Introduction – The Role of Deburring in Metal Precision Engineering

In precision metal fabrication, even the smallest burrs or sharp edges can compromise performance, assembly fit, or surface quality. A deburring machine eliminates these imperfections, ensuring that every edge meets the dimensional and aesthetic standards required by modern industries.

At ALPHA, we focus on one critical element of surface engineering: the automated deburring system. This system not only removes burrs efficiently but also enhances consistency, surface finish, and overall productivity — redefining how manufacturers achieve precision edge finishing.

Understanding the Deburring Process

Deburring is the process of removing residual burrs—microscopic projections formed during cutting, milling, drilling, or stamping.

While manual deburring once dominated production floors, it lacked precision and repeatability. ALPHA’s automated deburring technology integrates intelligent control and advanced brush or abrasive belt systems to deliver uniform surface finishing with micron-level accuracy.

Key Deburring Functions:

-

Edge Smoothing: Eliminates sharp edges for safe handling.

-

Surface Polishing: Improves material texture and coating adhesion.

-

Oxide Layer Removal: Ensures clean metal contact surfaces.

-

Part Uniformity: Maintains consistent dimensions across batches.

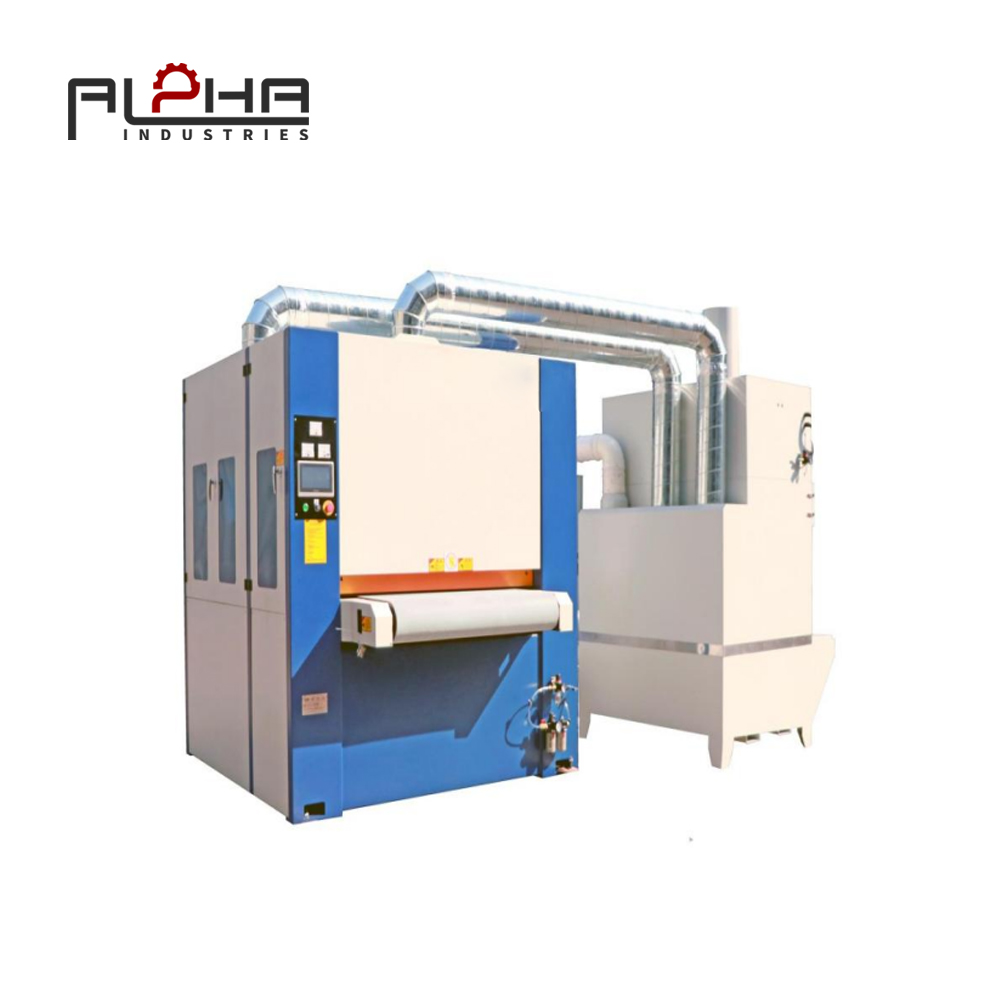

Structural Design of ALPHA Deburring Machines

Every ALPHA deburring machine is designed with modular architecture for flexibility and durability.

