VMC Spindle Thermal Stability in High-Precision Machining

In modern manufacturing, VMC (Vertical Machining Center) performance is increasingly judged not by rapid traverse speed alone, but by its ability to maintain stable accuracy during long and continuous machining cycles.

Among all influencing factors, spindle thermal stability plays a decisive role in dimensional consistency, surface finish, and repeatability.

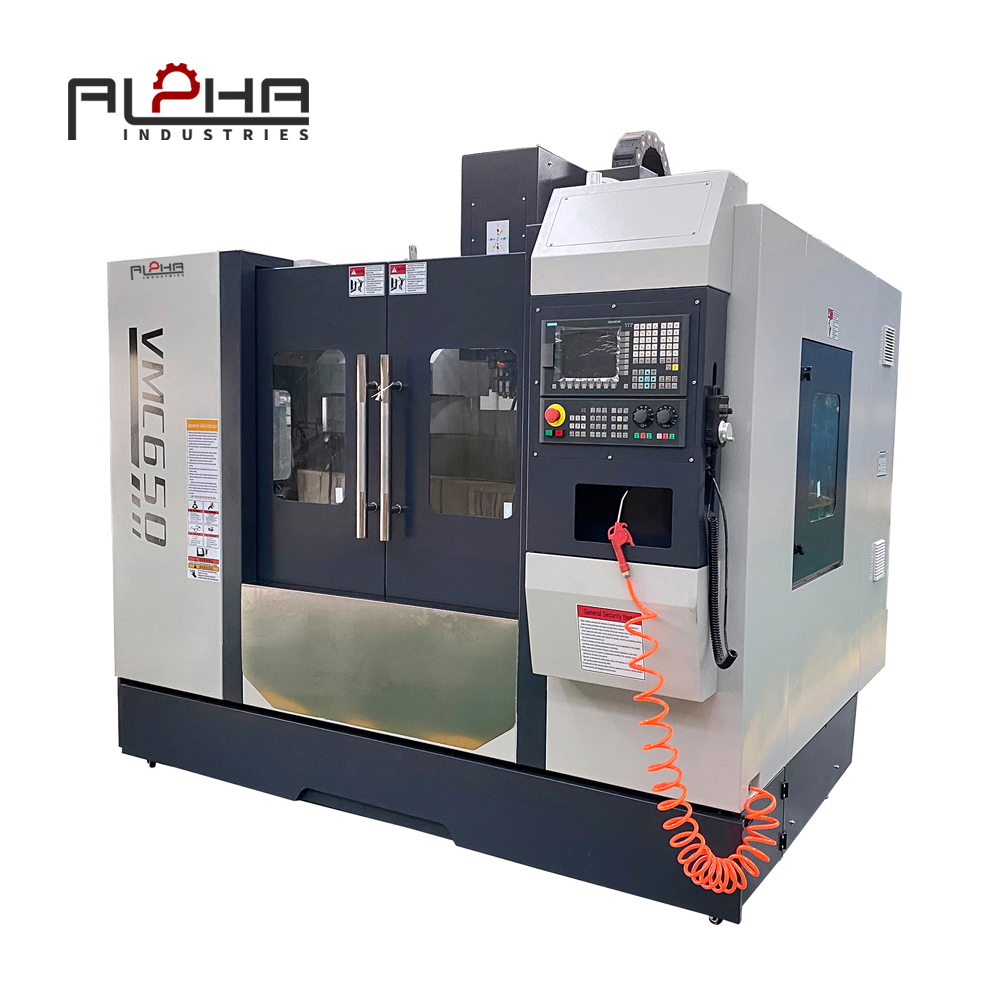

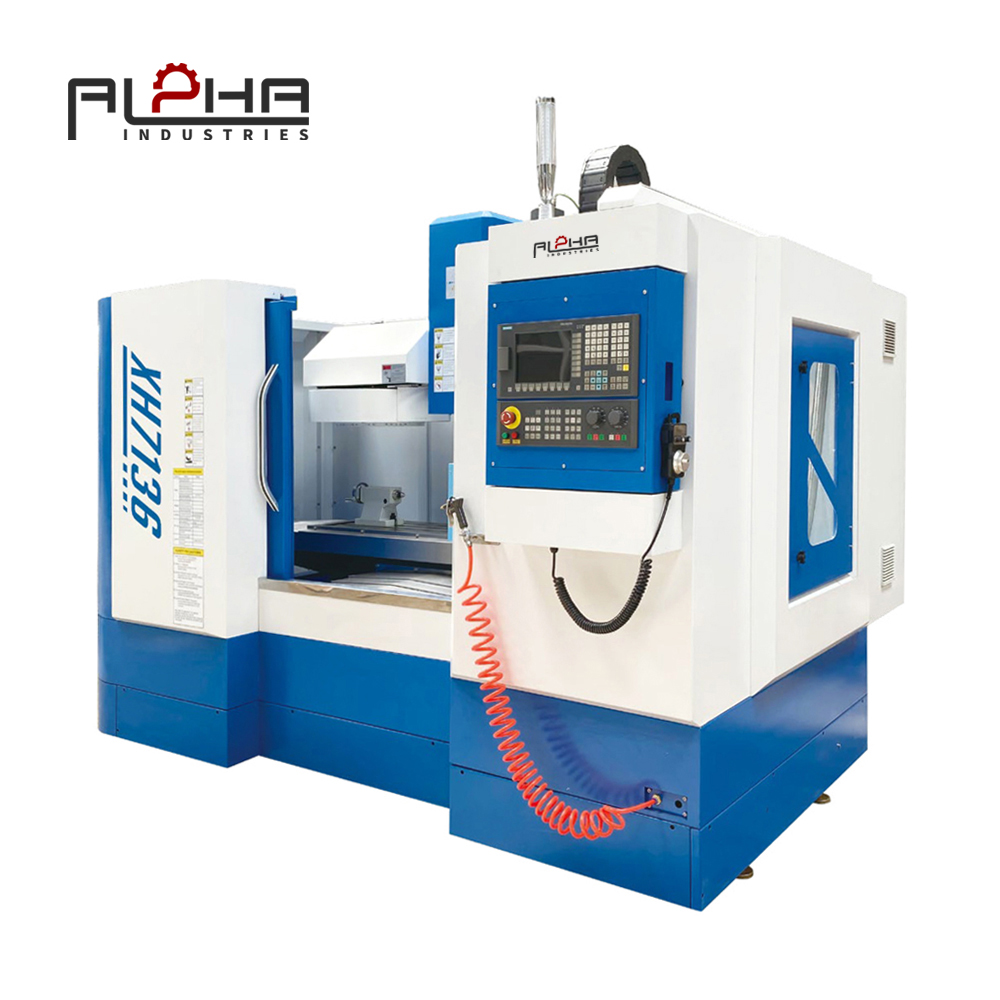

At ALPHA, VMC design focuses on controlling thermal behavior at the spindle level, ensuring machining accuracy remains stable from the first part to the last.

Why Spindle Thermal Stability Is Critical for VMC Accuracy

During machining, spindle rotation generates heat from:

-

Bearing friction

-

Motor operation

-

Cutting load transmission

-

Ambient temperature variation

Even minor temperature changes can cause micron-level spindle elongation, directly affecting:

-

Z-axis dimensional accuracy

-

Hole depth consistency

-

Surface flatness and parallelism

In high-precision parts, uncontrolled thermal growth results in cumulative dimensional errors.

Thermal Deformation — The Invisible Accuracy Killer in VMC Machining

How Thermal Growth Impacts Machining Results

Thermal deformation in the spindle leads to:

-

Tool length variation during operation

-

Inconsistent cutting depth

-

Poor surface finish in finishing passes

-

Loss of positional repeatability

Unlike mechanical backlash, thermal deformation occurs gradually, making it difficult to detect without proper design measures.

Spindle Structure Design for Thermal Stability

Optimized Spindle Bearing Arrangement

ALPHA VMC spindles adopt optimized bearing configurations to balance:

-

Load capacity

-

Rotational stability

-

Heat generation control

High-quality bearings reduce friction-induced heat, improving long-term spindle stability.

Balanced Spindle Shaft Design

Dynamic balancing of the spindle shaft minimizes vibration and uneven heat distribution, ensuring smooth rotation under high-speed operation.

