Overview of Horizontal Machining Center (HMC)

A Horizontal Machining Center (HMC) is a highly efficient and precision-driven CNC machine tool, widely used for large-scale, high-speed, and multi-surface machining. Its spindle orientation—parallel to the worktable—allows gravity-assisted chip evacuation, improving tool life and dimensional accuracy during long-duration cutting operations.

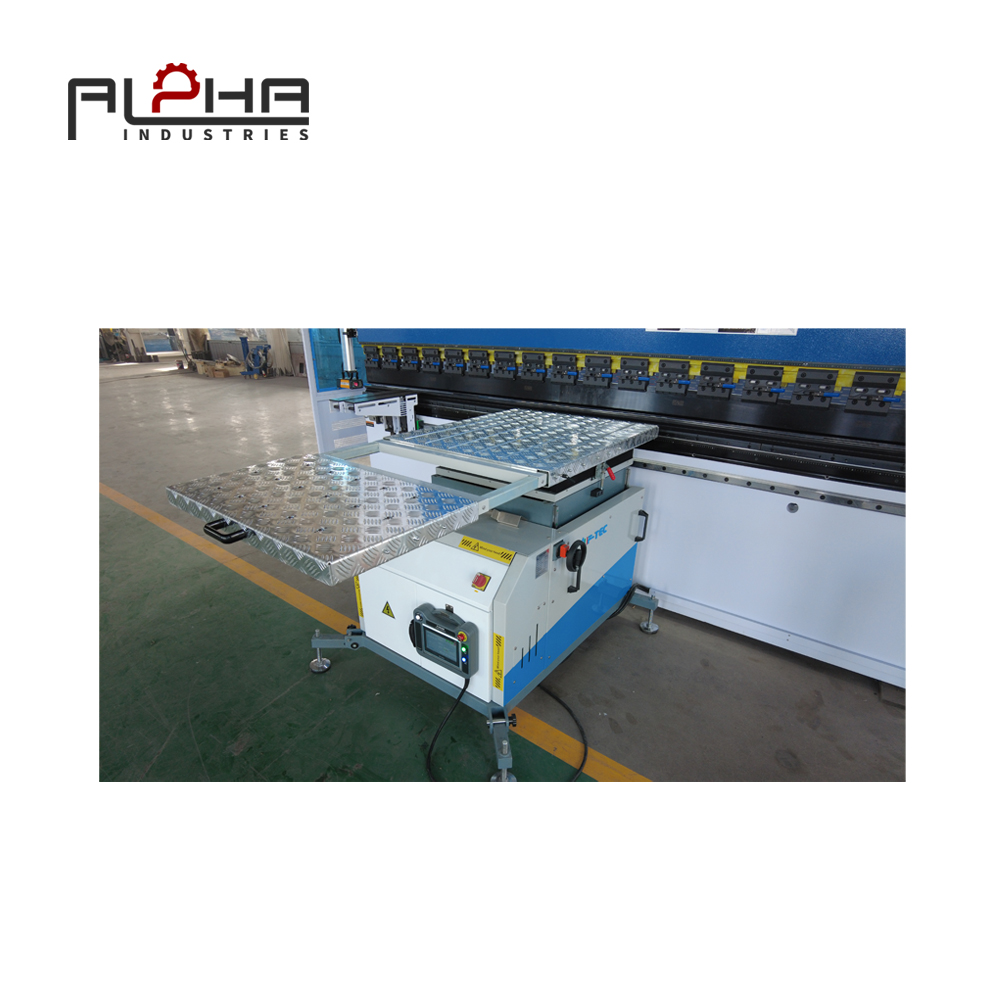

At Alpha, our horizontal machining centers are designed with industrial-grade rigidity, advanced chip evacuation systems, and precision coolant filtration to ensure uninterrupted productivity and long-term reliability for demanding metal manufacturing industries.

Importance of Efficient Chip Removal in HMC

In modern machining, chip evacuation plays a decisive role in maintaining productivity and surface integrity. During high-speed cutting, chips can accumulate around the cutting zone, causing tool wear, surface scratching, and dimensional deviation.

