A panel bending machine, also known as a sheet metal folding machine, is designed to bend or fold metal sheets into precise angles and complex profiles. It is widely used in HVAC ductwork, electrical enclosures, metal cabinets, and appliance manufacturing.

At Alpha, we focus on delivering high-precision panel bending machines that combine hydraulic or servo drives with advanced controls for superior folding accuracy, fast operation, and consistent repeatability.

Key Features of Panel Bending Machine

High Folding Precision

Alpha’s machines achieve accurate angles with minimal deviation, ensuring each panel meets design specifications.

Adjustable Folding Length and Angle

Equipped with programmable stops and adjustable clamps, the machine handles panels of different lengths and thicknesses, enabling multi-step folding.

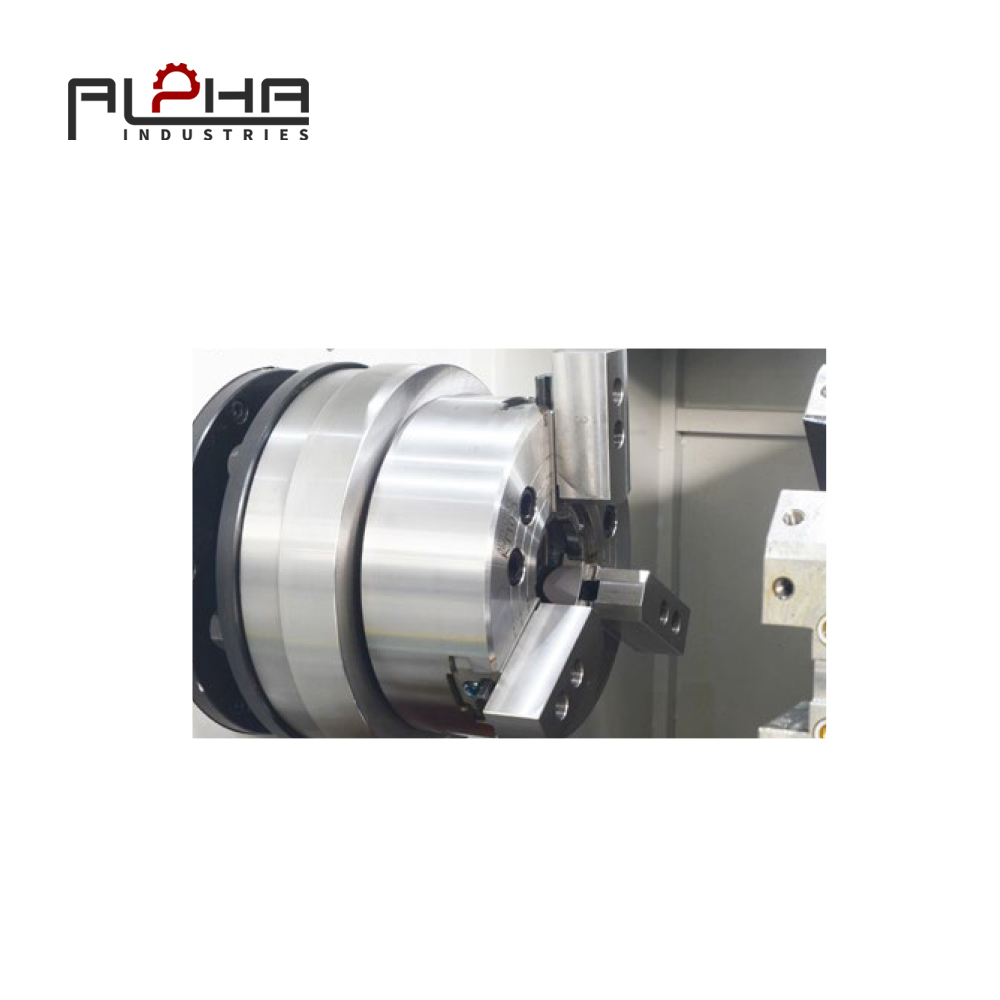

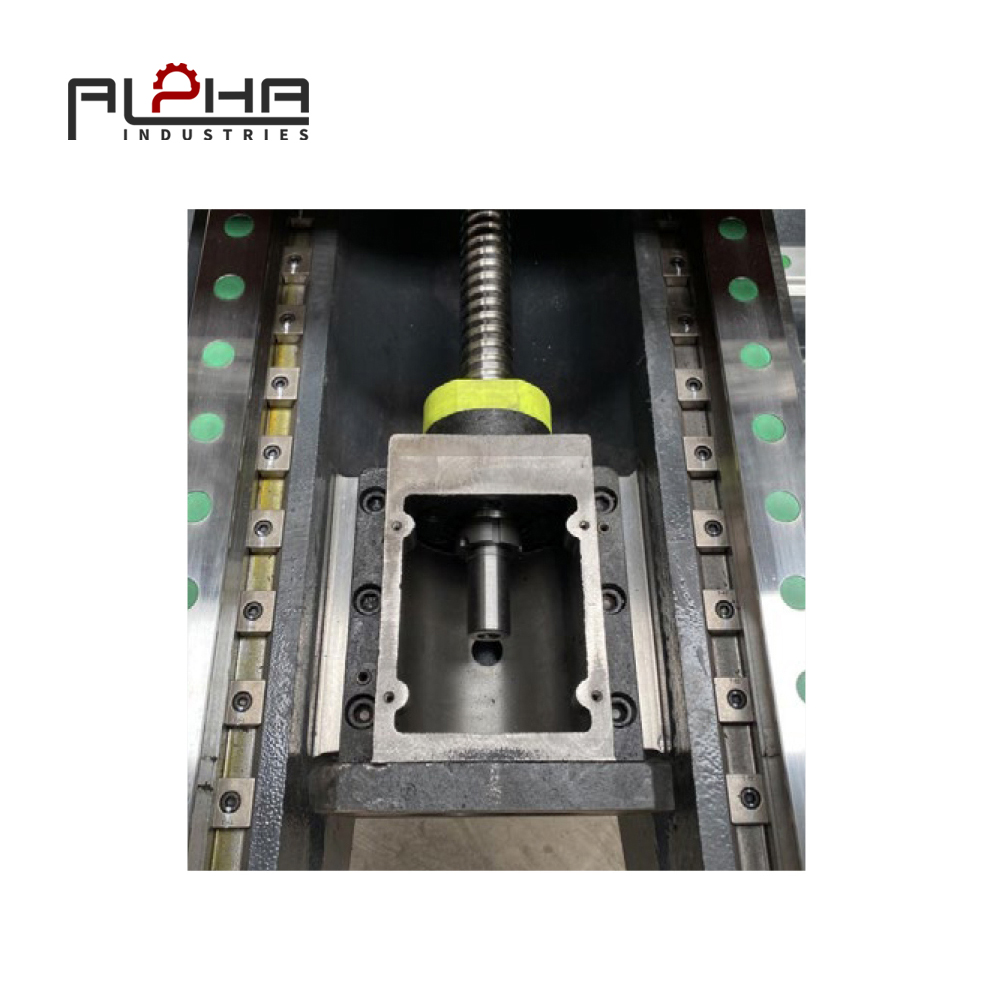

Robust Hydraulic or Servo Drive

Hydraulic systems provide strong force for thick sheets, while servo-driven machines enhance energy efficiency and precise movement control.

Automation and Smart Operation

CNC or semi-automatic systems allow programmed bending sequences, reducing manual intervention, setup times, and human error.

Working Principle of Panel Bending Machine

The metal sheet is placed on the machine bed, clamped securely, and the bending beam moves down to fold the sheet along a defined line. Depending on the type:

-

Hydraulic models – deliver high tonnage for thick panels.

-

Servo-electric models – offer precise control for thin or delicate materials.

-

CNC models – automate sequences for multiple bends and repeatability.

Applications of Panel Bending Machine

-

HVAC Duct Fabrication – air ducts and ventilation panels.

-

Electrical Cabinets – precise enclosures for switchgear and control panels.

-

