A tube bending machine is essential for manufacturers who require high-speed, automated bending of metal pipes and tubes. Unlike manual or semi-automatic benders, automated tube bending machines reduce cycle times, minimize human error, and ensure uniformity across large production runs.

At Alpha, our machines combine servo-electric drives, CNC controls, and robotic material handling to deliver fast, reliable, and precise bending for automotive, aerospace, HVAC, and industrial piping applications.

Key Features of High-Speed Tube Bending Machine

Automated Pipe Feeding and Handling

Integrated loaders and conveyors allow continuous production with minimal operator intervention.

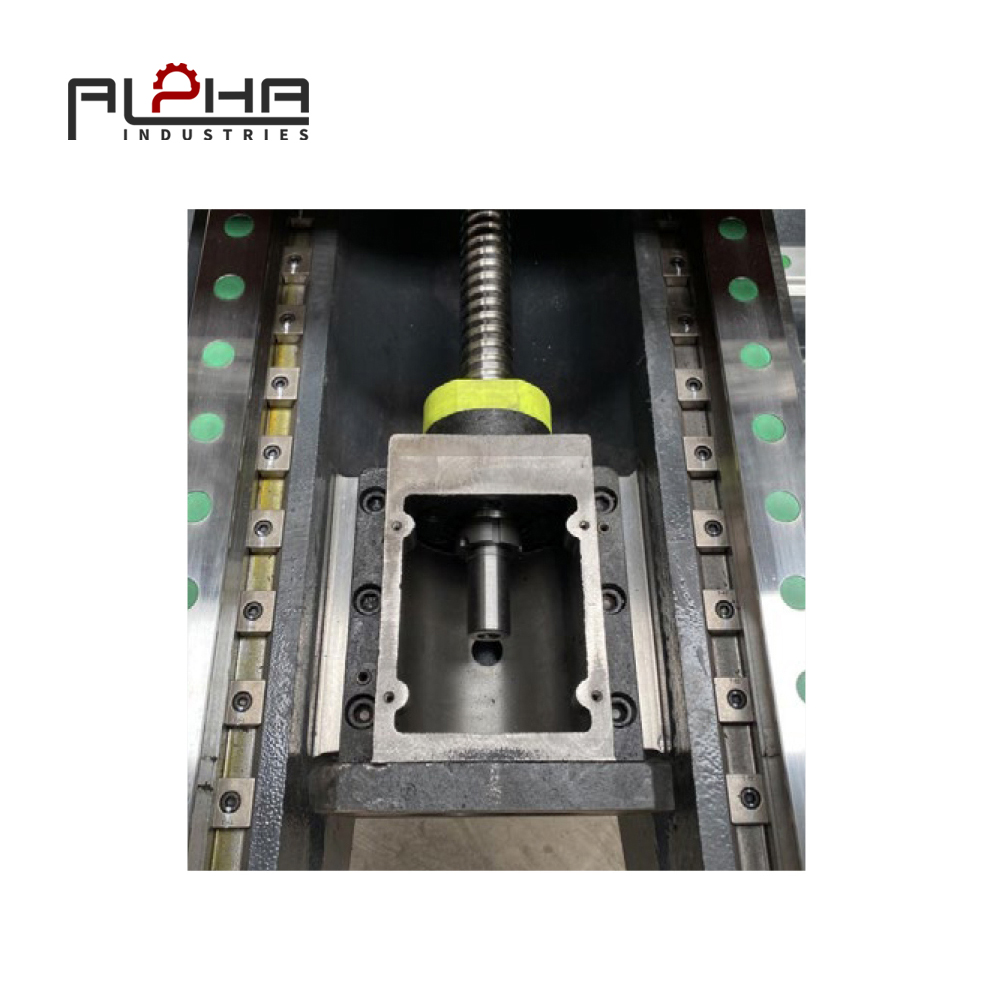

High-Speed Servo Drives

Servo-electric systems optimize speed and accuracy, achieving rapid bending cycles without sacrificing precision.

Multi-Radius and Complex Bends

CNC programming enables multi-radius, compound, and 3D bends for complex piping systems.

Real-Time Monitoring and Error Correction

Sensors and software track bending angles, wall thickness, and tube position, automatically correcting deviations to maintain quality.

How High-Speed Tube Bending Machines Work

-

Tube Loading: Pipes are automatically fed into the machine.

