Introduction to CNC Hydraulic Precision Control

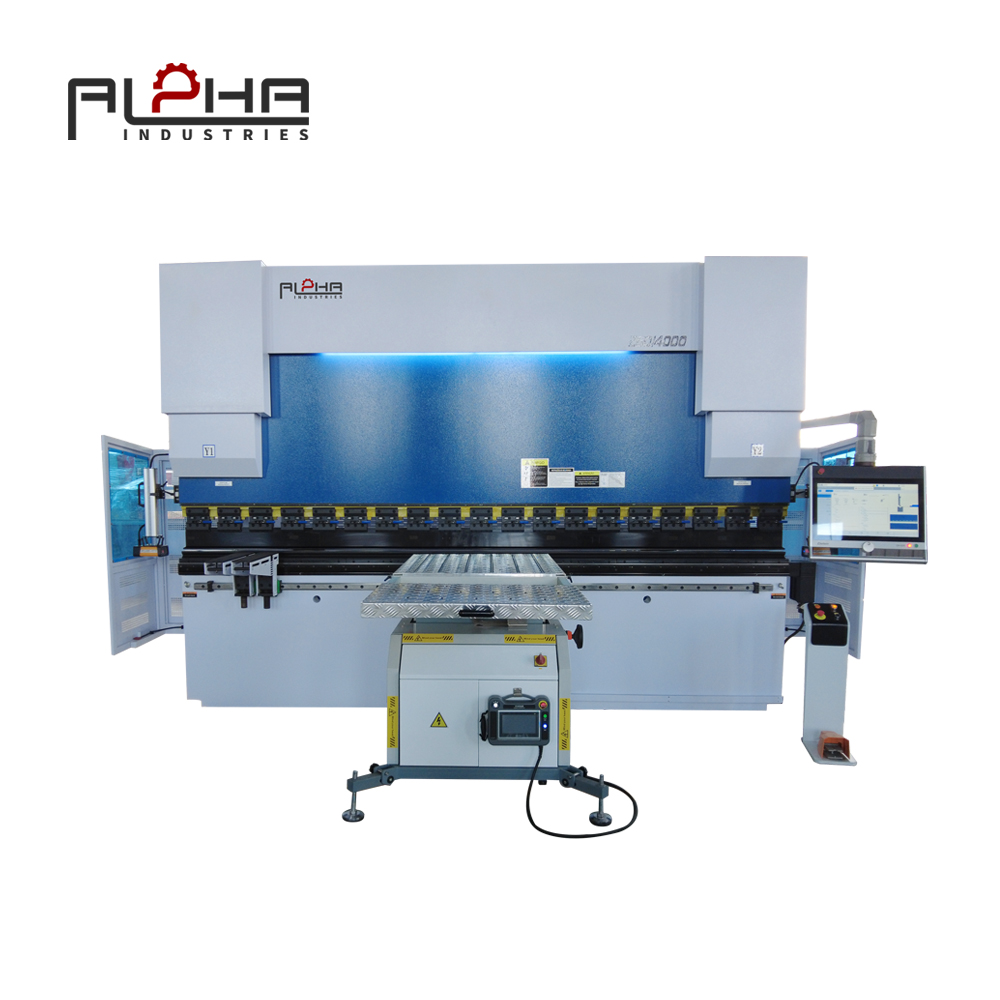

In modern sheet metal fabrication, CNC Press Brakes play an essential role in producing accurate, repeatable bends for a wide range of metal components. As production demands evolve, the hydraulic control system becomes the decisive element that determines precision, efficiency, and reliability.

Alpha’s CNC Press Brake integrates a servo-hydraulic proportional control system, enabling synchronized Y-axis movement, pressure feedback regulation, and micron-level bending accuracy. This technology ensures every operation—from light sheet forming to heavy-duty bending—meets strict dimensional tolerances.

