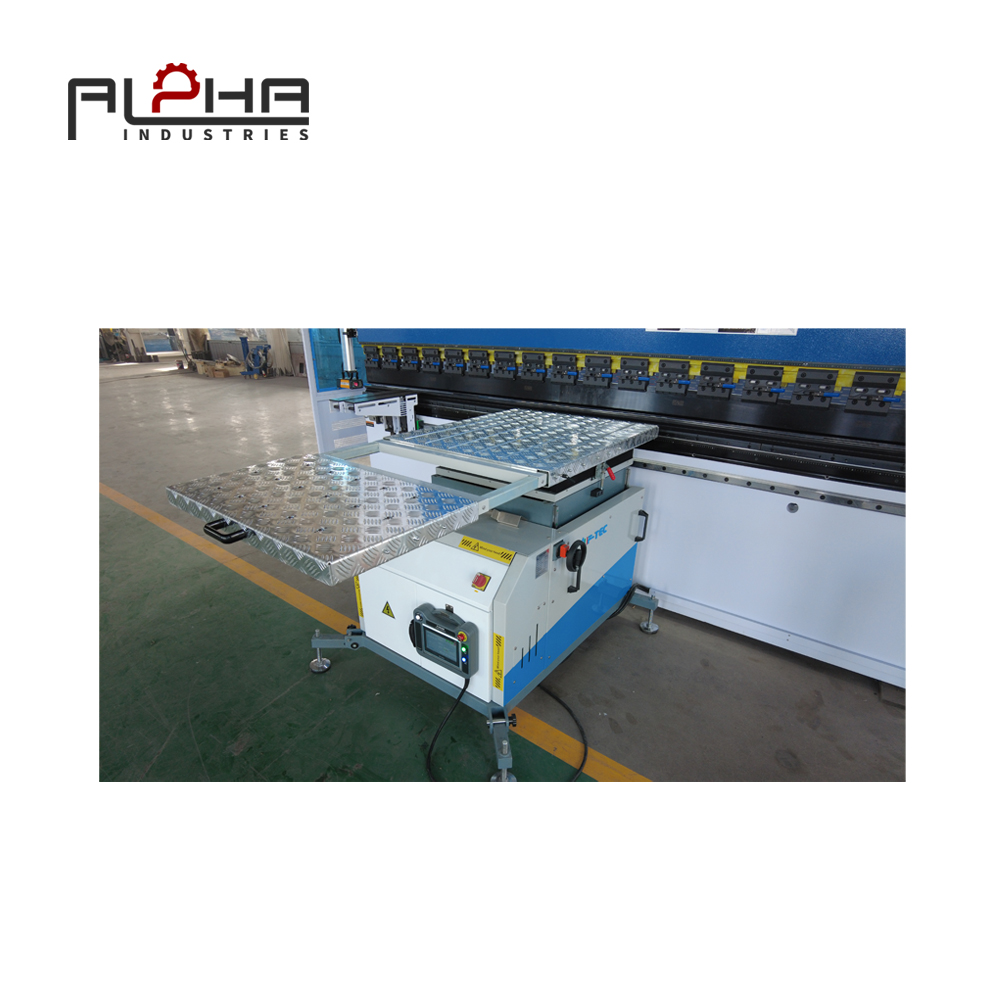

CNC Gantry Machine: Precise Surface Grinding of Large Workpieces

thisCNC gantry machineIt is a high-precision, fully automatic grinding system designed for planar processing of oversized and heavy components. The machine is integrated with advanced CNC controls to ensure surface effect advantages, consistent accuracy and high productivity in industrial-scale applications.

Heavy-duty grinding polymer gantry structure

The core of CNC Gantry Grinder isDouble column gantry structure, designed for maximum mechanical stability and vibration resistance. The base and cylinder areAdvanced Mihani Rock Cast Iron, stresses and their precise production to ensure dimensional integrity during continuous operation.

The gantry building supports the grinding head from above, so thatUniform pressure distributionAnd eliminate deformation, even under full load grinding conditions. This makes it idealMolds, molds, base plates, machine beds and other large flat components.

CNC control system enhances automation and accuracy

EquippedMulti-axis CNC system, Gantry Grinder provides complete programmability of grinding parameters including feed rate, wheel positioning, spark cycles and automatic compensation. Touch screen interface and intuitive programming enable operators toStore multiple part configuration filesQuick conversion and reduce downtime.

Closed-loop servo controlCombining a high resolution encoder ensures repeatability and micron-scale grinding accuracy.

Dynamic grinding performance with custom spindle options

Grinding spindle byHigh torque, variable speed motor, High RPM stability is supported by heavy duty bearings. Options for bothHorizontal and vertical grinding headsAvailableInverter-controlled wheel speedAdapt to different material types including hardened steel, cast iron, aluminum and tool steel.

Coolant system with high pressure pump and filtrationMaintain thermal balance and prevent burning of workpieces during prolonged operation.

Application for heavy industry

CNC gantry machine is the preferred solution in industries such as the following.

-

Aerospace and defense- Grinding precision basic components and tool holders

-

Railways and transportation- Finishing long beam cross-sections and track beds

-

Mold and mold industry- Processing large molds with high surface finish requirements

-

Heavy duty machinery- Surface grinding of casting bases and machine tools

Its processing powerExtra large and high weight workpiecesTolerances with microscopic levels make them an essential asset for high-value manufacturing.

Built-in measurement and safety system

Advanced models are equippedOnline measurement systemlikeLinear scales and probes in processDetect surface deviations and adjust the grinding path in real time. Safety features includeOverload protection,,,,,Wheel wear sensor, andCompletely closed guardEnsure safe operation even during an unattended cycle.

Customization and integration options

CNC Gantry Grinders can be configured:

-

Magnetic or vacuum labor table

-

Linear guide or static slide

-

Wheel dressing system (rotating or single-point diamond)

-

Automatic loading system or robot arm

These customizations allow the factory to integrate the machine intoWise cell grindingorIndustry 4.0Environment with real-time monitoring and remote diagnosis.

People will also ask (FAQ Architecture Content)

What is used in the CNC Gantry grinder?

CNC gantry grinders are used for high-precision flat surface grinding, large components such as molds, molds and machine alkalis, to provide microscopic level of accuracy automatically.

How is a gantry sharpener different from a conventional surface grinder?

Unlike traditional grinders, gantry mills use bridge-type structures to support the grinding heads, allowing them to handle large and heavy workpieces while keeping the surface flat and rigid.

Can CNC Gantry Grinders handle hardened materials?

Yes, using a strong spindle and suitable grinding wheels, CNC gantry moltening can handle steel, tool steel and other hard-to-play materials with excellent finishes.

Which industries benefit the most from CNC Gantry Grinding?

Industry such as aerospace, mold and mold manufacturing, energy, defense and heavy machinery have benefited greatly from the high precision and large-scale grinding of machines.

Are CNC Gantry Grinders compatible with automation systems?

Yes, they can be integrated with robots, pallet changers and MES/SCADA systems for complete automation, enabling unattended machining and real-time process control.

Call Action

Want to improve surface grinding capabilities through CNC automation?

Contact Us NowQuotes about aCNC gantry machineCustomized to your application needs.