Introduction – Why Cutting Accuracy Is the Core of Saw Machine Performance

In modern metalworking industries, the saw machine is one of the most essential processing equipment. From steel bars and aluminum profiles to pipes and structural materials, almost every metal product begins with an accurate cutting process.

While many buyers focus on cutting speed or machine price, the real value of an industrial saw machine lies in one key factor:

Cutting accuracy and stability.

Without accurate cutting, subsequent processes such as welding, machining, and assembly will all be negatively affected. That is why precision cutting capability has become the most important evaluation standard for high-quality saw machines.

At Alpha, we concentrate on designing and manufacturing professional industrial saw machines that deliver reliable accuracy, stable operation, and long-term performance.

The Importance of Cutting Accuracy in Metal Processing

Cutting is the first step in most metal fabrication workflows. Any error generated at this stage will be amplified in later processes.

Low cutting accuracy can lead to:

-

Dimensional deviation

-

Poor surface finish

-

Difficulty in assembly

-

Material waste

-

Increased rework cost

-

Reduced product quality

For industries such as machinery manufacturing, automotive parts, and steel structure fabrication, inaccurate cutting is simply unacceptable.

Therefore, choosing a high-precision saw machine is not only about improving efficiency—it is about ensuring overall production quality.

Key Factors That Affect Saw Machine Cutting Accuracy

Achieving high-precision cutting is not determined by a single component. It is the result of multiple technical factors working together:

1. Machine Structure Rigidity

A stable and heavy-duty machine frame minimizes vibration during cutting. Insufficient rigidity will directly cause:

-

Blade deviation

-

Uneven cutting surface

-

Poor straightness

Alpha saw machines adopt reinforced machine bodies to ensure maximum structural stability.

2. Blade Tension Control

Proper blade tension is critical for straight and accurate cutting.

If blade tension is too low:

-

The blade will bend

-

Cutting line will drift

-

Accuracy will drop

Professional saw machines use hydraulic or automatic blade tension systems to maintain optimal performance.

3. Guide Arm Precision

The blade guide system keeps the saw blade aligned during operation. High-quality guides ensure:

-

Reduced blade vibration

-

More accurate cutting path

-

Longer blade life

This is one of the core technologies of Alpha industrial saw machines.

4. Feed Rate Stability

Consistent feeding pressure and speed are essential for clean cuts. Modern automatic saw machines can intelligently adjust feed parameters according to:

-

Material hardness

-

Section size

-

Blade condition

5. Cooling and Lubrication System

Effective coolant supply helps to:

