VMC Spindle System Technology for High-Precision Machining

The spindle system is the heart of a Vertical Machining Center (VMC). It directly determines cutting accuracy, machining stability, tool life, and overall production efficiency. For high-speed milling, drilling, tapping, and contour machining, the performance of the VMC spindle system becomes the decisive factor that separates ordinary machines from true industrial-grade machining centers.

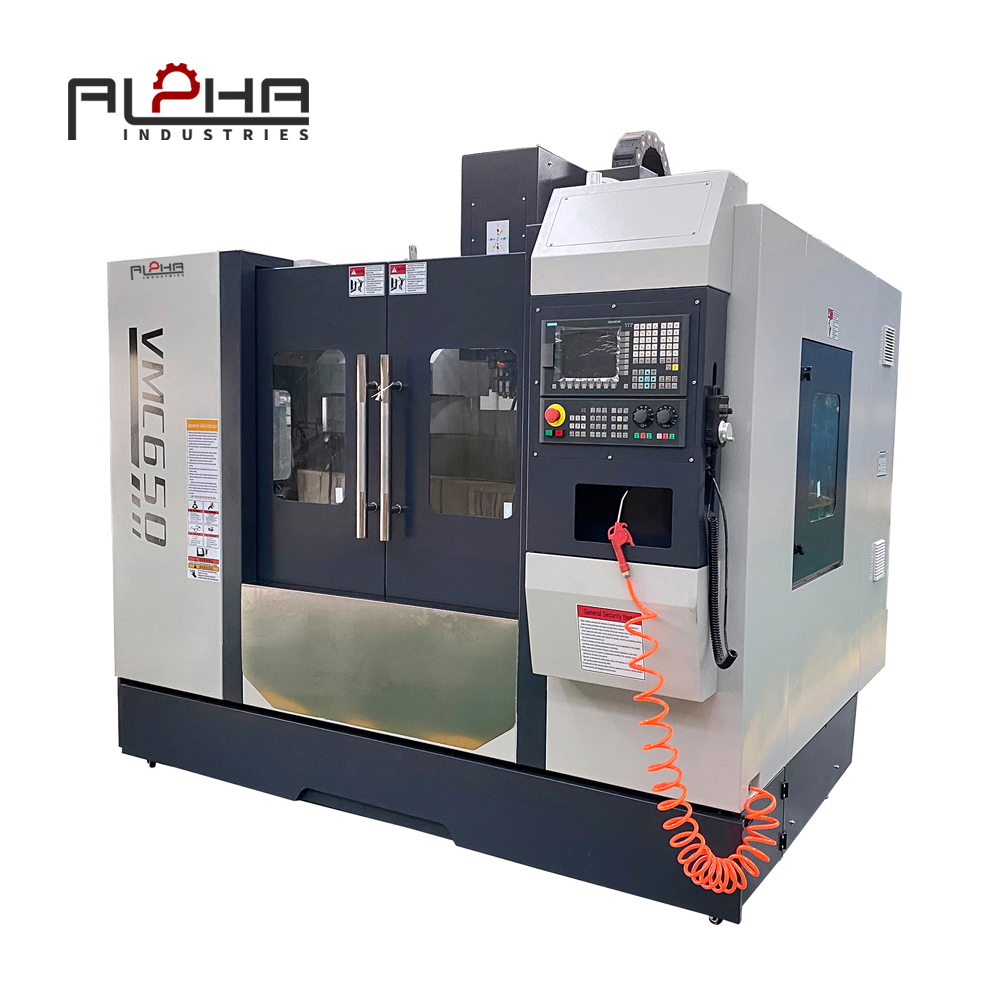

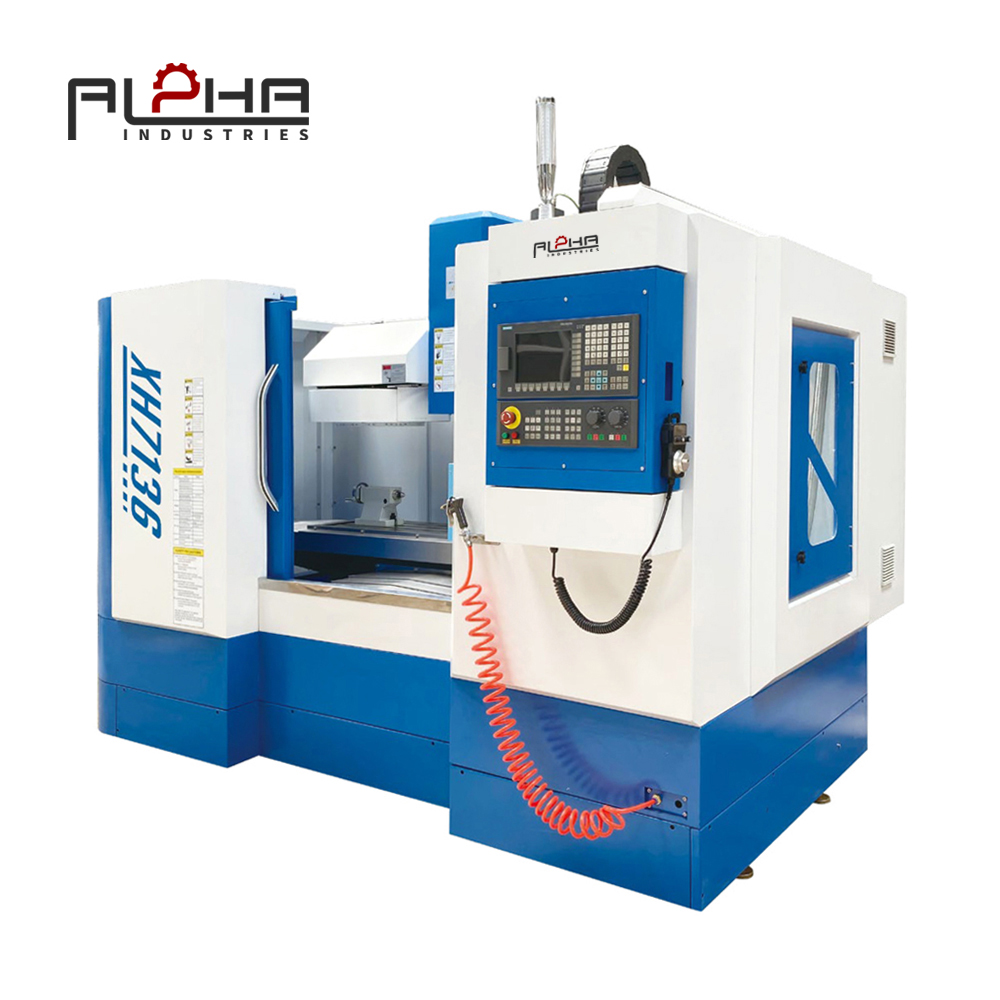

At Alpha, our VMC machines are engineered with high-rigidity, high-speed, and thermally stable spindle systems to meet the demanding requirements of aerospace, automotive, mold manufacturing, and precision component production.

What Is a VMC Spindle System?

The VMC spindle system is the rotating core component that holds and drives the cutting tool. It consists of:

-

Precision spindle shaft

-

High-speed bearings (angular contact or ceramic bearings)

-

Drive motor (belt-driven or direct-drive)

-

Lubrication system

-

Cooling and thermal control module

-

Tool clamping mechanism (BT40 / BT50 / HSK)

The spindle converts motor power into controlled, stable rotational motion, enabling accurate removal of material from the workpiece.

Why the Spindle System Determines VMC Accuracy

The machining accuracy of a VMC is not defined only by the guideways or servo motors. In high-speed cutting, spindle vibration, runout, and thermal deformation become the primary causes of dimensional deviation.

