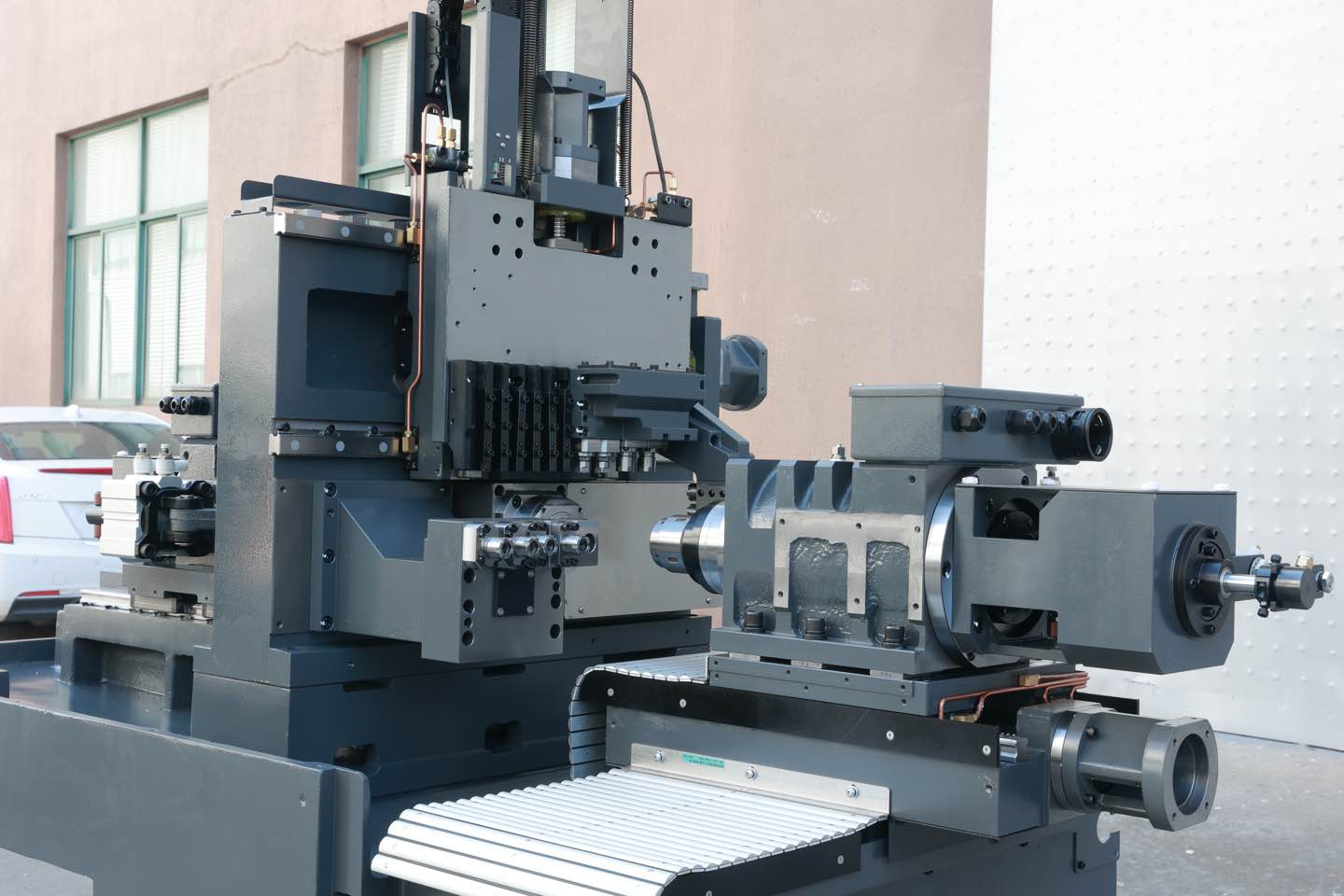

Alpha Vertical Machining Centers – Engineered for Precision and Efficiency

Alpha’s Vertical Machining Centers (VMCs) are built to meet the rigorous demands of modern metalworking industries. With a focus on accuracy, speed, and structural rigidity, our VMCs provide the ideal platform for precision parts production in industries ranging from aerospace to automotive and mold making.