Structure of the Hydraulic System

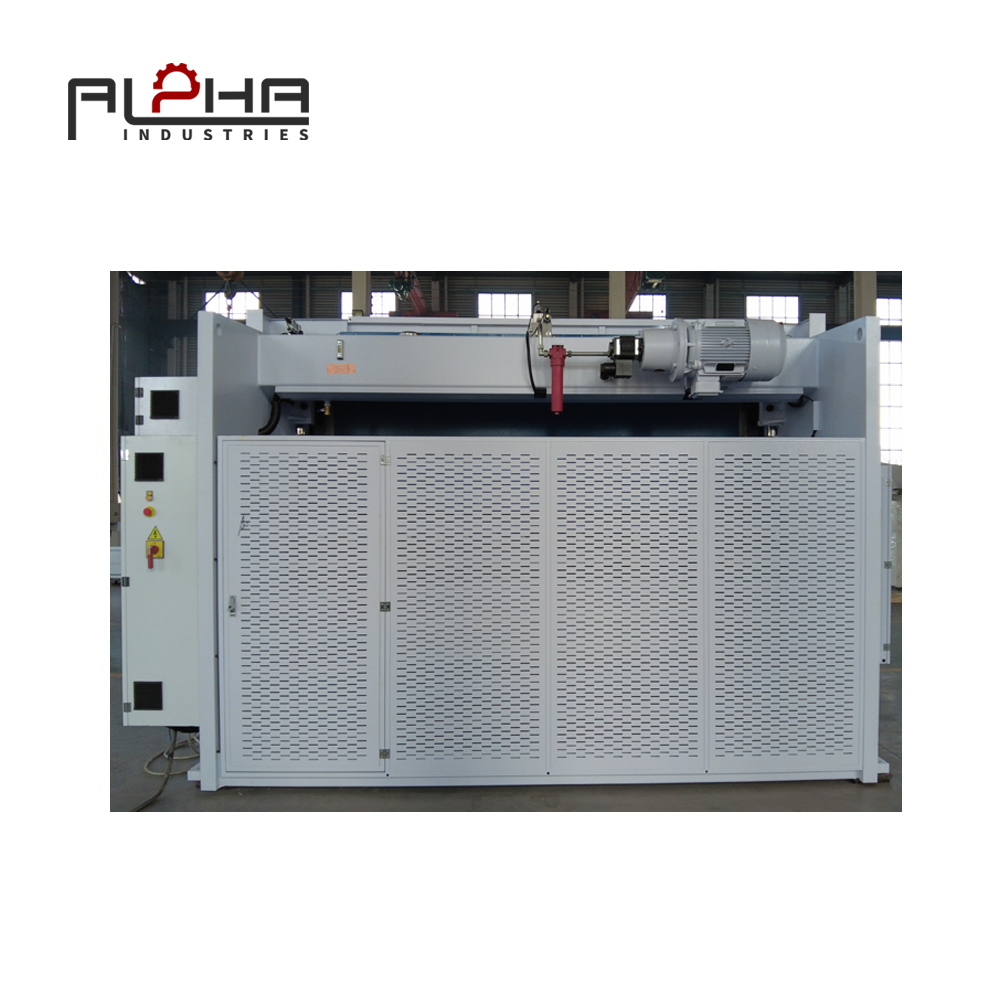

The hydraulic circuit of Alpha’s CNC Press Brake is designed for stable force transmission and precise motion control. It adopts servo-driven hydraulic pumps, electro-hydraulic proportional valves, and high-response position sensors to form a closed-loop control network.

Main Components Include:

-

Servo Pump Unit: Converts electrical input into proportional hydraulic pressure with energy-saving efficiency.

-

Proportional Valve Group: Regulates oil flow and pressure dynamically based on CNC feedback.

-

Pressure Sensors: Provide real-time feedback to maintain bending consistency.

-

Hydraulic Cylinders: Hardened and precision-ground for zero internal leakage and smooth motion.

Through this system, Alpha achieves both speed and stability, enabling fine-tuned control over every stage of the bending cycle.

CNC Control Algorithm for Bending Accuracy

The CNC system is the intelligence core of the press brake. It continuously monitors ram position, pressure values, and material resistance to ensure exact repeatability.

Alpha’s CNC control algorithm performs real-time data correction through adaptive learning, automatically compensating for material thickness variations, temperature changes, and hydraulic drift.

Precision Features:

-

Y1 & Y2 Axis Synchronization: Maintains ram parallelism within ±0.01 mm.

-

Angle Feedback Loop: Integrates a digital angle sensor for instant correction.

-

Dynamic Pressure Compensation: Adjusts pressure output based on resistance curves.

