Boost Productivity with Alpha Vertical Machining Centers

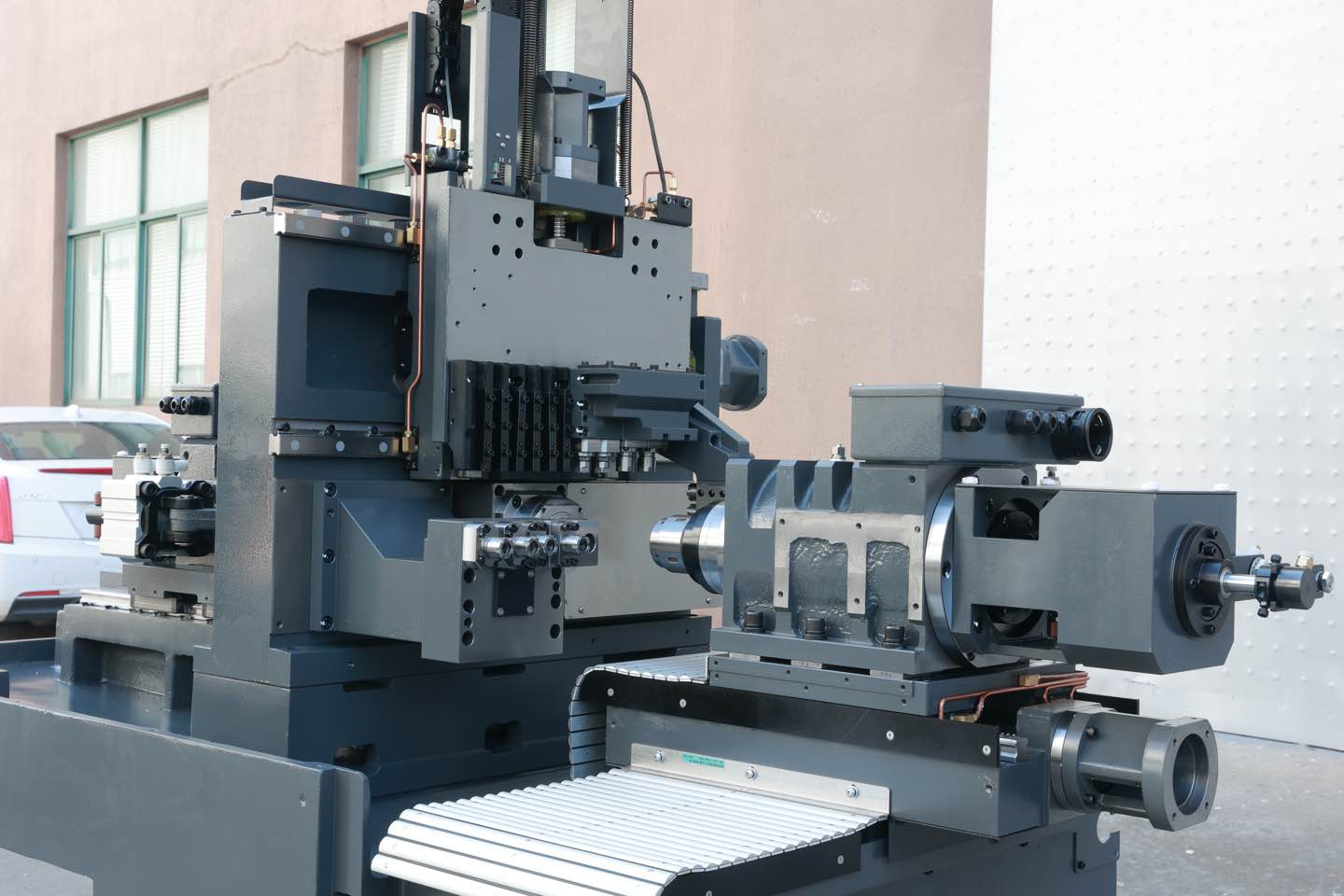

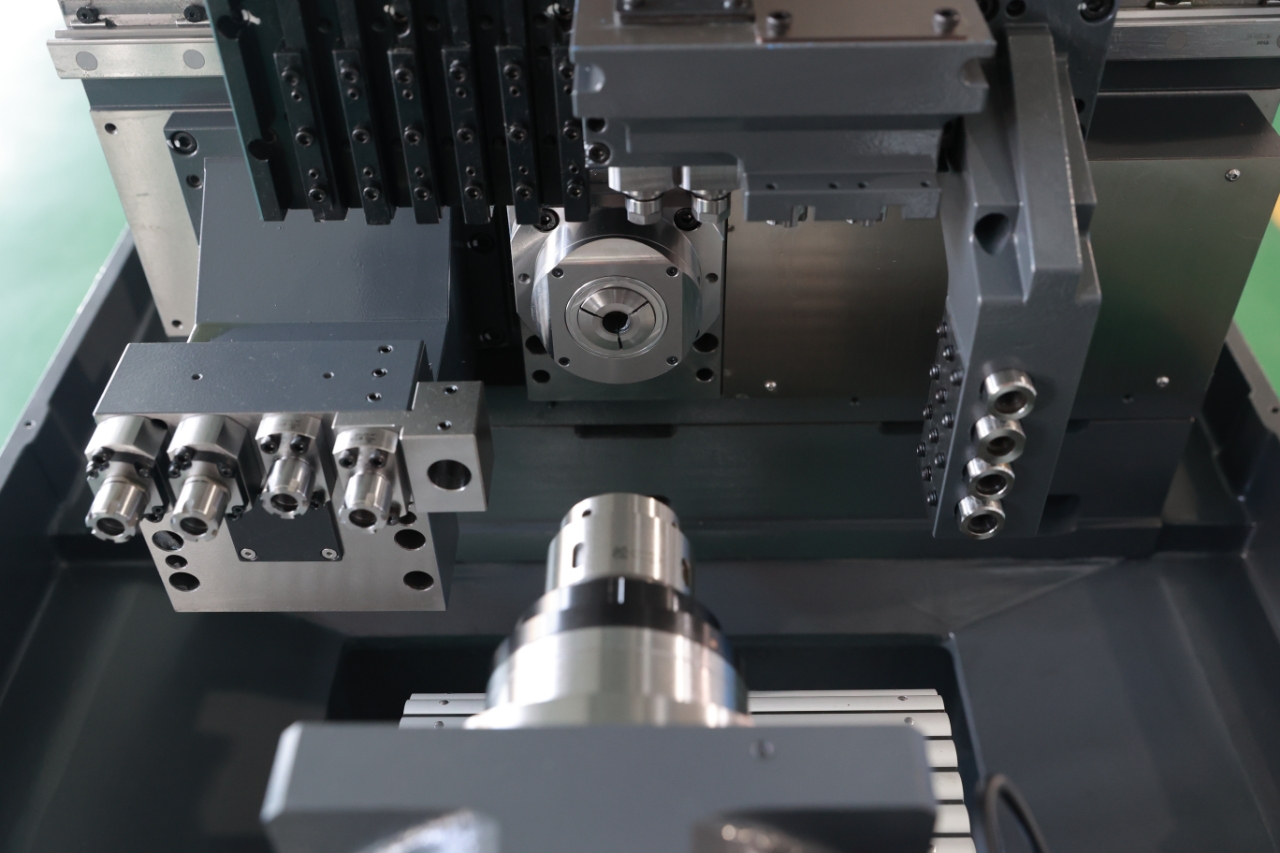

In today’s manufacturing landscape, consistency and speed are the keys to profitability. Alpha’sVertical Machining Centers (VMCs)are designed for high-volume production environments that demand stable accuracy, long working hours, and automated cycles.

From batch production of automotive components to precise contouring of aerospace parts, Alpha VMCs provide fast tool changes, wide machining envelopes, and seamless integration with production lines.

Key Features of Alpha Industrial VMCs

-

High-Rigidity Meehanite Casting Structure

All main machine parts are made of stress-relieved high-grade cast iron to ensure long-term mechanical stability during heavy-duty cutting. -

