Why Spindle Accuracy Is the Core Value of a Lathe

In metal turning operations, no component influences machining accuracy more directly than the spindle. While feed systems, tool holders, and control software all play important roles, the spindle remains the mechanical heart of any lathe.

A lathe can only achieve true precision when its spindle rotates with:

-

Minimal runout

-

High structural rigidity

-

Long-term thermal stability

This article focuses on lathe spindle accuracy as the single most critical performance factor, explaining how spindle design, bearing systems, and structural rigidity directly define turning quality, repeatability, and production reliability.

What Is Spindle Accuracy in a Lathe?

Lathe spindle accuracy refers to the degree to which the spindle maintains perfect rotational alignment under real cutting conditions, including load, speed variation, and continuous operation.

Key indicators include:

-

Radial and axial runout

-

Rotational stability at different speeds

-

Deflection under cutting force

-

Long-term consistency during batch production

Even microns of spindle deviation can result in:

-

Poor dimensional accuracy

-

Surface chatter or vibration marks

-

Reduced tool life

-

Assembly fit issues

Why Spindle Rigidity Is as Important as Spindle Precision

Accuracy without rigidity is unstable. During turning, cutting forces act continuously on the spindle. If the spindle lacks sufficient rigidity:

-

The tool-workpiece contact becomes unstable

-

Dimensional tolerances drift

-

Surface finish deteriorates

-

Repeatability decreases

High spindle rigidity ensures that accuracy is maintained not only at idle rotation, but under real cutting load.

The Main Factors That Determine Lathe Spindle Accuracy

1. Spindle Bearing System

Bearings are the foundation of spindle precision. High-quality lathes use:

-

Precision angular contact bearings

-

Optimized preload design

-

Controlled thermal expansion

These features ensure:

-

Minimal runout

-

Stable rotation

-

Long service life

2. Spindle Shaft Design and Material

A precision-ground spindle shaft with optimized diameter and material strength:

-

Resists bending under load

-

Reduces vibration

-

Maintains concentricity

Heat-treated alloy steel spindles are commonly used for high-performance lathes.

3. Headstock Structural Rigidity

The spindle does not operate alone. The headstock housing must:

-

Absorb cutting vibration

-

Maintain alignment

-

Prevent deformation

A rigid, stress-relieved headstock casting is essential for stable spindle accuracy.

4. Thermal Stability of the Spindle System

Heat generated by:

-

High-speed rotation

-

Bearing friction

-

Continuous cutting

can cause thermal growth and accuracy drift. Advanced lathe designs focus on:

-

Thermal balance

-

Optimized lubrication

-

Heat dissipation paths

How Spindle Accuracy Directly Affects Turning Quality

| Machining Aspect | Influence of Spindle Accuracy |

|---|---|

| Dimensional Tolerance | Directly determines roundness & concentricity |

| Surface Finish | Reduces vibration and chatter |

| Tool Life | Stable cutting extends tool usage |

| Repeatability | Ensures batch consistency |

| Productivity | Reduces trial cuts and adjustments |

Why Spindle Accuracy Matters More in Modern Production

Modern manufacturing demands:

-

Tighter tolerances

-

Higher surface quality

-

Longer unattended operation

-

Stable batch production

Without high spindle accuracy:

-

Automation loses reliability

-

Inspection costs increase

-

Scrap rates rise

For industries such as:

-

Automotive components

-

Precision shafts

-

Hydraulic parts

-

Machinery assemblies

Spindle accuracy defines production competitiveness.