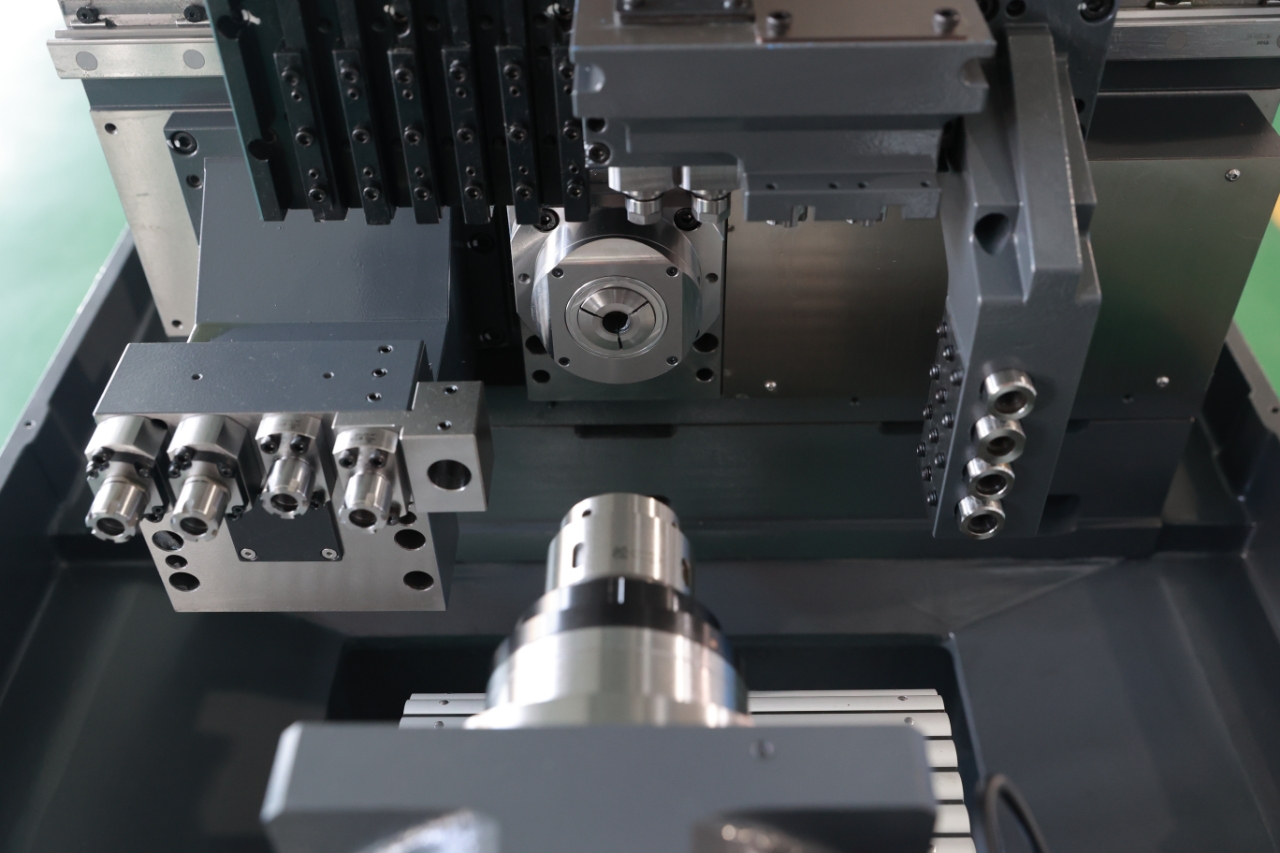

The combination of high-speed spindle systems, powerful servo drives, and stable meehanite cast frames ensures smooth contouring, accurate drilling, and efficient 3D profiling operations.

Key Features of Alpha VMC Machines

-

Rigid One-Piece Column and Base Design

Improves overall machine stability and absorbs vibration during high-speed machining. -

