Introduction: Why Deburring Consistency Matters More Than Burr Removal Itself

In modern metal manufacturing, deburring is no longer a simple post-processing step—it is a quality-critical operation that directly affects part performance, safety, and downstream assembly.

While many manufacturers focus on whether burrs are removed, the real industrial challenge lies in how consistently burrs are removed across every edge, every part, and every production batch. Inconsistent deburring leads to unstable surface quality, unpredictable assembly behavior, and hidden quality risks.

This article focuses on deburring consistency as the core value of modern deburring systems, explaining how automated deburring technology achieves repeatable, controlled, and industrial-grade surface finishing.

What Is Deburring Consistency?

Deburring consistency refers to the ability of a deburring process to deliver uniform edge quality and surface condition under real production conditions, regardless of:

-

Part geometry variation

-

Material hardness differences

-

Burr size inconsistency

-

Batch-to-batch production changes

A consistent deburring process produces:

-

Uniform edge radius

-

Stable surface roughness

-

Predictable finishing results

-

Repeatable quality over time

Why Inconsistent Deburring Is a Hidden Quality Risk

Manual or poorly controlled deburring often results in:

-

Over-deburring on thin edges

-

Under-deburring on thick sections

-

Uneven edge rounding

-

Variable surface finish

These issues can cause:

-

Assembly interference

-

Premature wear

-

Safety hazards from sharp edges

-

Rework and inspection overload

In high-volume production, even minor inconsistencies multiply into major cost and quality problems.

The Core Challenge: Controlling Material Removal

Deburring is fundamentally a controlled material removal process. Achieving consistency requires precise control over:

-

Contact pressure

-

Tool speed

-

Feed rate

-

Tool wear compensation

-

Part positioning stability

Without automation, maintaining these parameters consistently is nearly impossible.

Automated Deburring: The Foundation of Consistent Results

Automated deburring systems replace operator-dependent actions with controlled, repeatable mechanical processes, ensuring stable edge quality.

