Pipelines used in oil fields, gas and water industries rely on high-precision threaded connections to ensure seal integrity, resistivity and structural strength. CNC lathes designed for pipe threads provide the accuracy, repeatability and productivity necessary to manufacture Api-Standard and Premium threads on casings, pipes and drills.

Key requirements for pipelines

-

Thread configuration file accuracy:Ensure full interaction and leak-proof sealing at high pressure.

-

Consistency across batches:Maintain the same thread size that is interchangeable.

-

Material versatility:Ability to tighten carbon steel, stainless steel and high strength alloys.

-

Durability and tool life:Large diameter pipelines and hard materials are required for oil and gas sectors.

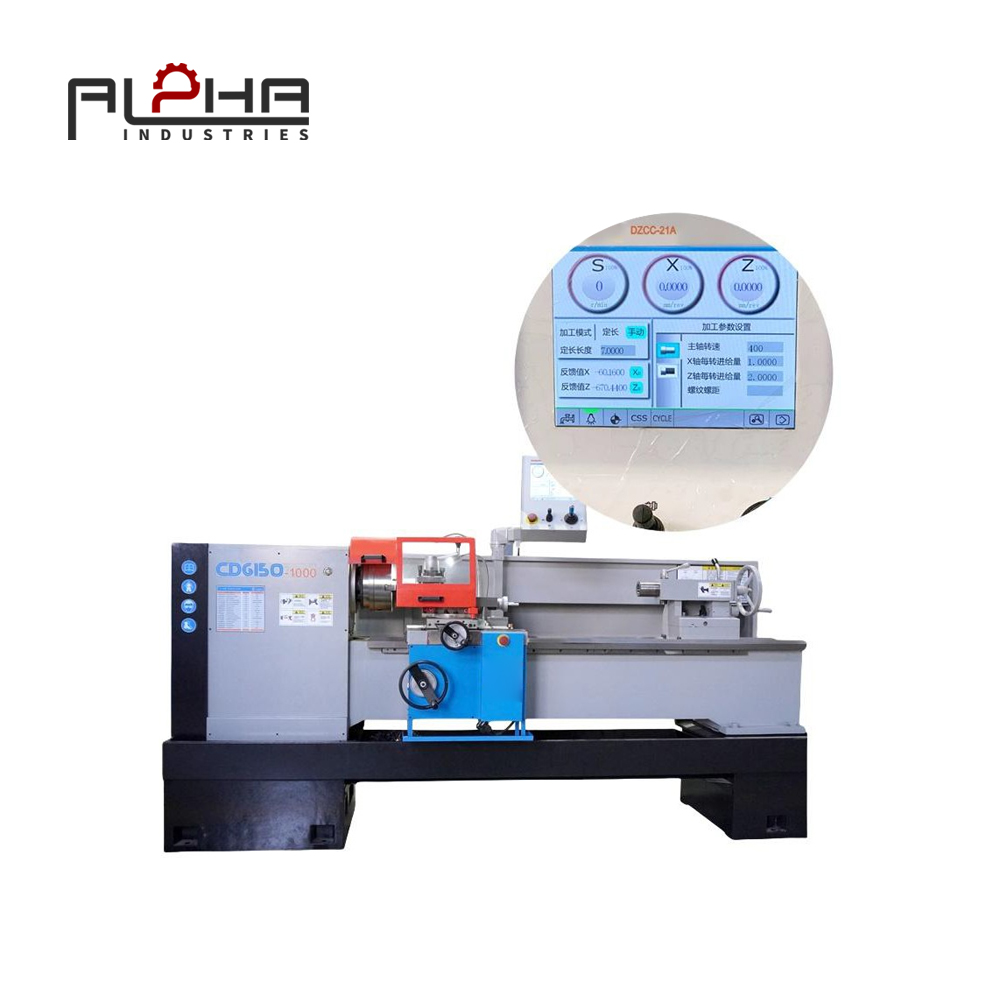

The main features of CNC lathes are used for pipe threads

-

Heavy spindle:Conveying high torque at low speeds is crucial for threaded large diameter pipes.

