Press Brake Focus Overview: The Core of Bending Angle Consistency

In modern sheet metal fabrication, bending angle accuracy and consistency over long workpieces are the ultimate quality benchmarks. Even a minor deviation of 0.5° across a 3–6 meter sheet can cause assembly failure, structural stress, and cosmetic defects. The Alpha Press Brake is engineered specifically to solve this challenge through advanced crowning systems, synchronized ram control, and real-time pressure compensation.

Unlike standard bending machines, Alpha’s industrial press brake delivers uniform bending angles from edge to edge, regardless of material thickness, tensile strength, or production batch size.

Why Bending Angle Consistency Is a Critical Manufacturing Problem

During long-length bending operations, several factors naturally cause angle deviation:

-

Ram deflection at high tonnage

-

Frame elastic deformation

-

Uneven material grain structure

-

Variations in sheet thickness

-

Inconsistent hydraulic pressure distribution

-

Tool wear and die deformation

Without proper compensation, these variables result in:

-

Middle-section under-bending

-

Edge over-bending

-

Repeated trial bending and scrap

-

High rework cost and unstable quality

A high-accuracy press brake must control deflection dynamically, not statically.

Crowning System: The Mechanical Foundation of Angle Uniformity

The crowning system is the most critical structure for angle consistency in a press brake. Alpha integrates CNC-controlled dynamic crowning directly into the lower table.

Working Principle

During bending, the machine automatically generates an inverse micro-deflection curve to counteract ram and frame bending. This ensures that the pressure along the entire bending length remains uniform.

Technical Advantages

-

Real-time compensation based on tonnage

-

Automatic adjustment for different materials

-

No manual shimming required

-

Repeatable accuracy in mass production

Without dynamic crowning, long-sheet bending accuracy simply cannot be guaranteed.

Ram Synchronization Technology for Parallel Motion Control

Alpha press brakes utilize servo-hydraulic or electro-hydraulic synchronization systems to control the left and right cylinders independently while maintaining perfect parallelism.

Key Functions:

-

Electronic synchronization of Y1 and Y2 axes

-

Position feedback via high-resolution linear scales

-

Closed-loop control with real-time correction

This prevents:

-

Torsion deformation of the ram

-

Asymmetric angle deviation

-

Tool misalignment and uneven die wear

Hydraulic Pressure Uniformity & Load Distribution

Angle consistency is directly linked to hydraulic pressure stability. Alpha integrates:

-

Independent proportional valves for each cylinder

-

Pressure sensors for closed-loop feedback

-

Automatic load balancing algorithms

This guarantees:

-

Equal tonnage distribution across the bending length

-

Stable force output during full stroke

-

No pressure lag between left and right sides

Press Brake Frame Rigidity & Anti-Deflection Design

Alpha press brake frames are fabricated from high-strength steel plates using full-penetration welding and multi-stage stress relief heat treatment. This structure offers:

-

Extremely low elastic deformation

-

Long-term geometric stability

-

Resistance to cyclic fatigue under high tonnage

A rigid frame is the structural prerequisite for any precision crowning and synchronization system.