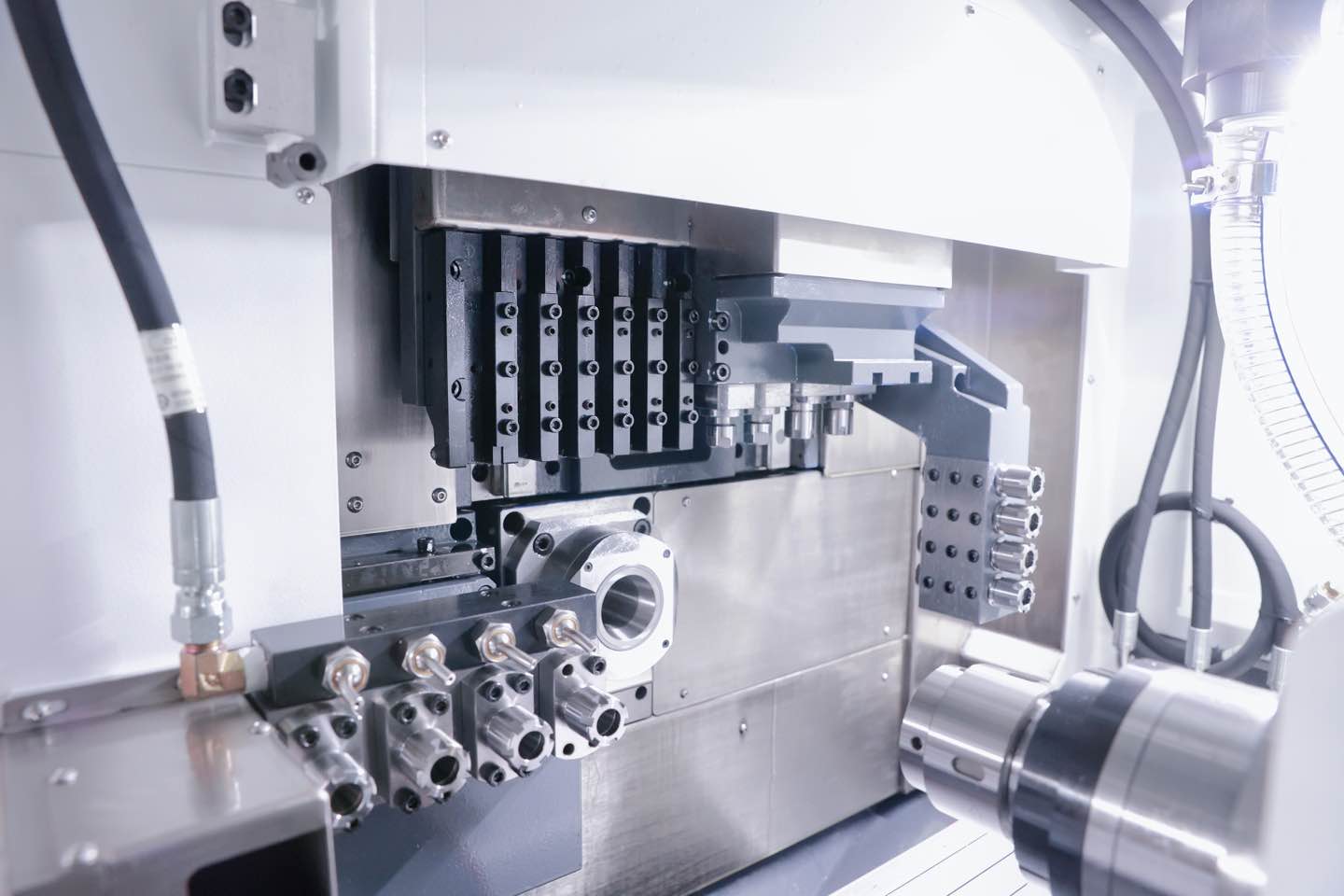

High-Speed Spindle System

Available in direct-drive or belt-drive configurations with speeds from 8000 to 15000 rpm. -

