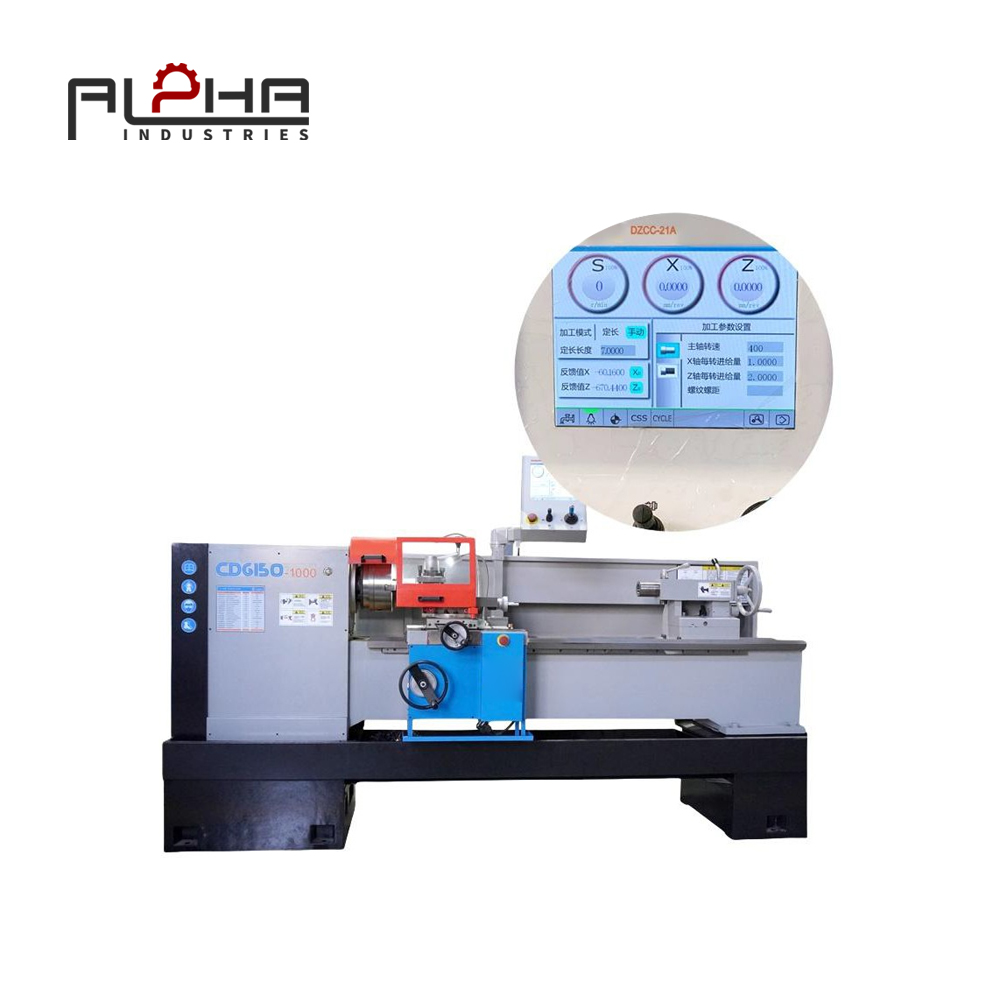

CNC lathes are the cornerstone of precision machining, offering automated turning solutions with exceptional repeatability. Designed to rotate a workpiece against a stationary cutting tool, CNC lathes are widely used across industries like aerospace, automotive, electronics, and toolmaking. With computer numerical control, they deliver consistent results in high-volume production or complex part manufacturing.

Core Features of CNC Lathes

CNC lathes combine mechanical stability with intelligent programming. Key components include the spindle, turret, bed, tailstock, and control panel. The servo motors and ball screw mechanisms enable precise axis movement. Tool turrets allow for automatic tool changes, significantly reducing cycle time.