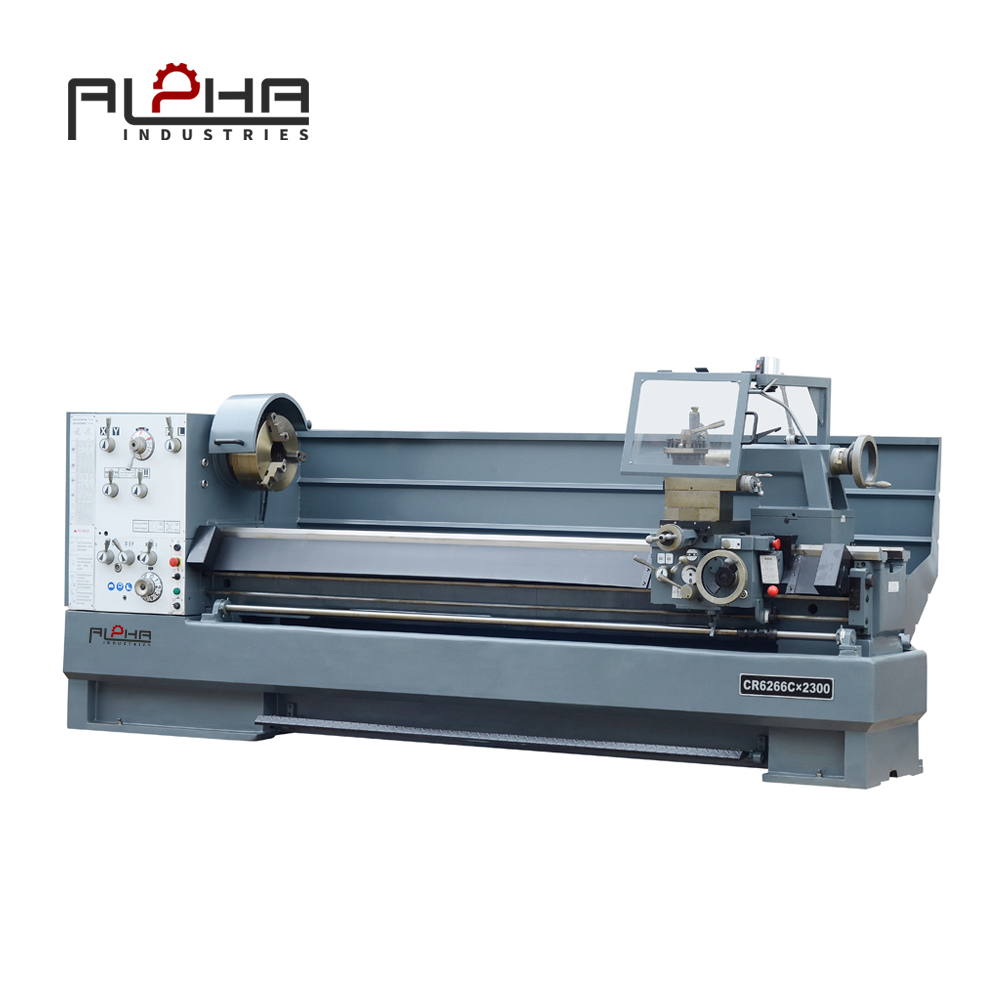

Alpha Lathe Design Philosophy: Precision Starts at the Spindle

At Alpha, lathe development begins with spindle system engineering, not just machine specifications.

Key spindle-focused design features include:

-

High-precision bearing arrangements

-

Rigid spindle-headstock integration

-

Optimized preload and lubrication systems

-

Precision grinding and dynamic balancing

-

Structural stress relief for long-term stability

These design principles ensure:

-

Stable accuracy over years of operation

-

Reliable performance in continuous production

-

Consistent results across varying cutting conditions

FAQ

What causes poor accuracy in a lathe?

Poor accuracy is often caused by spindle runout, worn bearings, insufficient rigidity, or thermal deformation.

How does spindle accuracy affect surface finish?

Higher spindle accuracy reduces vibration and chatter, resulting in smoother surface finishes.

Is spindle accuracy important for heavy cutting?

Yes. High rigidity and precision are especially critical during heavy or interrupted cutting.

How can spindle accuracy be maintained over time?

Proper lubrication, bearing quality, thermal control, and rigid machine structure are essential.

Does spindle accuracy affect CNC lathe automation?

Absolutely. Automated and unattended machining requires stable spindle accuracy for consistent results.

Conclusion: Spindle Accuracy Is the True Benchmark of a Lathe

A lathe is not defined by swing diameter or spindle speed alone.

True lathe performance is determined by spindle accuracy and rigidity.

By investing in spindle-focused engineering and structural stability, manufacturers can achieve:

-

Higher machining precision

-

Lower scrap rates

-

Longer tool life

-

Stronger market competitiveness

👉 Explore Alpha Lathe Machine Solutions:

https://alpha-cnc.com/products/lathe