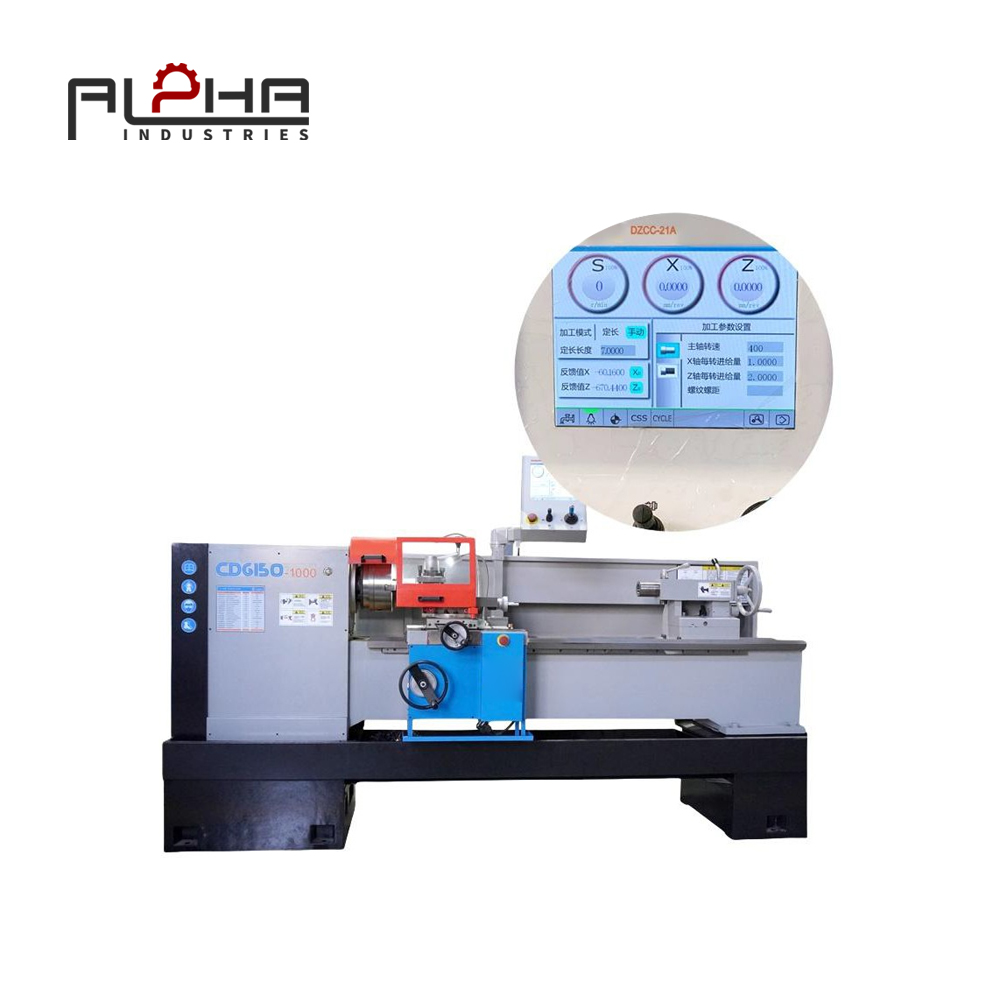

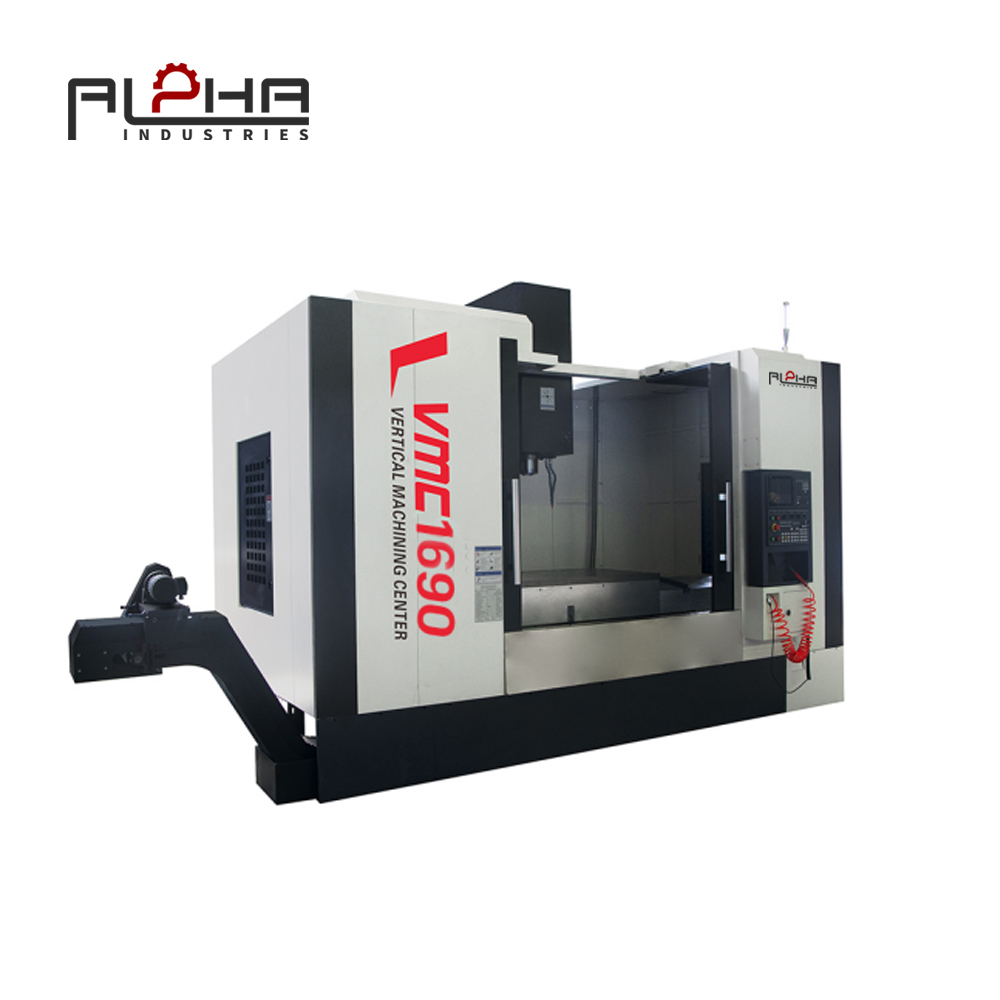

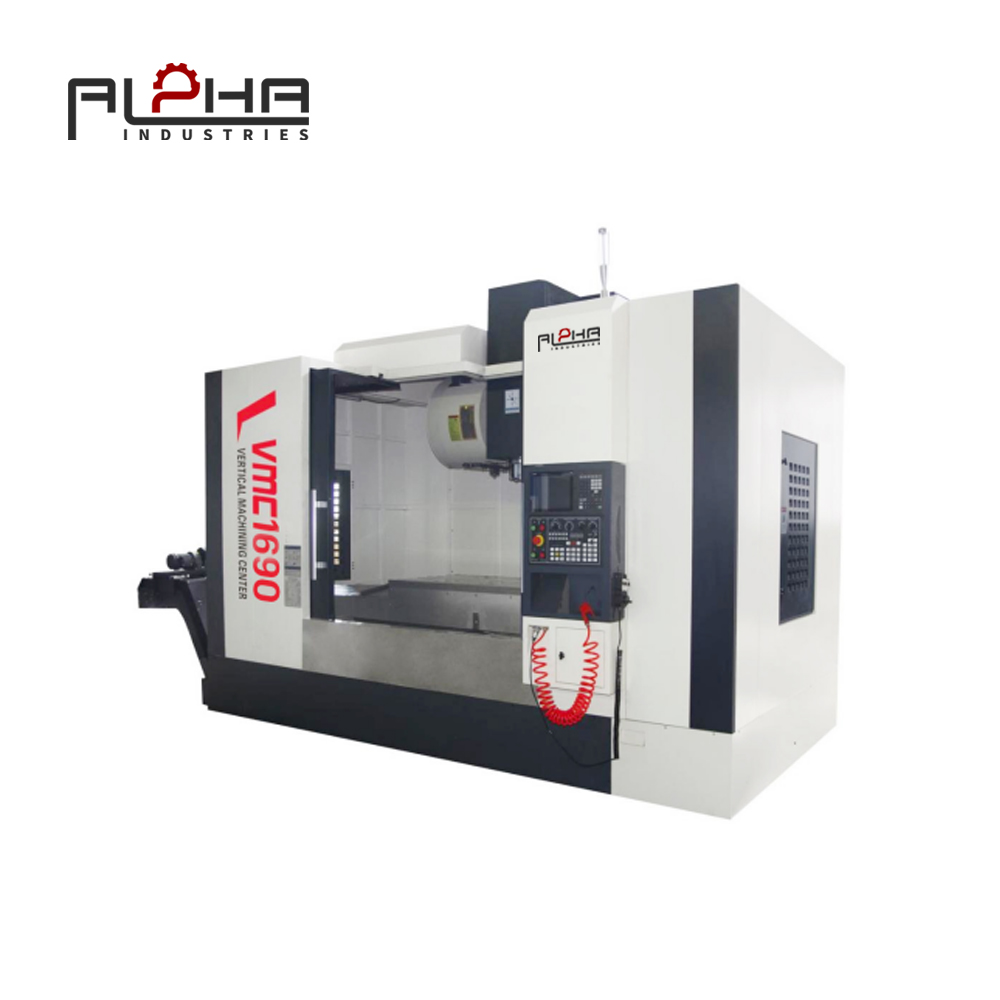

Precision Meets Productivity — Alpha Lathe Machines

In modern manufacturing,precision and reliability are not optional — they’re essential.Alpha’s lathe machines are designed for professionals who demand tight tolerances, consistent surface finish, and flexibility for future automation upgrades.

Whether you're producing parts in batches or working on high-precision prototypes, Alpha lathes ensure flawless metal turning performance with strong structural integrity and smooth mechanical movement.

Advanced Features of Alpha Precision Lathes

-

High-Rigidity Base with Finite Element Analysis (FEA):

Machine frames are reinforced for optimal stiffness and vibration dampening during prolonged cutting. -

Precision-Ground Slideways:

Ensure ultra-smooth movement and reduced wear over time, ideal for demanding tolerance applications. -

Spindle System with Timken Bearings:

Delivers low runout and high-speed stability — critical for precision shaft and component machining. -

