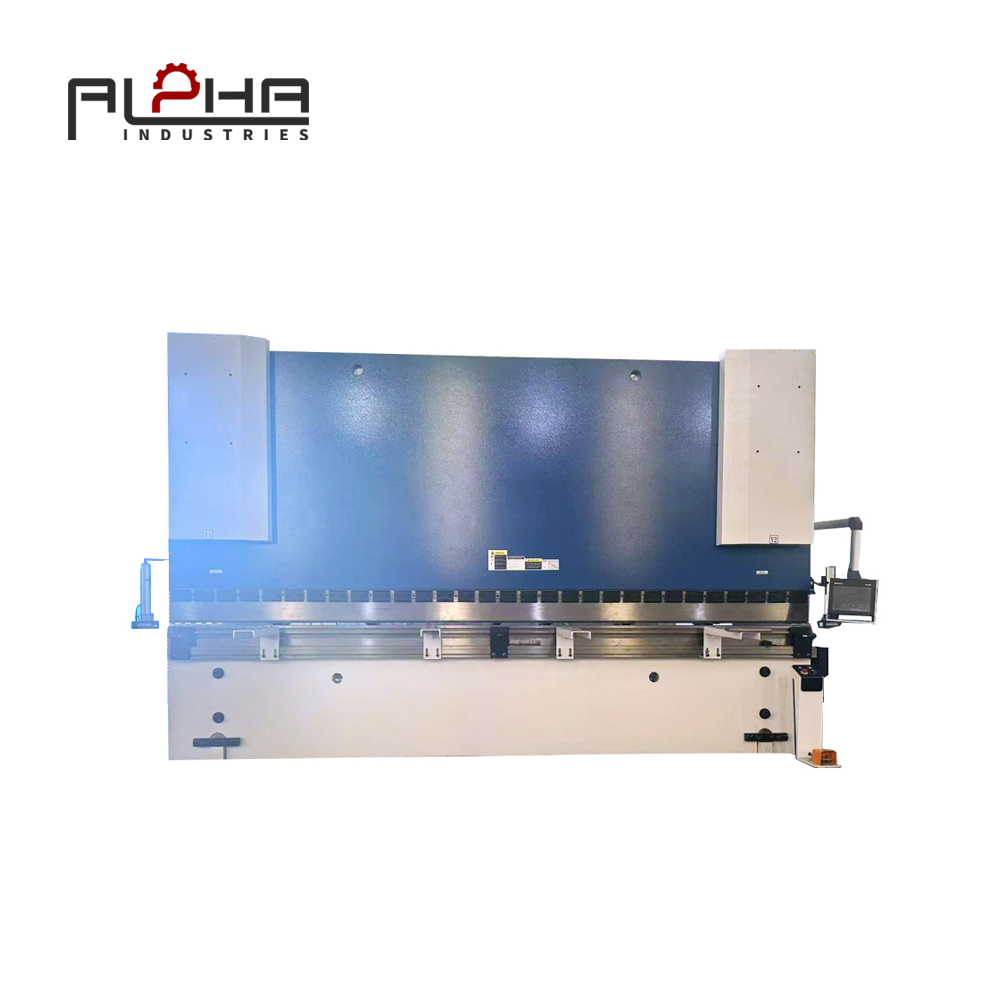

Application Scenarios Demanding Hydraulic Stability

Hydraulic system stability is essential for:

-

Precision enclosure and cabinet production

-

Multi-bend components with tight tolerances

-

Long workpiece bending

-

High-strength material forming

-

Continuous multi-shift production

Alpha press brakes are engineered to meet these demanding application requirements with consistent performance.

