Why Surface Consistency Matters in Belt Grinding Machines

In metal fabrication and finishing operations, surface consistency is often the defining factor of product quality.

Regardless of cutting accuracy or forming precision, uneven grinding marks, inconsistent roughness, or uncontrolled material removal can compromise the final result.

The Belt Grinding Machine from Alpha is engineered specifically to solve this challenge by focusing on controlled, repeatable surface finishing, rather than simple material removal.

This article concentrates on one decisive technical factor:

👉 How belt stability and controlled grinding pressure ensure uniform surface finishing in industrial belt grinding machines.

Understanding Surface Finishing in Belt Grinder Machines

Surface finishing quality depends on more than abrasive grit size.

In a professional belt grinding machine, consistency is determined by:

-

Belt speed stability

-

Grinding pressure control

-

Contact wheel rigidity

-

Belt tracking accuracy

-

Drive system torque output

Without precise control of these elements, surface roughness can vary across the workpiece, leading to rework and scrap.

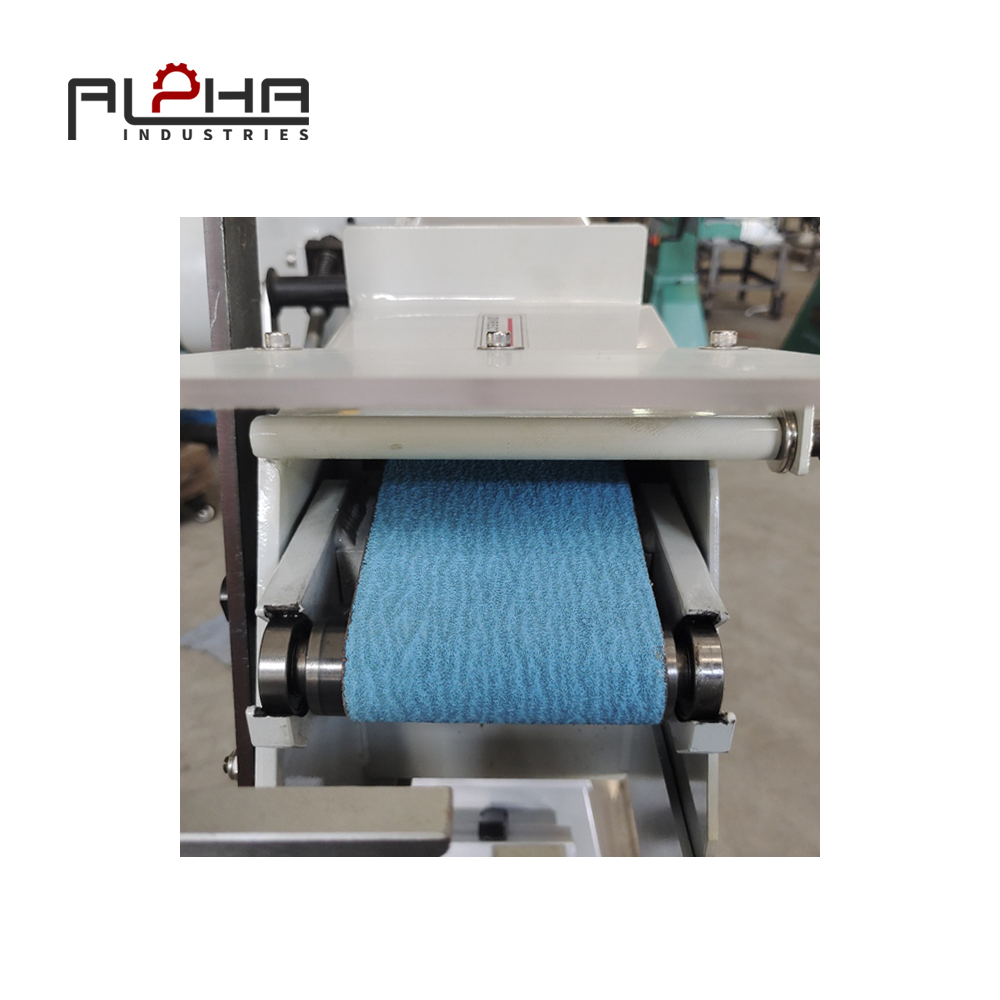

Stable Belt Tracking: The Foundation of Uniform Grinding

Unstable belt movement is a primary cause of surface inconsistency.

Alpha belt grinding machines feature:

-

Precision belt tracking mechanisms

-

Adjustable tracking control

-

High-stability belt tension systems

These ensure the abrasive belt runs straight and centered during operation, preventing edge wear, vibration, and surface irregularities.

Result:

✔ Uniform grinding marks

✔ Extended belt life

✔ Consistent surface texture

Constant Belt Speed Control for Even Material Removal

Fluctuating belt speed directly affects surface quality.

