Why Spindle Accuracy Defines VMC Performance

In modern CNC machining, precision is the ultimate benchmark of machine performance.

At the heart of every Vertical Machining Center (VMC) lies the spindle system, which directly determines cutting accuracy, surface quality, and long-term stability.

No matter how advanced the control system or how rigid the machine structure, spindle accuracy ultimately defines machining results.

For manufacturers targeting tight tolerances and consistent output, spindle precision is not a specification detail—it is a strategic capability.

This article focuses on one critical performance factor:

👉 VMC spindle accuracy, how it is engineered, measured, and maintained in real industrial production.

What Is Spindle Accuracy in a VMC?

Spindle accuracy refers to the spindle’s ability to rotate with minimal radial and axial deviation during operation.

Key elements of spindle accuracy include:

-

Radial runout

-

Axial runout

-

Rotational stability

-

Thermal stability

In a high-quality VMC, spindle runout is typically controlled within micron-level tolerances, ensuring precise tool positioning at all speeds.

Why Spindle Accuracy Matters in Vertical Machining

Spindle accuracy directly affects:

-

Dimensional precision of machined parts

-

Surface finish quality

-

Tool life and wear rate

-

Machining repeatability

Even a small deviation at the spindle nose can lead to:

-

Poor surface finish

-

Inconsistent dimensions

-

Increased vibration

-

Higher scrap rates

For precision components, spindle accuracy often determines whether a part passes or fails inspection.

Spindle Runout: The Most Critical Accuracy Metric

Spindle runout is the deviation of the spindle’s rotational axis from its ideal centerline.

Types of runout:

-

Radial runout – affects hole roundness and side wall finish

-

Axial runout – affects face milling flatness and depth control

High-performance VMC spindles typically achieve runout values of ≤ 0.003 mm at the spindle nose.

Lower runout ensures:

-

Accurate tool paths

-

Smooth cutting action

-

Reduced vibration during high-speed machining

Bearing System Design and Spindle Precision

The spindle bearing system is the foundation of spindle accuracy.

High-precision VMC spindles use:

-

Angular contact ceramic bearings

-

Preloaded bearing arrangements

-

Optimized bearing spacing

These design choices provide:

-

High rotational accuracy

-

Excellent rigidity under load

-

Stable performance at high RPM

Bearing quality and assembly precision directly impact long-term spindle reliability.