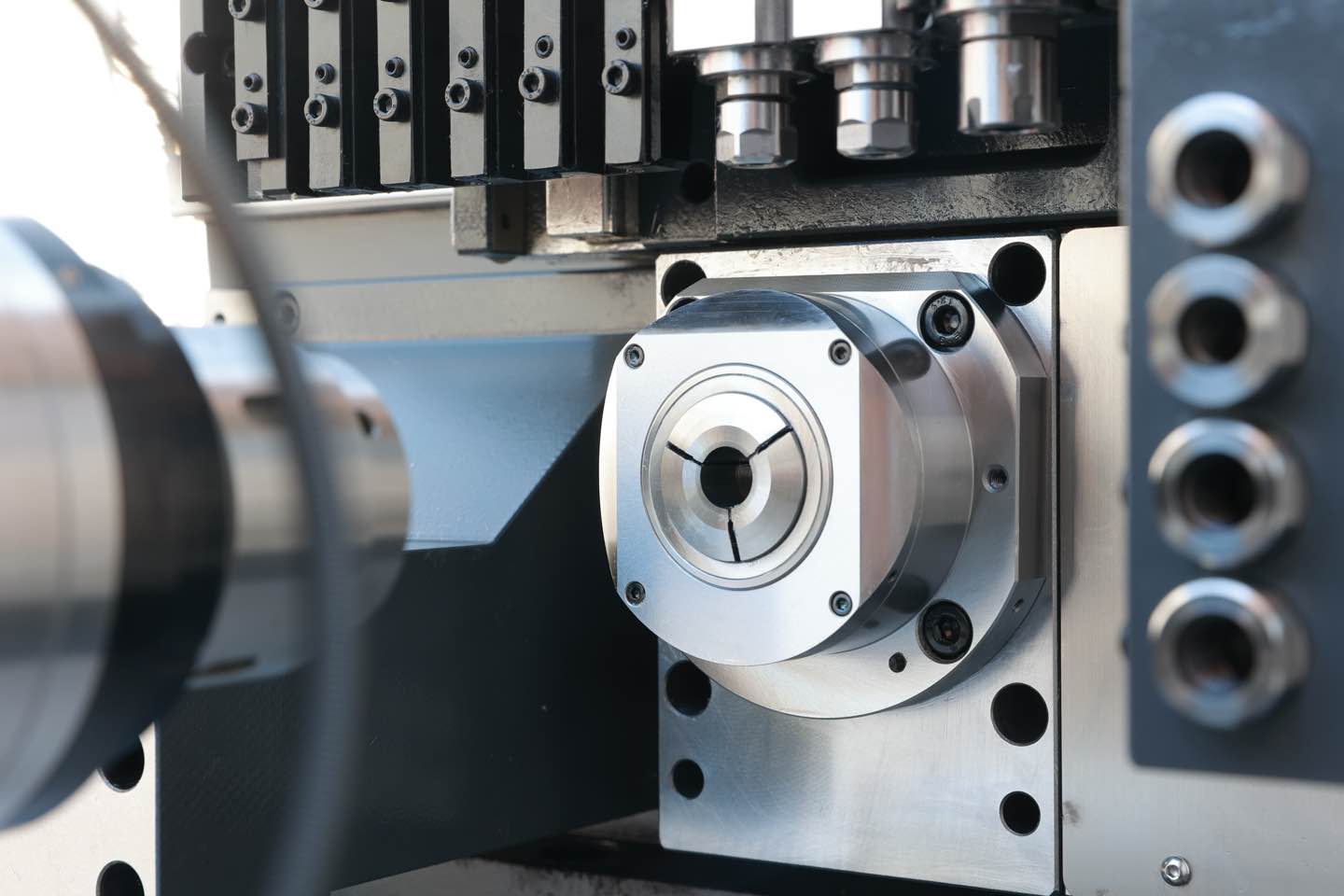

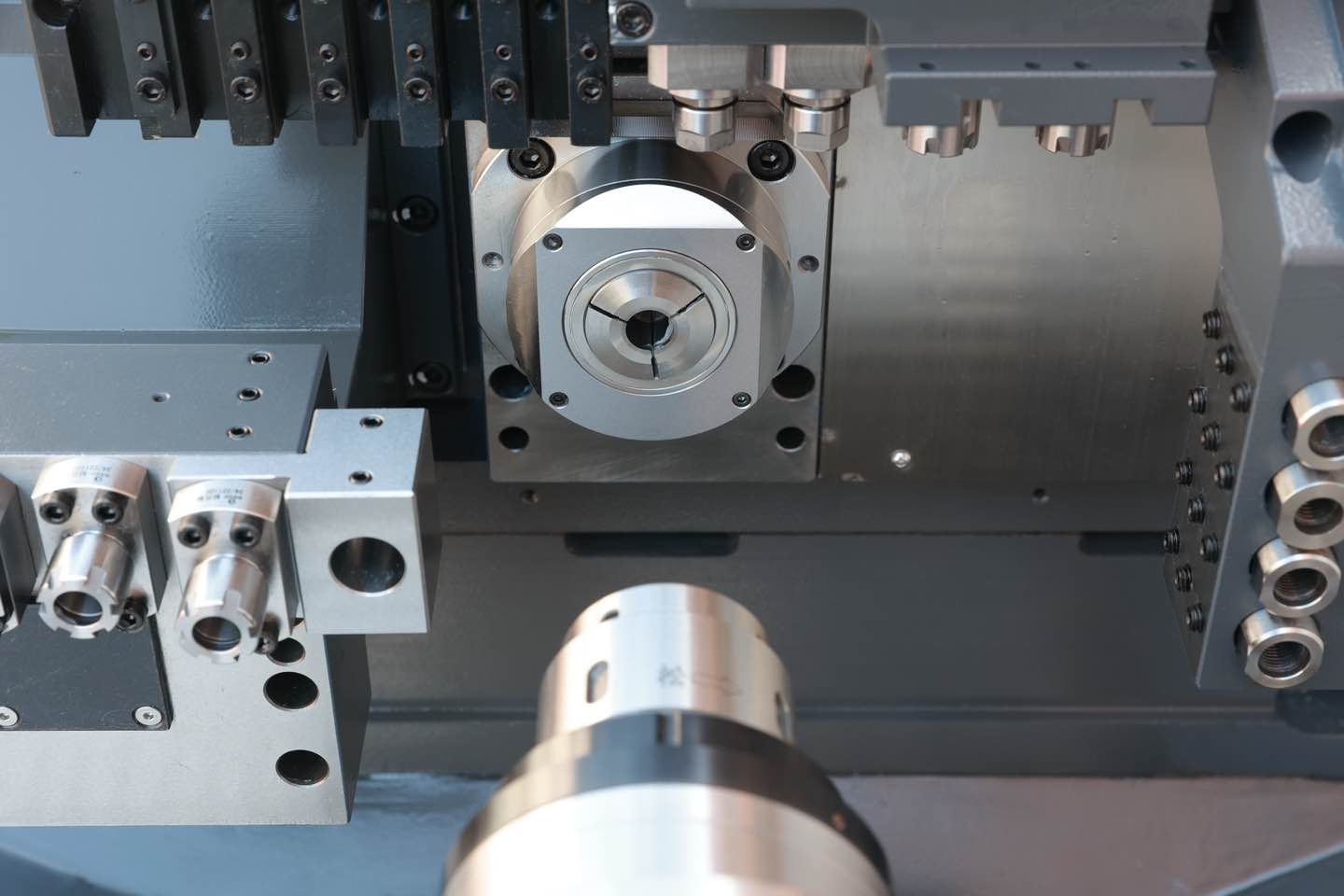

High-Speed and High-Torque Spindle

Motorized spindles or belt-driven options available, with torque-boosting at low rpm for stainless steel and hard metal applications. -