Alpha industrial belt grinders are equipped with:

-

High-efficiency motor systems

-

Stable transmission structures

-

Optional variable speed control

By maintaining constant belt speed under load, the machine ensures even material removal across the entire grinding area.

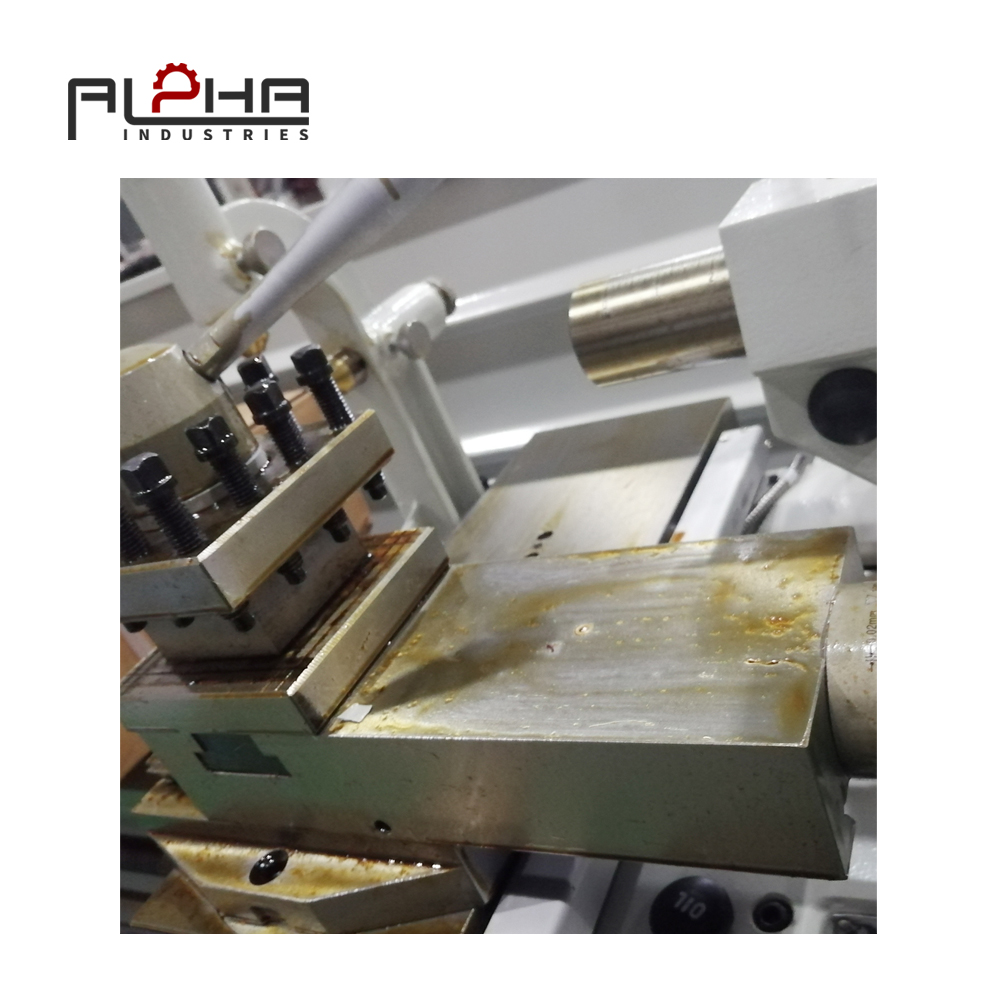

Controlled Grinding Pressure: Precision Over Aggression

Excessive grinding pressure often causes overheating and surface damage.

The Alpha belt grinding machine is designed to allow:

-

Smooth, controllable operator pressure

-

Rigid grinding arms and contact wheels

-

Balanced machine weight distribution

This controlled interaction between belt and workpiece improves surface consistency and reduces operator fatigue.

Contact Wheel Design and Surface Uniformity

The contact wheel directly influences surface finish.

Alpha machines use:

-

High-quality rubber or polyurethane contact wheels

-

Optimized hardness levels for different applications

-

Precision-balanced wheel structures

These features help distribute grinding pressure evenly, producing a uniform surface finish.

Heat Control for Surface Integrity

Uneven heat buildup can discolor materials and distort surface texture.

Alpha belt grinders address heat control through:

-

Efficient belt speed regulation

-

Smooth belt-to-surface contact

-

Optional dust extraction and cooling configurations

Effective heat management preserves surface integrity, especially when grinding stainless steel and aluminum.

Surface Finishing Across Different Materials

Different materials respond differently to belt grinding.

Alpha belt grinding machines are suitable for:

-

Carbon steel

-

Stainless steel

-

Aluminum

-

Non-ferrous metals

By adjusting belt grit and speed, operators can achieve consistent surface finishes across material types.

