Precision at the Core – Alpha Vertical Machining Centers

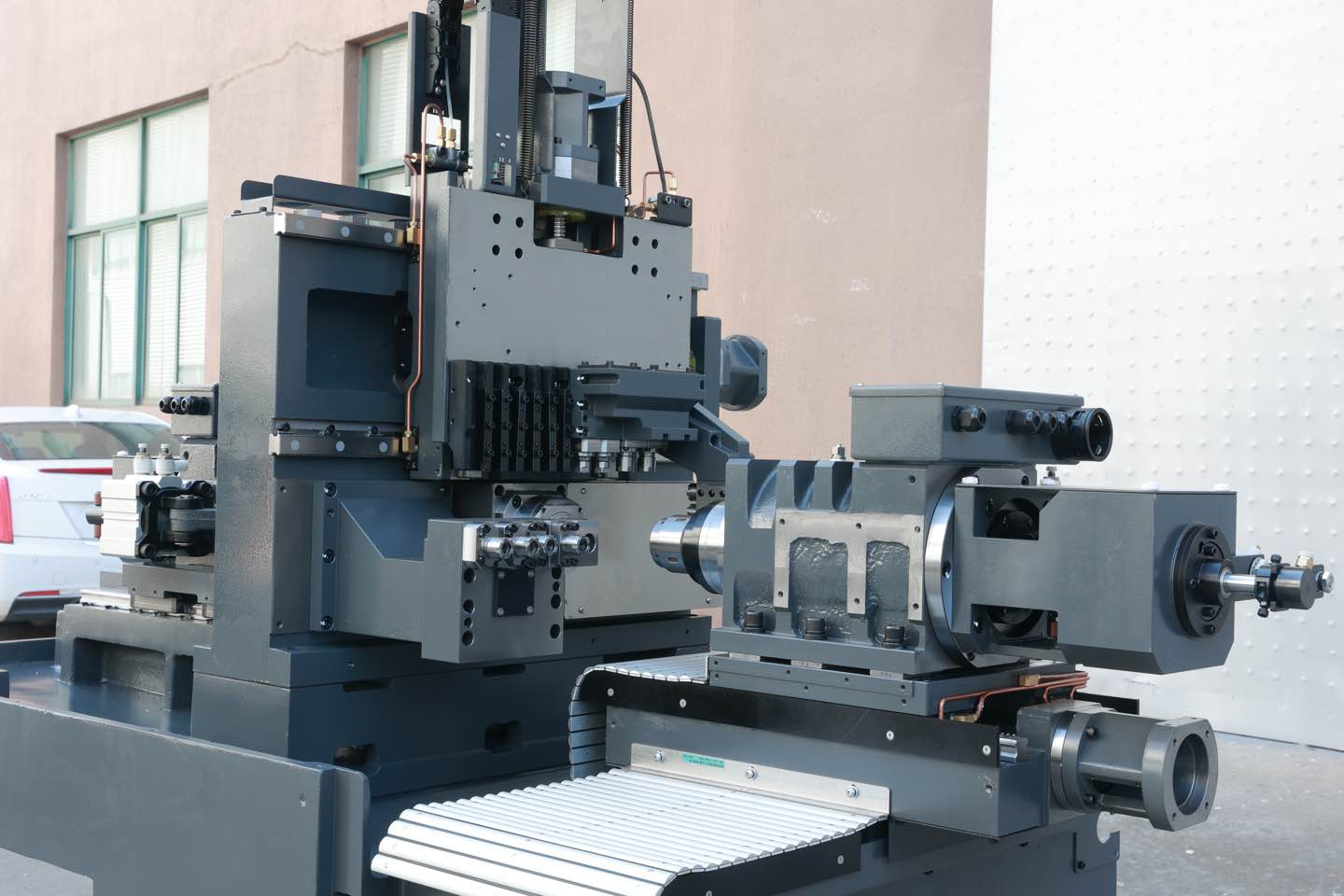

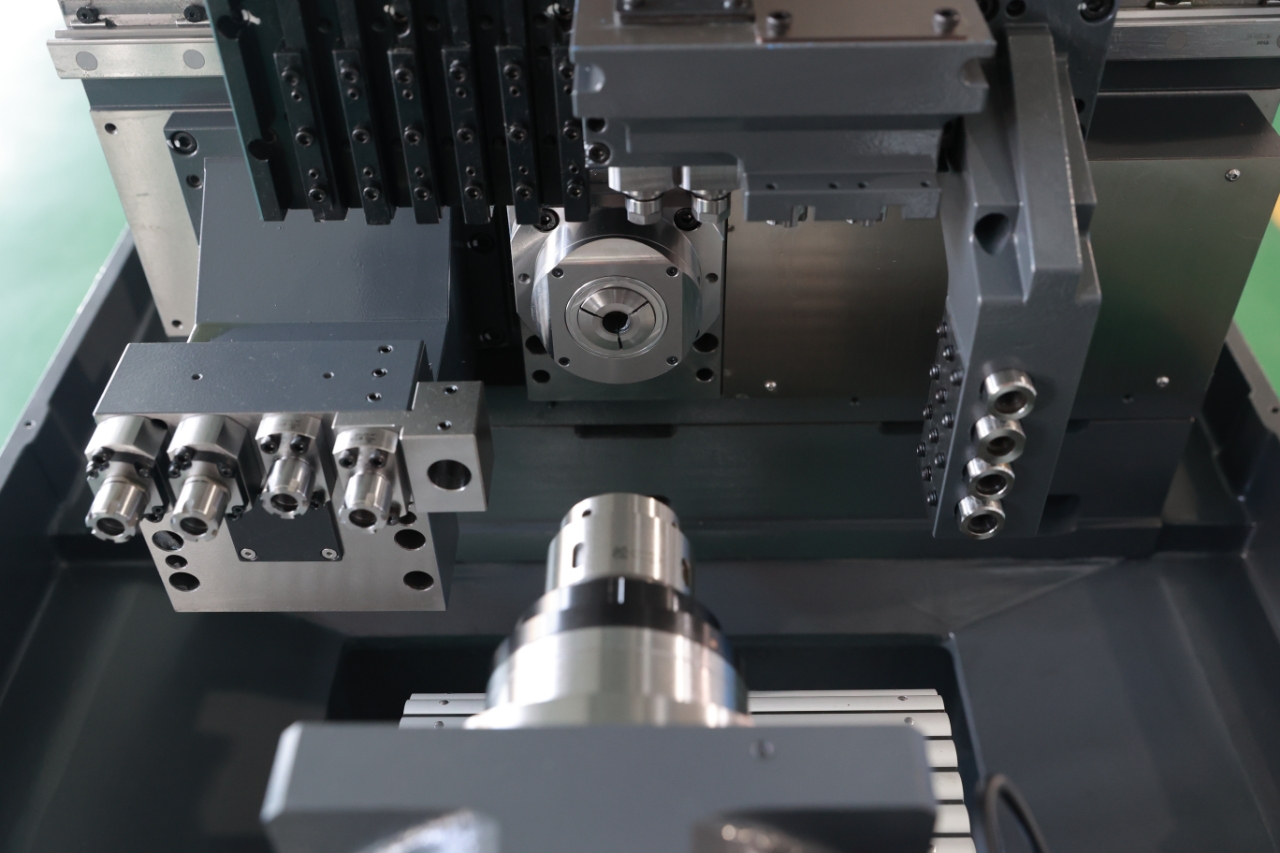

In mold manufacturing and complex component production, precision is everything. Alpha’s Vertical Machining Centers (VMCs) are engineered to achieve micron-level accuracy with excellent surface finish.

Equipped with high-speed spindles, advanced thermal control systems, and ultra-smooth feed drives, our VMCs meet the strictest quality requirements in industries such as die casting, injection molding, aerospace, and medical device manufacturing.

