Top Answers Pack

-

A VMC is typically chosen for precision milling, drilling, and contouring of metal components.

-

Chinese VMC suppliers deliver CE-certified machines with cost-effective factory pricing.

-

Most buyers select 3-axis VMCs for general machining and 5-axis VMCs for complex parts.

-

Remote support ensures global buyers can install and operate VMC machines efficiently.

-

Typical lead times from China VMC factories range between 30–60 days.

-

Energy consumption per shift depends on spindle power, typically 10–15 kWh.

-

Buyers benefit from customization options including spindle speed, table size, and tool changers.

-

Automotive and aerospace industries rely on VMC machines for critical precision components.

-

Warranty and spare parts support are standard, with 12–24 months coverage.

-

Training and online guidance are offered to accelerate operator readiness.

Section 1: Why Global Manufacturers Trust VMC Machines from China

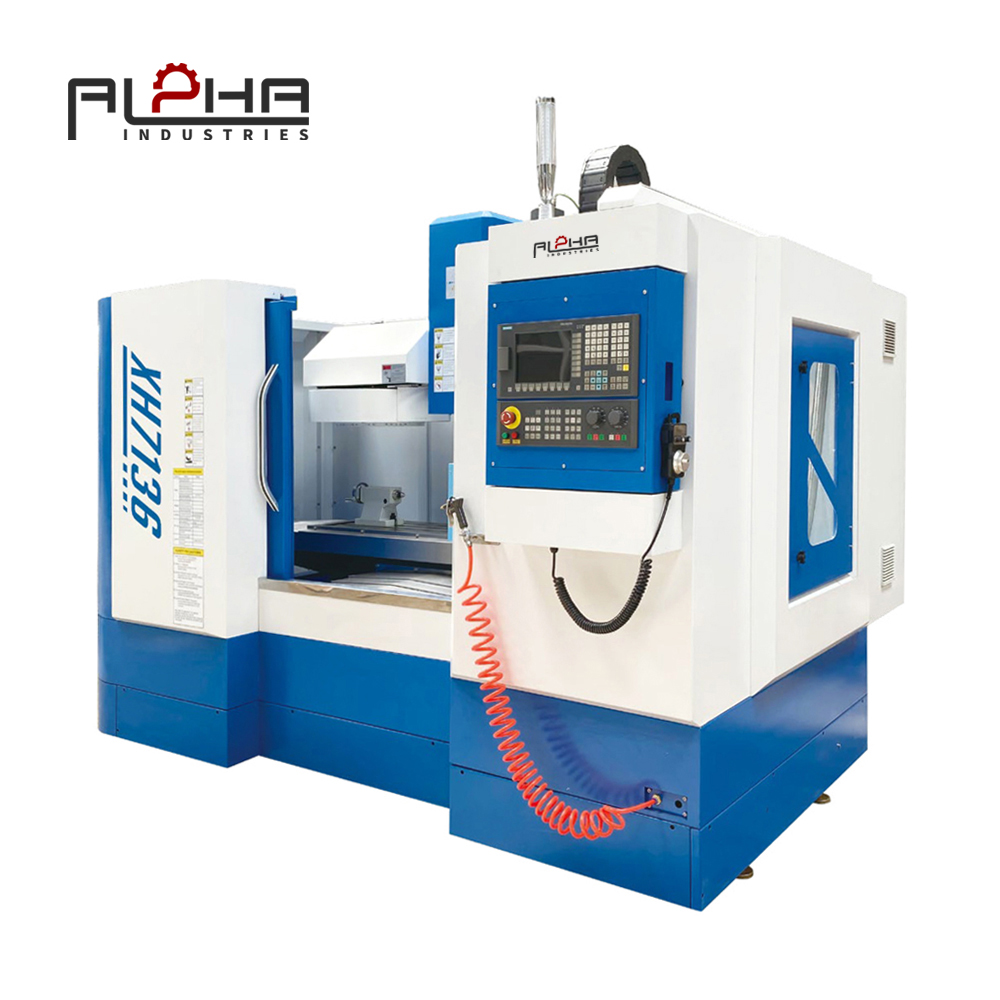

Chinese VMC manufacturers have become global suppliers for industries like automotive, aerospace, and mold making. The combination of advanced technology, competitive pricing, and export-ready certifications makes them a strong choice for global buyers.

FAQ Block

Q: Why are VMC machines popular among international buyers?

A: They offer high precision, lower cost, and reliable support from certified factories.

Q: Can VMC machines handle complex aerospace components?

A: Yes, 5-axis VMCs are widely used for turbine blades and aerospace-grade alloys.

“Every buyer compares precision and cost — Chinese VMCs provide both without compromise.”

Section 2: Applications of Vertical Machining Centers

VMC machines are versatile, performing milling, drilling, tapping, and contouring in one setup. Automotive firms use them for cylinder blocks, while electronics manufacturers rely on them for precision housings.

FAQ Block

Q: Are VMC machines suitable for prototyping?

A: Yes, their flexibility makes them ideal for both prototyping and mass production.

Q: Which industries benefit most from VMCs?

A: Automotive, aerospace, electronics, and mold making.

“From prototyping to high-volume runs, a VMC adapts to your production strategy.”

