In the sheet metal fabrication industry, the press brake is one of the most widely used and most important forming machines. From small workshops to large industrial factories, nearly every metal product requires bending operations.

While many users focus on tonnage, working length, or speed, the real factor that defines press brake performance is stability. Without stable performance, even a powerful press brake cannot produce reliable bending results.

At Alpha, we believe that hydraulic press brake stability is the true foundation of high-quality sheet metal bending.

Why Stability Is the Core of Press Brake Performance

A press brake is a heavy-duty forming machine that converts hydraulic force into precise bending motion. During every bending cycle, the machine must withstand:

-

Extremely high pressure

-

Continuous mechanical load

-

Material resistance

-

Tool impact

-

Long working hours

If the machine system is not stable, the bending angle will constantly change, leading to inconsistent product quality.

Stability determines:

-

Whether each part is the same

-

Whether angles remain accurate

-

Whether production is efficient

-

Whether maintenance cost stays low

For professional manufacturers, a stable press brake is far more valuable than a fast but unreliable one.

What Creates Stability in a Hydraulic Press Brake

True press brake stability is not created by a single component. It is the result of several technical factors working together.

1. Hydraulic System Stability

The hydraulic system is the “heart” of a press brake. All bending force and ram movement depend on hydraulic oil pressure.

A stable hydraulic system must provide:

-

Smooth pressure output

-

Accurate force control

-

Consistent speed

-

Reliable synchronization

-

Low temperature fluctuation

Any pressure instability will directly cause:

-

Angle deviation

-

Inconsistent bending depth

-

Unstable movement

-

Poor surface quality

Alpha hydraulic press brakes are designed with high-quality hydraulic circuits and premium components to ensure long-term operational stability.

2. Machine Frame Strength

Even the most advanced hydraulic system cannot work well without a rigid structure.

During bending, the machine frame must resist enormous force. If the structure is weak, problems will occur:

-

Frame deformation

-

Uneven force distribution

-

Angle variation

-

Long-term accuracy loss

Alpha press brakes use heavy-duty welded frames with professional stress-relief treatment. This guarantees that the machine remains stable and accurate even after years of operation.

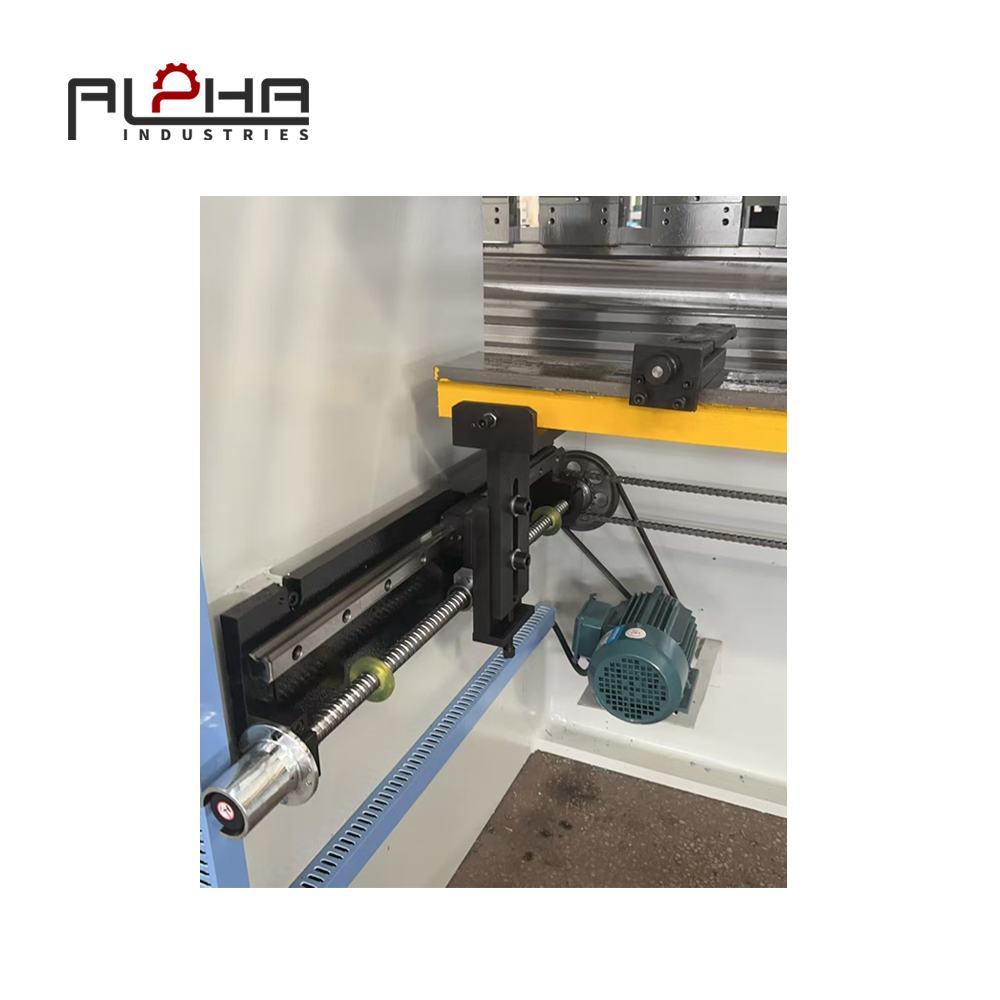

3. Mechanical Transmission Reliability

A press brake contains many mechanical elements such as:

-

Ram guides

-

Slide blocks

-

Linkage mechanisms

-

Synchronization systems

These components must move smoothly and precisely. Any looseness or wear will reduce stability.

Alpha focuses on precision machining and high-standard assembly to ensure perfect mechanical coordination.

4. Tooling System Stability

The press brake tooling is the direct contact point with sheet metal. Even if the machine is stable, poor tooling will still destroy bending consistency.

Stable tooling requires:

-

High hardness

-

Accurate dimensions

-

Proper alignment

-

Correct installation

Alpha provides professional tooling solutions optimized for our hydraulic press brakes to maintain maximum bending stability.

How Stability Affects Real Production

In real factories, stability directly influences production results.

A stable hydraulic press brake provides:

-

Consistent bending angles

-

Identical parts in batch production

-

Less adjustment time

-

Lower scrap rate

-

Higher production efficiency

On the contrary, an unstable machine will cause:

-

Frequent rework

-

Wasted materials

-

Operator frustration

-

Unpredictable quality

For any company aiming at professional manufacturing, press brake stability is not optional – it is essential.

Common Causes of Unstable Bending

Many bending problems originate from instability, such as:

-

Fluctuating hydraulic pressure

-

Weak machine frame

-

Poor maintenance

-

Worn tooling

-

Incorrect setup

-

Temperature changes

Understanding these causes helps users take preventive actions and maintain consistent bending quality.

How to Improve Press Brake Stability

Manufacturers can improve stability through:

-

Choosing a high-quality hydraulic press brake

-

Using professional tooling

-

Performing regular maintenance

-

Checking hydraulic oil condition

-

Keeping the machine properly calibrated

-

Training operators correctly

Alpha provides full technical guidance to help customers maintain long-term machine stability.

Applications Requiring High Stability

Many industries depend heavily on stable press brakes:

-

Electrical cabinets

-

Elevator components

-

Steel doors

-

Construction panels

-

Machinery covers

-

Metal furniture

-

Industrial enclosures

In these applications, even small angle differences can cause serious assembly problems. Stable bending is the key to success.