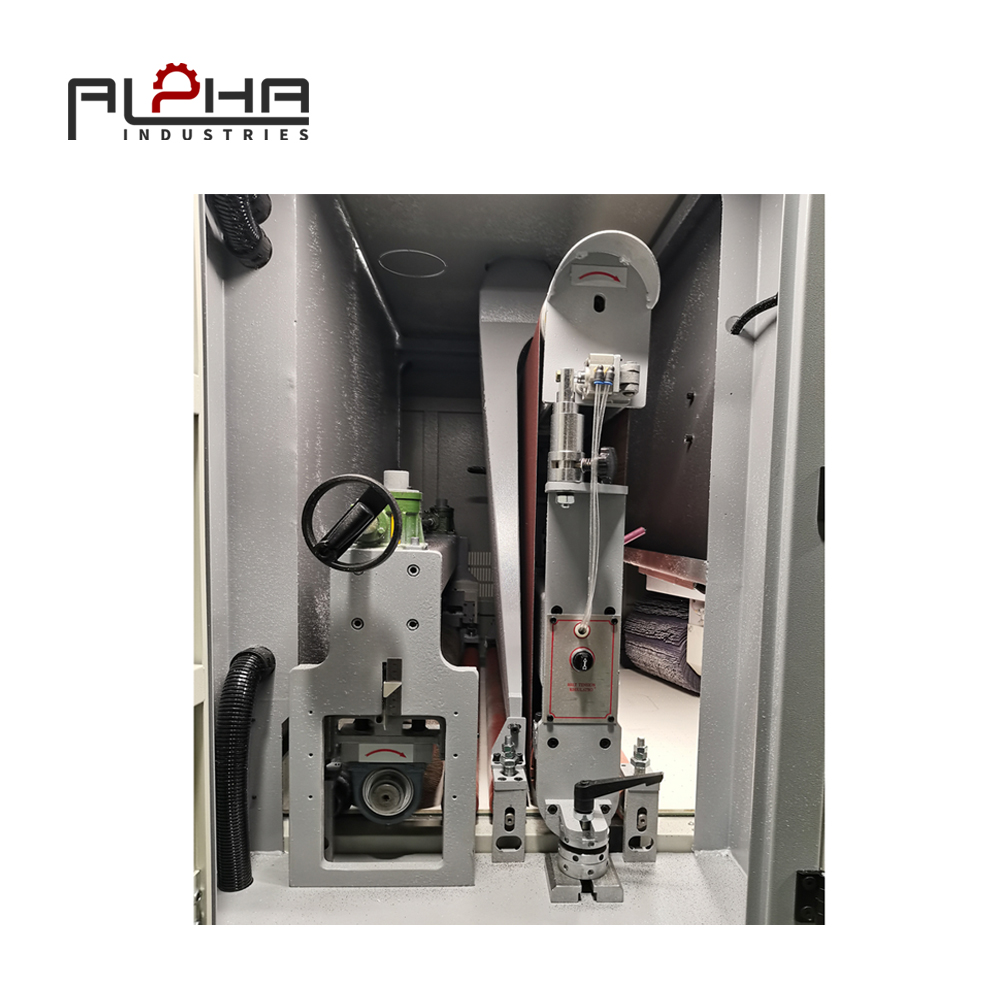

Key Elements That Enable Consistency

1. Controlled Contact Pressure

Automated systems maintain constant pressure, preventing over- or under-processing.

2. Stable Feed Speed

Uniform feed rates ensure even material removal along the entire edge.

3. Tool Wear Compensation

Advanced deburring machines compensate for abrasive wear to maintain consistent results.

4. Repeatable Part Positioning

Fixtures and conveyor systems eliminate positional variation.

Deburring Machines vs Manual Deburring

| Aspect | Manual Deburring | Automated Deburring |

|---|---|---|

| Consistency | Operator-dependent | Process-controlled |

| Repeatability | Low | High |

| Surface Quality | Variable | Stable |

| Productivity | Limited | Scalable |

| Labor Cost | High | Reduced |

For manufacturers seeking predictable quality and scalable production, automation is no longer optional.

How Automated Deburring Achieves Batch-to-Batch Consistency

-

Parts enter machine with fixed reference points

-

Deburring tools engage with predefined pressure

-

Abrasive action removes burrs uniformly

-

Edge rounding is controlled within tolerance

-

Process parameters remain constant across batches

-

Quality output remains repeatable

Why Deburring Consistency Is Critical for Downstream Processes

Consistent deburring directly impacts:

-

Welding quality

-

Coating adhesion

-

Painting uniformity

-

Assembly accuracy

-

Product safety compliance

In industries such as:

-

Sheet metal fabrication

-

Automotive components

-

Electrical enclosures

-

Machinery parts

Deburring consistency directly determines final product quality.

