Without high-quality lathe machines, this is the cornerstone of manufacturing and manufacturing, modern workshops are incomplete. These powerful devices are essential for shaping materials such as metals and wood with excellent accuracy. With the development of technology, lathes have also evolved from manually operated equipment to complex systems such as CNC lathes, which provide unparalleled control and repeatability. The right machine converts raw materials into perfect finished products, making it a key investment for any serious processing enterprise focusing on quality and efficiency.

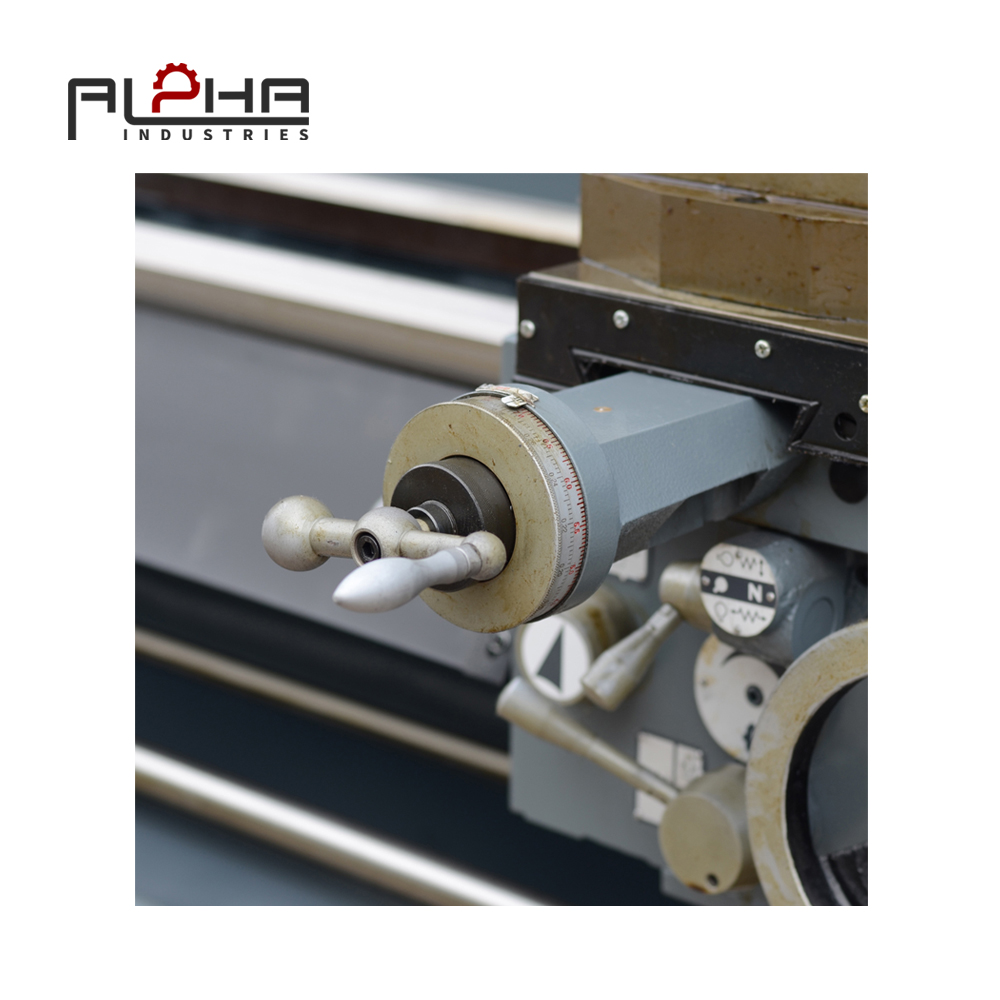

Achieve unparalleled precision and control

The core of any effective lathe operation is the ability to perform precise machining. Modern lathes keep this goal in mind. They feature a fine detailed control mechanism with smooth operation of the dial and a clearly calibrated to ensure that every cut is accurate. The focus on accuracy allows operators to meet the most demanding industry standards with confidence. Whether you are working on complex projects or simple plastic surgery tasks, the precision provided by a well-designed machine separates professional results from amateur work. Intuitive control simplifies the entire lathe operation and enables the user to effectively implement complex geometry.