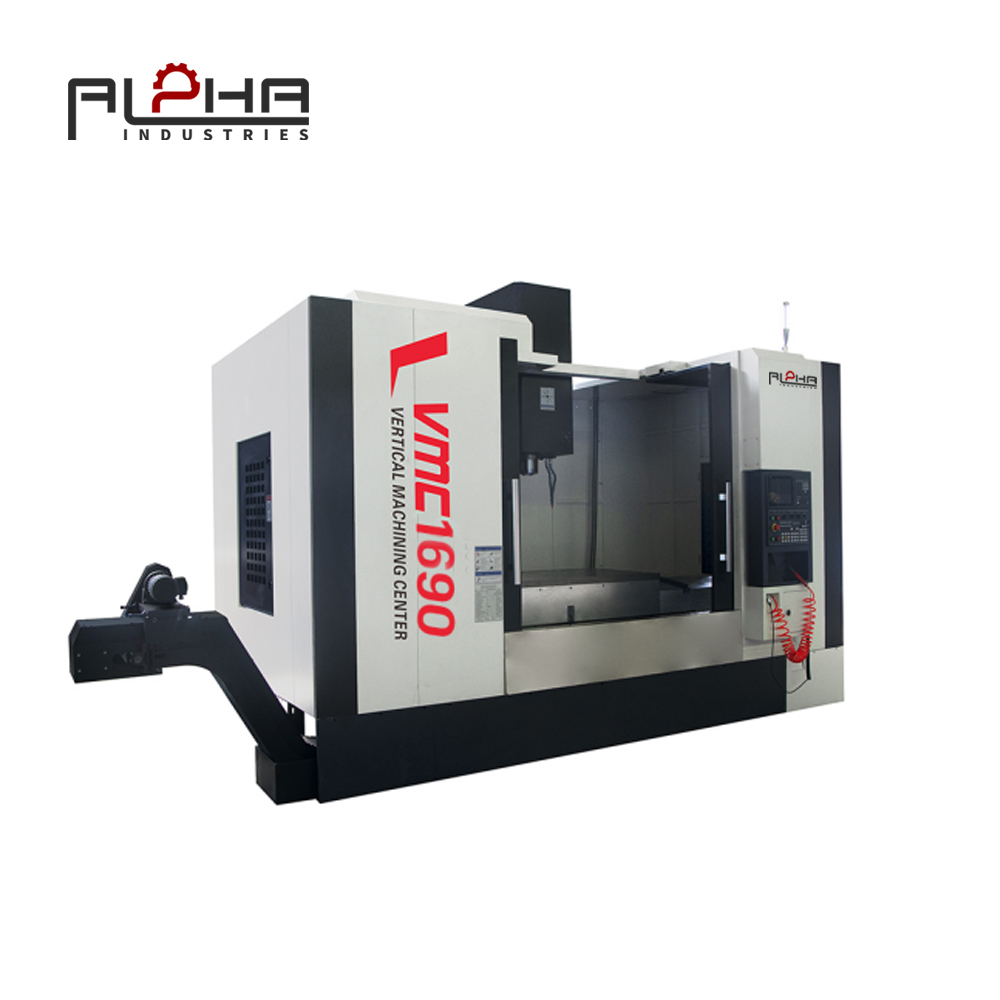

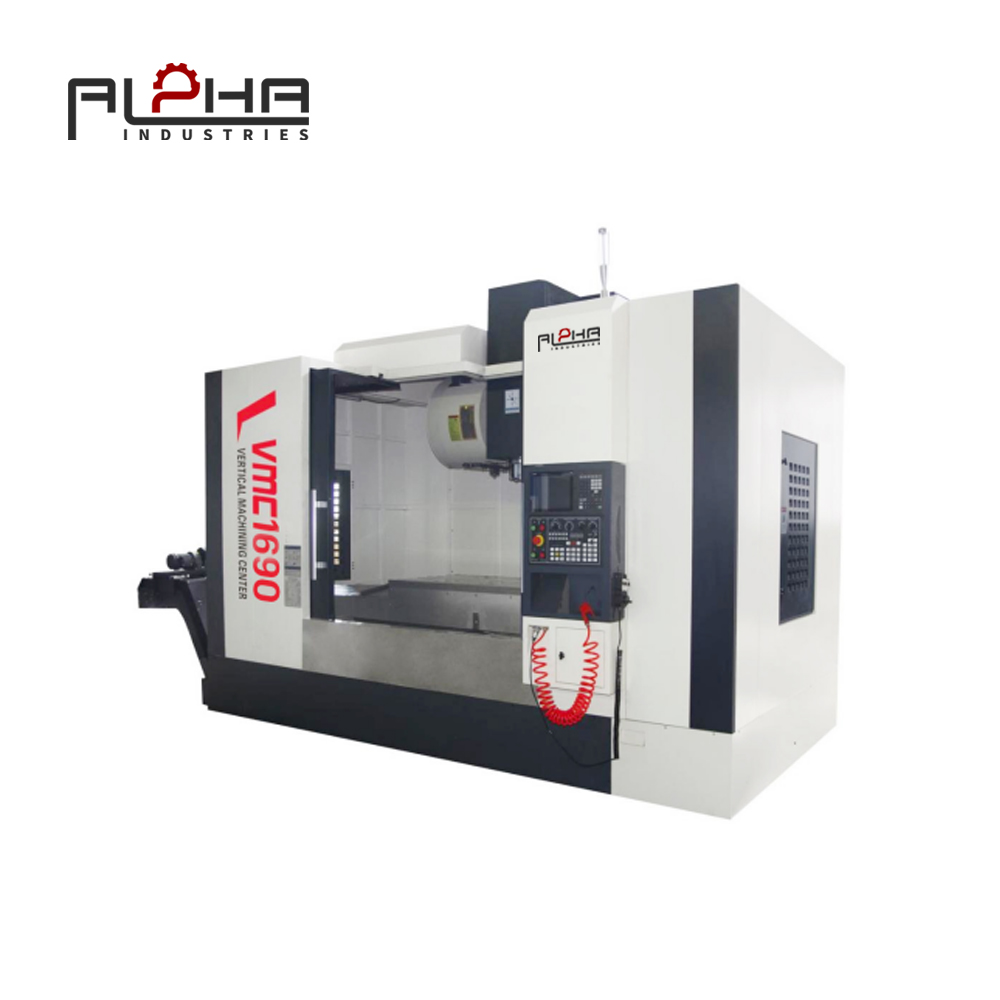

Common configurations include horizontal and vertical types, with slant bed designs offering improved chip evacuation and tool access. Advanced models are equipped with multi-axis capability, live tooling, and Y-axis functions for drilling, milling, and tapping—all in one setup.

Advantages of CNC Lathe Machines

-

High Precision: Micron-level accuracy in contouring and turning.

-

Automation: Programmable operations reduce reliance on manual labor.

-

Productivity: Capable of continuous, unattended machining.

-

Versatility: Supports external, internal, facing, grooving, threading, and parting operations.

-

Consistency: Produces identical parts with minimal dimensional deviation.

-

Safety: Enclosed workspaces and interlocks enhance operator safety.

Common Applications

CNC lathes are essential in producing shafts, bushings, pulleys, sleeves, fasteners, and flanges. From stainless steel and carbon steel to brass, aluminum, and engineered plastics, these machines handle a wide range of materials with ease. In industries like defense or energy, tight tolerance and roundness control are vital, and CNC lathes excel in meeting such requirements.

Control Systems and Programming

Modern CNC lathes use control systems like FANUC, Siemens, or Mitsubishi. Operators can input G-code directly or use conversational programming interfaces. Offline CAM software allows for simulation and error detection before real-time machining begins. Integrated diagnostics and touch probes streamline setup and tool compensation.

Maintenance and Reliability

