CNC lathe machines are the cornerstone of modern turning operations in industries that demand accuracy, efficiency, and automation. With computer-controlled capabilities, CNC lathes enable precise and repeatable turning, facing, threading, grooving, and drilling operations on various materials including steel, aluminum, and cast iron.

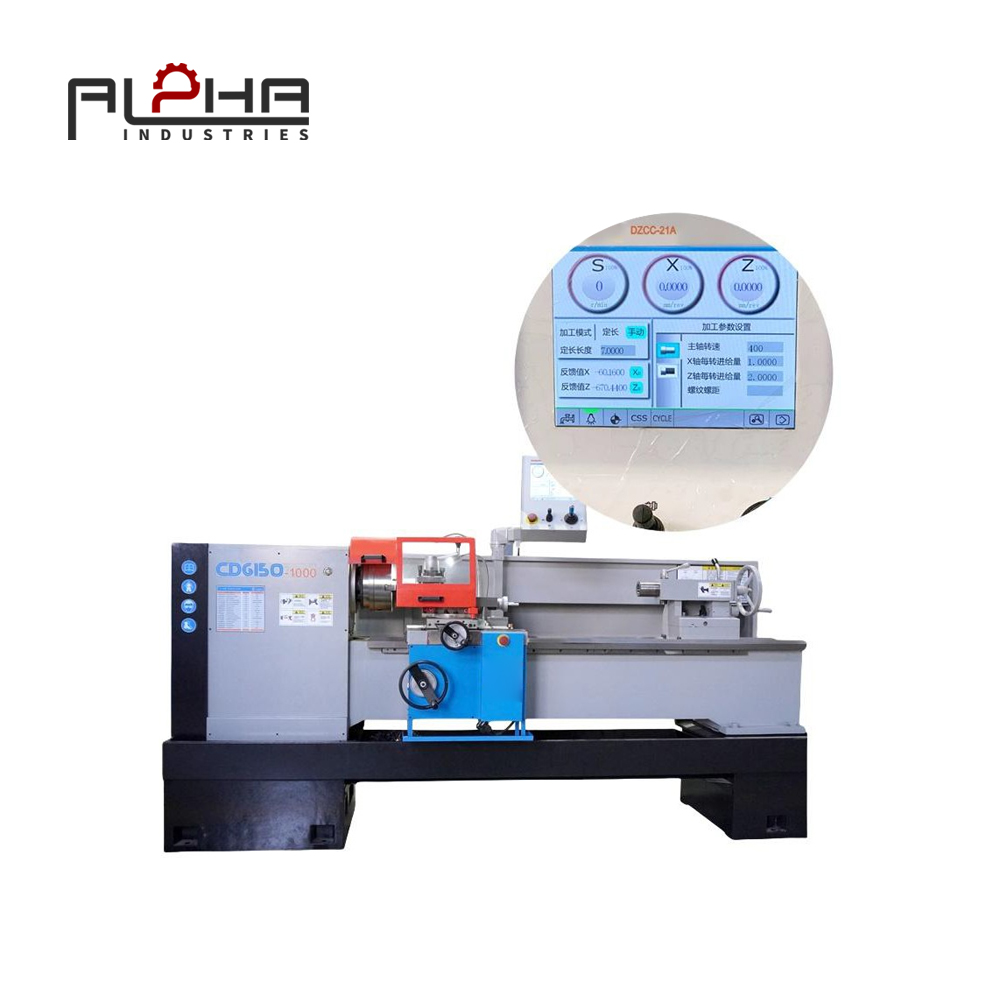

Alpha’s CNC lathe series is designed to meet the diverse needs of both entry-level and high-precision manufacturing. Featuring high-rigidity cast iron structures, advanced servo control systems, and slant bed configurations, our machines deliver smooth performance and consistent machining quality, even during complex or long-duration operations.

The slant bed design enhances chip evacuation, improves cutting stability, and reduces thermal deformation, making it particularly suitable for high-speed, high-precision applications. The guideways—either linear or hardened box types—are selected according to workload and precision demands, ensuring long-term accuracy and durability.

Each CNC lathe is equipped with an automatic tool changer (turret), hydraulic or pneumatic chucking systems, and advanced programming interfaces compatible with G-code, Fanuc, Siemens, or other controllers. This facilitates not only manual operation but also full automation for batch production.

From small diameter shafts to large-diameter flanges, Alpha's CNC lathes can handle a wide range of part sizes. Optional accessories such as tailstocks, bar feeders, chip conveyors, and part catchers can be integrated to further streamline production.

Whether for automotive components, aerospace parts, or industrial fittings, a CNC lathe plays a critical role in shaping raw materials into high-precision products. Our models offer fast tool indexing, reduced cycle times, and intelligent diagnostics, empowering factories to maximize output while minimizing downtime.

To ensure the best fit for your workflow, we offer customization options based on spindle bore size, chuck diameter, bed length, and turret type. Our engineering team supports machine setup, programming, and training to help clients integrate CNC lathes quickly into their operations.

Alpha exports CNC lathes to over 35 countries and maintains strong partnerships in metal processing, aerospace, mechanical parts, and general manufacturing sectors. With reliable after-sales service and technical support, our machines are trusted by clients worldwide.

FAQs:

What are the advantages of using a CNC lathe over manual lathes?

CNC lathes provide automation, higher accuracy, better surface finishes, and faster cycle times compared to manual lathes. They also reduce operator fatigue and improve consistency in mass production.

What is the difference between a flat bed and slant bed CNC lathe?

Slant bed CNC lathes offer better chip removal and rigidity, especially during heavy cutting, while flat bed lathes are more suitable for large-diameter and heavy workpieces with less complexity.

Can CNC lathes handle both soft and hard materials?

Yes. With proper tooling and spindle configurations, CNC lathes can effectively machine soft metals like aluminum and plastics as well as hard materials such as hardened steel and stainless steel.

How do I choose the right CNC lathe model for my needs?

Consider the workpiece size, material type, required tolerance, production volume, and available space. Our team can help recommend a model based on your application.

Are Alpha CNC lathes customizable?

Yes. We offer customization for spindle power, chuck type, turret configuration, tailstock presence, and automation options based on customer requirements.