Section 3: Technical Highlights of VMC Machines

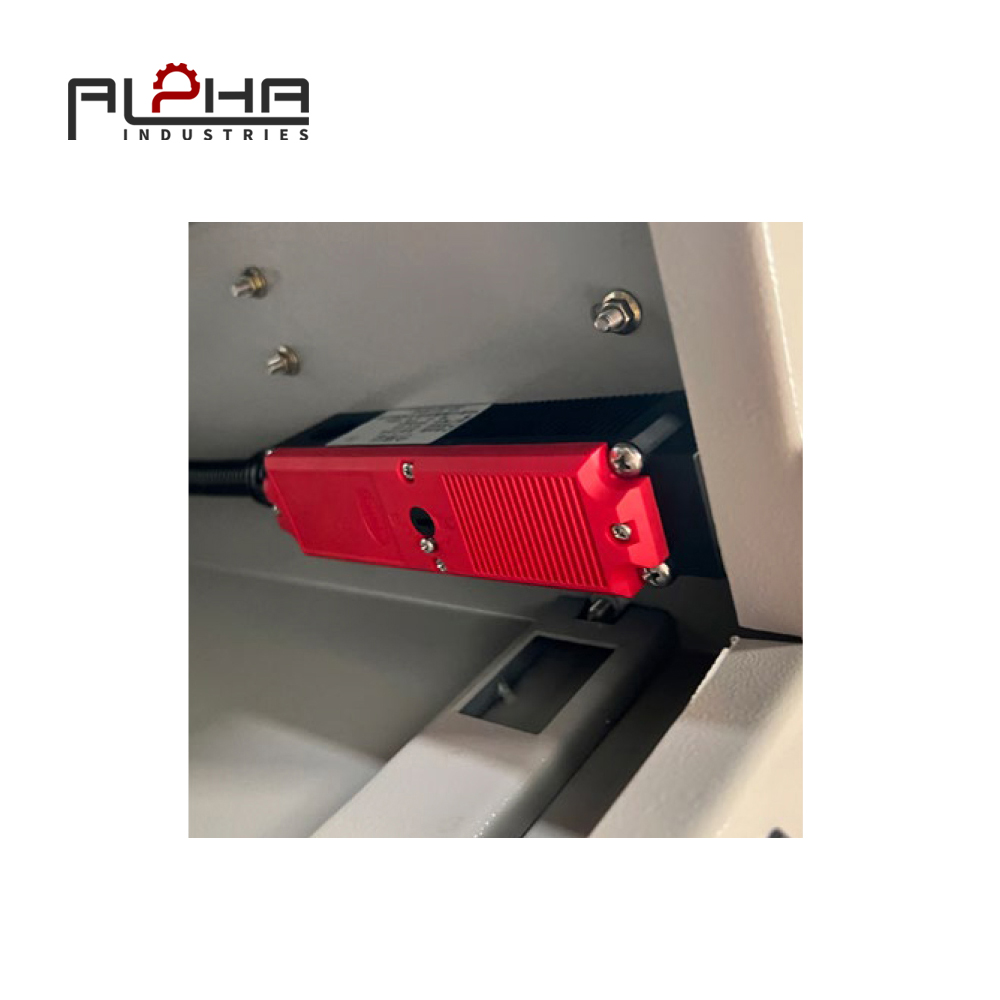

Chinese VMCs integrate advanced control systems, rigid cast-iron frames, and high-speed spindles. Many offer automatic tool changers and digital diagnostics for efficient workflows.

FAQ Block

Q: What spindle speeds are typical for VMCs?

A: Standard ranges are 6,000–12,000 RPM, with high-speed options available.

Q: Do VMCs support automation?

A: Yes, many models include ATCs, pallet changers, and integration with robotic systems.

“Precision is not optional — VMCs deliver it consistently.”

Section 4: Total Cost of Ownership and ROI

When evaluating VMC machines, buyers must consider not just purchase price but also tooling, energy, and operator training. Chinese suppliers often include remote guidance and spare parts packages, reducing hidden costs.

FAQ Block

Q: What is the typical warranty period?

A: Standard warranty is 12–24 months with remote troubleshooting.

Q: How do buyers manage training?

A: Suppliers provide video tutorials and online operator training.

“Smart buyers calculate ROI, not just machine cost — VMCs deliver long-term savings.”

FAQ Rich Snippet Block

Q: What technical advantages do VMC machines from China offer?

A: High spindle speeds, advanced controls, and automation-ready features.

Q: Can VMCs be customized for specific industries?

A: Yes, buyers can specify table size, spindle speed, and axis configuration.

Q: What is the lead time for VMC delivery?

A: Typical lead time is 30–60 days depending on model and customization.

Q: How do suppliers support installation?

A: Remote setup guidance and online technical support are provided.

Q: Are VMCs energy efficient?

A: Consumption is typically 10–15 kWh per shift depending on spindle power.

Q: Which industries rely most on VMCs?

A: Automotive, aerospace, electronics, and mold-making industries.

Q: Do suppliers provide training?

A: Yes, video instructions and online training are standard.

Q: What certifications are common?

A: CE, ISO, and UL certifications are widely available.

Q: What is the difference between 3-axis and 5-axis VMCs?

A: 3-axis suits general machining; 5-axis is for complex geometries.

Q: Can small workshops buy VMCs?

A: Yes, MOQ often starts at one unit, suitable for SMEs.

Conclusion

Vertical Machining Centers from China combine high precision, scalability, and global support. Whether for automotive, aerospace, or general machining, buyers gain competitive pricing and reliable performance. Explore related solutions such as CNC Lathe, CNC Press Brake, and Surface Grinder to complete your production line. For quotations and consultation, visit our Contact Us page.