-

Reduce cutting heat

-

Prevent blade wear

-

Improve surface quality

-

Maintain dimensional accuracy

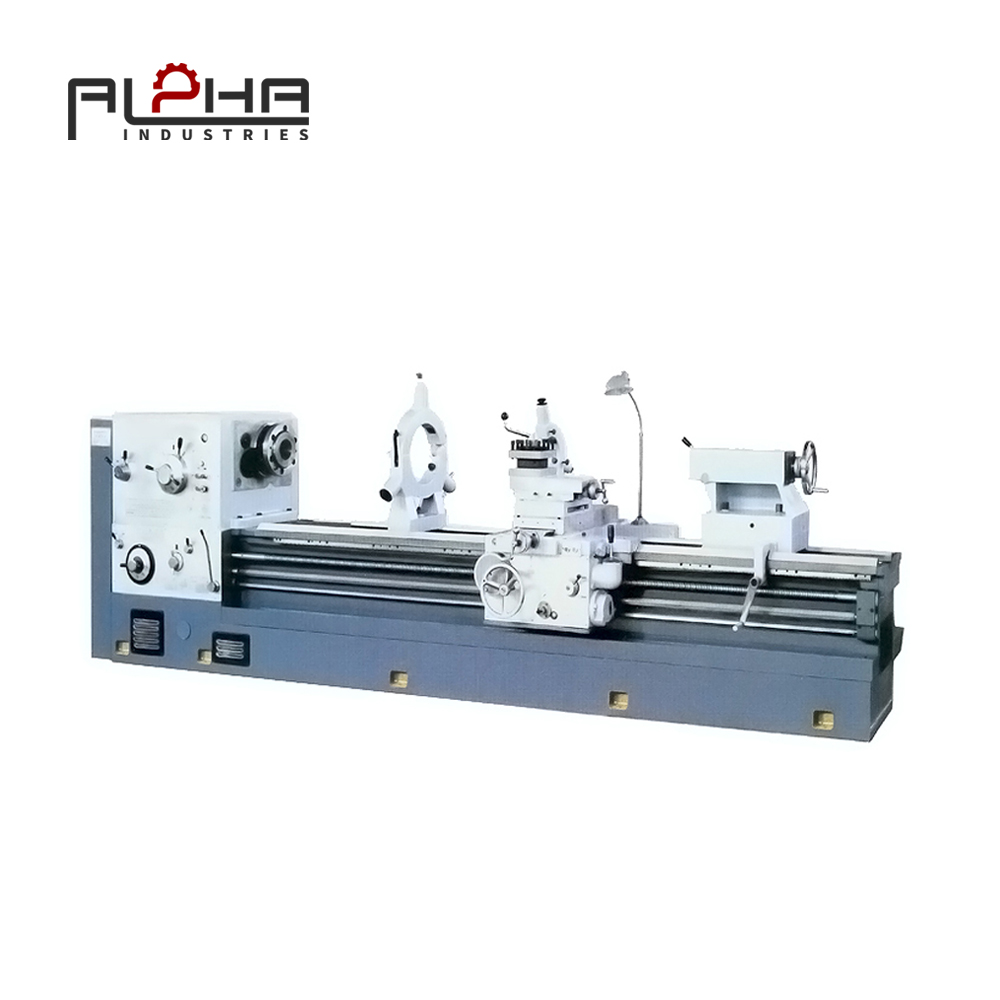

How Alpha Saw Machines Guarantee High Precision

Alpha focuses on every technical detail to ensure outstanding cutting performance.

Our saw machines are equipped with:

-

Heavy-duty cast iron frames

-

High-precision blade guides

-

Hydraulic blade tension systems

-

Intelligent feed control

-

Advanced coolant circulation

-

Automatic material clamping

These features work together to provide:

-

Straight and burr-free cuts

-

Repeatable accuracy

-

Stable long-term operation

-

Reduced material waste

Applications That Require High-Precision Saw Machines

Accurate saw cutting is crucial in many industries:

-

Steel structure manufacturing

-

Mechanical engineering

-

Automotive components

-

Aerospace parts

-

Metal fabrication workshops

-

Pipe and profile processing

Any factory that demands strict dimensional control relies heavily on professional saw machines.

Horizontal Band Saw vs Circular Saw – Which Is Better for Accuracy?

When it comes to precision metal cutting, different saw machines serve different purposes.

Horizontal Band Saw Machine

-

Better for large sections

-

More stable cutting

-

Lower material waste

-

Excellent straightness

Circular Saw Machine

-

Faster cutting speed

-

Suitable for smaller profiles

-

Higher surface finish

For most industrial applications where stability and accuracy are required, band saw machines are the preferred solution.