-

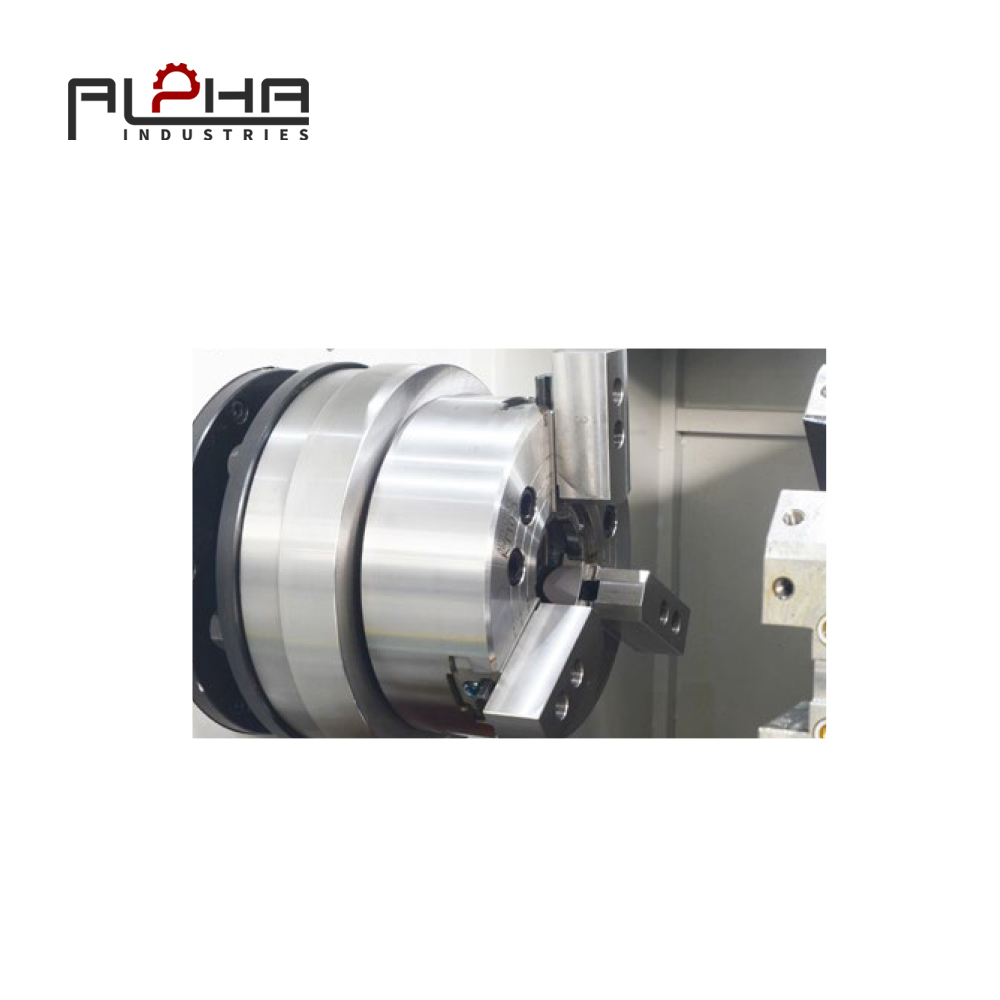

Clamping and Rotation: The tube is clamped, and the bending die rotates to achieve the programmed angle.

-

Real-Time Feedback: Angle and radius are monitored and adjusted dynamically.

-

Unloading: Completed pipes are conveyed out for inspection or next processing stage.

This system enables high-volume production with consistent quality, ideal for industrial-scale operations.

Applications of High-Speed Tube Bending Machines

-

Automotive: Exhaust pipes, fuel lines, chassis frames, and safety roll cages.

-

Aerospace: Hydraulic lines, structural tubing, and cabin components.

-

HVAC & Energy: Boiler tubes, gas pipelines, and ventilation piping.

-

Furniture Manufacturing: Tubular frames for chairs, tables, and modular structures.

-

Medical Equipment: Precision tubing for devices and hospital equipment.

Advantages of Choosing Alpha High-Speed Tube Bending Machine

-

Maximized production efficiency with automation

-

Minimal operator intervention and reduced labor costs

-

High repeatability and multi-radius bending capability

-

CE-certified safety and global after-sales support

-

Customizable tooling for different pipe diameters and materials

Frequently Asked Questions (FAQ) on High-Speed Tube Bending Machine

What is a high-speed tube bending machine used for?

It is used for rapid, automated bending of metal pipes with consistent angles and radii, ideal for mass production.

How is it different from standard tube bending machines?

High-speed machines feature automation, servo-electric drives, and real-time feedback, enabling faster cycles, multi-radius bends, and higher throughput.

Can it handle different pipe diameters and materials?

Yes, with interchangeable tooling and adjustable settings, it can bend various pipe sizes and materials including steel, aluminum, and copper.

Which industries benefit most from high-speed tube bending?

Automotive, aerospace, HVAC, energy, furniture, and medical equipment industries benefit from faster production, precision, and repeatability.

Does Alpha provide customized automation solutions for tube bending?

Yes. Alpha offers robotic loading/unloading, CNC sequence optimization, and smart monitoring systems for fully tailored automation solutions.

Partner with Alpha for Automated Tube Bending

Alpha delivers advanced high-speed tube bending machines designed to enhance productivity, accuracy, and scalability. Whether for industrial mass production or high-mix manufacturing, our solutions meet global quality standards.

Contact our experts today: Contact Us