-

Special thread cycle:CNC programming includes dedicated thread cycles that control depth, pitch and lead accuracy.

-

Hydraulic self-centered chucks:Firmly clamp the pipes to ensure accurate alignment throughout the machining process.

-

High pressure tail rod:Provides stable support for the long tube to prevent bending and misalignment.

-

Threaded tool holder with multi-point insertion:Enhance tool life and improve threaded finish.

Supports threading standards

-

API thread:Includes API 5CT for casing and pipes, API 7 for drilling to ensure compliance with global oilfield standards.

-

Advanced threading:Proprietary threaded form for enhanced sealing and torque capability in deep wells and offshore drilling.

-

Custom thread configuration file:Used for water pipes, mechanical accessories or specialized industrial applications.

Processing function

-

External thread:Male lines are generated on PIPE OD with precise lead and pitch control.

-

Internal thread:Create female lines when needed and maintain strict tolerances.

-

Face and chamfer:Prepare threaded pipe ends to ensure optimal tool engagement and thread start accuracy.

-

Grooves:Folds are processed to seal rings or coupling features.

Material compatibility

-

Carbon steel:It is widely used in oilfield pipelines due to its strength and cost efficiency.

-

High-strength low alloy (HSLA) steel:To enhance resilience in demanding environments.

-

Stainless steel:Used for corrosion resistance applications on offshore and chemical pipelines.

-

Duplex and super duplex steel:High corrosion and stress resistance in subsea applications.

Quality control system

-

Thread measurement:Process checks using accurate measurement tables to ensure accuracy of size and form.

-

Optical profile:Used to measure thread geometry, pitch and high resolution.

-

Non-destructive testing (NDT):For critical pipelines, ensure thread integrity without damaging components.

Industrial Applications

-

Oil and gas industry:Casing, pipes, drilling, pipe pipes with API or high-quality threads.

-

Water pipe manufacturing:Threaded joints for water transport and distribution systems.

-

Buildings and Infrastructure:Mechanical and structural pipes have precise thread requirements.

Benefits of CNC lathe pipeline

-

Accurate compliance:Comply with strict international threading standards such as API and Premium specifications.

-

Improve productivity:Automation cycles can be fast, consistent threading in large production volumes.

-

Reduce defects:CNC control minimizes human error, ensuring thread quality and joint reliability.

-

Extended tool lifespan:Optimized cutting parameters can retain tools, thereby reducing operational costs.

in conclusion

Pipe threaded CNC lathes are essential in the pipeline manufacturing chain, ensuring that each threaded connection meets the mechanical and sealing needs of high-pressure, high-risk environments. Whether used in oil fields, offshore drilling or water infrastructure, precision line pipelines protect operational integrity and performance.

FAQ:

1. What is the difference between API threads and advanced threads?

API threads are defined by standardized connections used in U.S. oil fields. Advanced threads are proprietary designed to drill holes for important wells and offshore (for example, enhance seals, torque strength and fatigue resistance).

2. How to ensure consistent thread accuracy on CNC lathes?

CNC lathes use precise control of thread loops for thread pitch, depth and lead, combined with in-process measurement tools to maintain thread accuracy across batches.

3. Can CNCs be threaded on the inner and outer pipe surfaces?

Yes, CNC lathes can use specialized tools to process internal (female) and external (male) threads, ensuring an accurate fit for threaded connections.

4. Which material is best for CNC pipelines?

Materials such as carbon steel, stainless steel, HSLA steel and double-chain alloys are usually used, based on strength, corrosion resistance and application environment selection.

5. What standards control oil field pipelines?

Common standards include API 5CT for casing and pipes, API 7 for drilling, and a variety of advanced thread specifications developed by major oilfield service companies.