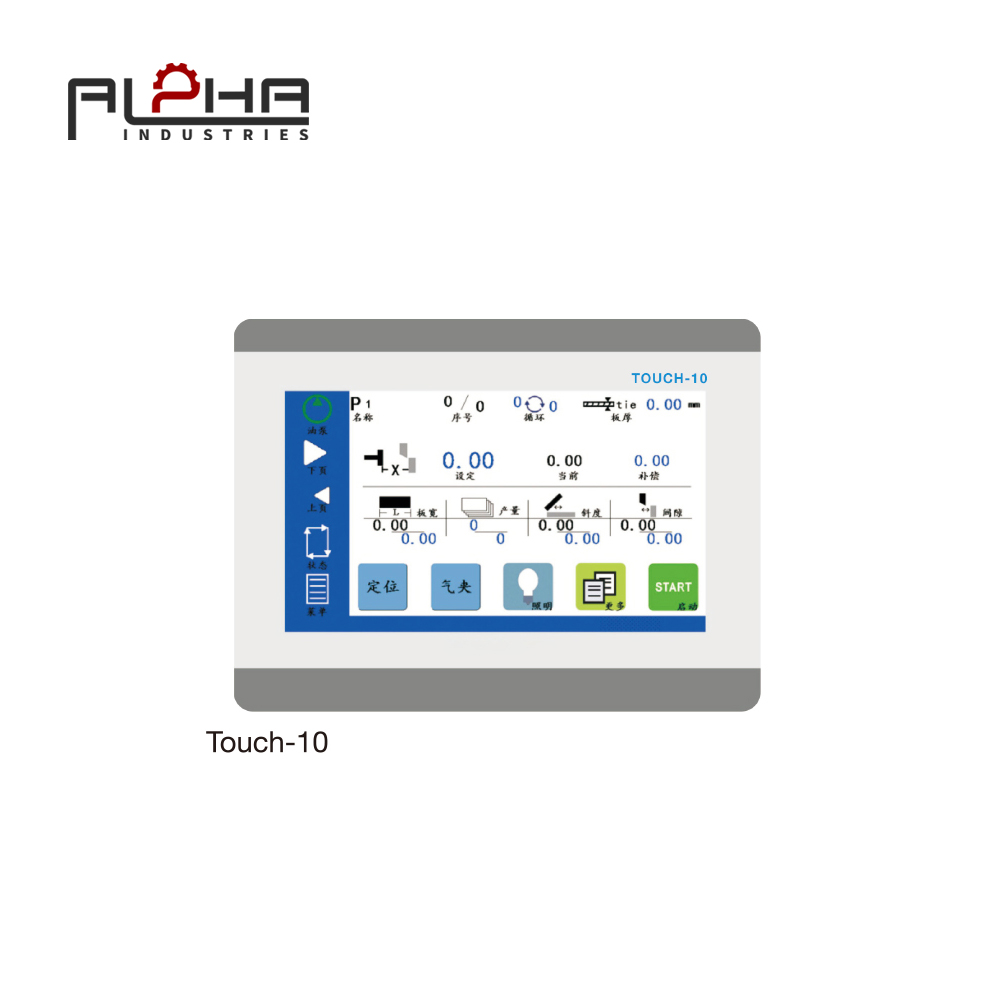

The Role of Automation in Cutting Accuracy

Manual operation often causes inconsistent results. That is why more factories are switching to:

Automatic saw machines

Automation brings:

-

Programmed cutting lengths

-

Automatic feeding

-

Reduced human error

-

Higher repeatability

Alpha provides fully automatic saw machines designed for modern smart manufacturing lines.

Maintenance – The Hidden Key to Long-Term Precision

Even the best saw machine requires proper maintenance to maintain accuracy.

Regular maintenance should include:

-

Blade replacement

-

Guide adjustment

-

Coolant cleaning

-

Alignment inspection

-

Hydraulic system check

Alpha offers complete technical support to help customers maintain peak machine performance.

Why Choose Alpha as Your Saw Machine Partner

With years of industry experience, Alpha delivers:

-

Reliable machine quality

-

Professional technical service

-

Customized cutting solutions

-

Global after-sales support

-

Competitive pricing

Our goal is to help every customer achieve:

-

Higher productivity

-

Better cutting quality

-

Lower operating cost

Frequently Asked Questions

Q1: What is a saw machine used for?

A saw machine is used to cut metal bars, pipes, profiles, and plates into required lengths with high accuracy.

Q2: Which saw machine is best for metal cutting?

For most industrial metal cutting tasks, a horizontal band saw machine offers the best combination of accuracy and efficiency.

Q3: How to improve saw machine cutting accuracy?

Improve blade quality, maintain proper tension, ensure stable feeding, and use a rigid, high-quality machine like Alpha saw machines.

Q4: What causes inaccurate cutting in saw machines?

Common reasons include poor blade condition, low machine rigidity, incorrect feed rate, and worn guide systems.

Q5: Is automatic saw machine better than manual saw machine?

Yes. Automatic saw machines provide higher precision, better consistency, and greater production efficiency.

Conclusion – Accuracy Determines the Value of a Saw Machine

In metal processing, cutting is the foundation of all subsequent operations. The accuracy of this first step directly determines final product quality.

A professional industrial saw machine must provide:

-

Stable structure

-

Precise cutting

-

Reliable performance

-

High efficiency

Alpha is committed to delivering high-precision saw machine solutions that help manufacturers upgrade their production capability and compete in global markets.