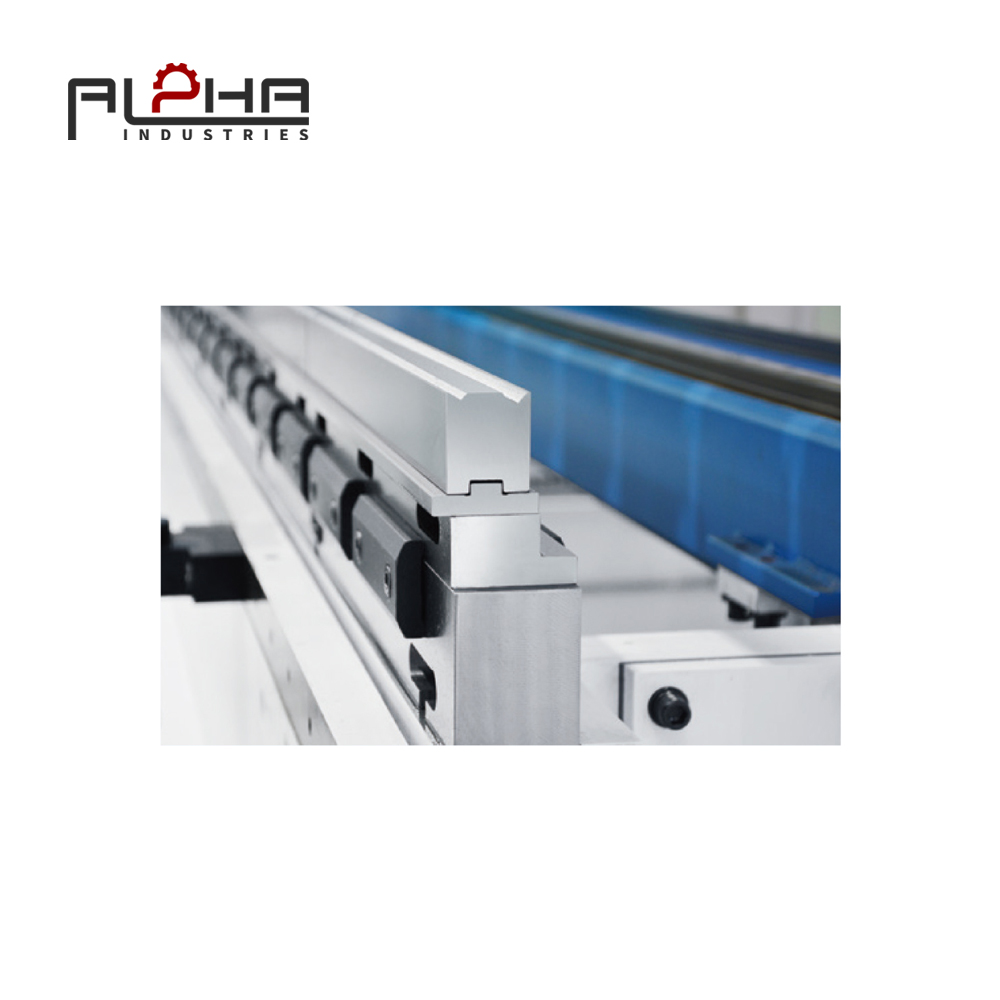

Tooling Precision and Its Impact on Angle Stability

Even the most advanced press brake cannot maintain accuracy without high-precision tooling. Alpha press brakes are compatible with:

-

Hardened segmented punches

-

Precision-ground V-dies

-

Quick clamping systems with micron-level repeatability

This ensures:

-

Identical tool positioning in every cycle

-

Stable neutral axis position

-

Uniform material flow during bending

Back Gauge Control for Repeatable Bending Geometry

Repeatable angle consistency requires perfect flange positioning. Alpha press brakes integrate:

-

High-speed servo-driven back gauge

-

Multi-axis positioning (X, R, Z, X1, X2)

-

Automatic compensation for tool height

This guarantees:

-

Identical bending geometry for every part

-

Stable batch-to-batch accuracy

-

Minimal human adjustment error

Angle Measurement & Automatic Correction

For high-end production, Alpha supports laser angle measurement systems that provide:

-

Real-time angle feedback after each bend

-

Automatic press depth correction

-

Closed-loop bending accuracy without test pieces

This reduces:

-

First-piece adjustment time

-

Operator dependency

-

Material waste and tool setup errors

How Angle Consistency Improves Production Economics

High bending consistency directly results in:

-

40–60% reduction in scrap rate

-

30% faster setup time

-

Higher assembly pass rate

-

Lower tool replacement cost

-

Shorter production cycles

This transforms the press brake from a “forming machine” into a precision-controlled manufacturing system.

Industries That Demand Extreme Angle Consistency

Alpha press brakes are widely used in:

-

Electrical enclosure manufacturing

-

Elevator panels and rails

-

Precision HVAC duct systems

-

Automotive body and frame parts

-

Stainless steel kitchen equipment

-

Cabinet and rack fabrication

These industries require long-sheet flatness, tight angular tolerances, and perfect dimensional symmetry.

Alpha Press Brake Quality Control for Angle Accuracy

Every Alpha press brake undergoes:

-

Laser straightness inspection of ram and table

-

Full-load deflection simulation testing

-

Repeated long-sheet bending verification

-

Crowning response curve calibration

-

Hydraulic pressure consistency testing

Only machines that meet strict industrial accuracy standards are released for shipment.

FAQ

Q1: What causes bending angle inconsistency on long sheets?

Ram deflection, frame deformation, uneven hydraulic pressure, and material variation are the primary causes.

Q2: How does a crowning system improve press brake accuracy?

It generates reverse deflection to offset natural ram bending, ensuring uniform pressure along the full bending length.

Q3: Why is hydraulic synchronization important for angle control?

It prevents left-right tilt of the ram, maintaining perfect parallel bending.

Q4: Can angle inconsistency be corrected automatically?

Yes. With laser angle measurement and closed-loop correction, the press brake can auto-adjust depth in real time.

Q5: Is back gauge accuracy related to bending angle?

Yes. Incorrect flange positioning causes angular deviation even if the press system itself is precise.

If your production requires perfect long-length bending accuracy, zero edge-to-center angle deviation, and stable batch consistency, Alpha’s Press Brake Machine is engineered to meet the highest industrial standards.

👉 Explore Alpha Metal Processing Equipment:

-

CNC Lathe Slant – High-precision turning solution

-

Vertical Machining Center – Multi-axis milling system

-

Drilling & Milling Machine – Dual-function machining

-

Laser Cutting Machine – High-speed sheet processing

-

Surface Grinder – Ultra-fine finishing accuracy