-

Automatic Bending Program Optimization: Suggests optimal pressure and stroke depth settings.

This results in high consistency, particularly important for batch production of precision components such as automotive brackets, elevator panels, and stainless-steel enclosures.

Intelligent Hydraulic System with Energy-Saving Design

Traditional hydraulic press brakes consume energy even when idle. Alpha solves this through servo hydraulic technology, allowing the pump motor to run only when pressure is required.

System Advantages:

-

Energy Reduction up to 60% compared to conventional models.

-

Reduced Noise & Heat Generation for improved working environment.

-

Rapid Response Time: Servo pump starts and stops within milliseconds.

-

Extended Hydraulic Component Life due to lower oil temperature and minimal pressure fluctuation.

The intelligent standby mode automatically shuts down non-essential functions between bending cycles, further optimizing power consumption without compromising accuracy.

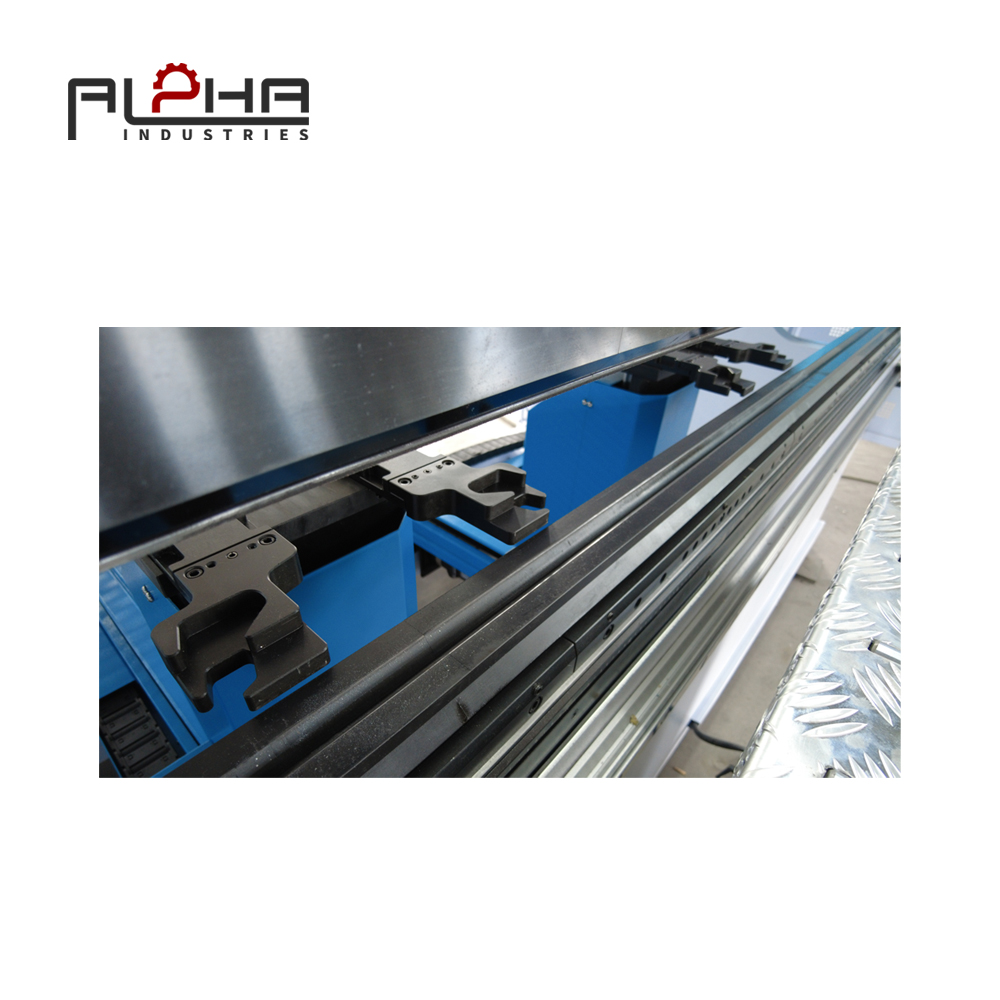

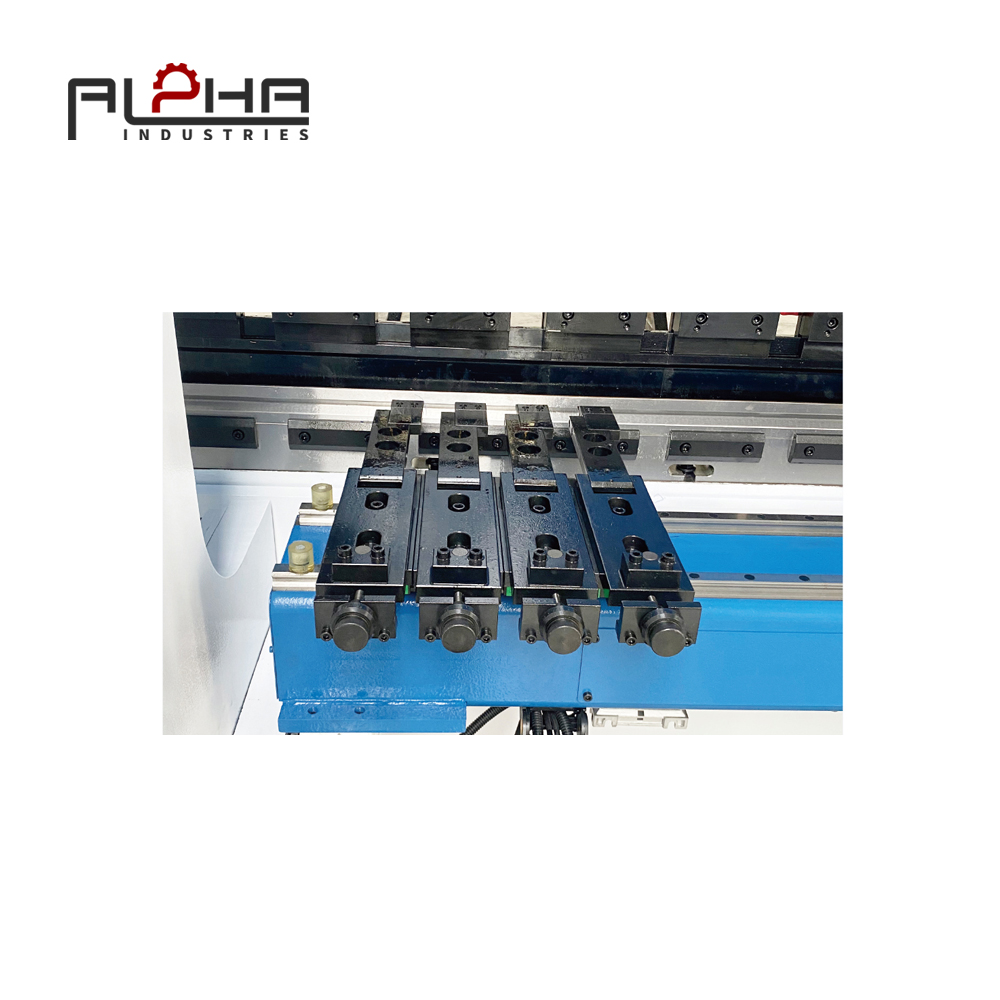

Backgauge Precision and Axis Control

The backgauge system is vital to positioning accuracy. Alpha’s CNC Press Brake employs a multi-axis servo backgauge, capable of X, R, and Z movement for complex bending tasks.

Technical Highlights:

-

Ball Screw and Linear Guideways: Provide smooth, backlash-free motion.

-

Servo Motor Control: Ensures ±0.02 mm repeat positioning accuracy.

-

Programmable Gauge Finger: Allows automatic adjustment to different workpiece sizes.

-

Multi-Step Bending Function: Supports up to 99 sequential bends in one setup.

These features allow Alpha’s CNC Press Brake to efficiently handle custom, multi-bend parts in a single automated cycle, significantly improving throughput.

Real-Time Pressure & Position Feedback System

Alpha’s precision bending performance relies on dual closed-loop control — one loop for position (Y1, Y2 axes) and one for pressure.

-

Position Loop: Measures ram stroke via linear optical scales with 1 μm resolution.

-

Pressure Loop: Monitors real-time hydraulic output for exact bending force.

