In modern manufacturing, speed and consistency are critical. Manual deburring is labor-intensive and prone to inconsistency, making automated deburring machines an essential solution.

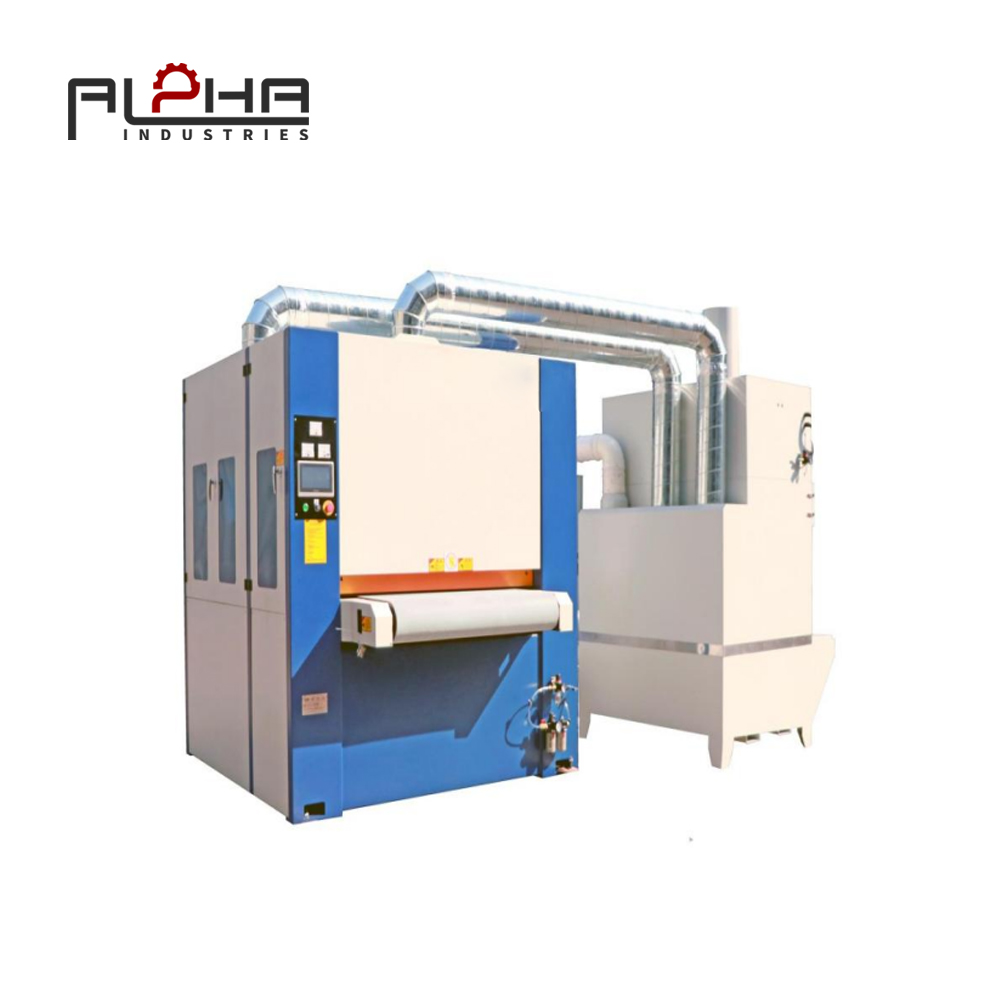

ALPHA Deburring Machines integrate automation and precision engineering to improve cycle times, reduce labor requirements, and ensure uniform finishing across all parts.

Explore our Deburring Machine product range for models that maximize productivity in your factory.