Mechanical Highlights:

-

Heavy-Duty Steel Frame: Reduces vibration during high-speed brushing.

-

Independent Pressure Control System: Adapts brush contact force automatically.

-

Multi-Station Design: Supports deburring, edge rounding, and polishing in a single pass.

-

Dynamic Conveyor Feed System: Guarantees stable part movement for uniform finish.

This structural integrity ensures smooth and stable operation even under continuous industrial workloads, suitable for steel, aluminum, copper, and stainless-steel components.

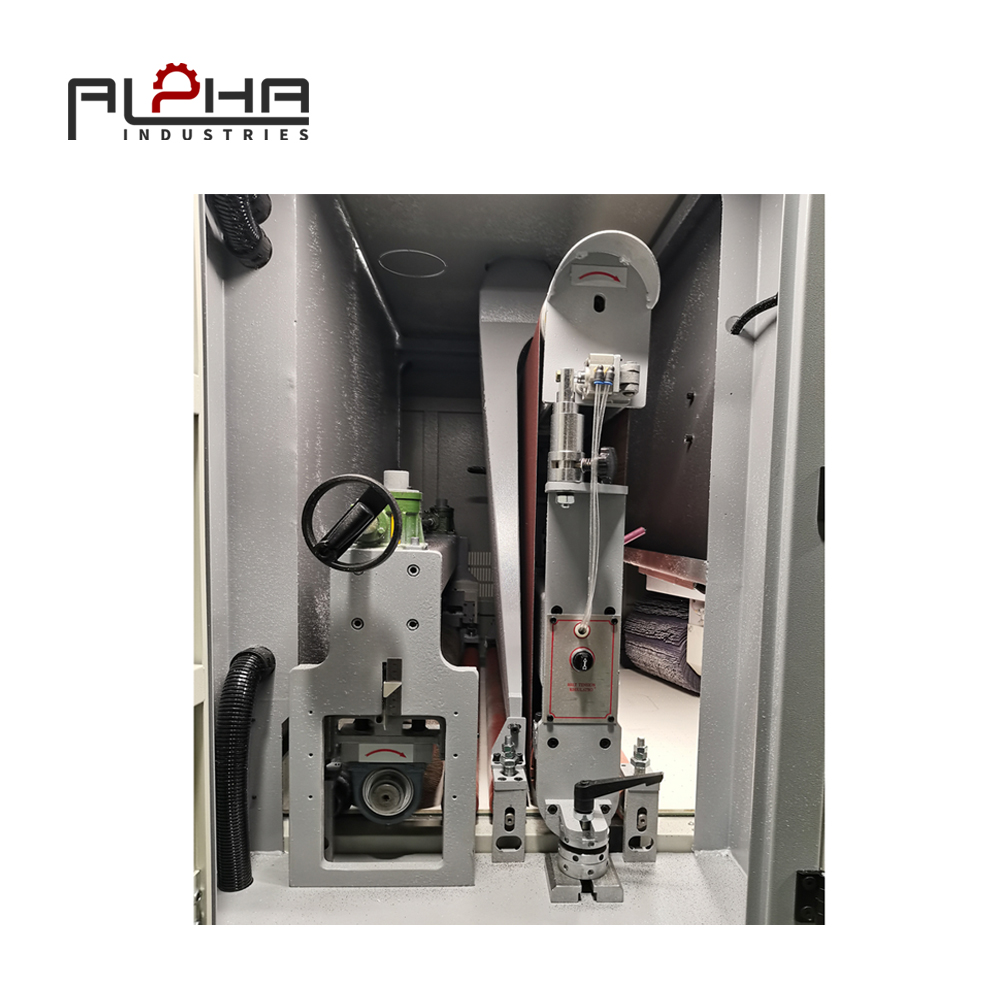

Automated Edge Detection and AEO-Enhanced Control

The most advanced aspect of ALPHA’s system is its AEO (Automated Edge Optimization) technology — a combination of smart sensors, pressure feedback control, and edge detection algorithms.