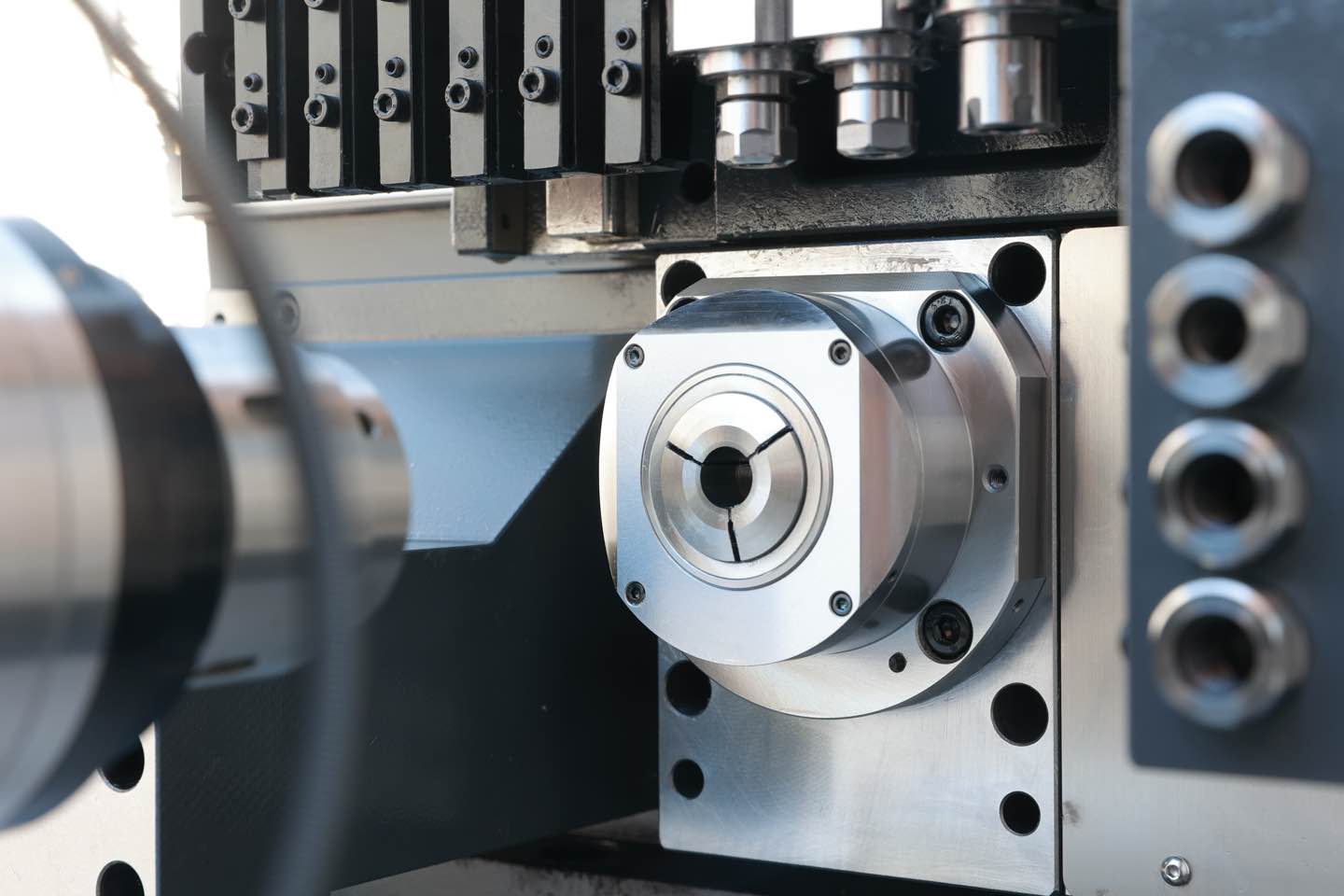

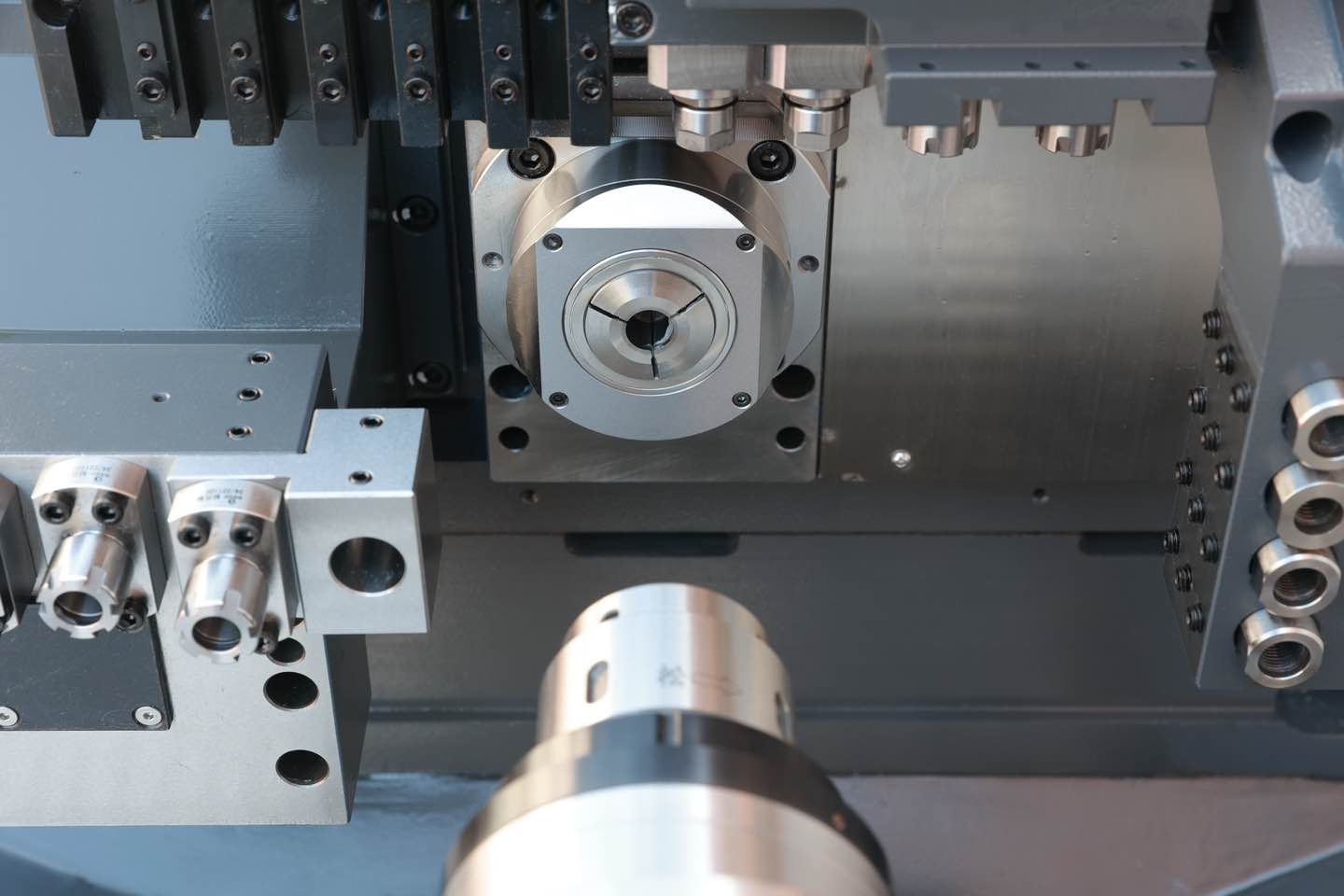

Precision Linear Guideways (or Box Ways)

Provide accurate movement across all axes with minimal backlash. -

Automatic Tool Changer (ATC)

Supports 16–24 tools with fast tool-change cycles for improved cycle time. -

CNC Controller Compatibility

FANUC, Siemens, Mitsubishi, or GSK options for global operator familiarity and integration.

Typical VMC Applications

-

Die and Mold Machining

-

Aerospace Structural Components

-

Automotive Engine Parts

-

Precision Plate Drilling and Slotting

-

Aluminum and Steel Part Contouring

-

Electronic Housing and Connector Milling

Why Choose Alpha Vertical Machining Centers

-

Precision-matched components and German-standard assembly

-

Long-term geometric stability through heat-treated machine structures

-

Easy integration with automation systems (robotic arm, pallet changers)

-

ISO-standard calibration with laser interferometer and ball bar test

-

Full technical support and local service teams in 35+ countries

FAQs:

1. What is a vertical machining center used for?

VMCs are used for a variety of precision milling tasks including drilling, boring, tapping, and contouring on vertical planes. They are ideal for high-speed, high-accuracy applications.

2. What is the difference between VMC and CNC milling machine?

A VMC is a type of CNC milling machine with the spindle in vertical orientation. VMCs offer better chip evacuation and are generally easier to set up and operate.

3. Can I use Alpha VMCs for mold making?

Yes. Our VMCs are widely used for plastic injection mold and die-casting mold production due to their high spindle speed, tool accuracy, and 3D surface control.

4. Do Alpha VMCs support fourth-axis machining?

Yes. Optional rotary tables can be installed for 4-axis positioning and contouring, expanding part complexity capability.

5. How is thermal stability handled in your machines?

Alpha VMCs include thermal compensation functions and optional spindle chiller systems to maintain machining accuracy over long hours.