The evolution of precision: Understanding the dragon gate

The manufacturing environment is evolving, driven by the ongoing demand for higher accuracy, efficiency and the ability to handle increasingly complex components. The forefront of this evolution is Gantry CNC grinding, a specialized machining process that combines the powerful architecture of the gantry system with the accuracy of computer numerical control (CNC) grinding. This technology is crucial for industries that require unusually smooth surface finishes and tight dimensional tolerances on large workpieces, setting new benchmarks for production quality and capability. As we dig deeper, we will explore how these complex systems, including advanced CNC grinders, can transform modern manufacturing.

The core of Gantry CNC system: CNC grinder and others

The CNC grinding mechanism has become the backbone of modern abrasive processing, providing unparalleled control over the grinding process. When integrated into the gantry dragon structure, their abilities are greatly amplified. Unlike smaller conventional grinders, the gantry CNC grinding system has a large bridge-like structure (gantry) supporting the grinding head. The design provides excellent stability and allows machining of very large and heavy-duty components, which can be difficult to manage for other types of grinders that are popular in CNC machining. The gantry moves along the X-axis along the precise guideway, while the grinding shafts can traverse on the Y-Z-axis, allowing full coverage and complex material removal on a spacious surface. This reliable configuration ensures minimal vibration and deflection, which is essential for the ultra-high accuracy required in industries such as aerospace, automotive and mold manufacturing.

Distinguish between dragon gate and dragon gate mill system

Although both Gantry CNC grinding and gantry grinding systems utilize similar overhead gantry structures for stability and greater workpiece adaptability, their core functions and tools vary widely. Gantry milling systems are designed for material removal using rotary cutting tools such as end mills and face mills, focusing on shaping and engraving parts. In contrast, gantry CNC grinding uses abrasive wheels to achieve very fine finishes and very precise dimensions, usually after initial milling or turning. Although some advanced gantry CNC machining centers may provide functionality for milling and grinding, specialized grinding systems have been optimized for specific needs of abrasive machining, including coolant delivery, SWARF management, and the rigidity required to maintain secondary micron accuracy during grinding.

