Conventional Lathe Machine for Precision Metal Turning

A conventional lathe machine remains a fundamental tool in metalworking, designed to rotate a workpiece against a cutting tool to remove material and form accurate cylindrical parts. Unlike CNC lathes, which rely on programmed control, conventional lathes provide manual control and mechanical feedback, giving operators full command over cutting depth, feed rate, and surface finish.

At ALPHA, we manufacture industrial-grade manual lathes that combine mechanical strength, machining precision, and reliability—engineered to meet the needs of professional metalworkers and heavy-duty industries worldwide.

Working Principle of a Conventional Lathe

A conventional lathe operates through rotational motion transmitted from the spindle to the workpiece, while the cutting tool moves linearly along the axis. The operator manually controls the feed, depth of cut, and spindle speed to achieve the desired shape, diameter, and surface finish.

Major Components of a Lathe Machine

-

Bed: Rigid base structure ensuring stability and alignment.

-

Headstock: Houses the spindle and gear mechanism for speed transmission.

-

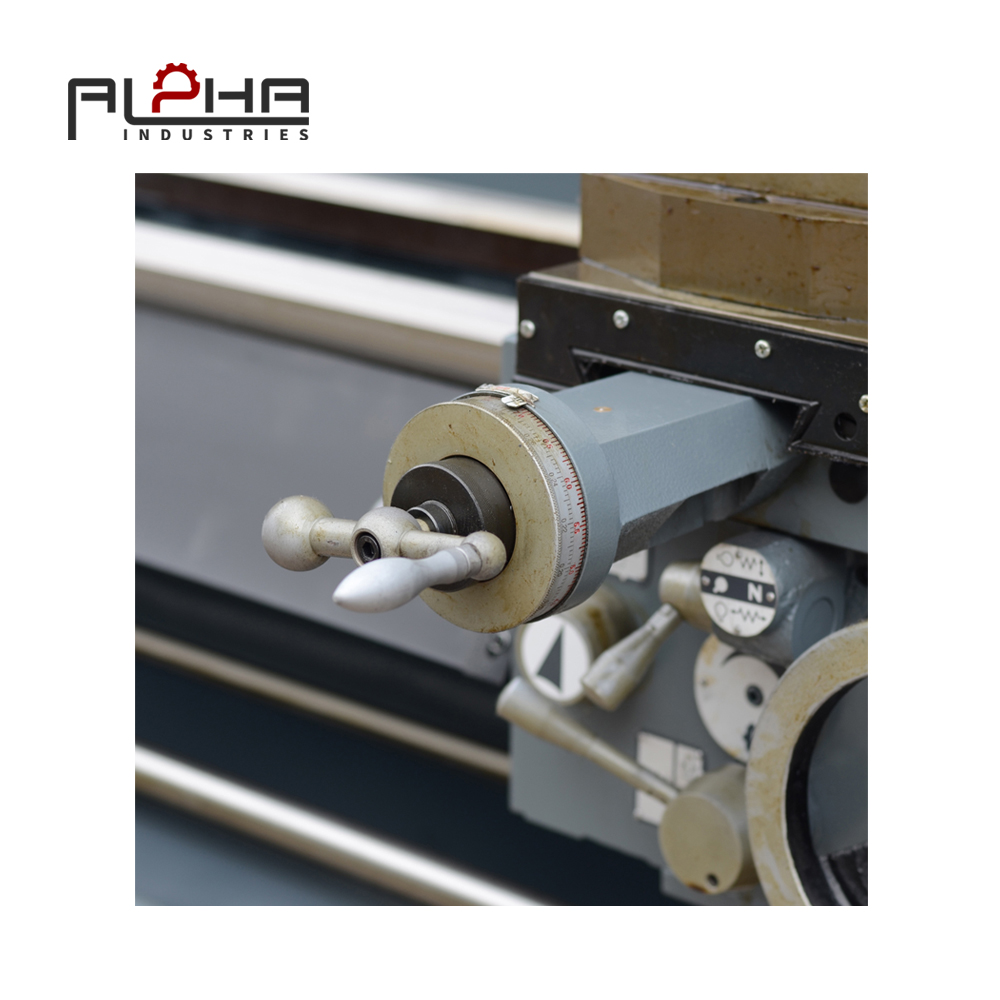

Tailstock: Supports the workpiece and facilitates drilling or reaming.