How Automation Improves Deburring Efficiency

-

Consistent Quality Across Parts

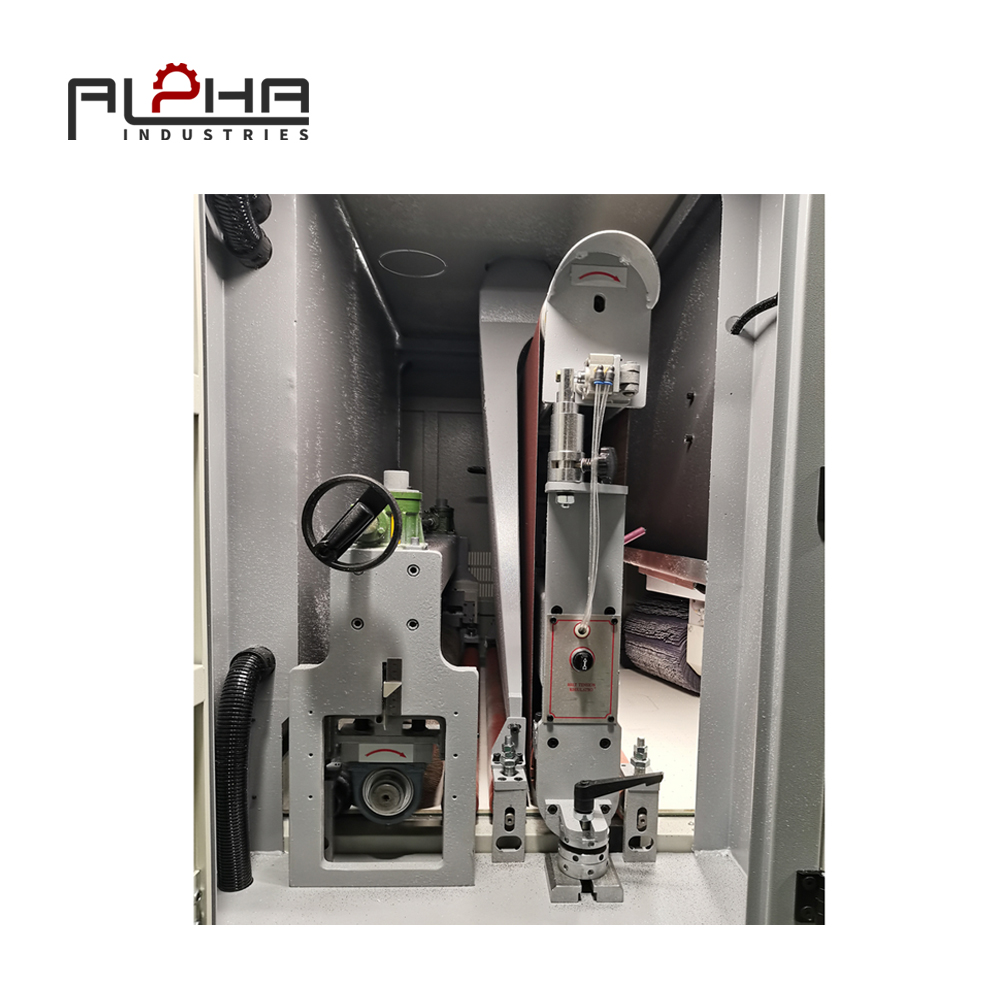

Automated brushing and abrasive systems guarantee uniform burr removal, eliminating operator-dependent variability. -

Reduced Labor Costs

Automation minimizes the need for manual finishing, allowing operators to supervise multiple machines at once. -

Faster Cycle Times

High-speed belt and brush systems enable rapid deburring of complex parts, increasing throughput. -

Improved Safety

Automation reduces operator exposure to sharp edges and rotating tools, lowering workplace risks.

Learn more about productivity strategies in our Deburring Machine efficiency article.

Common Productivity Challenges and Solutions

Even automated systems can face efficiency-related challenges. Here’s how to solve them:

1. Uneven Finishing

Cause: Worn brushes or unbalanced abrasives.

Solution:

-

Replace brushes and belts on schedule.

-

Perform weekly equipment alignment checks.

2. Slow Processing Speed

Cause: Incorrect feed rate or abrasive settings.

Solution:

-

Optimize feed speeds based on material type.

-

Adjust abrasive pressure for consistent results.

3. High Downtime

Cause: Lack of preventive maintenance.

Solution:

-

Implement a regular maintenance checklist.

-

Keep critical spare parts in stock.

Applications of Automated Deburring

ALPHA Deburring Machines are widely used in industries requiring high-volume, precise finishing:

-

Automotive manufacturing: Engine parts, brackets, and panels

-

Aerospace industry: Precision structural components

-

Electronics: Small metal housings and connectors

-

Sheet metal processing: HVAC ducts, machine covers, and cabinets

See real-world case studies in our Deburring Machine applications article.

Maintenance Tips for Automated Deburring Machines

-

Daily Cleaning: Remove dust and debris from belts and brushes.

-

Lubrication: Follow manufacturer’s schedule for smooth operation.

-

Monitoring Sensors: Ensure CNC and automated sensors are calibrated.

-

Spare Parts Readiness: Keep essential brushes, belts, and bearings in inventory.

For service and spare parts, contact us via ALPHA contact page.

Why Choose ALPHA Deburring Machines

-

Automation for Higher Output

-

Flexible Solutions for Various Materials

-

Durable Construction for Industrial Use

-

Comprehensive Support and Training

Explore the full ALPHA Deburring Machine product line to find the right machine for your business.

Get Your ALPHA Deburring Machine Product Brochure

For complete specifications, automation features, and available models, download the ALPHA Deburring brochure here.