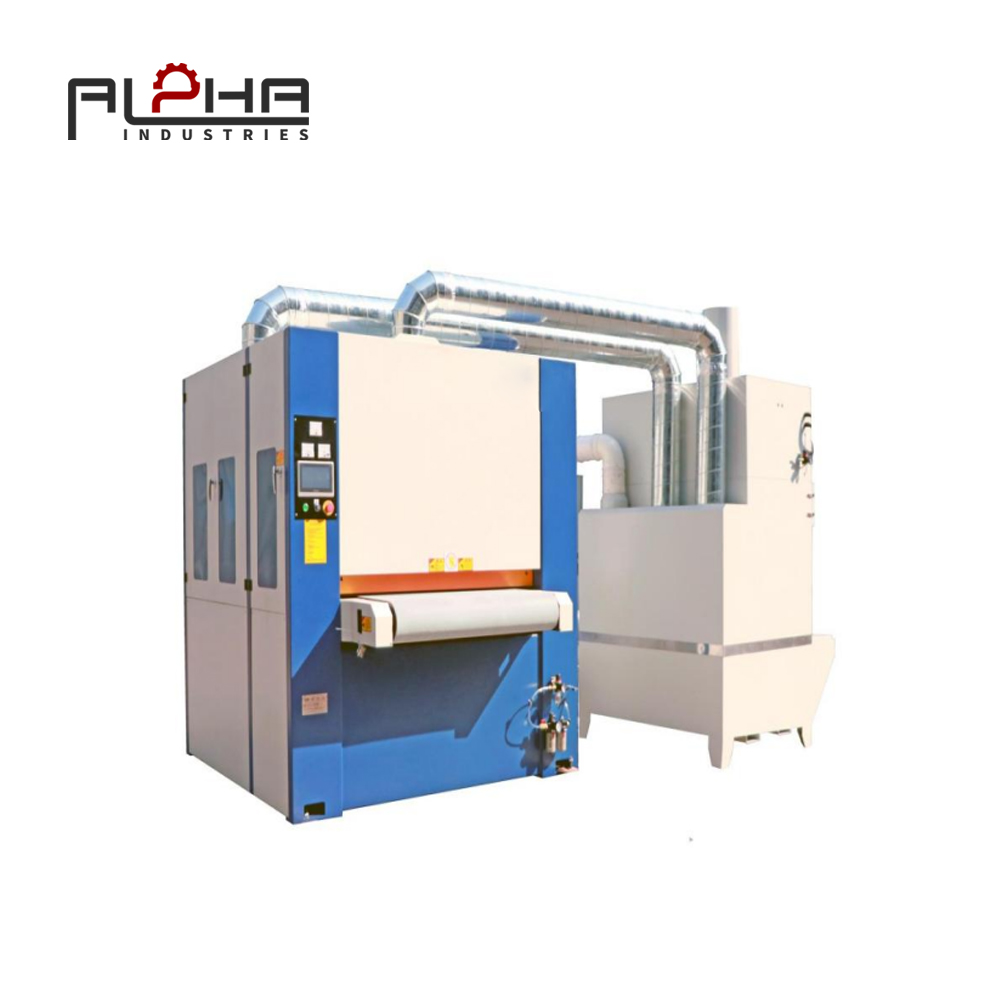

Alpha Deburring Solutions: Designed for Consistency

At Alpha, deburring machines are engineered with process consistency as the primary design objective, not just burr removal capability.

Key consistency-focused design features include:

-

Rigid machine structure for vibration-free processing

-

Automated pressure control systems

-

Multi-stage deburring and finishing configurations

-

Long-life abrasive systems with wear compensation

-

User-friendly control interfaces for stable parameter management

These design principles ensure:

-

Uniform edge quality

-

Reduced operator dependency

-

Stable performance in long-term production

FAQ

What is the main purpose of deburring?

The main purpose of deburring is to remove sharp edges and burrs while ensuring safe handling, proper assembly, and stable surface quality.

Why is automated deburring better than manual deburring?

Automated deburring provides consistent, repeatable results with higher efficiency and lower quality variation.

Does deburring affect surface finish?

Yes. Controlled deburring improves surface smoothness and prepares parts for coating or welding.

Can deburring be standardized across different parts?

With automated systems and adjustable parameters, deburring processes can be standardized for various part sizes and materials.

Is deburring required after laser or plasma cutting?

Yes. Thermal cutting processes often leave hardened burrs that require controlled deburring for quality assurance.

Conclusion: Consistency Is the True Measure of Deburring Quality

Deburring is not just about removing burrs—it is about removing variability.

In modern manufacturing, deburring consistency defines surface quality, production stability, and brand reliability.

By adopting automated deburring systems designed for consistency, manufacturers can achieve:

-

Higher product quality

-

Lower rework rates

-

Safer components

-

Stronger market competitiveness

👉 Explore Alpha Deburring Machine Solutions:

https://alpha-cnc.com/products/deburring