Why Bending Accuracy Is the Core Value of a CNC Press Brake

In modern sheet metal fabrication, bending accuracy is not just a specification—it is the foundation of product quality, assembly consistency, and production efficiency. Regardless of tonnage, speed, or automation level, a CNC press brake ultimately succeeds or fails based on its ability to deliver repeatable, stable bending angles across the full working length.

Among all influencing factors, machine deflection control and crowning technology play the most decisive role. This article focuses on how CNC press brake bending accuracy is achieved through advanced crowning systems, and why this single technical point has become a critical evaluation standard for industrial buyers.

What Is Bending Accuracy in a CNC Press Brake?

Bending accuracy refers to the degree to which the actual bending angle matches the programmed angle, consistently and repeatedly, under real production conditions.

Accuracy is typically measured by:

-

Angle deviation (±°)

-

Consistency along the full bending length

-

Stability across different material thicknesses

-

Repeatability in batch production

Even a 0.5° deviation can result in:

-

Poor assembly fit

-

Increased rework

-

Material waste

-

Reduced production efficiency

The Real Enemy of Accuracy: Machine Deflection

During bending, enormous force is applied between the upper punch and lower die. This force causes elastic deformation (deflection) of:

-

Ram (upper beam)

-

Worktable (lower beam)

-

Machine frame

What Happens Without Crowning?

Without compensation:

-

Center angle becomes larger

-

Edge angles become smaller

-

Long workpieces show inconsistent bends

-

Accuracy drops as length and tonnage increase

This phenomenon becomes more severe when:

-

Bending long sheets

-

Working with thick materials

-

Operating at high tonnage

Crowning Technology: The Key to Consistent Bending Precision

What Is Crowning in a CNC Press Brake?

Crowning is a controlled compensation mechanism that counteracts natural machine deflection during bending, ensuring uniform angle distribution across the entire bending length.

Instead of allowing the machine to bend unevenly, crowning intentionally introduces an opposite curve, resulting in a straight, accurate final bend.