-

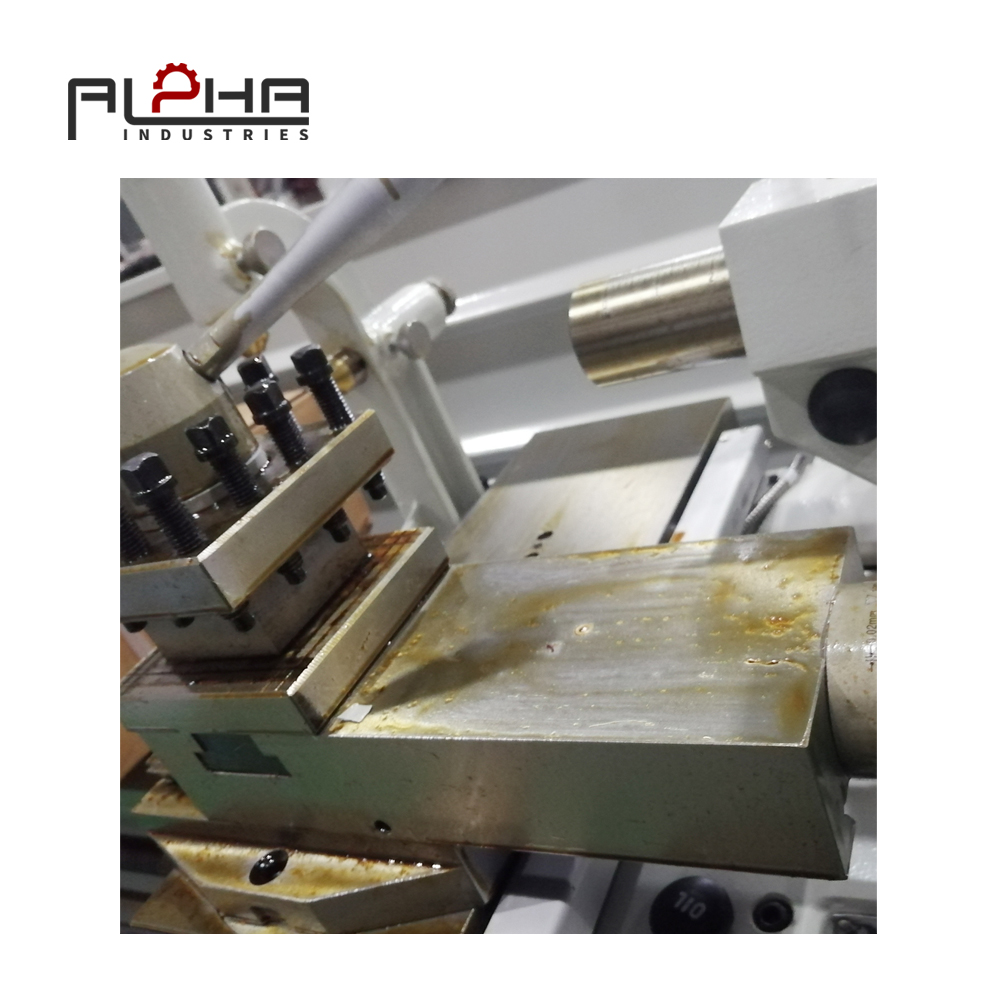

Carriage Assembly: Holds and moves the cutting tool precisely along the workpiece.

-

Lead Screw & Feed Shaft: Enable thread cutting and controlled longitudinal feed.

This manual interaction gives machinists greater flexibility and tactile feedback, making it ideal for one-off production, prototyping, and repair work.

Structural Features and Rigidity

Heavy-Duty Cast Iron Bed

ALPHA lathes feature high-strength cast iron beds that are heat-treated and precision-ground to ensure rigidity and vibration resistance. The wide bed design enhances load-bearing capacity and stability during heavy turning operations.

Precision Spindle System

The spindle is supported by tapered roller bearings or hydrodynamic bearings, providing smooth rotation and high radial load capacity. This ensures minimal runout and consistent machining accuracy.

Hardened and Ground Guideways

The slideways are induction-hardened and precision-ground, ensuring long service life, smooth movement, and superior wear resistance even under continuous use.

Operational Advantages of ALPHA Conventional Lathe

Manual Precision Control

Operators can finely adjust feed and cutting speed manually, achieving desired surface roughness and dimensional tolerance. The handwheel and feed lever system ensures intuitive and responsive control.

High Torque and Versatile Speed Range

The lathe’s gearbox offers a wide speed range (20–1600 RPM), enabling it to handle both roughing and finishing operations on various materials—such as carbon steel, aluminum, brass, and cast iron.

Durable Transmission Mechanism

ALPHA lathes utilize a hardened gear train and multi-speed gearbox, ensuring consistent power transmission with minimal noise and wear.

Thread Cutting Capability

Equipped with a leadscrew and change gear system, the lathe can cut both metric and imperial threads with accuracy—making it a versatile solution for general machining and maintenance workshops.

Applications of Conventional Lathe Machines

The flexibility and simplicity of manual lathes make them indispensable across many sectors:

-

Tool Rooms and Repair Shops – for maintenance and part restoration

-

Educational Institutions – for training machinists and technicians

-

Automotive Workshops – for turning shafts, bushings, and pulleys

-

Manufacturing Plants – for prototype production and precision components

ALPHA’s lathes are available in various swing diameters and center lengths to meet diverse machining needs—from light bench lathes to heavy-duty floor models.

Maintenance and Longevity

ALPHA designs its conventional lathes for easy maintenance and long-term durability.

