Why Precision Is the Core Value of a CNC Press Brake

In modern sheet metal fabrication, precision is no longer optional—it is the foundation of production efficiency, cost control, and product quality.

Among all bending equipment, the CNC Press Brake stands out as the most reliable solution for achieving repeatable, high-accuracy bending across small batches and mass production.

Unlike conventional hydraulic bending machines, a CNC Press Brake integrates numerical control systems, servo-driven components, and real-time positioning feedback, allowing manufacturers to achieve micron-level consistency even when handling complex parts.

This article focuses on one critical performance factor:

👉 Precision bending accuracy of CNC Press Brake systems, and how it is engineered, measured, and maintained in real industrial applications.

What Determines Bending Accuracy in a CNC Press Brake?

Precision bending accuracy is not a single parameter—it is the result of multiple coordinated systems working together.

Key accuracy-influencing elements include:

-

Ram positioning repeatability

-

Backgauge servo accuracy

-

Machine frame rigidity

-

CNC control algorithm

-

Tool alignment and compensation logic

Among these, ram and backgauge control accuracy are the most decisive.

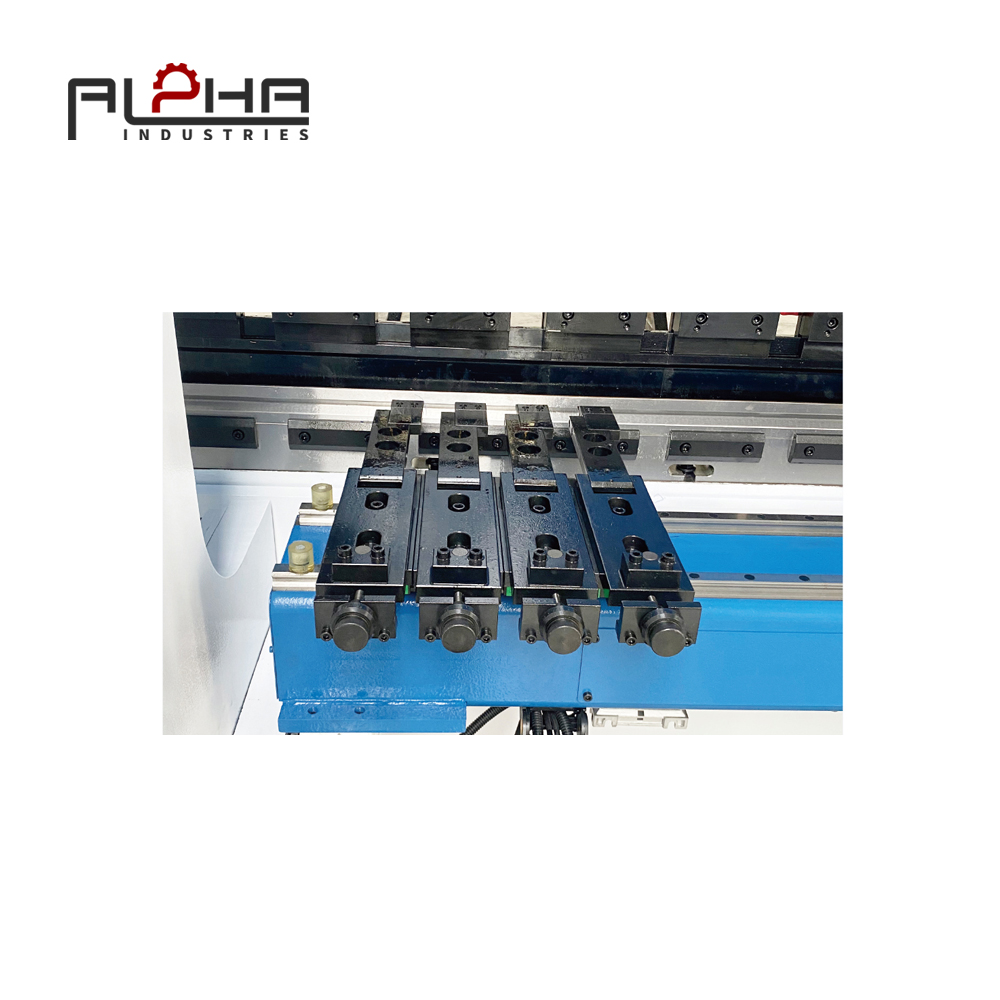

Ram Positioning Accuracy: The Foundation of Precise Bending

The ram is the vertical moving component that applies force to bend sheet metal.

In a CNC Press Brake, ram motion is controlled by servo-hydraulic or full servo systems, rather than traditional hydraulic valves.

How precision is achieved:

-

High-resolution linear encoders monitor ram position in real time

-

CNC systems adjust stroke depth dynamically

-

Repeat positioning accuracy can reach ±0.01 mm or better

This ensures that each bend angle remains consistent, even when repeating the same program hundreds of times.