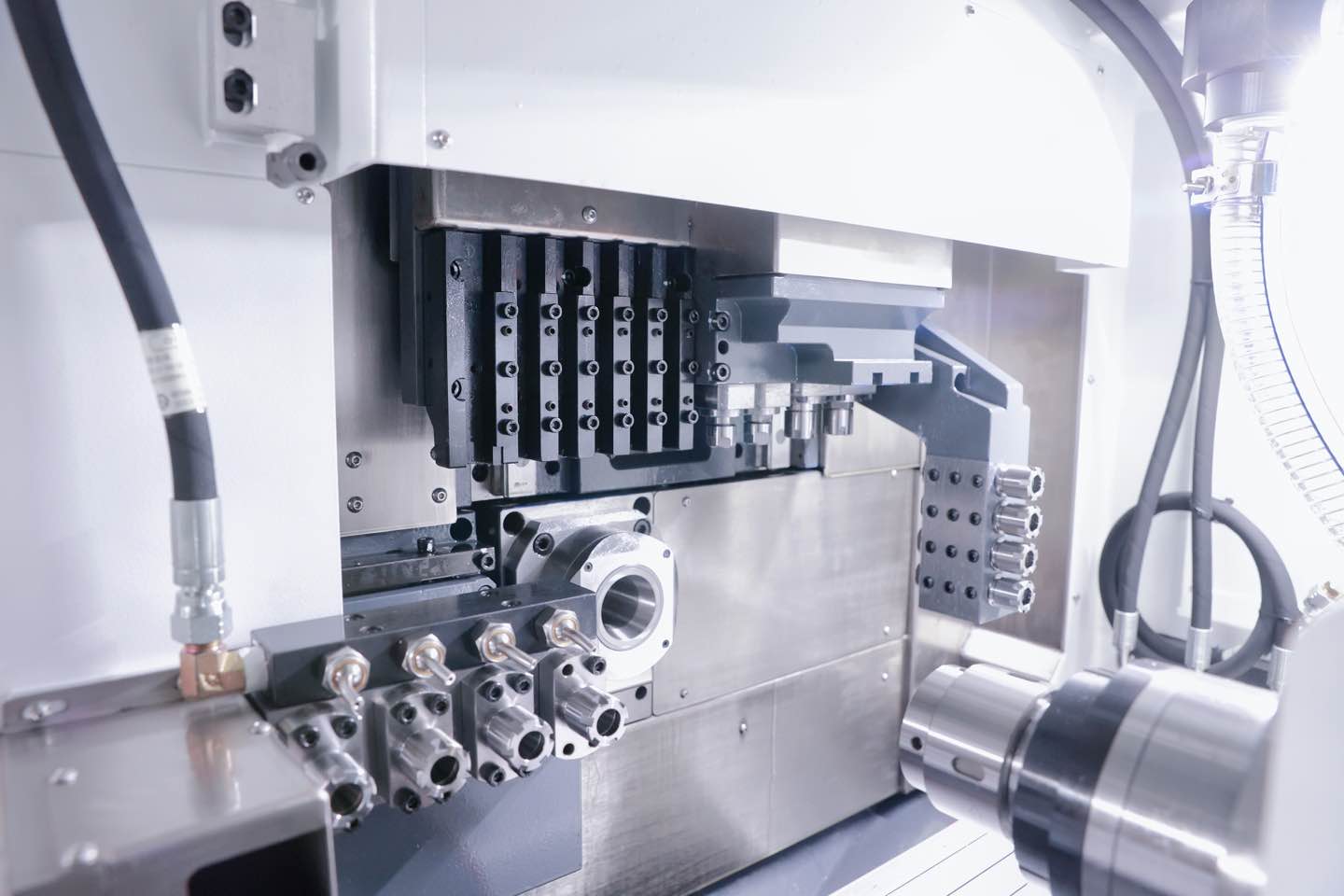

Key Features for Mold & Precision Machining

-

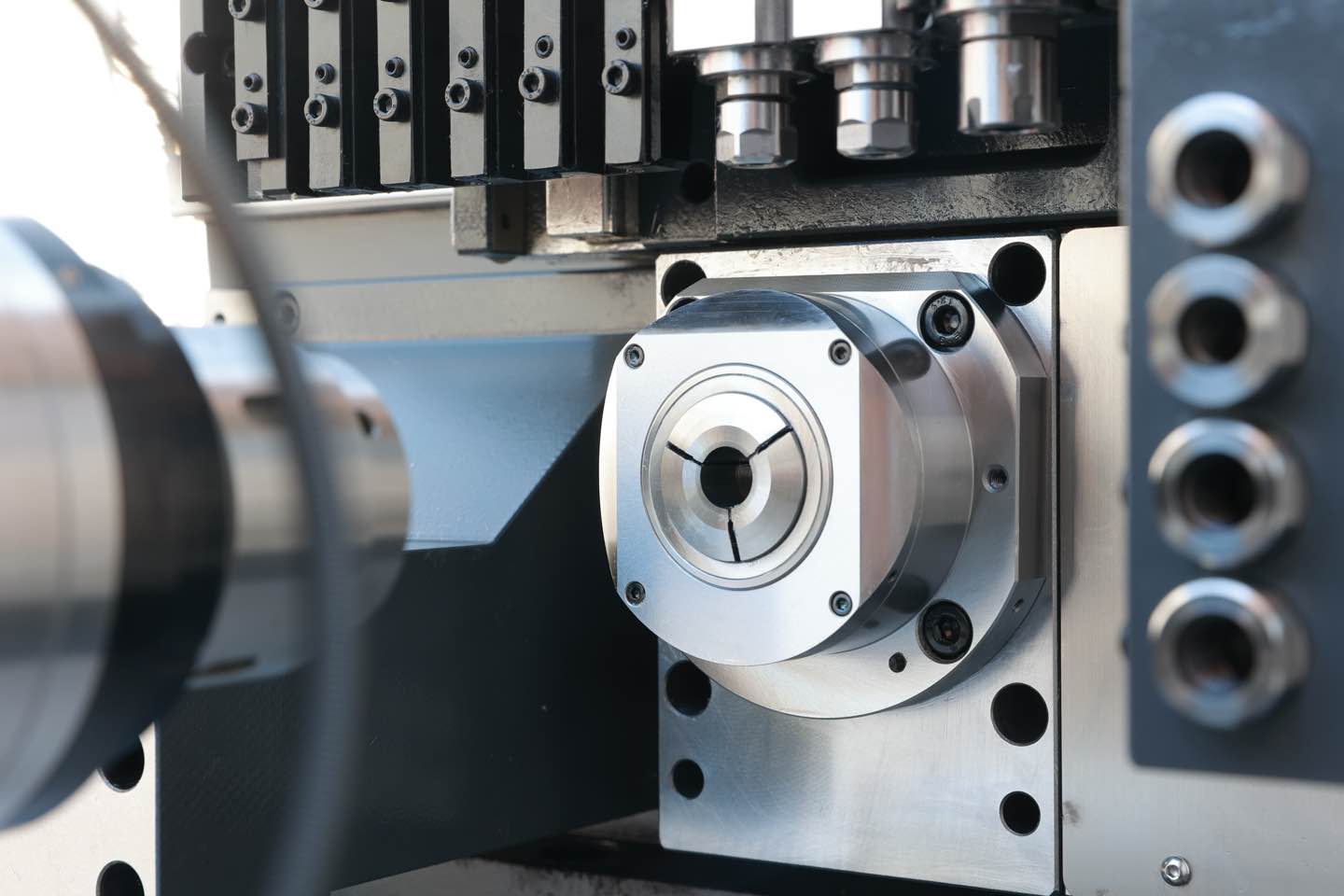

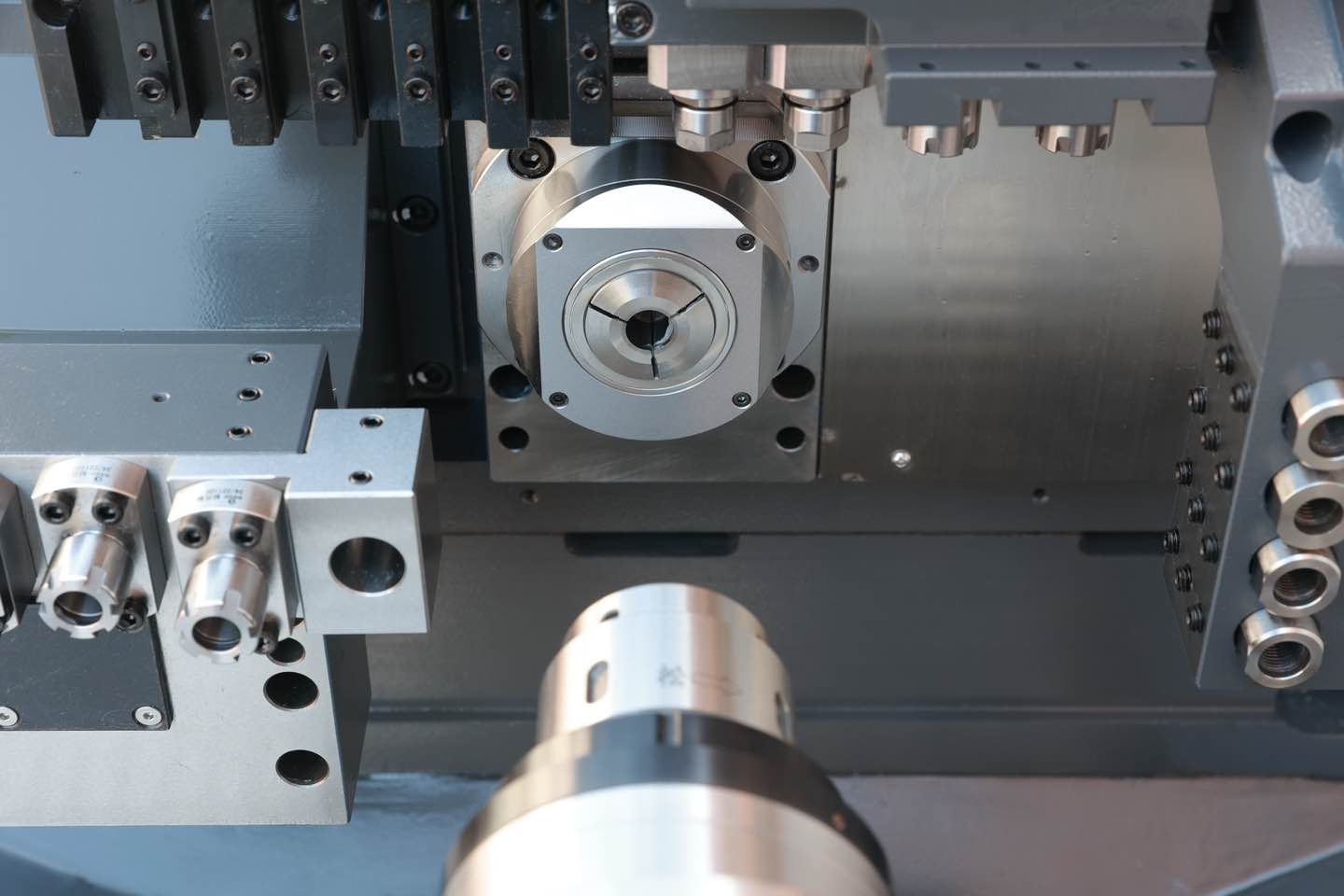

High-Speed Direct-Drive Spindle

Speeds up to 15000 rpm for fine finishing of mold surfaces. -

Thermal Compensation & Spindle Cooling

Maintains dimensional stability over long machining cycles. -

High-Accuracy Linear Scales

Glass scales on all axes for precise positioning and repeatability. -

Rigid Casting Structure with Damping Design

Reduces vibration during fine finishing to improve surface quality. -

Advanced CNC Controls

Support for high-speed machining codes, look-ahead functions, and smooth contouring.