The logo of excellence: precise grinding service of gantry technology

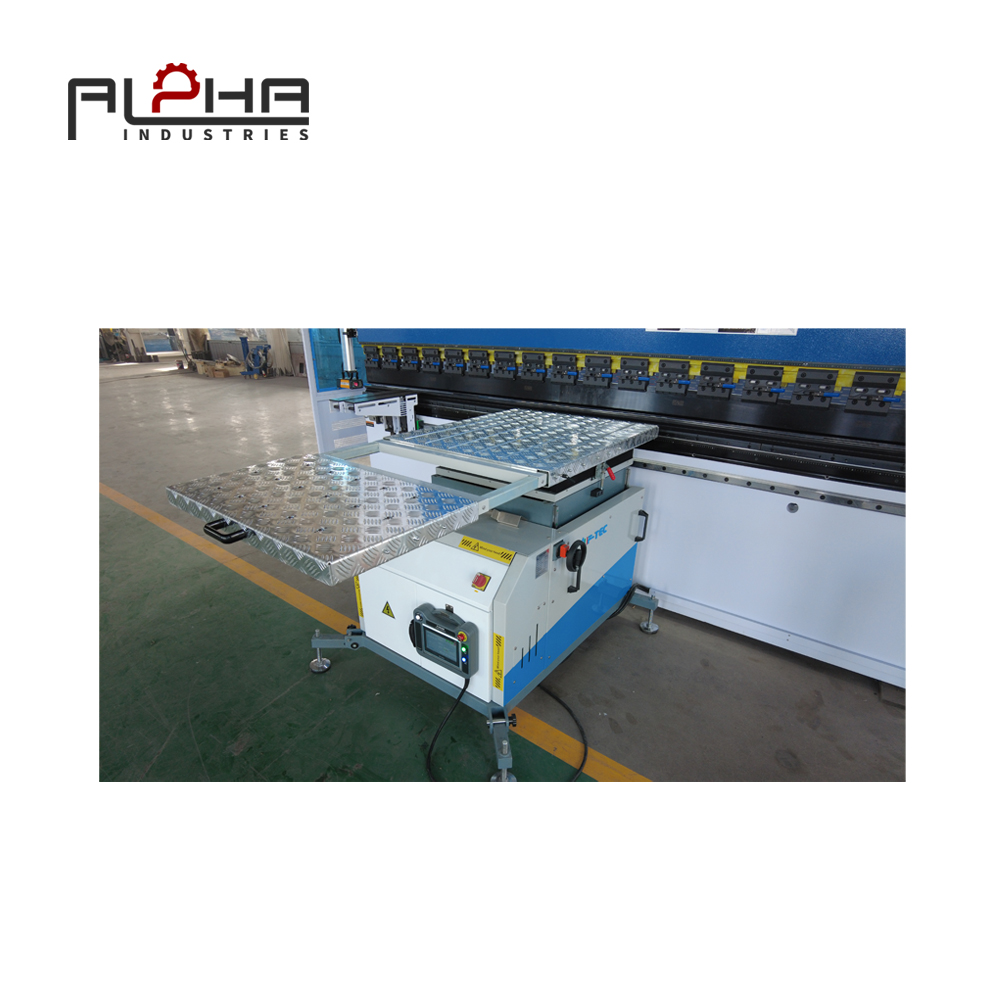

As engineering tolerances become more stringent, demand for precise grinding services surges. Gantry CNC grinding is specialized in providing these services, especially for components that are too large or complex for traditional grinding setups. The inherent stability of the gantry design, coupled with advanced CNC controls, cut off the material, enabling high-quality finishes (usually measured at RA or RZ values) and dimensional accuracy. Companies such as Nanjing Alpha CNC Co., Ltd are at the forefront of providing such advanced solutions. Their product, Alpha FSC2550HV, represents the functionality of a modern Gantry CNC machining center. The machine is heavily designed with cutting-edge capabilities to handle large machining projects with unrivalled precision, making it ideal for industries that rely on top-notch precision grinding services for critical components.

Alpha FSC2550HV: A typical example of Gantry CNC machining center

The Alpha FSC2550HV provided by Nanjing Alpha CNC Co., Ltd is a testament to the advancement of the Gantry CNC machining center. This machine is more than just grinding; it represents an overall approach to mass precision manufacturing. Its grand gantry structure ensures excellent stability, which is essential for precise grinding and exquisite operation. Well-designed components ensure precise movement, allowing the operator to achieve tight tolerances and complex finishes. In addition, its extended frame and work area can accommodate extremely large workpieces, greatly expanding the scope of projects that can be carried out. These machines are essential for departments that require fine finishing on components such as large machine tools, aerospace structural parts or large molds, and even minor imperfections can lead to failure. The capability of this CNC grinder changes the generation of these critical parts.

Integrate gantry system into modern CNC machining workflow

Whether it is for grinding or a versatile CNC machining center, the integration of the gantry CNC system will revolutionize the CNC machining workflow. These systems facilitate larger, more accurate parts production, often reducing the need for multiple settings, thereby increasing overall efficiency. Precise grinding services provided through the Gantry Party Platform ensure that the final product meets the highest quality standards. For example, Alpha's FSC2550HV can maintain high productivity while reducing downtime thanks to its intelligent monitoring system and seamless operation feedback. This advanced automation and control is the hallmark of contemporary CNC machining. As Nanjing Alpha CNC Co., Ltd emphasizes, they are not only machine sellers, but also solutions providers that can assist customers in integrating such powerful machines into a complete production line and support them with professional R&D and timely customer support. Their commitment to world-class design and manufacturing ensures that the business can significantly improve its capabilities. The ability to handle multiple materials and complex geometries on these systems further emphasizes their value in competitive manufacturing environments. When the gantry milling system handles roughness and shaping, the gantry grinder brings the workpiece to its final precise form.

The future is accurate: Embrace advanced gantry grinding solutions

Manufacturing depends on a future where higher levels of accuracy and efficiency are achieved, especially in large and complex components. In this journey, advanced Gantry CNC grinding solutions, including sophisticated CNC grinding machines and multi-function machining centers, are crucial in this journey. These systems allow the industry to push possible boundaries to produce parts with excellent accuracy and surface quality. With support from companies such as Nanjing Alpha CNC Co., Ltd, such technology is adopted to ensure manufacturers can meet the strict needs of modern applications from aerospace to energy. The continuous development of CNC machining and gantry milling systems continues to complement advances in grinding, resulting in more integrated and capable manufacturing solutions. Investment in high-quality precision grinding services promoted by strong gantry technology is an investment in future competitiveness and outstanding products.