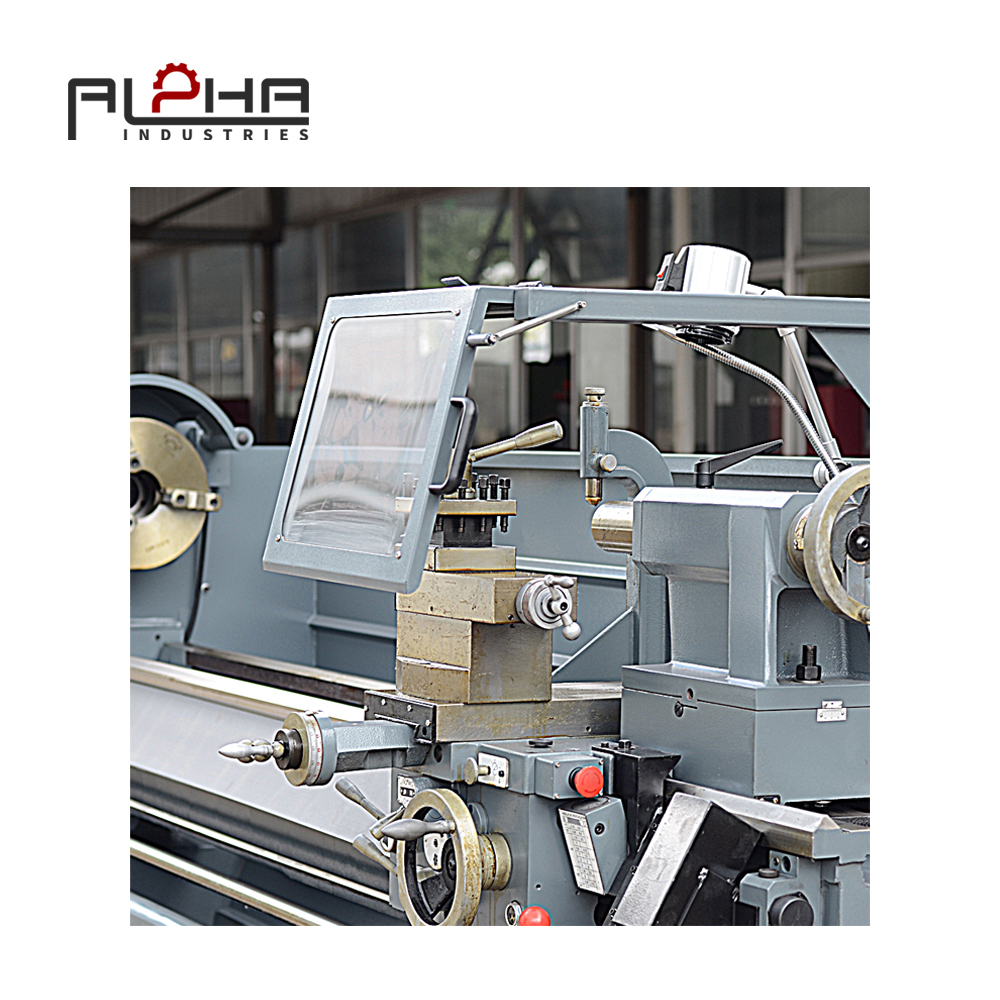

Designed for durability and operator efficiency

Lathes are a major investment and their lifespan is crucial. Leading manufacturers use powerful high-end materials to build machines that can withstand years of powerful and heavy workload. Built for flexibility, ensuring stable performance transfer after shifts. In addition to the original strength, modern design emphasizes ergonomics. Thoughtfully placed controls and profile handles reduce operator strain during extended lathe operation, thus improving safety and productivity. From the smallest knob to the spindle, each component forms a critical lathe part designed for both durability and ease of use, reflecting a commitment to construction machinery for long-term reliability.

The versatility of modern lathe tools and functions

Today’s lathe machine is much more than a simple turning tool. This is a powerful and versatile power. With the right lathe tool, a machine can perform a wide variety of tasks, including threading, cutting, face and shaping. Alpha's advanced models integrate complex engineering, such as balanced spindle designs, to minimize vibration and maintain consistency in all functions. This versatility allows the workshop to quickly adapt to different project requirements, reducing machine downtime and amplifying output. The ability to seamlessly switch between features makes modern CNC lathes an essential asset for any manufacturing or custom manufacturing business to improve its workflow and expand its capabilities.

Select the right partner among lathe suppliers

Choosing the right machine is only part of the equation; choosing the right partner from the ocean of lathe supplier is equally crucial. A well-known supplier is more than just selling equipment. Companies such as Nanjing Alpha CNC Co., Ltd act as solutions providers, guiding customers to choose a machine to design the entire production line. Through a professional R&D team, they provide world-class design and manufacturing capabilities to ensure you have access to machines targeted to precise machining. When you work with experienced lathe suppliers, you will receive expert support, safe and cost-effective transportation and the confidence that you bring to invest in reliable, high-performance lathe parts and systems. Improve your business by choosing a supplier dedicated to your success and operational excellence.