Types of Crowning Systems in CNC Press Brakes

1. Mechanical Crowning System

-

Manual or motorized wedges

-

Adjusts worktable curvature

-

Suitable for basic applications

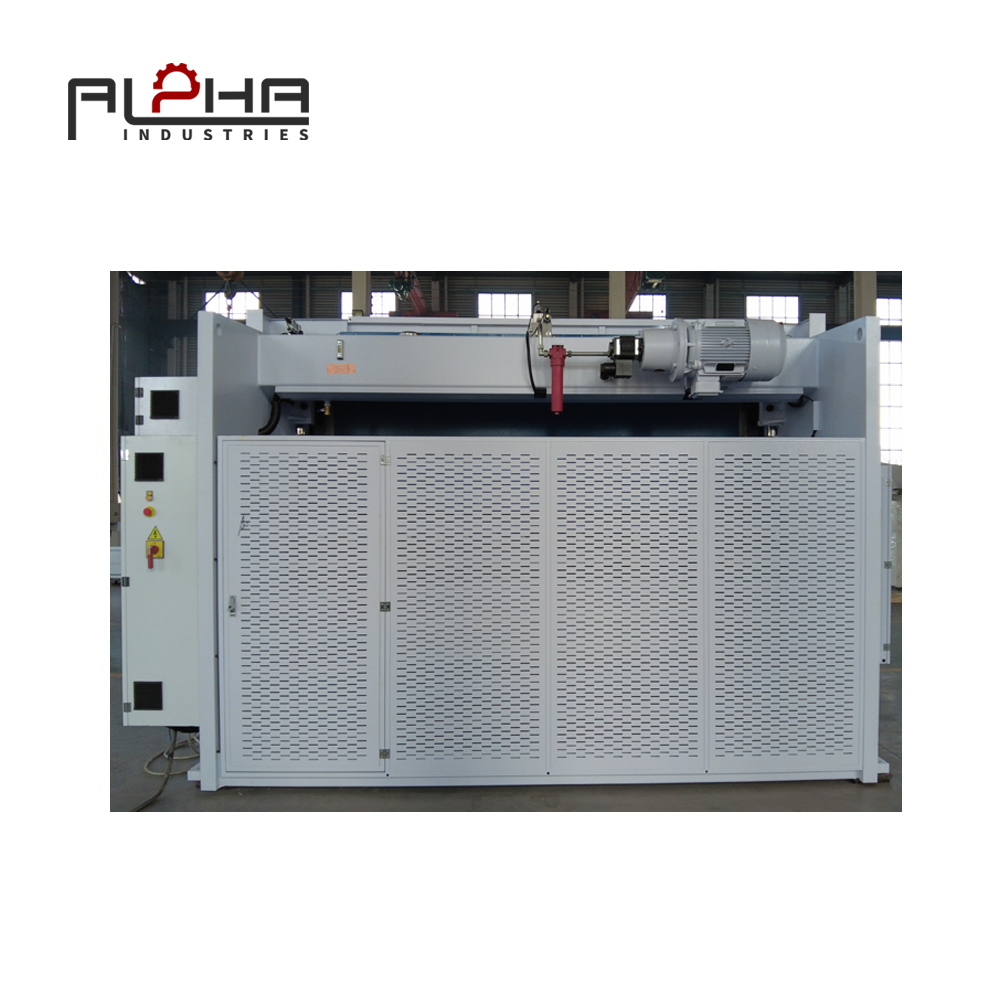

2. Hydraulic Crowning System

-

Independent hydraulic cylinders

-

Real-time pressure adjustment

-

Better precision under varying loads

3. CNC Intelligent Crowning System (Advanced)

-

Fully integrated with CNC controller

-

Automatic compensation based on:

-

Material thickness

-

Bending length

-

Tonnage

-

-

High repeatability and minimal operator intervention

High-end CNC press brakes rely on intelligent hydraulic crowning systems for industrial-grade accuracy.

How CNC Crowning Improves Bending Accuracy Step by Step

-

CNC system calculates bending force

-

Deflection curve is predicted automatically

-

Crowning cylinders apply precise counter-force

-

Ram and table remain effectively “straight”

-

Uniform angle achieved from left to right

-

Repeatability maintained across batch production

Why Crowning Accuracy Matters More Than Speed

Many buyers focus on bending speed, but in real production:

-

Speed without accuracy increases scrap

-

Accuracy reduces setup time

-

Stable bending lowers skill dependency

-

Precision improves downstream assembly

For industries such as:

-

Electrical enclosures

-

Elevator components

-

Automotive parts

-

Machinery frames

Accuracy directly determines production profitability.