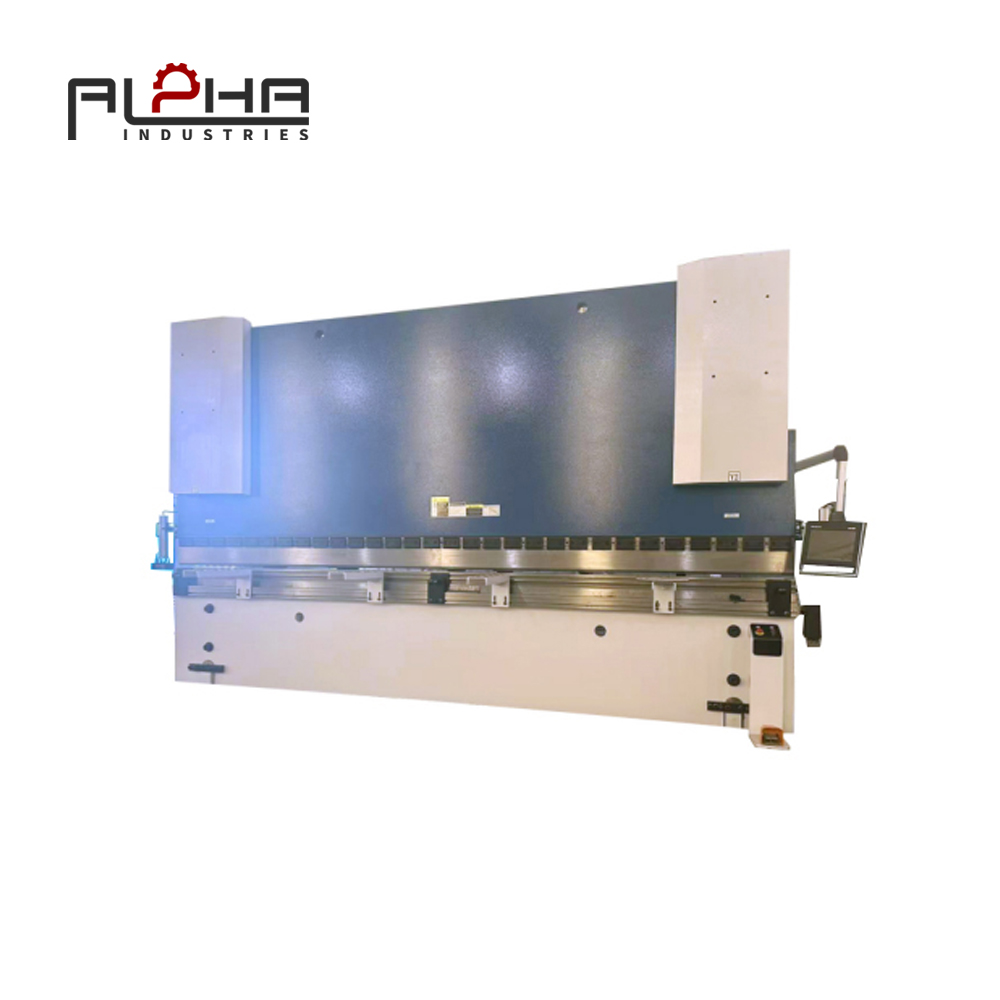

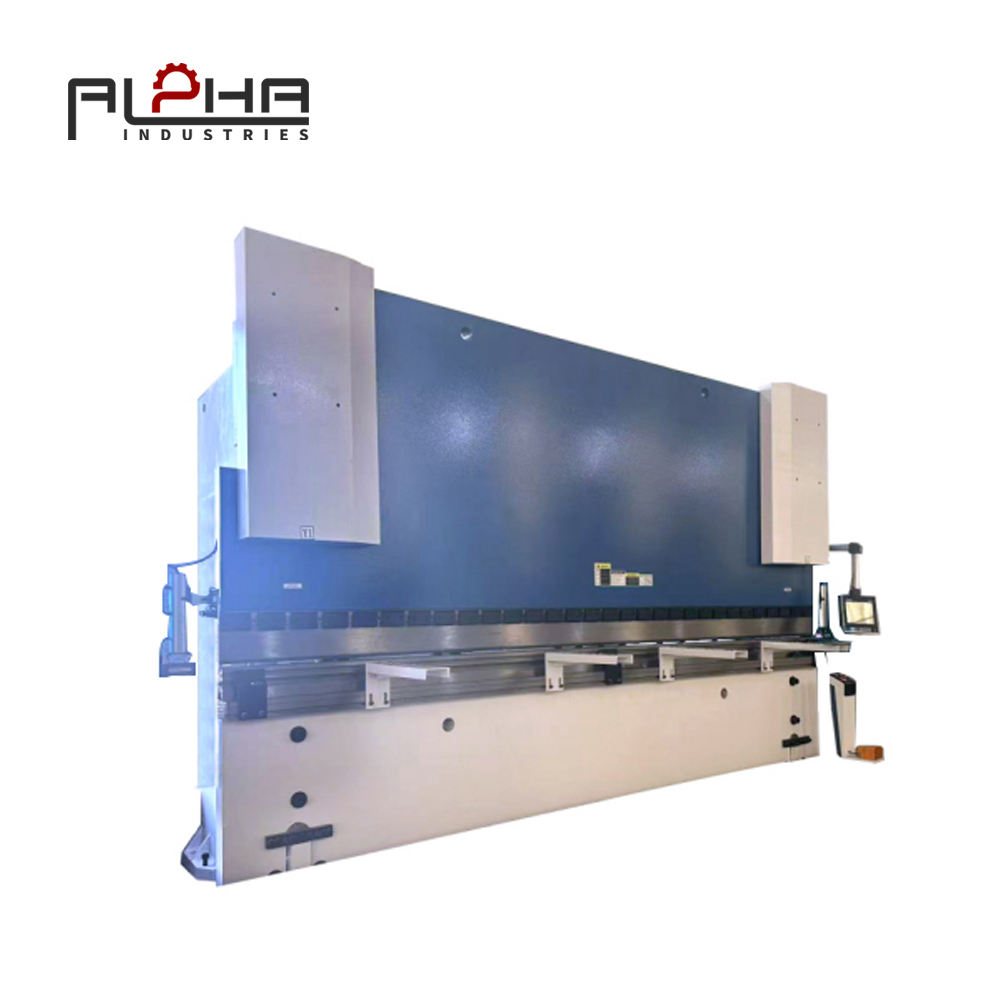

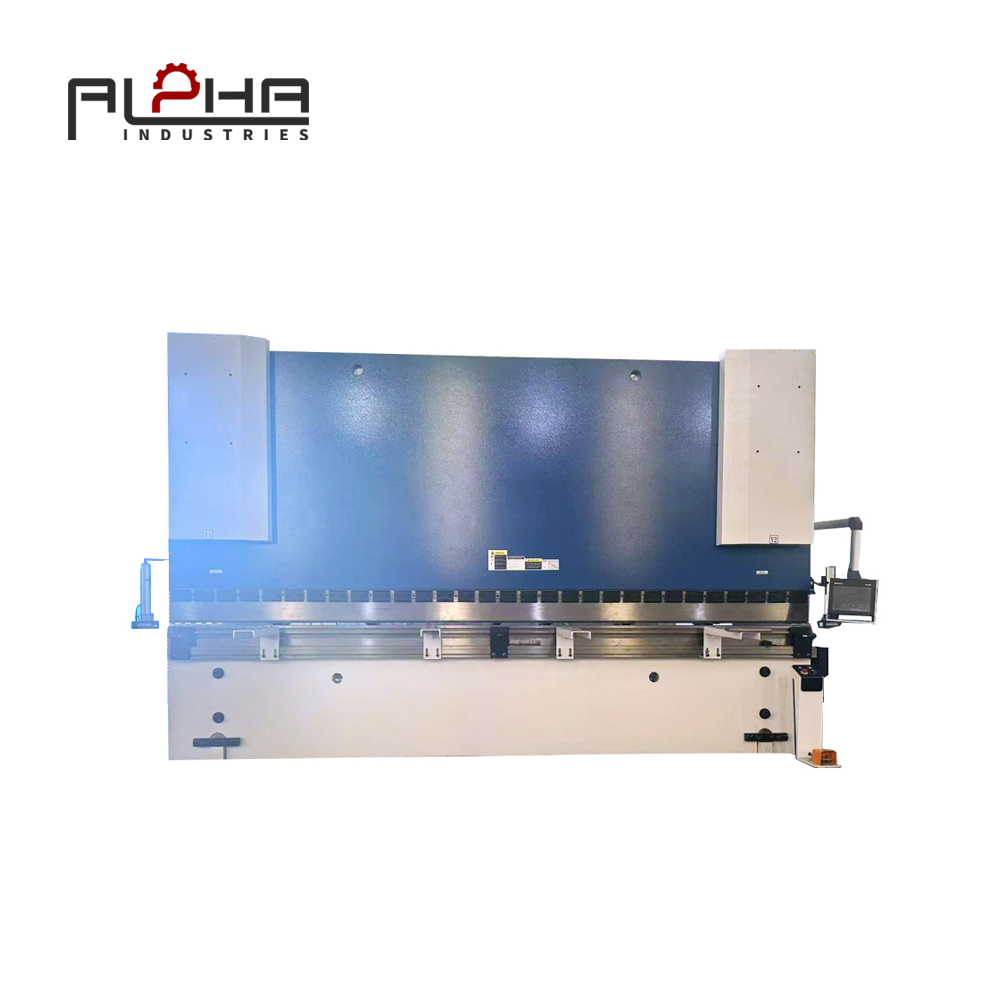

Alpha Hydraulic Press Brakes – Built for Stability

Alpha hydraulic press brakes are engineered with one main goal:

👉 Delivering reliable and stable bending performance

Our machines feature:

-

Heavy-duty rigid frame design

-

High-quality hydraulic components

-

Professional assembly process

-

Durable mechanical structure

-

Optimized tooling compatibility

-

Long service life

Every Alpha press brake is manufactured to ensure that customers can achieve consistent and predictable bending results.

FAQ

Q1: What is press brake stability?

Press brake stability means the machine can produce the same bending result consistently without fluctuation.

Q2: Why is hydraulic stability important in a press brake?

Because hydraulic pressure directly controls ram movement and bending force. Unstable pressure causes angle variation.

Q3: What factors influence press brake stability?

Hydraulic system quality, machine frame rigidity, mechanical components, tooling condition, and maintenance level.

Q4: Can tooling affect bending stability?

Yes. Poor or worn tooling will lead to inconsistent angles even on a good machine.

Q5: How can users maintain stable bending performance?

Through regular maintenance, proper setup, quality tooling, and correct operation.

Q6: Are Alpha press brakes designed for stable production?

Yes. Alpha hydraulic press brakes are specifically engineered for long-term stability and reliable industrial use.

Conclusion – Stability Defines the Value of a Press Brake

In sheet metal bending, true machine performance is not measured only by power or specifications. The most important indicator is stability.

A stable hydraulic press brake brings:

-

Reliable accuracy

-

Consistent repeatability

-

Lower production cost

-

Higher efficiency

-

Better product quality

That is why Alpha always puts stability at the center of press brake design and manufacturing.

If you are searching for a professional hydraulic press brake that delivers dependable and consistent bending results, Alpha is your trusted partner.

Explore more about Alpha press brake solutions:

👉 Contact Us – Alpha