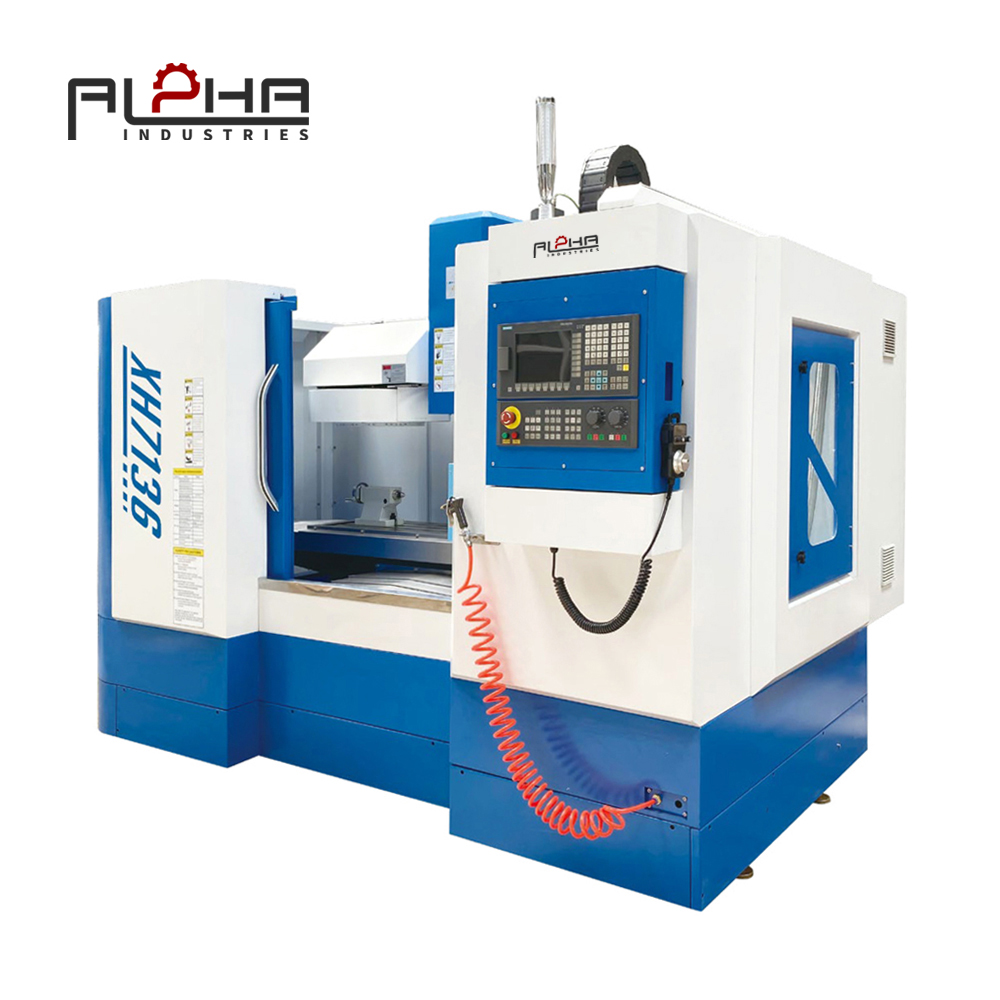

VMC Structural Rigidity and Cutting Stability in Precision Machining

In modern metal cutting, VMC (Vertical Machining Center) performance is no longer defined solely by spindle speed or feed rate.

For real-world production environments, structural rigidity and cutting stability determine whether a machine can maintain accuracy under heavy loads, long cutting cycles, and varying materials.

At ALPHA, VMC engineering emphasizes high-rigidity structural design, ensuring stable cutting performance across a wide range of machining conditions.

Why Structural Rigidity Is the Foundation of VMC Performance

Structural rigidity directly influences:

-

Machining accuracy under load

-

Vibration resistance during cutting

-

Surface finish consistency

-

Tool life and cutting efficiency

-

Long-term machine reliability

Without sufficient rigidity, even the most advanced control system cannot compensate for mechanical deformation during cutting.

Cutting Forces and Their Impact on VMC Structure

During milling operations, cutting forces act on:

-

Spindle and tool interface

-

Headstock and column

-

Saddle and worktable

-

Machine base

If any part of the structure lacks stiffness, these forces cause:

-

Micro deflection

-

Tool chatter

-

Inconsistent material removal

-

Dimensional deviation

High structural rigidity allows the VMC to absorb and distribute cutting forces effectively.

Column and Base Design — The Backbone of VMC Rigidity

One-Piece Column Structure

ALPHA VMC machines adopt a rigid column design with:

-

Thick-walled casting structure

-

Optimized internal ribbing

-

Balanced mass distribution

This design resists bending and torsional deformation during aggressive cutting.

Heavy-Duty Machine Base

A high-mass base provides:

-

Lower vibration amplitude

-

Improved damping characteristics

-

Stable support for the entire machine

This is especially critical in heavy-duty steel and cast iron machining.