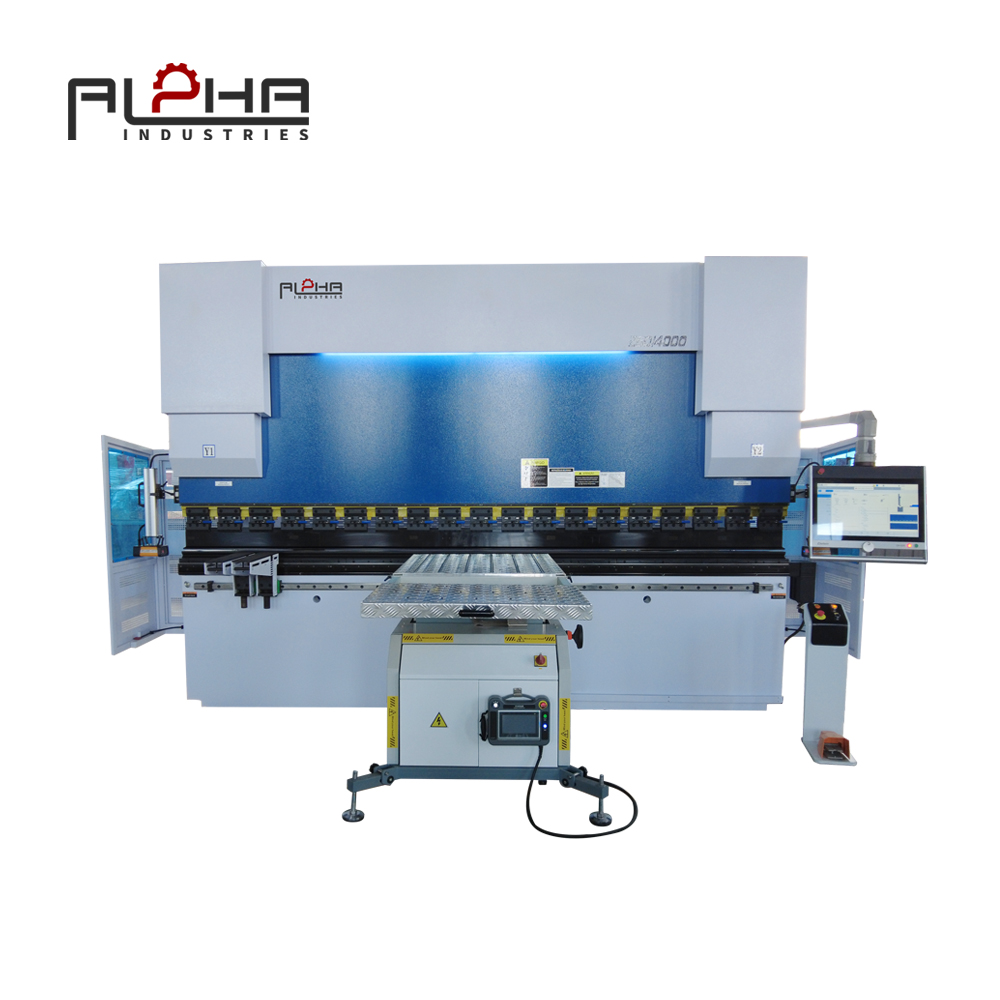

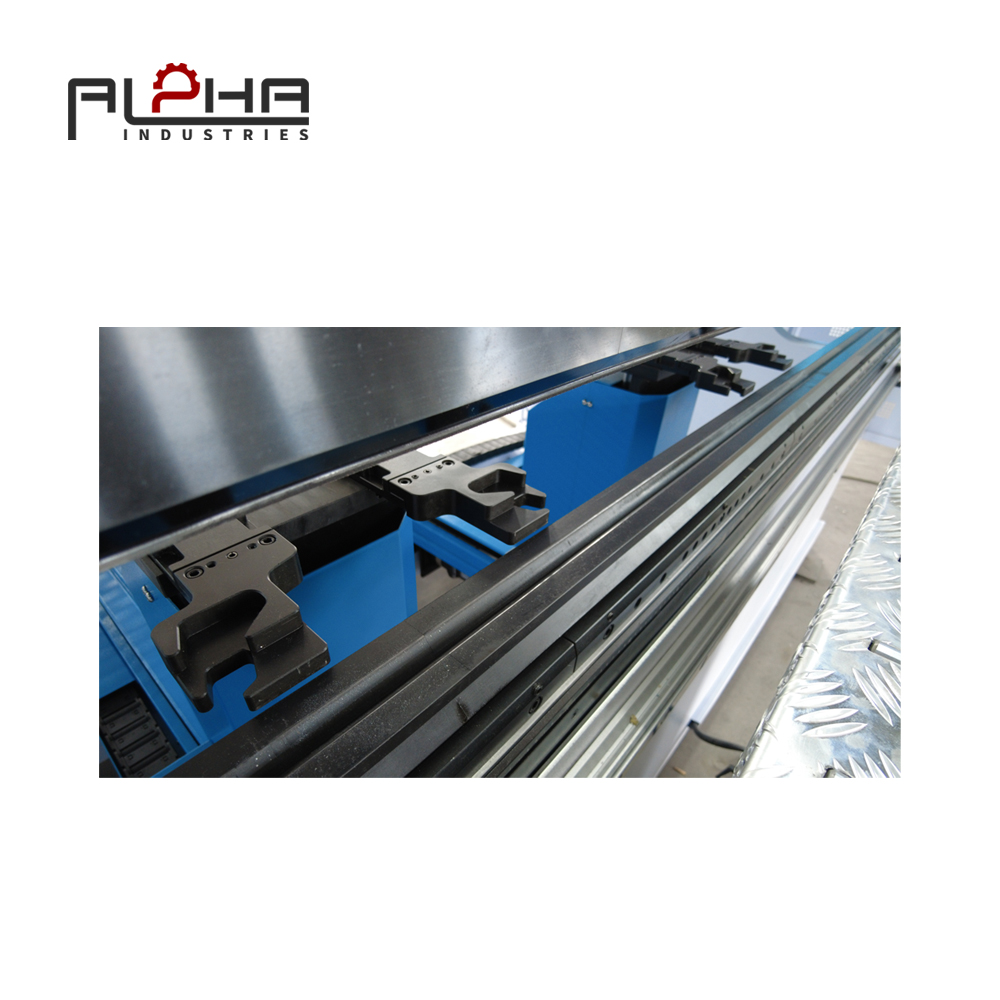

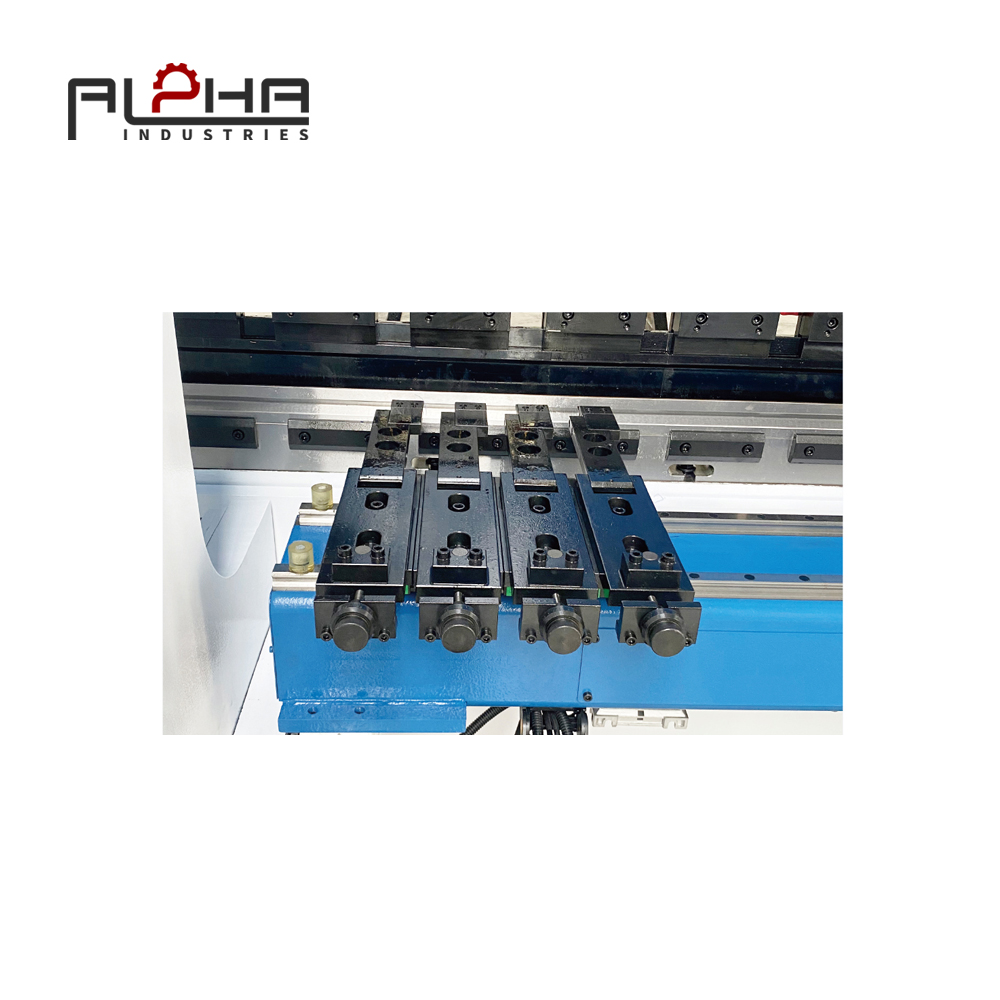

Alpha CNC Press Brake: Precision Engineered for Bending Accuracy

At Alpha, CNC press brakes are designed with bending accuracy as the primary engineering objective.

Key accuracy-focused design elements include:

-

High-rigidity welded steel frame

-

Stress-relieved structure for long-term stability

-

CNC-controlled hydraulic crowning system

-

Precision-machined ram and table surfaces

-

Advanced control algorithms for deflection compensation

This ensures:

-

Stable accuracy over years of operation

-

Consistent bending across full machine length

-

Reduced trial bending and adjustment time

FAQ

What determines bending accuracy in a CNC press brake?

Bending accuracy is mainly determined by machine rigidity, crowning technology, CNC control algorithms, tooling quality, and material consistency.

Why is crowning necessary for long bending lengths?

Because machine deflection increases with length, crowning compensates for center sagging to maintain uniform angles.

Is hydraulic crowning better than mechanical crowning?

Yes. Hydraulic crowning offers real-time, automatic compensation and higher accuracy for variable bending conditions.

Can CNC crowning adjust automatically?

Modern CNC press brakes feature intelligent crowning systems that automatically adjust based on bending parameters.

Does crowning affect repeatability?

Yes. Proper crowning significantly improves repeatability in batch production.

Conclusion: Accuracy Is the True Benchmark of a CNC Press Brake

A CNC press brake is not defined by tonnage alone. True value lies in bending accuracy, and bending accuracy is fundamentally controlled by advanced crowning technology.

By investing in precision-oriented design and intelligent compensation systems, manufacturers can achieve:

-

Higher product quality

-

Lower operational cost

-

Stronger market competitiveness

👉 Learn more about Alpha CNC Press Brake solutions:

https://alpha-cnc.com/products/cnc-press-brake-series