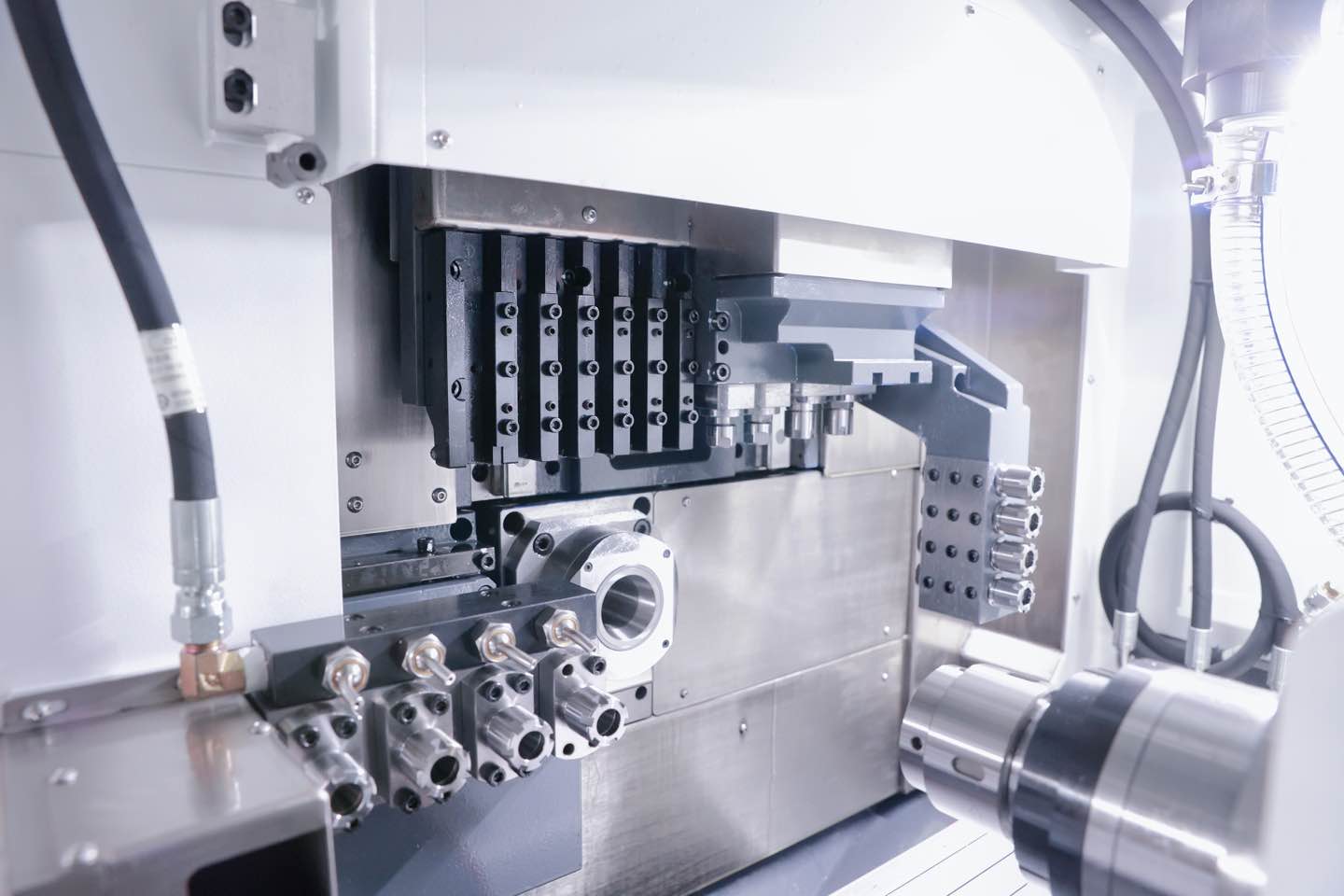

Fast Automatic Tool Changer (ATC)

Up to 24 tools with fast arm-type ATC for reduced cycle time in mass production lines. -

Large Work Envelope

Allows for complex parts or multiple workpieces to be machined in one setup, improving throughput. -

Efficient Chip Management System

Rear or side chip removal conveyors plus coolant flushing enhance machine cleanliness and reduce downtime.

Ideal for the Following Applications

-

Automotive Brake Discs, Engine Blocks, and Housings

-

Aluminum Aerospace Components

-

Hydraulic and Pneumatic System Machining

-

Industrial Valve Bodies

-

Mass Production of Plates, Covers, and Shafts

-

High-Speed Tapping and Drilling in Electronics Industry

Why Alpha VMCs Are Trusted for Mass Production

-

Proven durability in 24/7 factory environments

-

Repeatable positioning accuracy of ±0.005 mm

-

Tailored solutions for automation integration

-

User-friendly interfaces with FANUC, Siemens, Mitsubishi, or GSK

-

Extensive customer base across 35+ countries

FAQs:

1. How do Alpha VMCs support mass production?

They feature fast tool changers, high-speed spindle options, and compatibility with automation systems such as robotic loaders and pallet changers, enabling uninterrupted operations.

2. Are Alpha machines suitable for hard materials?

Yes. We offer high-torque spindle options and rigid bed designs to handle stainless steel, titanium alloys, and other hard metals with stability.

3. What’s the typical accuracy of Alpha VMCs?

Repeatable positioning accuracy is typically ±0.005 mm, with machines calibrated using laser interferometers and ball-bar testing.

4. Can Alpha VMCs integrate with MES or ERP systems?

Yes. Depending on the control system, Alpha VMCs can interface with factory management software via standard communication protocols.