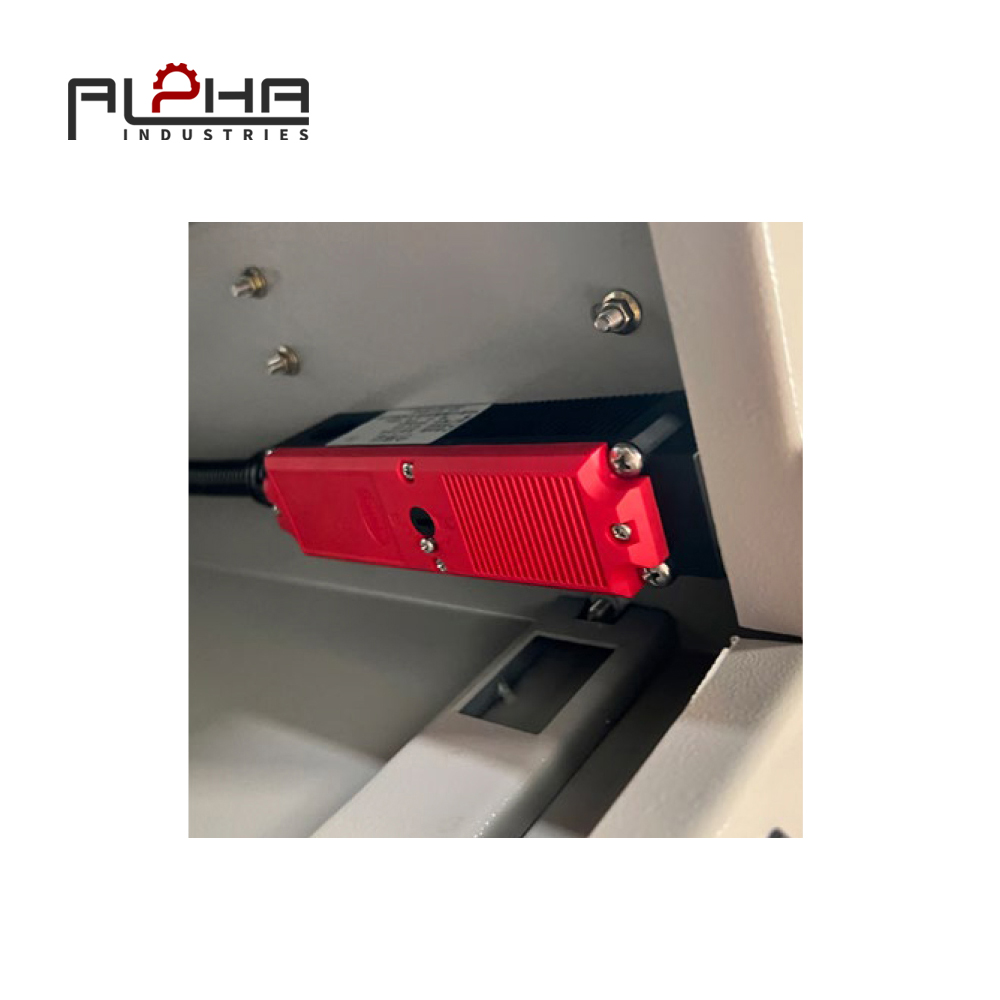

Thermal Stability: Maintaining Accuracy Over Time

During high-speed machining, heat generation is unavoidable.

Without proper thermal control, spindle expansion can compromise accuracy.

Advanced VMC spindle systems include:

-

Spindle cooling jackets

-

Oil-air lubrication systems

-

Temperature monitoring sensors

Thermal stability ensures:

-

Consistent accuracy during long machining cycles

-

Reduced thermal drift

-

Reliable dimensional control

Spindle Taper Quality and Tool Interface

The spindle taper is the direct interface between the spindle and cutting tool.

High-quality VMCs use:

-

Precision-ground BT / CAT / HSK tapers

-

Strict taper angle tolerances

-

Controlled contact surface finish

A precise taper interface ensures:

-

Firm tool clamping

-

Minimal micro-movement

-

Stable torque transmission

Poor taper accuracy can negate even the best spindle bearing design.

Spindle Speed, Torque, and Accuracy Balance

Higher spindle speed does not automatically mean better accuracy.

A well-designed VMC spindle balances:

-

Speed capability

-

Torque output

-

Rotational stability

Advanced spindle motors and drive systems allow:

-

Smooth acceleration and deceleration

-

Stable cutting across material types

-

Reduced vibration at both low and high speeds

This balance is essential for precision machining.

How Spindle Accuracy Improves Production Efficiency

High spindle accuracy delivers measurable production benefits:

-

Better surface finish reduces secondary operations

-

Stable cutting extends tool life

-

Higher feed rates without loss of quality

-

Reduced scrap and rework

Over time, a precision spindle significantly lowers cost per machined part.

Key Spindle Accuracy Parameters Buyers Should Evaluate

When selecting a VMC, buyers should examine:

-

Spindle runout tolerance (mm)

-

Maximum spindle speed (RPM)

-

Bearing type and preload method

-

Thermal control system

These parameters are often more important than axis travel alone.

