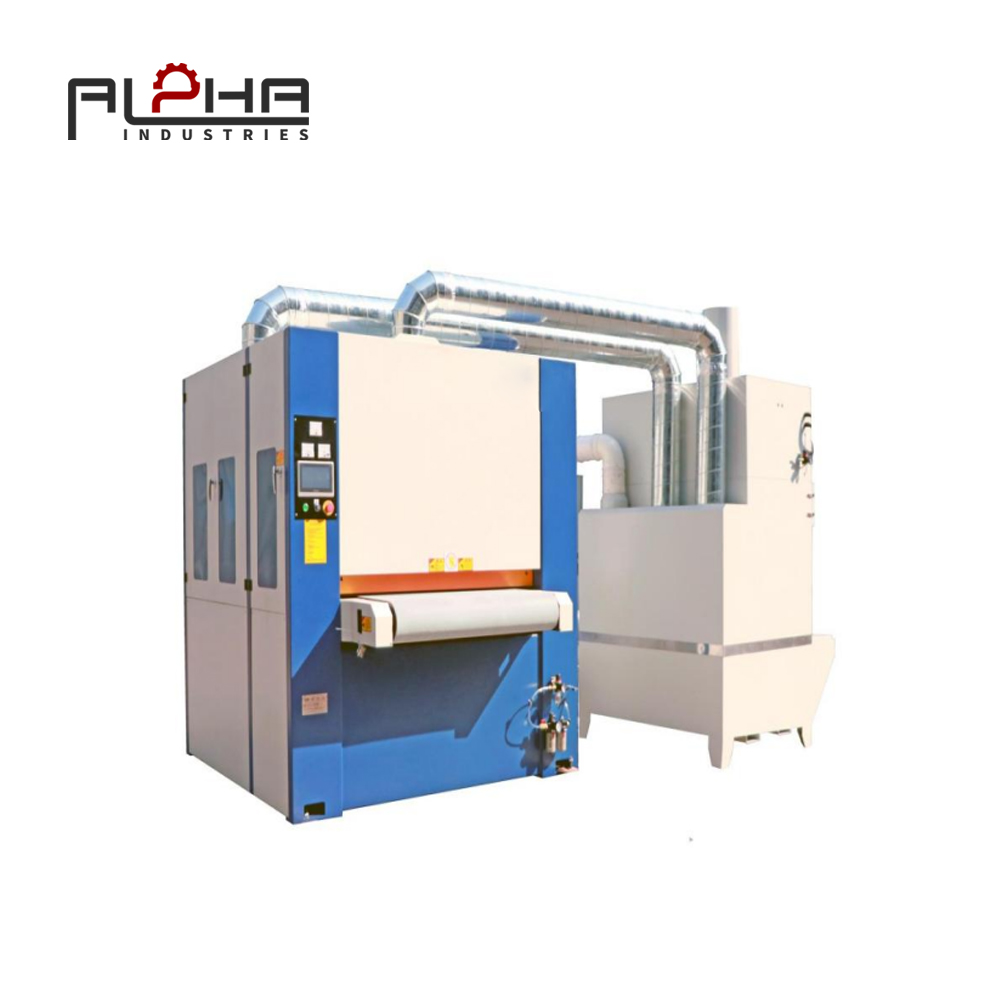

Deburring Edge Quality Consistency in Modern Metal Manufacturing

In modern metal manufacturing, deburring is no longer a secondary finishing step.

For high-volume production and precision assemblies, edge quality consistency after deburring directly affects product safety, assembly accuracy, coating performance, and long-term reliability.

At ALPHA, deburring systems are engineered with a clear objective:

deliver uniform, repeatable edge quality across every part, every batch, and every shift.

Why Edge Quality Consistency Matters in Deburring

Burrs and sharp edges are inevitable after cutting, punching, laser cutting, or machining.