Metal Furniture – panels for cabinets, racks, and frames.

-

Appliance Manufacturing – casings for ovens, refrigerators, and industrial equipment.

-

Construction Industry – wall panels, roofing sheets, and decorative metal elements.

Advantages of Choosing Alpha Panel Bending Machine

-

CE-certified safety and reliability

-

Customizable folding length, thickness, and angle

-

Energy-efficient operation for hydraulic and servo models

-

Short lead times and global after-sales service

-

High repeatability and precision for industrial production

Frequently Asked Questions (FAQ) on Panel Bending Machine

What is a panel bending machine used for?

A panel bending machine is used to fold or bend metal sheets into precise angles, profiles, or enclosures while maintaining material integrity.

How do I choose the right panel bending machine?

Consider sheet thickness, folding length, tonnage, and automation level. For repeated high-volume production, CNC or servo-electric models are recommended.

What industries commonly use panel bending machines?

Industries include HVAC, electrical cabinet manufacturing, appliance production, metal furniture, and construction.

What is the difference between hydraulic and servo panel bending machines?

-

Hydraulic machines: strong force, suitable for thicker panels.

-

Servo machines: energy-efficient, precise, and ideal for high-volume, thin-sheet folding.

Can Alpha provide customized panel bending solutions?

Yes, Alpha offers custom folding lengths, tooling, and automation features tailored to client requirements.

Partner with Alpha for High-Precision Panel Bending

Alpha delivers reliable, high-precision panel bending machines engineered to improve efficiency, accuracy, and safety in metal sheet fabrication. Our solutions are suitable for both small workshops and large-scale industrial production.

Contact our team today: Contact Us