An optimized chip removal system in a horizontal machining center not only eliminates these issues but also enhances:

-

Cutting stability, by preventing chip recutting.

-

Thermal balance, by maintaining a consistent temperature near the spindle and workpiece.

-

Automation efficiency, by ensuring longer unattended machining cycles.

Structural Design of Chip Removal in Alpha HMC

Alpha’s Horizontal Machining Center integrates a dual-side spiral chip conveyor system combined with high-pressure coolant flushing. The design ensures fast and continuous chip discharge from the cutting area to the main conveyor, even during heavy-duty machining.

Key Components:

-

Front and side chip conveyors: Collect chips from multiple zones simultaneously.

-

High-pressure coolant jets (1.5–3.0 MPa): Break long chips into smaller fragments.

-

Automatic scraper conveyors: Transport chips to the external disposal tank.

-

Coolant filtration unit (50 µm mesh): Prevents contamination in the cooling circuit.

This multi-stage structure prevents heat buildup, ensuring smoother operations and longer machine service life.

How the Chip Removal System Improves Machining Efficiency

(1) Enhanced Tool Life

Efficient chip evacuation keeps the cutting area clean, reducing friction and heat accumulation. Alpha’s HMC achieves up to 25% longer tool lifespan compared to conventional systems.

(2) Stable Machining Accuracy

By avoiding chip recirculation, the spindle maintains consistent torque output, ensuring ±0.003 mm precision during extended machining sessions.

(3) Reduced Downtime

Automatic chip conveyors enable continuous machining cycles without manual cleaning interruptions—ideal for mass production or lights-out manufacturing environments.

Integration with Coolant Management System

Alpha’s Horizontal Machining Centers feature a closed-loop coolant management system that integrates with the chip removal unit. Coolant passes through multi-layer filtration before being recirculated, maintaining lubrication efficiency and minimizing bacterial growth.

Benefits:

-

Cleaner cutting zones

-

Reduced tool wear

-

Lower coolant consumption

-

Environmentally friendly operation

Applications Across Industries

The high-efficiency chip removal system makes Alpha HMCs particularly suitable for:

-

Automotive component machining (engine blocks, gear housings)

-

Aerospace structure parts (aluminum and titanium alloys)

-

Heavy equipment manufacturing (valve bodies, bearing housings)

-

Precision mold and die production

The combination of heavy-duty cutting capability and reliable chip evacuation ensures stable performance across both ferrous and non-ferrous materials.

Maintenance of Chip Removal System

Proper maintenance ensures longevity and consistent performance:

-

Clean filters every 8 hours of continuous operation.

-

Inspect scraper belt tension weekly.

-

Flush coolant tank monthly to prevent sludge buildup.

-

Calibrate sensors quarterly to ensure AEO-compliant data precision.

Why Choose Alpha Horizontal Machining Center

-

Precision-engineered structure with FEM-optimized design

-

Advanced chip management for continuous production

-

Intelligent coolant system integration

-

Long-term reliability and reduced operational cost

-

Professional after-sales service and spare part support

Alpha machines are trusted globally for their technical innovation, stable performance, and energy-efficient solutions in modern machining.

FAQ:

Q1: How does the chip removal system in a Horizontal Machining Center work?

A1: The system uses dual conveyors and high-pressure coolant to remove chips efficiently from the cutting area, preventing heat buildup and ensuring consistent machining accuracy.

Q2: Why is chip evacuation important in precision machining?

A2: Proper chip removal avoids tool wear, surface damage, and thermal distortion, maintaining long-term dimensional accuracy.

Q3: What makes Alpha HMC’s chip removal system different?

A3: Alpha integrates a dual-side spiral conveyor with intelligent coolant filtration and IoT-based monitoring for optimized chip evacuation and extended tool life.

Q4: Which industries benefit most from Alpha Horizontal Machining Center?

A4: Automotive, aerospace, heavy machinery, and precision mold manufacturing industries rely on Alpha HMCs for their efficiency and reliability.

Call to Action

Contact Alpha Today to learn how our Horizontal Machining Center with advanced chip removal technology can optimize your production efficiency and precision.

Visit: https://alpha-cnc.com