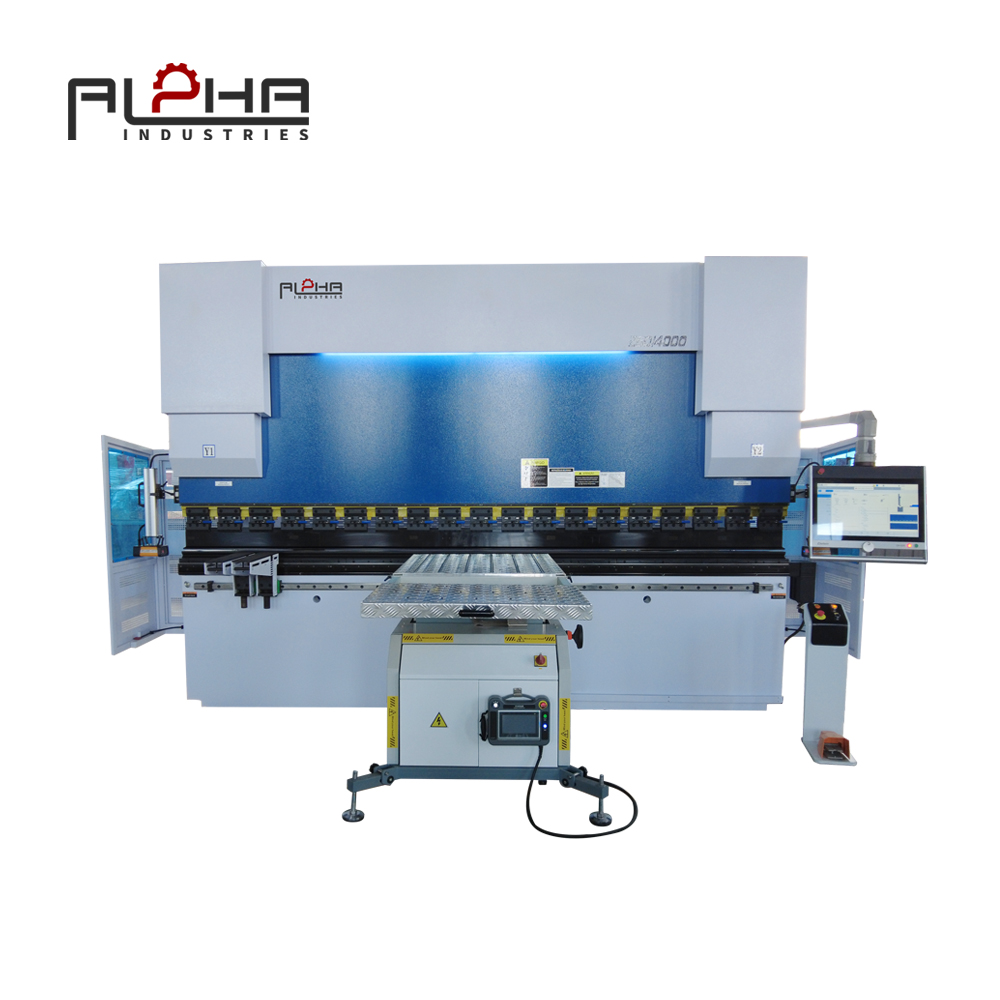

Why Bending Accuracy Defines CNC Press Brake Performance

In modern sheet metal fabrication, bending accuracy is the single most critical performance indicator of a CNC press brake. Even minor angular deviations can lead to assembly issues, material waste, and costly rework. As production tolerances tighten across automotive, enclosure, elevator, and machinery industries, manufacturers increasingly rely on advanced crowning technology to maintain consistent bending precision.

At Alpha, CNC press brakes are engineered with precision-focused crowning systems to ensure stable, repeatable results even during long bending cycles and high-tonnage operations.

The Core Challenge: Ram Deflection in CNC Press Brake Bending

During bending, a CNC press brake applies significant force across the full working length of the machine. This force naturally causes ram and bed deflection, especially when bending long or thick metal sheets.

Common Effects of Uncontrolled Deflection

-

Center angle larger than edge angles

-

Inconsistent bend radius across length

-

Poor repeatability in batch production

-

Increased need for manual angle correction

Without compensation, even a high-quality CNC press brake cannot achieve true linear bending accuracy.

What Is a CNC Press Brake Crowning System?

A press brake crowning system is a mechanical, hydraulic, or CNC-controlled structure designed to counteract ram deflection during bending.