Applications

-

Injection Mold Cavities & Cores

-

Die-Casting Mold Components

-

Precision Medical Equipment Parts

-

Aerospace Structural and Engine Components

-

Complex 3D Surfaces and Contours

-

High-Accuracy Jigs and Fixtures

Why Alpha for Precision Machining

-

Proven performance in mold industries worldwide

-

Laser-calibrated accuracy before shipment

-

Customizable to integrate with EDM and mold polishing processes

-

Superior surface finish (Ra ≤ 0.4 μm) achievable in standard setup

-

Supported by a global network of service engineers

FAQs:

1. Can Alpha VMCs handle hardened steel molds?

Yes. With high-torque cutting modes and rigid structural design, our machines handle hardened tool steel up to HRC 55 efficiently.

2. What’s the typical surface finish from Alpha VMCs?

With proper tooling and parameters, Ra ≤ 0.4 μm is achievable, suitable for final mold surfaces without heavy polishing.

3. Can the machine be used for both roughing and finishing?

Absolutely. High-torque modes allow for aggressive roughing, and high-speed spindle modes are ideal for fine finishing.

4. Do you provide on-site calibration?

Yes. Our service team can calibrate the machine at your factory to ensure optimal accuracy.

5. Are custom table sizes available?

Yes. We can design table sizes and travels according to your specific mold sizes.