Result:

-

Stable bend angles

-

Minimal angle deviation

-

Reduced need for manual adjustment

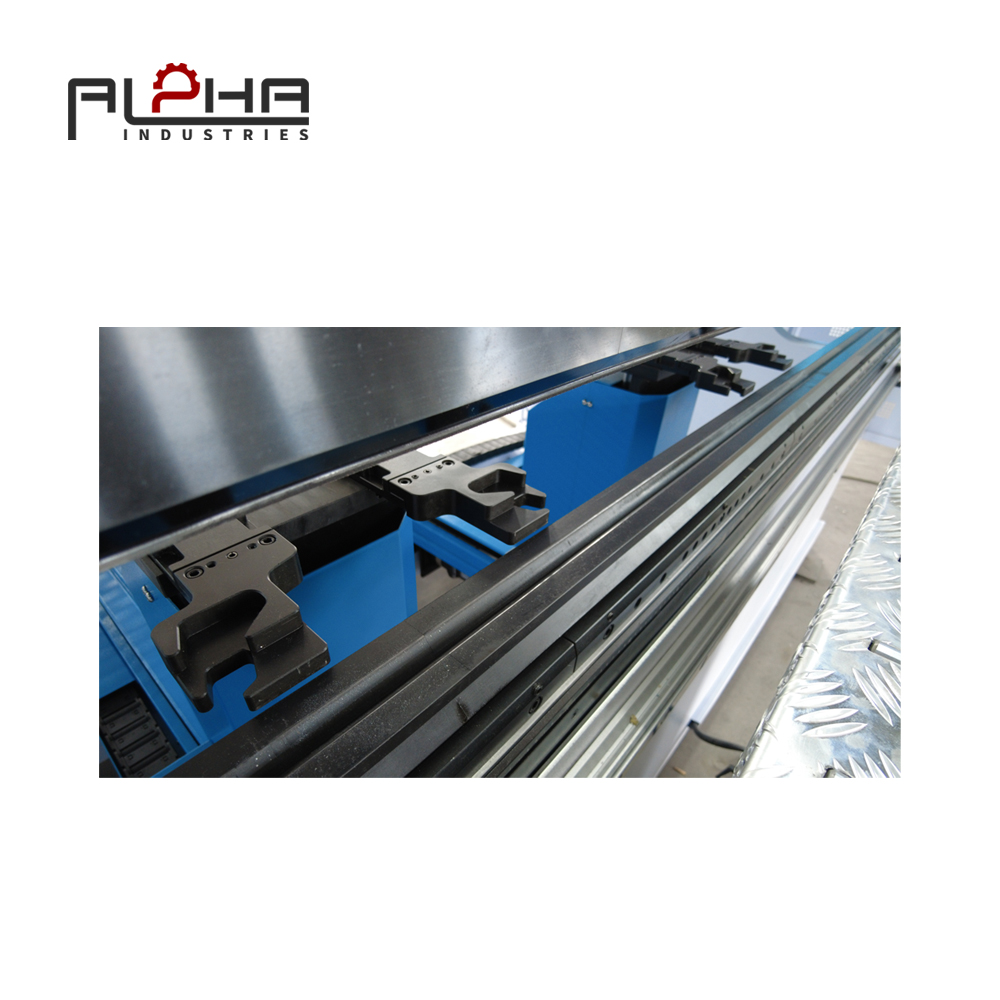

CNC Backgauge System: Accuracy Starts Before the Bend

While the ram controls angle, the backgauge controls bend position.

A CNC Press Brake typically uses a multi-axis servo backgauge system (X, R, Z, and optional axes).

Precision benefits:

-

Servo motors provide high-speed, high-accuracy positioning

-

Ball screw drives eliminate backlash

-

CNC memory stores exact positions for repeated jobs

This allows operators to:

-

Maintain tight dimensional tolerances

-

Achieve uniform flange lengths

-

Switch between jobs without re-measuring

For complex parts, backgauge accuracy directly determines final product consistency.