Belt Grinding Machine for Precision Surface Applications

Industries that demand consistent surface quality include:

-

Sheet metal fabrication

-

Stainless steel processing

-

Architectural metal finishing

-

Industrial equipment manufacturing

-

Decorative metal components

The Alpha belt grinding machine meets the surface quality standards required in these applications.

Reduced Rework Through Controlled Surface Finishing

Inconsistent grinding leads to rework and higher costs.

Through:

-

Stable belt tracking

-

Controlled grinding pressure

-

Consistent belt speed

Alpha belt grinders significantly reduce surface defects and secondary finishing operations.

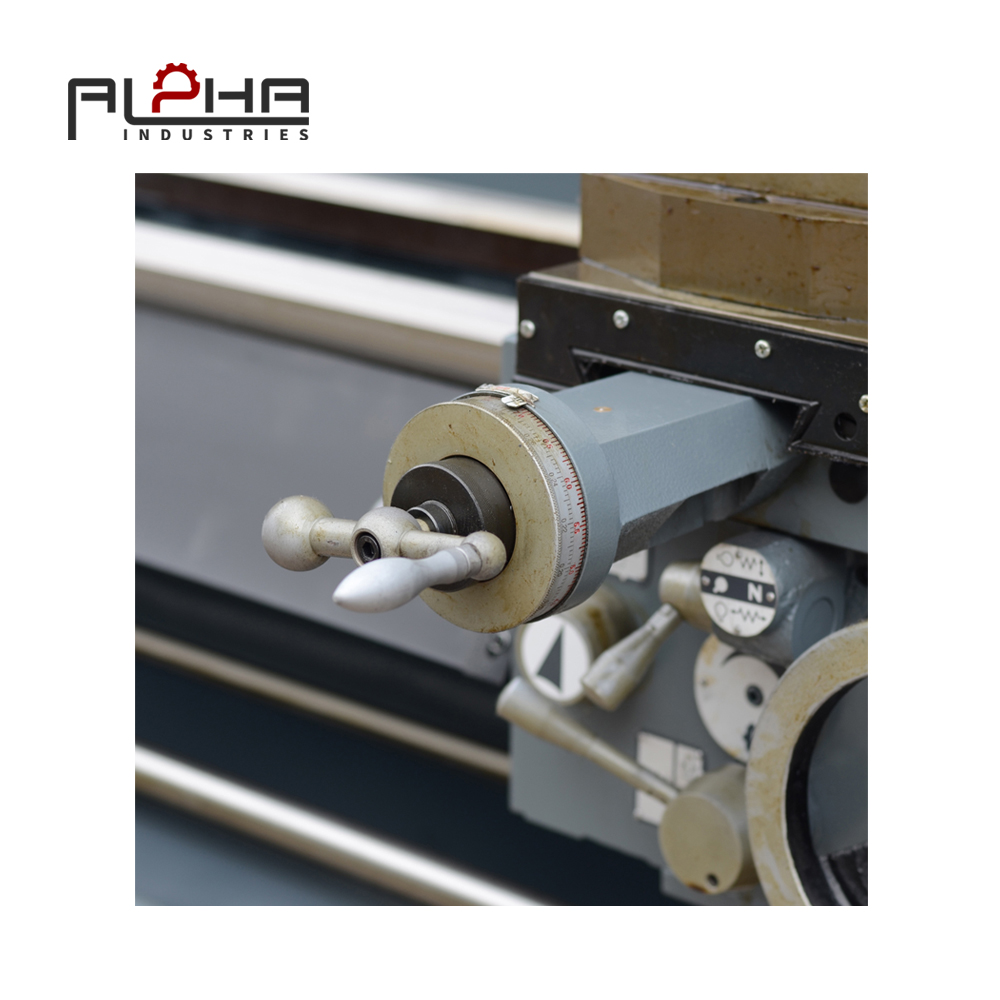

Long-Term Stability and Industrial Reliability

Surface consistency must be maintained over long production cycles.

Alpha belt grinding machines are built with:

-

Rigid machine frames

-

Durable drive components

-

Industrial-grade bearings and shafts

This ensures consistent performance in continuous industrial use.

FAQ

What is a belt grinding machine used for?

A belt grinding machine is used for surface finishing, deburring, polishing, and controlled material removal on metal workpieces.

How does a belt grinder ensure consistent surface finishing?

Consistency is achieved through stable belt tracking, constant belt speed, controlled grinding pressure, and rigid machine construction.

What materials can be processed with a belt grinding machine?

Belt grinders are suitable for carbon steel, stainless steel, aluminum, and other non-ferrous metals.

Is belt speed important in surface finishing?

Yes. Stable and appropriate belt speed ensures uniform material removal and prevents surface defects.

Why Choose Alpha Belt Grinding Machines

Alpha focuses on surface quality–driven machine design, not generic grinding solutions.

With Alpha belt grinding machines, manufacturers gain:

-

Consistent surface finishing

-

Controlled material removal

-

Industrial-grade stability

-

Reduced rework and scrap