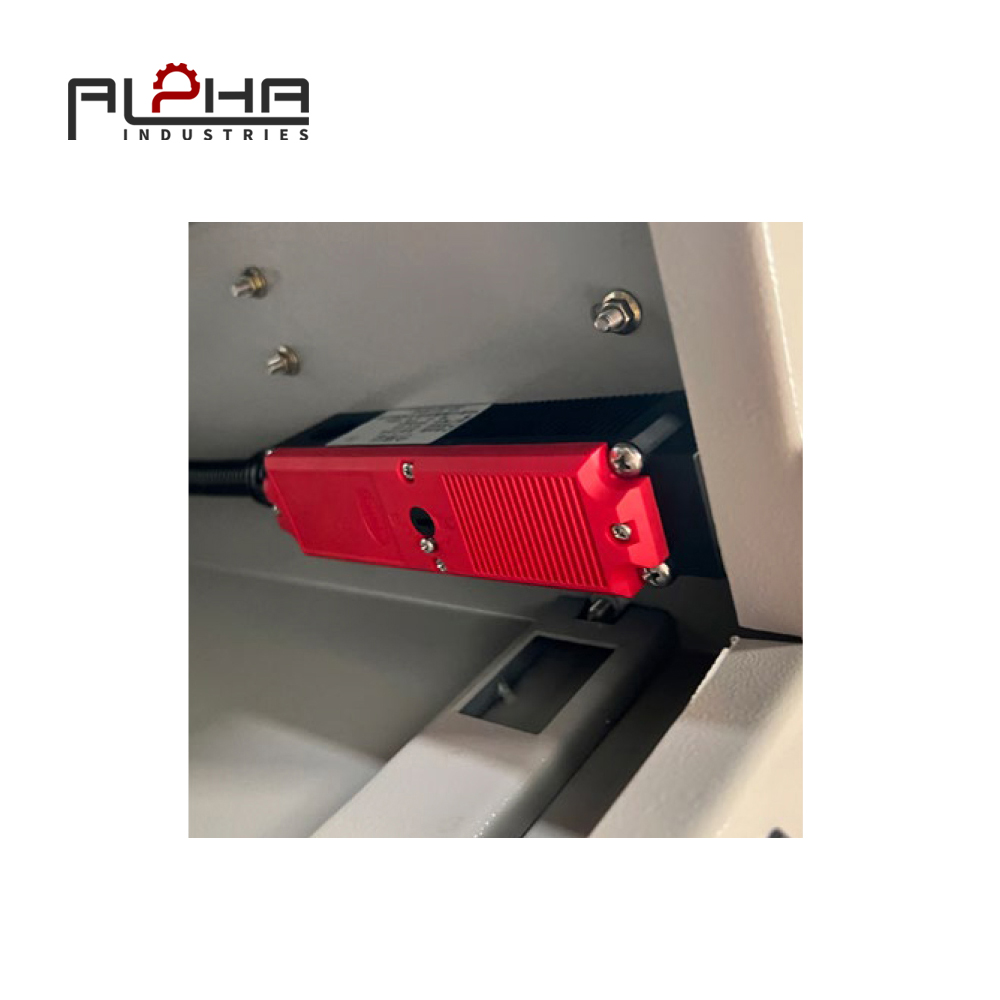

Guideway System and Its Role in Cutting Stability

Linear Guideways vs Box Ways

Cutting stability depends heavily on guideway design.

ALPHA selects guideway systems based on application needs, focusing on:

-

High load-bearing capacity

-

Smooth axis movement under cutting force

-

Resistance to vibration-induced wear

A rigid guideway system ensures accurate axis positioning even under high cutting loads.

Spindle Mounting and Headstock Rigidity

Rigid Spindle-to-Headstock Interface

The interface between spindle and headstock must maintain:

-

Precise alignment

-

Minimal deformation

-

Stable cutting geometry

ALPHA VMC headstocks are engineered to minimize structural compliance, supporting stable spindle operation during heavy milling.

Vibration Control and Damping in VMC Structures

Why Damping Matters

Rigidity alone is not enough.

Effective damping reduces vibration amplitude and prevents resonance during cutting.

ALPHA VMC structural design focuses on:

-

High-mass cast components

-

Optimized rib structures

-

Natural vibration absorption

This results in smoother cutting and improved surface quality.

Structural Rigidity and Surface Finish Quality

A rigid VMC structure provides:

-

Stable tool engagement

-

Reduced chatter marks

-

Uniform material removal

This is especially important in finishing operations where surface roughness directly affects part functionality and appearance.

How ALPHA Achieves Structural Stability in Real Production

ALPHA VMCs follow a system-level rigidity design philosophy, integrating:

-

High-strength cast iron structures

-

Optimized column and base geometry

-

Rigid headstock and spindle mounting

-

Stable guideway configurations

The result is consistent machining accuracy under real cutting conditions, not just no-load positioning precision.

Applications That Require High VMC Rigidity

High-rigidity VMC machines are essential in:

-

Mold and die roughing and finishing

-

Automotive structural components

-

Steel and cast iron machining

-

Heavy plate and frame components

In these applications, cutting stability directly affects productivity and tool life.

FAQ

What does rigidity mean in a VMC?

Rigidity refers to the machine’s ability to resist deformation under cutting forces.

How does low rigidity affect machining results?

Low rigidity causes vibration, tool chatter, poor surface finish, and dimensional errors.

Is higher rigidity always better for a VMC?

Yes, especially for heavy-duty cutting and precision machining, higher rigidity improves stability and accuracy.

Can software compensate for poor VMC rigidity?

No. Structural rigidity is a mechanical characteristic that cannot be corrected by control systems alone.

Structural Rigidity vs Theoretical Accuracy

A VMC may show excellent positioning accuracy without load, but only a rigid structure can maintain that accuracy during actual cutting.

ALPHA focuses on cutting-condition accuracy, not just specification-sheet numbers.

Conclusion — Rigidity Defines True VMC Capability

Structural rigidity is not an optional feature; it is the core capability that defines whether a VMC can deliver reliable machining results under real production conditions.

By prioritizing rigid structural design and cutting stability, ALPHA VMC solutions provide dependable accuracy, surface quality, and productivity for demanding industries.

Learn more about ALPHA Vertical Machining Center Solutions → /vmc