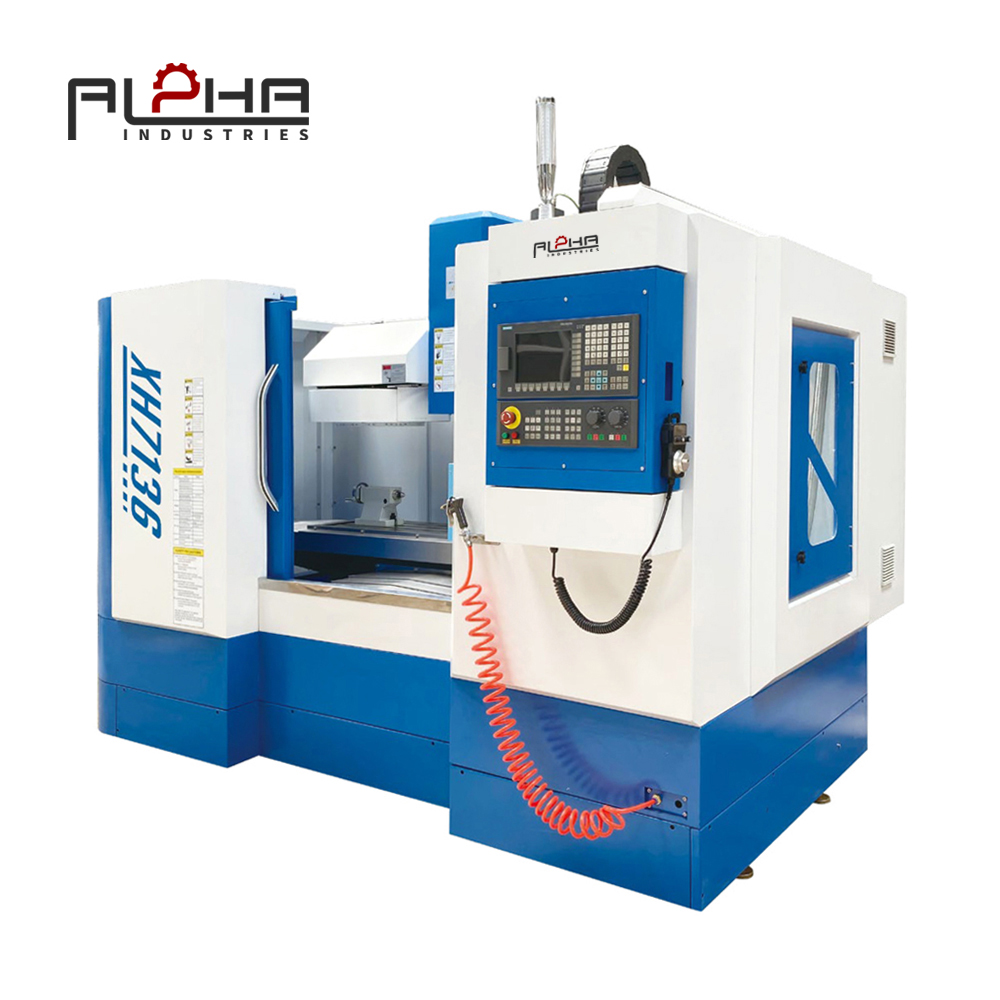

Alpha VMC Spindle Engineering

At Alpha, VMC spindle systems are engineered with precision as a core principle.

Key design features include:

-

High-precision bearing assemblies

-

Rigid spindle housing structures

-

Advanced cooling and lubrication systems

-

Strict assembly and testing standards

This ensures long-term spindle accuracy even in demanding industrial environments.

Applications Where VMC Spindle Accuracy Is Critical

High spindle accuracy is essential in:

-

Mold and die machining

-

Aerospace components

-

Automotive precision parts

-

Medical equipment components

-

High-tolerance mechanical housings

In these industries, micron-level deviations are unacceptable.

FAQ

Q1: How accurate is a VMC spindle?

High-quality VMC spindles typically achieve runout of ≤ 0.003 mm at the spindle nose.

Q2: What affects VMC spindle accuracy the most?

Bearing quality, spindle assembly precision, thermal stability, and taper accuracy are the key factors.

Q3: Does spindle accuracy affect surface finish?

Yes. Higher spindle accuracy directly results in smoother surface finish and better dimensional control.

Q4: Can spindle accuracy degrade over time?

Without proper maintenance, bearing wear and thermal stress can reduce accuracy. Well-designed spindles maintain precision for long service life.

Spindle Accuracy Is the Heart of a High-Performance VMC

Spindle accuracy is the defining factor of VMC performance.

Through precision bearings, thermal control, and optimized taper design, a high-quality VMC delivers consistent accuracy, superior surface finish, and reliable productivity.

For manufacturers pursuing precision and efficiency, choosing a VMC with an advanced spindle system is not an expense—it is a long-term competitive advantage.

👉 Learn more about Alpha VMC solutions:

https://alpha-cnc.com/