A high-performance VMC spindle directly influences:

-

✅ Surface roughness (Ra value)

-

✅ Dimensional tolerance

-

✅ Tool life and wear rate

-

✅ Cutting stability at high RPM

-

✅ Production cycle consistency

Poor spindle rigidity leads to micro-chatter, tool deflection, and poor surface finish—even if the machine uses high-end controllers.

Alpha High-Precision VMC Spindle Technical Features

Alpha VMC machines adopt industrial-grade spindle assemblies, designed for continuous high-load machining:

1. High-Speed Spindle Options

-

8,000 / 10,000 / 12,000 / 15,000 RPM configurations

-

Suitable for aluminum, steel, stainless steel, and titanium alloys

-

Optimized for both roughing and finishing operations

2. Ultra-Low Runout Design

-

Spindle runout ≤ 0.003 mm

-

Ensures high circularity and flatness

-

Ideal for precision mold cavities and bearing housings

3. Thermal Balance & Cooling System

-

Oil-air lubrication for bearings

-

Spindle temperature rise controlled within ±2°C

-

Eliminates thermal drift during long machining cycles

4. Heavy-Duty Bearing Structure

-

High preload angular contact bearings

-

Excellent axial and radial rigidity

-

Supports heavy cutting loads without vibration

Belt-Driven vs Direct-Drive Spindle in VMC

| Type | Advantages | Applications |

|---|---|---|

| Belt-Driven Spindle | Cost-effective, high torque at low RPM, easy maintenance | Steel, cast iron, heavy roughing |

| Direct-Drive Spindle | Higher speed, lower vibration, faster spindle response | Mold making, aluminum, surface finishing |

Alpha offers both belt-driven and direct-drive VMC spindle configurations, allowing customers to select the most suitable solution based on material and production demands.

Industry Applications Demanding High-Precision VMC Spindles

High-performance spindle systems are essential in industries where any deviation results in part rejection:

-

Automotive parts (engine blocks, transmission housings)

-

Aerospace components (aluminum structural parts)

-

Precision molds and dies

-

Medical device components

-

5G communication aluminum enclosures

These industries demand high RPM stability, zero vibration, and micron-level accuracy—fully supported by Alpha VMC spindle technology.

How the VMC Spindle Improves Cutting Efficiency

An advanced spindle system increases:

-

Material removal rate (MRR)

-

Tool change stability

-

Chip evacuation efficiency

-

Continuous 24/7 machining reliability

With optimized torque curves and thermal stabilization, Alpha VMC machines can achieve faster feed rates with consistent surface quality, reducing overall production cost per part.