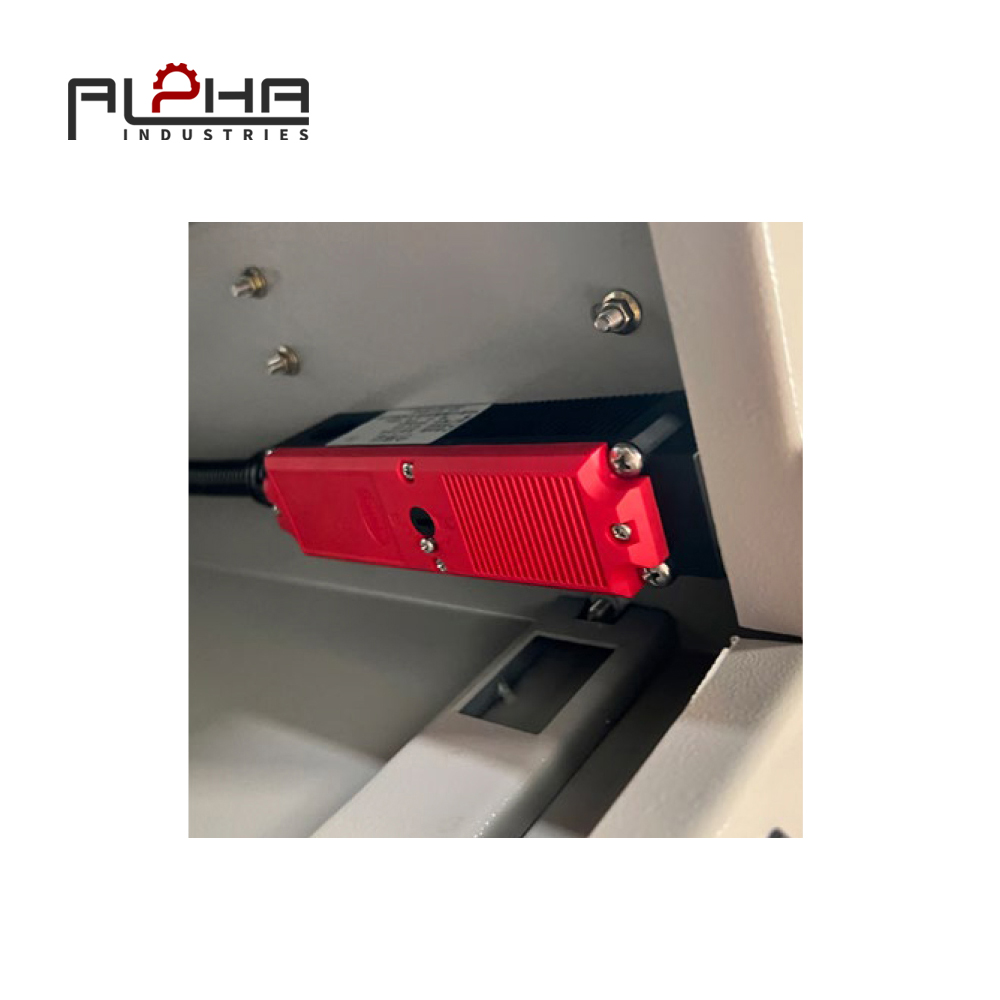

Thermal Management and Cooling Strategies

Controlled Spindle Cooling Systems

Effective thermal control requires consistent heat dissipation.

ALPHA integrates controlled spindle cooling strategies to:

-

Stabilize spindle temperature rise

-

Prevent sudden thermal expansion

-

Maintain consistent cutting conditions

This ensures dimensional accuracy is preserved throughout extended machining cycles.

Machine Structure and Thermal Symmetry

Thermal Symmetry in Headstock and Column Design

Thermal stability is not limited to the spindle alone. Machine structure plays a critical role.

ALPHA VMC machines emphasize:

-

Symmetrical headstock structure

-

Optimized heat flow paths

-

Reduced thermal gradients

This minimizes thermal distortion affecting spindle alignment.

Relationship Between Spindle Thermal Stability and Surface Finish

A thermally stable spindle provides:

-

Constant cutting engagement

-

Reduced tool vibration

-

Uniform chip load

As a result, surface roughness remains consistent even during long finishing operations, especially in mold, die, and precision component machining.

How ALPHA Ensures Stable Spindle Performance in Real Production

ALPHA VMCs are engineered with a system-level thermal control philosophy, integrating:

-

Precision spindle design

-

Optimized bearing and shaft structures

-

Controlled cooling strategies

-

Thermally stable machine architecture

This approach ensures repeatable machining accuracy, not just short-term precision under ideal conditions.

Applications That Demand High Spindle Thermal Stability

VMC spindle thermal stability is especially critical in:

-

Mold and die manufacturing

-

Precision mechanical components

-

Automotive structural parts

-

Aerospace aluminum and steel components

In these applications, dimensional drift caused by heat directly impacts assembly and functional performance.

FAQ

What is spindle thermal stability in a VMC?

It refers to the spindle’s ability to maintain consistent position and length despite temperature changes during machining.

Why does spindle heat affect machining accuracy?

Heat causes spindle expansion, leading to tool length variation and dimensional errors in Z-axis machining.

How can spindle thermal deformation be reduced?

Through optimized spindle design, high-quality bearings, effective cooling systems, and thermally balanced machine structures.

Is spindle thermal stability important for long machining cycles?

Yes. Thermal stability is essential for maintaining accuracy during extended, continuous production.

VMC Thermal Stability vs Short-Term Precision

Short-term positioning accuracy does not guarantee production accuracy.

Only a VMC with controlled spindle thermal behavior can deliver stable, repeatable results over hours of machining.

ALPHA focuses on long-term machining reliability rather than laboratory-level specifications alone.

Conclusion — Thermal Stability Defines True VMC Performance

Spindle thermal stability is not an optional feature; it is a core engineering requirement for modern vertical machining centers.

By controlling thermal behavior at both spindle and structural levels, ALPHA VMC solutions deliver predictable, production-ready machining accuracy for demanding industries.

Learn more about ALPHA Vertical Machining Center Solutions → /vmc