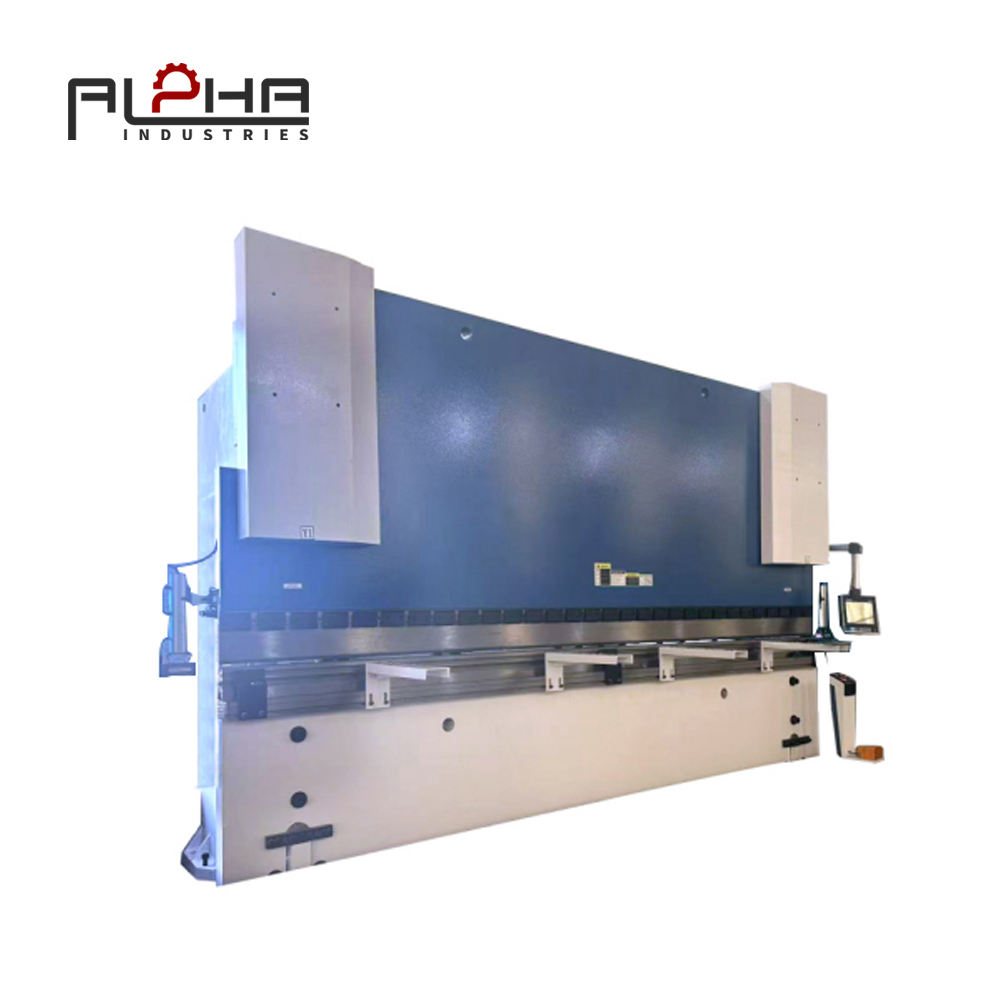

Alpha Press Brake Hydraulic Engineering Philosophy

At Alpha, hydraulic stability is treated as a system-level engineering goal. From component selection to circuit design and assembly testing, every hydraulic system is optimized for long-term consistency.

Each press brake undergoes full-load hydraulic testing to ensure pressure stability, response accuracy, and real-world reliability before delivery.

FAQs

What affects press brake bending accuracy the most?

Hydraulic pressure stability is a primary factor affecting bending consistency.

Why does hydraulic instability cause angle variation?

Pressure fluctuation changes applied bending force, directly altering bend angles.

Is hydraulic stability important for CNC press brakes?

Yes. CNC accuracy relies on stable hydraulic response to execute programmed bending precisely.

Can hydraulic system design reduce scrap rate?

A stable hydraulic system minimizes angle deviation, reducing rework and scrap.

Conclusion – Hydraulic Stability Defines Press Brake Reliability

A press brake’s true performance is defined by how consistently it delivers controlled bending force.

Hydraulic system stability transforms raw tonnage into repeatable precision.

By choosing a press brake engineered with a stable hydraulic system, manufacturers gain:

-

Higher bending accuracy

-

Improved batch consistency

-

Lower operating costs

-

Long-term production reliability

Alpha remains committed to delivering precision press brakes engineered for stable hydraulic performance in real industrial environments.

👉 Learn more about Alpha press brake solutions or Contact Us to discuss your sheet metal bending requirements.