By slightly altering the shape of the bed or ram under load, the crowning system ensures:

-

Uniform bending force distribution

-

Consistent bend angle from left to right

-

Improved dimensional stability

This technology is essential for any precision CNC press brake used in industrial production.

Types of Crowning Systems in CNC Press Brakes

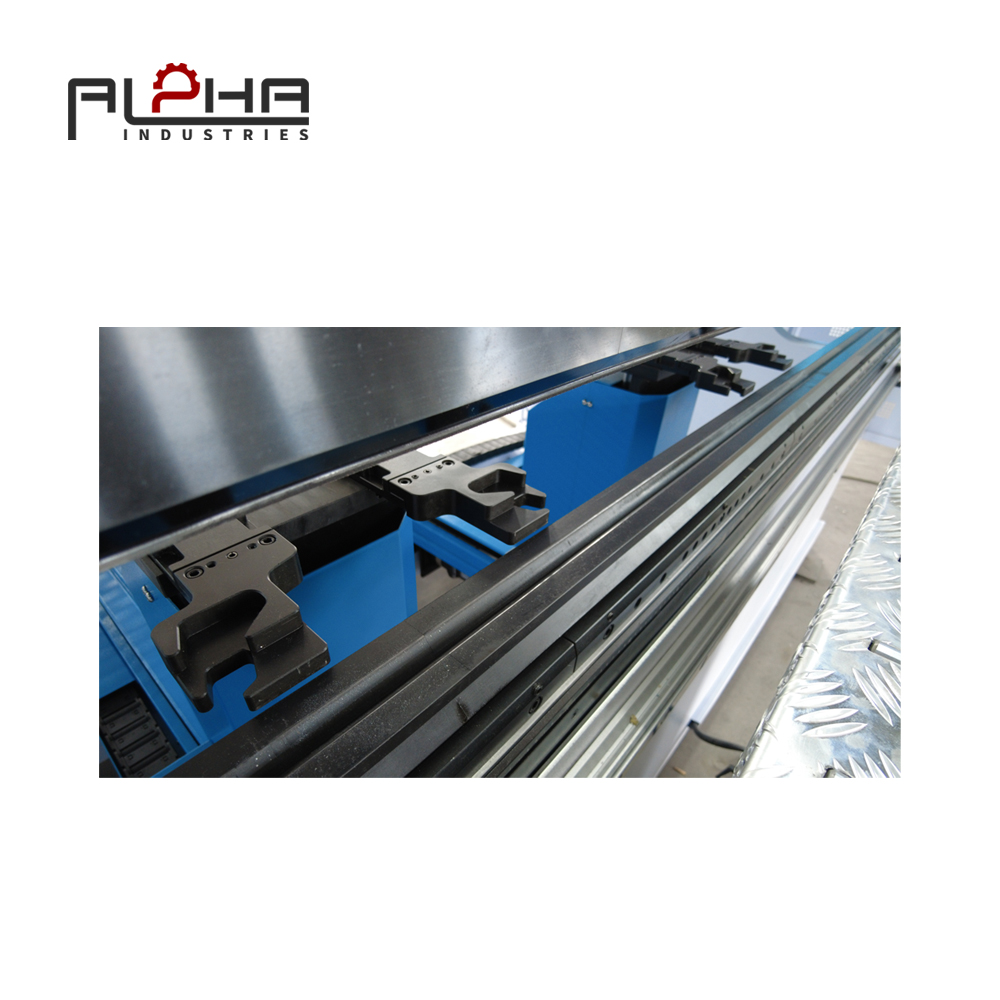

Mechanical Crowning

-

Uses wedge blocks or shims

-

Manual or semi-automatic adjustment

-

Suitable for standard bending tasks

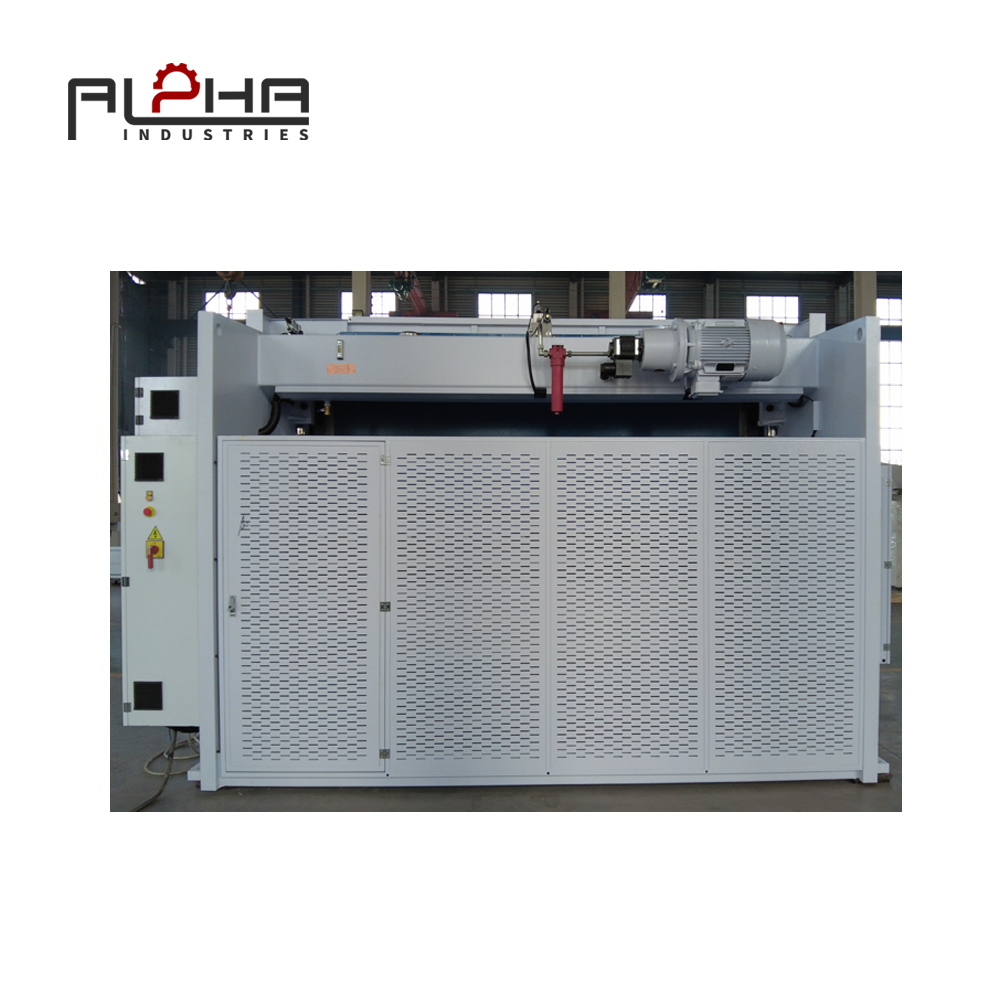

Hydraulic Crowning

-

Integrated hydraulic cylinders beneath the bed

-

Automatically compensates under load

-

High accuracy for medium to heavy plates

CNC Automatic Crowning (Recommended)

-

Fully controlled by CNC system

-

Real-time compensation based on material, length, and tonnage

-

Ideal for high-mix, high-precision production

Alpha CNC press brakes primarily adopt CNC automatic crowning for maximum accuracy and ease of operation.

How CNC Crowning Improves Bending Accuracy Step by Step

-

CNC system calculates bending force

-

Material length and thickness are analyzed

-

Crowning value is automatically set

-

Bed deformation is pre-compensated

-

Uniform bend angle achieved across entire workpiece

This closed-loop process dramatically improves angle consistency and repeatability.

Impact of Crowning on Sheet Metal Bending Quality

A CNC press brake with advanced crowning delivers measurable improvements:

-

±0.5° bending angle consistency

-

Reduced setup time

-

Lower scrap rate

-

Stable results across long workpieces

-

Minimal operator intervention

For manufacturers focused on efficiency, crowning is not optional—it is essential.

Material-Specific Benefits of CNC Press Brake Crowning

Different materials react differently under bending stress:

| Material | Crowning Benefit |

|---|---|

| Carbon Steel | Prevents center over-bending |

| Stainless Steel | Maintains angle under high tonnage |

| Aluminum | Reduces springback inconsistency |

| High-Strength Steel | Ensures repeatable forming |

A well-tuned CNC press brake adapts crowning parameters automatically based on material properties.