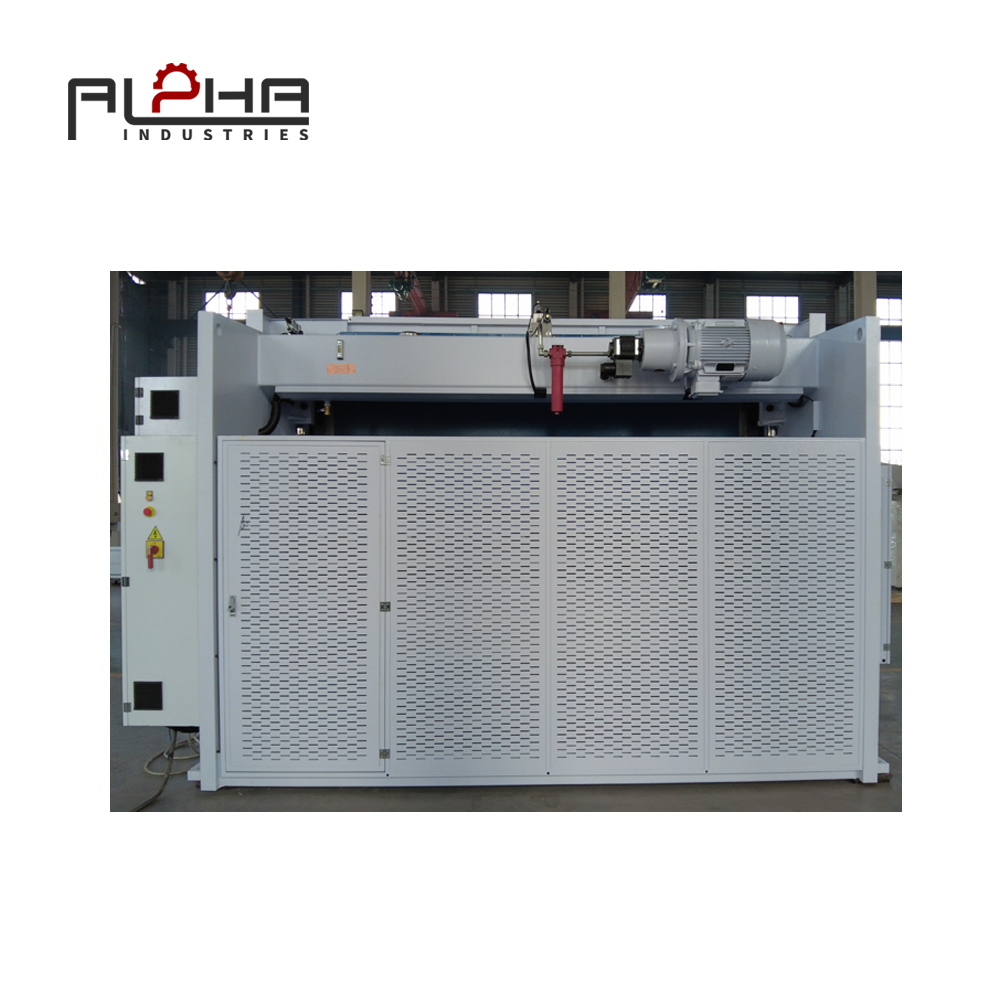

Frame Rigidity and Deflection Control

Even with perfect control systems, accuracy will fail if the machine frame flexes under load.

A high-quality CNC Press Brake uses:

-

Welded steel frames

-

Stress-relieved structures

-

Optimized side frame thickness

To further enhance accuracy, crowning or compensation systems are applied.

Compensation systems:

-

Manual crowning (mechanical adjustment)

-

CNC-controlled dynamic crowning

These systems counteract deflection, ensuring uniform bending angle along the full working length.

CNC Control System: The Brain Behind Precision

The CNC controller plays a critical role in accuracy by:

-

Calculating bend angles

-

Managing ram speed and stroke

-

Coordinating backgauge motion

Advanced controllers support:

-

Angle programming

-

Material thickness input

-

Tool geometry compensation

This allows the CNC Press Brake to automatically adjust parameters based on material changes, reducing human error.

Precision vs Traditional Press Brake: Real Accuracy Comparison

| Feature | Traditional Press Brake | CNC Press Brake |

|---|---|---|

| Angle repeatability | Low | High |

| Backgauge accuracy | Manual | Servo-controlled |

| Setup time | Long | Short |

| Error rate | High | Low |

| Production consistency | Unstable | Stable |

The difference becomes especially obvious in high-mix, low-volume production, where CNC precision delivers clear advantages.

How Precision Accuracy Improves Production Efficiency

High accuracy is not just about quality—it directly impacts cost.

Accuracy advantages include:

-

Less scrap material

-

Fewer reworks

-

Faster setup times

-

Reduced operator dependency

Over time, a precise CNC Press Brake significantly lowers total production cost per part.

Typical Accuracy Metrics Buyers Should Understand

When evaluating CNC Press Brake accuracy, buyers should focus on:

-

Ram repeatability (mm)

-

Backgauge positioning accuracy (mm)

-

Bending angle tolerance (°)

-

Full-length angle deviation

These parameters are more meaningful than tonnage alone.