However, inconsistent deburring results lead to serious downstream issues, including:

-

Unsafe sharp edges and operator injury risk

-

Poor assembly fit and alignment problems

-

Inconsistent coating adhesion

-

Premature wear in moving assemblies

-

High rework and inspection costs

Deburring quality must be controlled, not left to chance or manual variability.

What Defines Edge Quality in a Deburring Process?

Edge quality is not just “burr removed.”

From an engineering perspective, it includes:

-

Burr height removal consistency

-

Edge radius uniformity

-

Surface smoothness near the edge

-

Absence of secondary micro-burrs

-

Repeatability across part geometry

A professional deburring system must control all of these variables simultaneously.

The Challenge of Achieving Consistent Edge Quality

Manual deburring depends heavily on operator skill, pressure, and experience.

This results in:

-

Inconsistent edge radius

-

Over-deburring on thin parts

-

Under-deburring on thick or hard materials

-

Unstable production quality

Automated deburring machines eliminate human variability and establish process-driven consistency.

Deburring Machine Design and Edge Quality Control

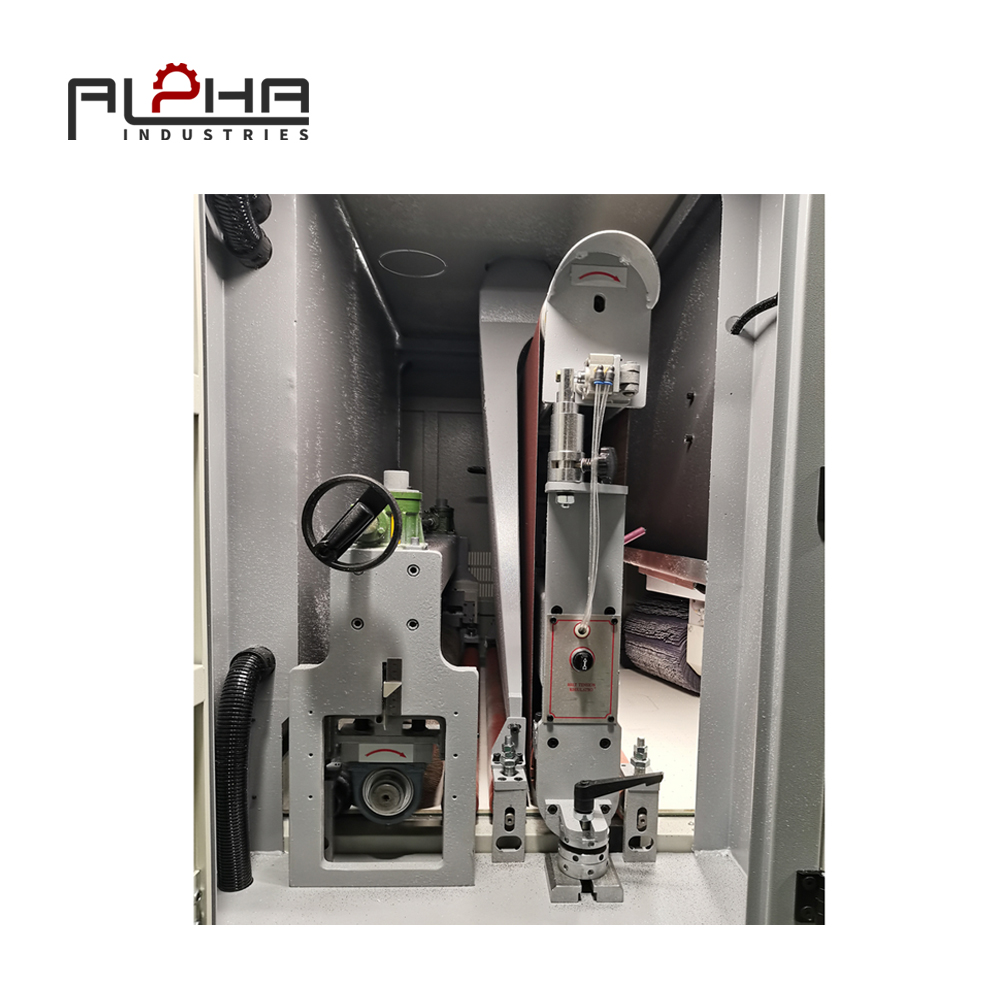

Controlled Abrasive Contact

ALPHA deburring machines are designed to maintain stable contact pressure between abrasive tools and workpiece edges, ensuring:

-

Uniform burr removal

-

Controlled edge rounding

-

Minimal material loss

This is critical for thin sheet metal and precision components.

Multi-Stage Deburring Process

For consistent edge quality, a single abrasive step is often insufficient.

ALPHA systems integrate:

-

Primary burr removal

-

Secondary edge rounding

-

Optional surface finishing

This staged approach ensures clean, smooth, and uniform edges without over-processing.

Material Variability and Deburring Consistency

Different materials respond differently to deburring:

-

Mild steel produces ductile burrs

-

Stainless steel forms tougher burrs

-

Aluminum generates smeared edges

ALPHA deburring solutions are configured to handle:

-

Material hardness differences

-

Thickness variation

-

Mixed-material production

Result: consistent edge quality regardless of material type.

Edge Quality and Downstream Process Performance

Assembly and Fit

Consistent deburring ensures:

-

Accurate part positioning

-

Reduced assembly force

-

Improved dimensional repeatability

Coating and Painting

Uniform edges prevent:

-

Paint thinning at sharp corners

-

Coating peel-off

-

Corrosion initiation points

Deburring directly improves coating durability and appearance.

Automated Deburring vs Manual Deburring (Edge Quality View)

| Aspect | Automated Deburring | Manual Deburring |

|---|---|---|

| Edge consistency | High | Operator-dependent |

| Repeatability | Excellent | Low |

| Production efficiency | Stable | Variable |

| Safety | High | Lower |

| Cost control | Predictable | Labor-intensive |

For consistency-driven production, automation is essential.

How ALPHA Ensures Edge Quality Consistency

ALPHA deburring systems are built around a process consistency philosophy, integrating:

-

Rigid machine structure

-

Stable abrasive engagement

-

Controlled feed and pressure

-

Repeatable processing parameters

This ensures deburring quality remains stable over long production runs, not just initial trials.

Applications That Demand High Deburring Consistency

Edge quality consistency is critical in:

-

Electrical cabinets and enclosures

-

Sheet metal brackets and frames

-

Automotive structural components

-

HVAC and duct systems

-

Precision industrial panels

In these industries, deburring quality directly impacts safety, performance, and brand perception.

FAQ

What is deburring in metal manufacturing?

Deburring is the process of removing burrs and sharp edges formed during cutting or machining.

Why is edge quality consistency important in deburring?

Consistent edges improve safety, assembly accuracy, coating quality, and product reliability.

Can deburring machines handle different materials?

Yes. Industrial deburring machines are designed to process steel, stainless steel, aluminum, and other metals consistently.

Is automated deburring better than manual deburring?

For production consistency, safety, and efficiency, automated deburring is significantly superior.

Edge Quality Consistency vs Burr Removal Alone

Removing burrs is not enough.

True deburring performance is measured by how consistent the edge quality remains across real production conditions.

At ALPHA, deburring solutions are evaluated based on repeatable edge results, not just visual burr removal.

Conclusion — Consistent Edges Define Professional Deburring

Deburring is a critical manufacturing process, not a cosmetic step.

By focusing on edge quality consistency, ALPHA deburring machines help manufacturers achieve:

-

Safer parts

-

Better assembly performance

-

Higher coating reliability

-

Stable, scalable production quality

In modern metal manufacturing, consistent deburring defines professional-grade production capability.

Learn more about ALPHA Deburring Machine Solutions/deburring-machine