Automation-Ready Design:

Optional interfaces available for chip conveyors, automatic tool changers (ATC), DROs, and CNC upgrades. -

Integrated Safety and Control System:

Overload protection, thermal alarms, and e-stop functions ensure operator confidence during operation.

Available Configurations

Manual Precision Lathes– Designed for expert-level control and repeatable tolerances.

Semi-Automatic Lathe Systems– Combine manual control with DRO, motorized feed, or digital threading modules.

CNC-Ready Base Lathes– Accepts servo upgrades and PLC interfaces for future automation.

Used In These Industries

-

Aerospace & Defense Components

-

High-Precision Automotive Parts

-

Energy Equipment (Flanges, Couplings)

-

Mold & Die Manufacturing

-

Hydraulic & Pneumatic Cylinder Machining

-

Research and Prototype Labs

Why Manufacturers Choose Alpha

-

Precision Engineering:All models undergo laser calibration and geometrical accuracy tests.

-

Automation Flexibility:Upgrade to CNC anytime without replacing the base machine.

-

Trusted Globally:Alpha lathes are running in 40+ countries with stable performance and minimal maintenance.

-

Complete Support:Fast parts availability, training support, and after-sales service from Alpha's global partners.

FAQs:

1. What makes Alpha lathe machines “precision” grade?

They use hardened and ground guideways, low-runout spindles, and precision lead screws to maintain sub-0.01 mm accuracy in turning operations.

2. Can Alpha lathe machines be upgraded to CNC later?

Yes. Selected models are CNC-ready, meaning you can install servo motors, PLCs, and control panels without changing the base structure.

3. What is the role of DRO in manual lathes?

DRO (Digital ReadOut) systems improve dimensional accuracy by providing real-time X/Z axis readings, reducing measurement errors.

4. Is operator training provided?

Alpha provides detailed manuals, online tutorials, and remote video sessions for international customers.

5. Can these machines work 24/7 under industrial load?

Yes. With proper lubrication and routine maintenance, Alpha lathes are capable of continuous operation in demanding production settings.