This dual feedback ensures the bending angle accuracy within ±0.3°, even during large or asymmetrical part forming. The feedback mechanism continuously corrects deviations during operation, maintaining consistent results throughout long production runs.

Frame Rigidity and Anti-Deformation Design

The mechanical frame plays a crucial role in maintaining bending precision. Alpha utilizes finite element analysis (FEA) during design to ensure structural stiffness.

Design Advantages:

-

Monoblock Welded Frame: Eliminates internal stress and deformation.

-

Full Stress Relief Treatment: Guarantees long-term geometric stability.

-

Optimized Cylinder Mounting Geometry: Balances force distribution on both sides.

This structural rigidity ensures parallel ram motion even under heavy load conditions, preventing angular distortion during full-length bending operations.

Bending Simulation and Angle Correction

For enhanced operator control, Alpha’s CNC system includes a 3D bending simulation interface, allowing users to visualize the forming sequence before execution.

Functional Advantages:

-

Virtual Bending Preview: Detects collision risks automatically.

-

Automatic Angle Correction: Uses feedback sensors to fine-tune ram position.

-

Real-Time Graphic Interface: Displays ram speed, stroke, and pressure curves.

This simulation-assisted control reduces setup time, avoids tool collisions, and ensures first-part accuracy.

Applications of CNC Hydraulic Press Brake

Alpha’s CNC Press Brakes serve industries where precision, reliability, and repeatability are mission-critical:

-

Aerospace: Thin sheet bending for engine covers and wing panels.

-

Automotive: Structural brackets, bumpers, and frames.

-

HVAC and Electrical Cabinets: Sheet enclosure bending with consistent angular accuracy.

-

Industrial Machinery: Thick-plate forming and heavy-duty structural parts.

Each machine is tailored to meet the unique forming needs of the customer, ensuring maximum productivity with minimal rework.

Maintenance and Reliability

Alpha emphasizes maintenance-friendly design for all CNC Press Brakes. Predictive maintenance modules track operating conditions to prevent unplanned downtime.

System Features:

-

Lubrication Monitoring: Ensures continuous guideway lubrication.

-

Oil Temperature Alarm: Protects hydraulic components from overheating.

-

Filter Condition Alerts: Prevents contamination-related system inefficiency.

-

Self-Diagnosis Function: Detects valve or sensor faults in real time.

This proactive maintenance architecture keeps uptime rates above 98%, essential for high-volume production environments.

Why Choose Alpha CNC Press Brake

With over 20 years of engineering experience, Alpha delivers press brakes that combine precision mechanics, intelligent hydraulics, and user-friendly control.

Core Advantages:

-

Micron-level hydraulic bending precision

-

Servo-controlled energy-efficient system

-

High rigidity frame structure

-

Intelligent CNC programming and feedback

-

Global service support with rapid spare part availability

Alpha’s CNC Press Brake is the ideal choice for companies pursuing smart, efficient, and precise sheet metal forming.

FAQ

Q1: How does the CNC system improve press brake accuracy?

A1: The CNC system monitors ram position and pressure in real time, automatically compensating for deviations to maintain ±0.01 mm positioning accuracy.

Q2: What are the advantages of a servo-hydraulic system in a CNC Press Brake?

A2: It reduces energy consumption, improves response speed, minimizes oil temperature rise, and enhances long-term reliability.

Q3: How is the Y-axis synchronization achieved in Alpha’s CNC Press Brake?

A3: Through dual independent servo valves and linear optical scales that maintain perfect ram parallelism across both sides.

Q4: What is the typical bending angle accuracy of Alpha’s CNC Press Brake?

A4: The system achieves bending angle precision within ±0.3°, thanks to dual-loop feedback and angle compensation algorithms.

Q5: Which industries benefit most from CNC hydraulic press brakes?

A5: Aerospace, automotive, HVAC, cabinet fabrication, and heavy machinery industries use CNC press brakes for precise and efficient metal forming.

Conclusion

The hydraulic precision control system is the foundation of modern CNC Press Brake performance. Alpha’s advanced servo-hydraulic technology provides unmatched bending accuracy, longer component lifespan, and superior energy efficiency.

Built with robust mechanics, intelligent electronics, and ergonomic design, Alpha’s CNC Press Brake empowers manufacturers to achieve future-ready production with consistent results and reduced energy cost.