Maintenance and Service Life of VMC Spindle

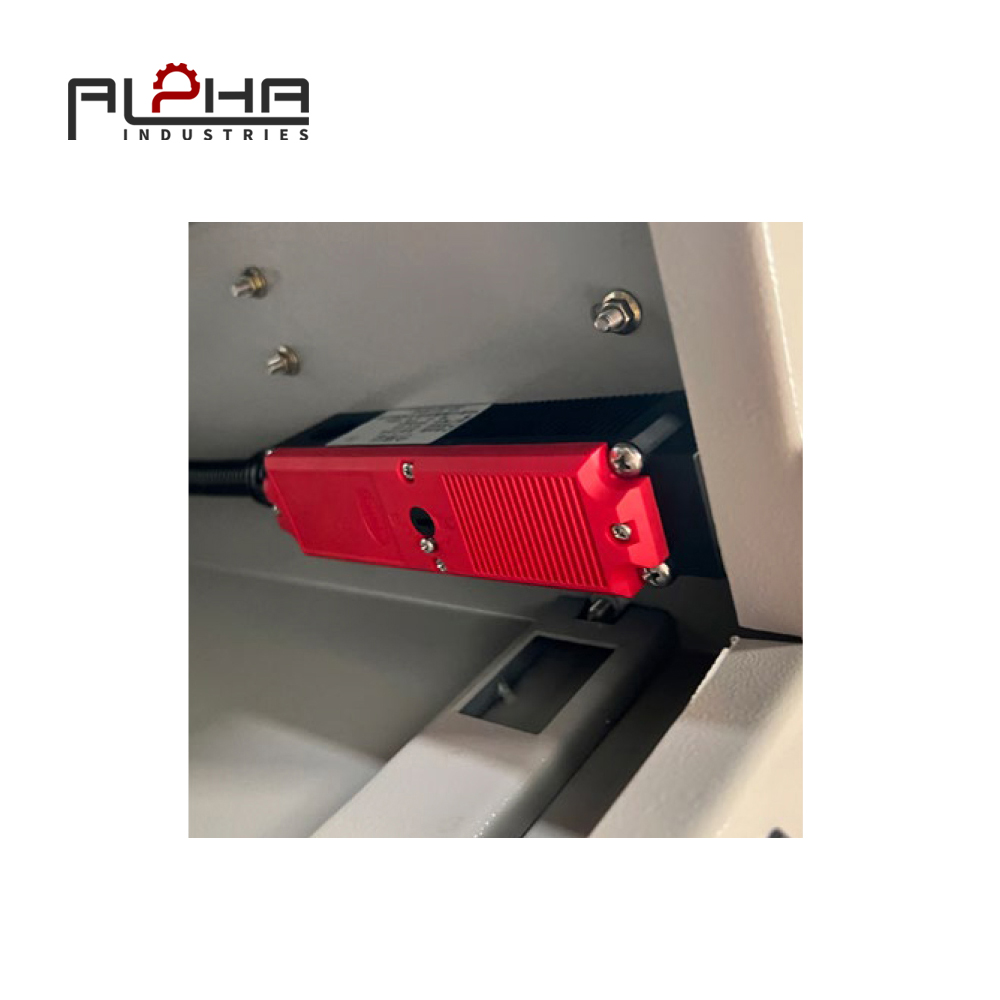

Proper spindle maintenance ensures long-term machining accuracy:

-

Automatic lubrication system prevents bearing wear

-

Spindle temperature monitoring avoids overheating

-

Balanced tool holders reduce vibration damage

-

Regular runout inspection maintains micron-level performance

Alpha VMC spindle systems are designed for long service intervals and low maintenance cost, ensuring stable output for mass production lines.

FAQ

Q1: What does a VMC spindle do?

A VMC spindle holds and rotates the cutting tool at controlled speeds, enabling precise material removal during milling, drilling, and tapping operations.

Q2: What spindle speed is best for a VMC?

The ideal spindle speed depends on material:

-

Aluminum: 10,000–15,000 RPM

-

Steel: 6,000–10,000 RPM

-

Stainless steel: 6,000–8,000 RPM

Q3: How does spindle rigidity affect machining accuracy?

Higher spindle rigidity reduces vibration and tool deflection, improving surface finish, dimensional tolerance, and tool life.

Q4: What is spindle runout in a VMC?

Spindle runout is the deviation of the spindle rotation axis. Low runout ensures high accuracy and consistent cutting performance.

Why Choose Alpha VMC with High-Precision Spindle System

At Alpha, every VMC spindle assembly undergoes:

-

Dynamic balancing testing

-

Thermal displacement compensation

-

Continuous load endurance testing

-

Precision runout inspection

This ensures that each Vertical Machining Center delivers industrial-grade performance, long-term accuracy, and stable production output for global manufacturing customers.

Call to Action

✅ Looking for a high-precision VMC for aluminum or steel machining?

✅ Need stable spindle performance for 24-hour continuous production?

✅ Want a custom spindle configuration for your industry?

👉 Contact Alpha today for professional VMC solutions and technical support.

To further explore Alpha’s machining solutions, please visit:

-

Vertical Machining Center Product Page:

https://alpha-cnc.com/products/vmc-series -

Press Brake Equipment:

https://alpha-cnc.com/products/cnc-press-brake-series -

Laser Cutting Machines:

https://alpha-cnc.com/products/laser-cutting -

CNC Lathe Slant Solutions:

https://alpha-cnc.com/products/cnc-lathe-slant