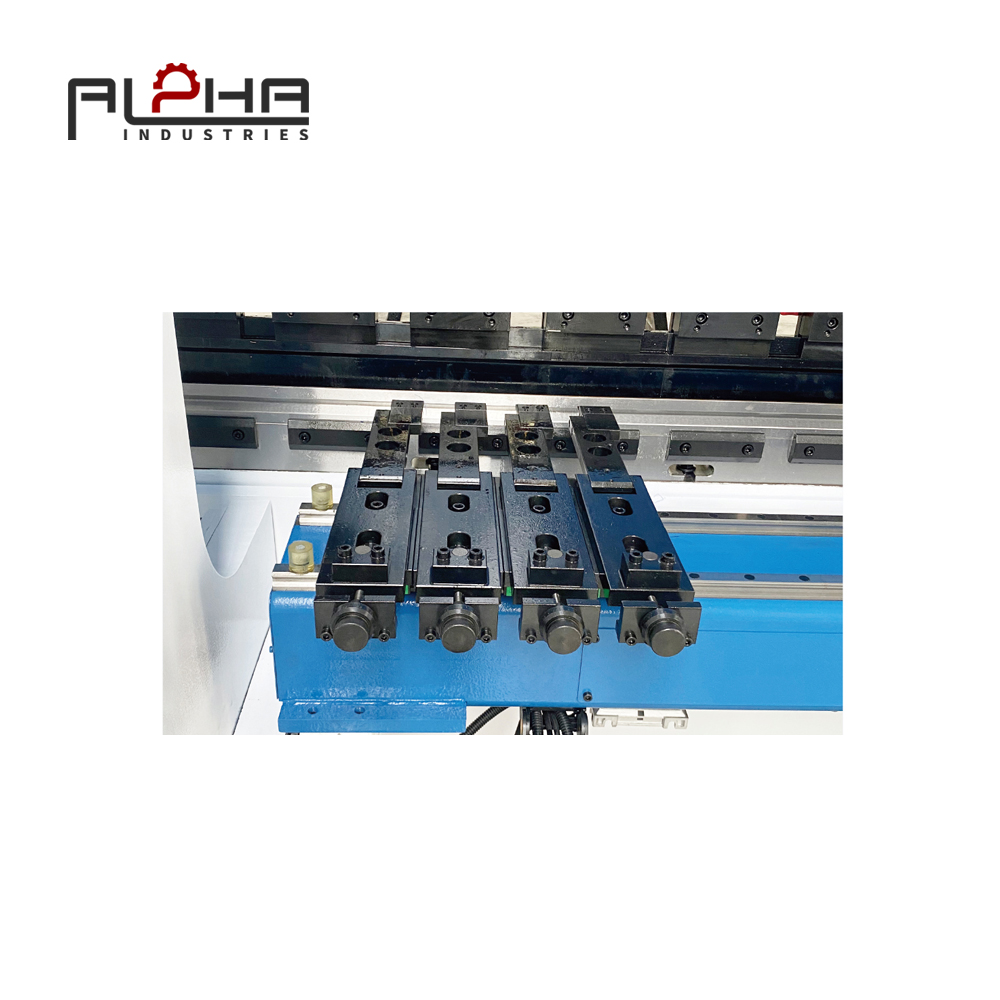

CNC Control Integration: The Key to Smart Bending

Modern CNC press brakes integrate crowning control directly into the CNC interface:

-

Bending programs store crowning values

-

Tool changes auto-adjust compensation

-

Multi-step bending remains consistent

This intelligent integration transforms the press brake into a smart bending center.

Applications Requiring High-Accuracy CNC Press Brake Crowning

-

Electrical cabinets

-

Elevator panels

-

HVAC duct components

-

Precision enclosures

-

Structural sheet metal parts

In these applications, angle deviation is unacceptable, making crowning indispensable.

Alpha CNC Press Brake Design Philosophy

At Alpha, CNC press brakes are designed with:

-

High-rigidity frames

-

Optimized bed structure

-

CNC-controlled crowning systems

-

Precision hydraulic synchronization

This ensures long-term accuracy, even under continuous industrial operation.

Maintenance and Calibration of Crowning Systems

Proper maintenance ensures lasting accuracy:

-

Regular CNC calibration

-

Hydraulic pressure inspection

-

Bed flatness verification

Alpha provides clear maintenance guidelines to keep CNC press brakes operating at peak precision.

FAQ

What is crowning in a CNC press brake?

Crowning is a compensation system that counteracts ram and bed deflection to ensure uniform bending angles.

Is CNC crowning necessary for short bends?

It becomes critical as material length, thickness, or accuracy requirements increase.

Can crowning reduce manual angle correction?

Yes, automatic crowning significantly reduces trial bending and re-adjustment.

Does crowning affect tool life?

Proper crowning reduces uneven load, extending tool lifespan.

Crowning Defines True CNC Press Brake Precision

A CNC press brake without an advanced crowning system cannot deliver consistent, industrial-grade bending accuracy. By intelligently compensating for deflection, crowning technology transforms raw bending force into precise, repeatable forming results.

For manufacturers seeking stable quality, lower waste, and higher efficiency, CNC press brake crowning is the foundation of precision sheet metal bending.