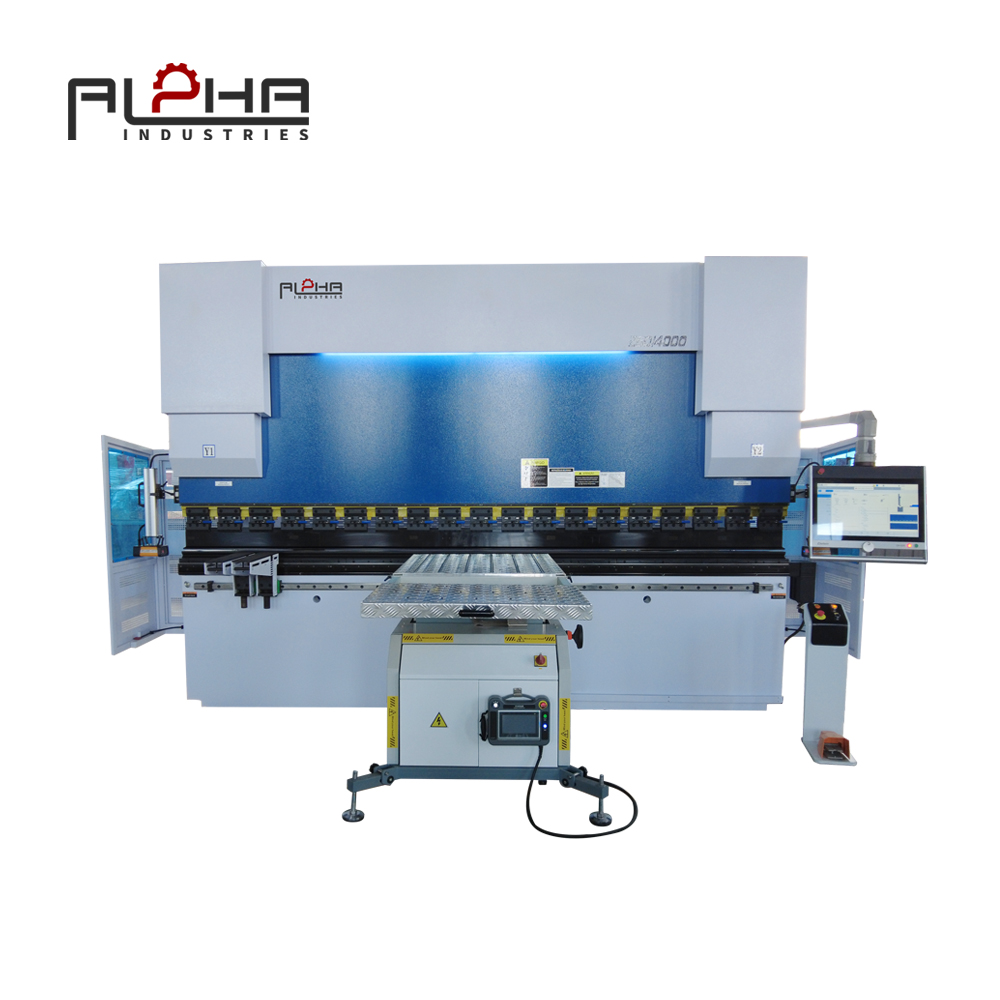

Alpha CNC Press Brake: Designed for Precision Stability

At Alpha, CNC Press Brakes are engineered with accuracy as a core design principle.

Key design features include:

-

High-rigidity frame structures

-

Servo-controlled ram and backgauge systems

-

Precision-ground mechanical components

-

CNC-controlled compensation solutions

This ensures stable bending accuracy even during long production cycles.

Application Scenarios Where Precision Matters Most

High-accuracy CNC Press Brakes are essential for:

-

Electrical cabinets

-

Sheet metal enclosures

-

Elevator components

-

Automotive brackets

-

Precision metal panels

In these industries, millimeter-level deviation is unacceptable.

FAQ

Q1: How accurate is a CNC Press Brake?

A CNC Press Brake typically achieves ram repeatability of ±0.01 mm and backgauge accuracy within ±0.02 mm, depending on configuration.

Q2: What affects CNC Press Brake bending accuracy most?

Key factors include ram positioning system, backgauge servo control, frame rigidity, and compensation technology.

Q3: Can CNC Press Brakes maintain accuracy over long runs?

Yes. With proper compensation and servo control, CNC Press Brakes maintain stable accuracy even during continuous production.

Q4: Is CNC Press Brake accuracy adjustable?

Yes. CNC systems allow operators to fine-tune parameters based on material thickness, tooling, and bend length.

Precision Defines the Value of a CNC Press Brake

Precision bending accuracy is the true measure of a CNC Press Brake’s value.

Through advanced servo systems, rigid frames, and intelligent CNC control, modern CNC Press Brakes deliver consistent, repeatable, and reliable bending results.

For manufacturers seeking higher quality and efficiency, investing in a precision-focused CNC Press Brake is not a cost—it is a competitive advantage.

👉 Learn more about Alpha CNC Press Brake solutions:

https://alpha-cnc.com/