Key maintenance features include:

-

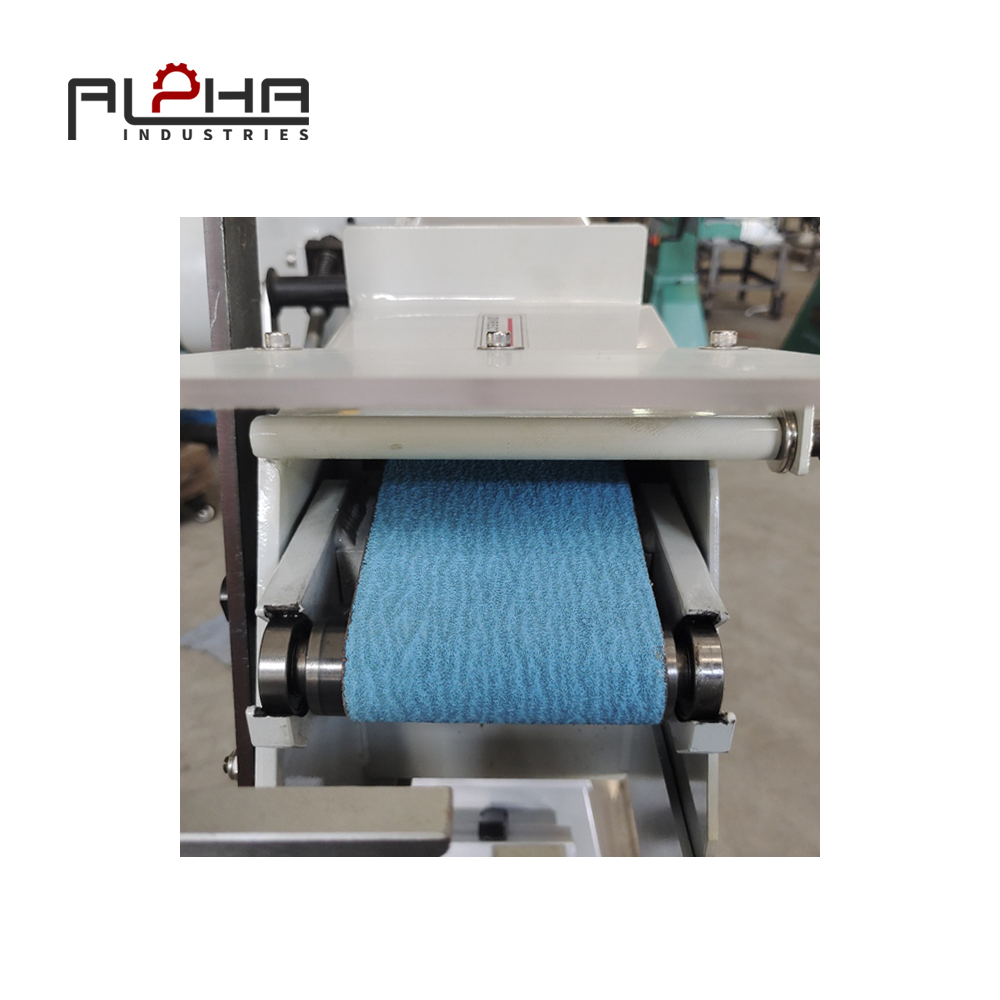

Centralized lubrication system for smooth slideways and feed mechanisms

-

Oil sight glass for monitoring gearbox lubrication levels

-

Adjustable gibs and backlash controls for maintaining precision over years of use

Proper maintenance ensures the machine retains accuracy and performance for decades, even under intensive workshop conditions.

Why Choose ALPHA Conventional Lathe Machines

-

Strong Construction: Reinforced bed and headstock structure for vibration-free turning.

-

High Accuracy: Precision spindle assembly ensures consistent cutting results.

-

Ease of Use: Manual controls suitable for both beginners and professionals.

-

Flexible Operation: Capable of facing, turning, tapering, threading, and drilling.

-

Long Service Life: Engineered components reduce wear and extend machine lifespan.

-

Global Support: ALPHA provides installation guidance, spare parts, and lifelong service.

Each ALPHA lathe reflects a commitment to craftsmanship, performance, and mechanical reliability—a benchmark in conventional metalworking technology.

FAQ

Q1: What is the main difference between a conventional lathe and a CNC lathe?

A conventional lathe is manually operated with mechanical feed systems, while a CNC lathe uses computer control for automated cutting and higher repeatability.

Q2: What materials can a conventional lathe machine handle?

It can process various metals such as mild steel, cast iron, aluminum, copper, and brass.

Q3: How is turning accuracy maintained in a manual lathe?

Accuracy is ensured through rigid bed design, precision-ground spindle bearings, and properly adjusted gibs and tool alignment.

Q4: Can a manual lathe cut threads?

Yes, ALPHA lathes include a leadscrew and gear mechanism that allow precise threading operations in both metric and imperial pitches.

Q5: What maintenance is required for a conventional lathe?

Regular lubrication, alignment inspection, and gear cleaning are essential to ensure smooth operation and maintain long-term accuracy.

Conclusion

The conventional lathe machine remains an irreplaceable tool in precision metalworking—valued for its reliability, operator control, and mechanical simplicity.

At ALPHA, we design and manufacture manual lathes that combine heavy-duty construction, smooth operation, and long-term accuracy—empowering craftsmen and industries to achieve exceptional turning performance.