Routine maintenance ensures long-term reliability. Key tasks include lubrication of guideways, checking hydraulic oil levels, spindle inspection, and calibration of axis positioning. Well-maintained CNC lathes can operate efficiently for years with minimal downtime.

Future Trends in CNC Turning

The integration of Industry 4.0 is reshaping CNC lathe usage. Real-time monitoring, cloud-based production data, and predictive maintenance are becoming standard features. Hybrid CNC machines that combine additive and subtractive processes are also gaining traction.

Call-to-Action

Ready to optimize your machining process with a high-precision CNC lathe? Explore our full range of CNC turning solutions designed for modern manufacturing environments.

FAQs

What materials can CNC lathes process?

CNC lathes can handle metals like steel, aluminum, copper, and titanium, as well as plastics like POM, PTFE, and nylon.

How accurate is a CNC lathe?

Most CNC lathes offer positioning accuracy of ±0.005 mm or better, depending on machine class and thermal control.

What’s the difference between a CNC lathe and CNC turning center?

A CNC turning center typically includes more advanced features like live tooling, sub-spindles, and Y-axis control, offering multifunctional capabilities beyond basic turning.

Can CNC lathes be used for small batch production?

Yes. With fast changeover and programmable settings, CNC lathes are well-suited for both mass production and small-lot, high-precision jobs.

Do CNC lathes require skilled operators?

While easier to operate than manual lathes, CNC machines still require trained operators for setup, programming, and troubleshooting.