Features of AEO Technology:

-

Vision-Based Edge Scanning: Detects burr height and distribution in real time.

-

Adaptive Force Feedback: Adjusts brush pressure to varying surface contours.

-

Predictive Load Monitoring: Prevents tool wear and ensures consistent quality.

-

Process Memory: Saves optimal parameters for repeated part types.

With AEO integration, the machine intelligently adapts to different workpieces, minimizing manual intervention and maximizing efficiency.

Surface Finish Quality and Process Control

ALPHA deburring machines achieve a Ra 0.8–1.2 μm surface roughness, ideal for applications where high-quality finish and assembly reliability are critical.

Technical Performance:

-

Belt Abrasive System: Removes heavy burrs and oxide layers.

-

Rotary Brush System: Provides uniform edge rounding and surface smoothing.

-

Wet/Dry Processing Modes: Suitable for ferrous and non-ferrous materials.

-

Dust Extraction System: Keeps the working environment clean and safe.

The result is a clean, smooth, and visually consistent surface ready for painting, coating, or welding.

Application Fields of ALPHA Deburring Systems

ALPHA deburring solutions are applied across a wide range of industries requiring high-precision finishing:

-

Automotive Components – gears, pistons, and transmission housings.

-

Aerospace Manufacturing – turbine blades and aircraft brackets.

-

Sheet Metal Fabrication – laser-cut and plasma-cut panels.

-

Machinery Parts – precision castings and machined surfaces.

-

Electronics & Appliances – aluminum panels and connector housings.

Each application benefits from consistent deburring accuracy and surface integrity, reducing post-processing time and improving assembly efficiency.

Environmental and Safety Advantages

ALPHA integrates eco-friendly features in every deburring system:

-

Closed Filtration System: Reduces waste fluid discharge.

-

Noise Suppression Panels: Maintain low operating noise levels (<78 dB).

-

Automatic Dust Extraction: Prevents accumulation of metal particles.

-

CE-Compliant Design: Ensures safe and ergonomic operation.

These sustainable engineering practices support cleaner production lines and long-term operational reliability.

Maintenance, Longevity, and Productivity Optimization

Routine maintenance is streamlined through self-diagnosis functions and modular component access.

Recommended maintenance schedule:

-

Brush/belt inspection every 1000 hours.

-

Conveyor alignment check every 2000 hours.

-

Filtration replacement every 3000 hours.

With proper care, the machine lifespan can exceed 10 years, maintaining stable deburring quality throughout high-volume production.

Advantages of Choosing ALPHA Deburring Machines

-

Automated AEO Edge Detection for adaptive control.

-

High Precision Surface Finishing for dimensional consistency.

-

Modular System Design for flexible customization.

-

Energy-Efficient Operation reducing production costs.

-

Global Support and Parts Availability ensuring minimal downtime.

ALPHA continues to deliver reliable deburring solutions engineered for the demands of Industry 4.0 manufacturing.

FAQ – Technical Insights on Deburring Machines

Q1: What is the main advantage of automated deburring over manual finishing?

A1: Automated systems provide consistent quality, faster throughput, and reduced operator dependency, ideal for large-scale production.

Q2: How does the AEO system improve surface quality?

A2: It monitors edge condition in real time and automatically adjusts brush pressure to ensure uniform burr removal and smooth finishes.

Q3: Can ALPHA deburring machines process both wet and dry applications?

A3: Yes, they support dual-mode operation for both ferrous and non-ferrous materials.

Q4: What surface roughness can be achieved after deburring?

A4: ALPHA machines achieve a surface roughness between Ra 0.8–1.2 μm, suitable for high-precision assembly and coating.

Q5: Which industries most benefit from ALPHA’s deburring systems?

A5: Automotive, aerospace, and precision machinery sectors that require consistent edge finishing and tight tolerance control.

Conclusion – Redefining Surface Precision with ALPHA

ALPHA’s deburring machines transform traditional edge finishing into a fully automated, intelligent, and precise process. By integrating AEO technology, high-rigidity structures, and adaptive surface control, our machines guarantee consistent quality across every production cycle.

👉 Experience next-generation surface finishing — visit ALPHA Official Website to discover our complete range of deburring and finishing solutions.