Hydraulic VR Guillotine Shear – The Importance of Cutting Angle Control

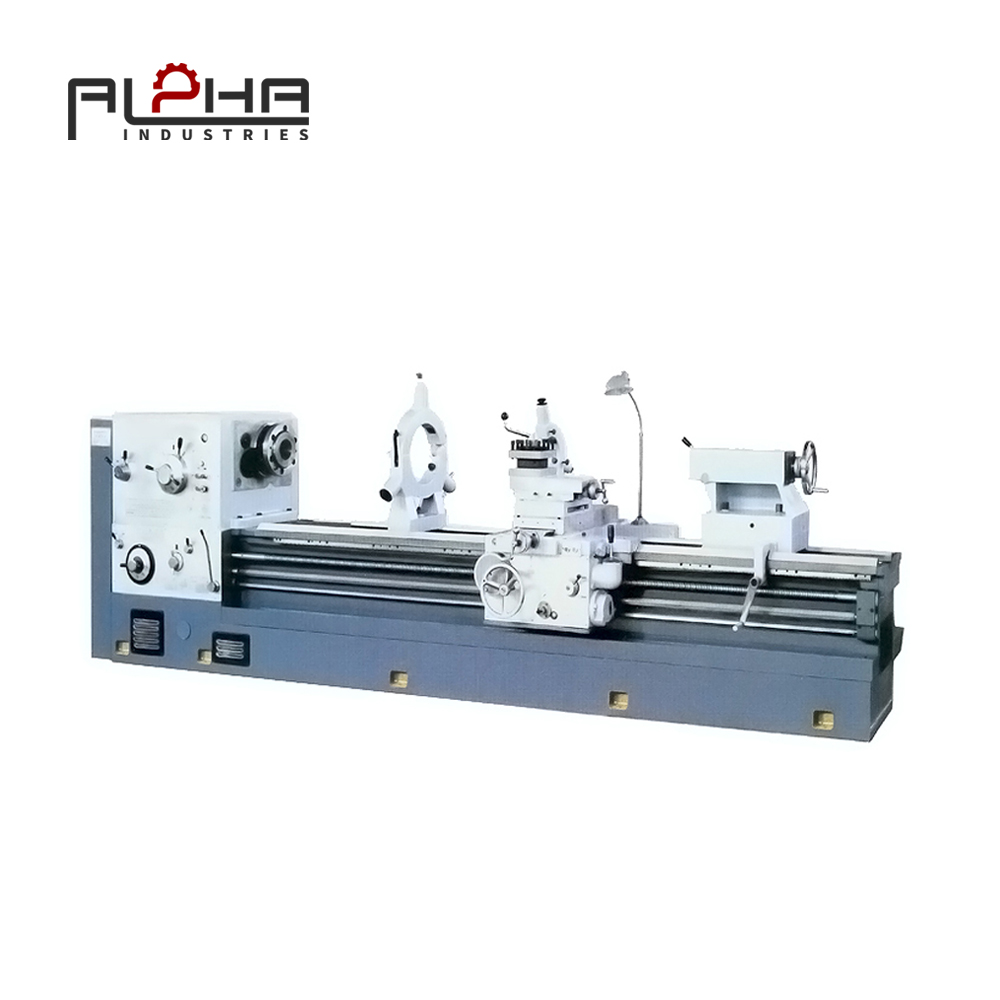

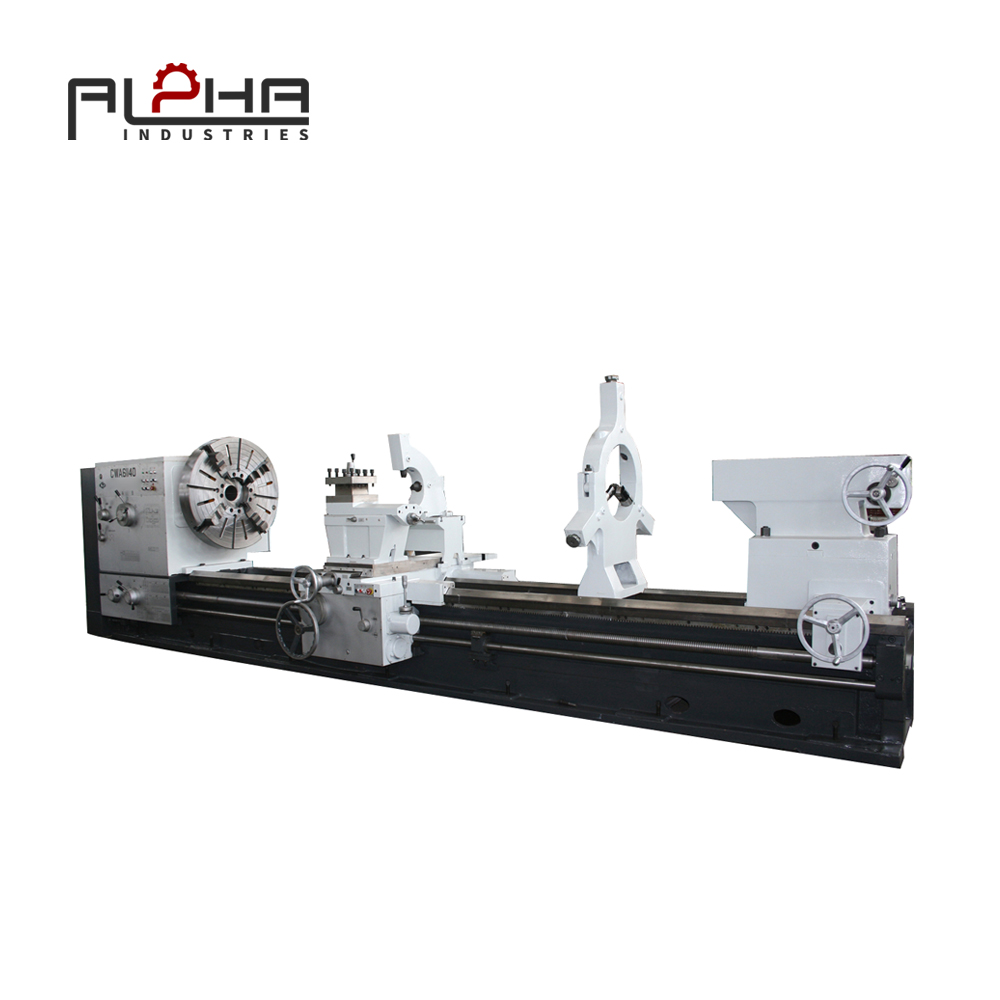

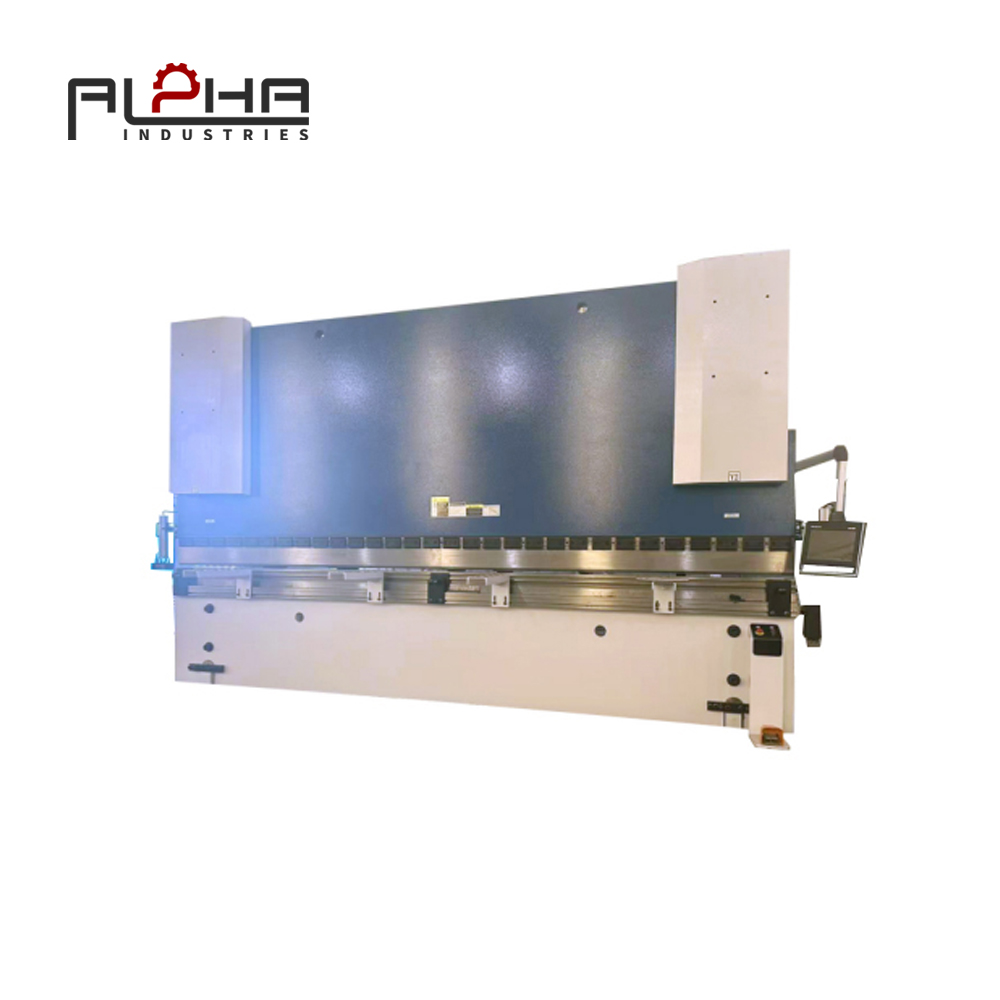

In sheet metal fabrication, the guillotine shear is one of the most essential processing machines. Among different types of shearing equipment, the Hydraulic VR Guillotine Shear stands out because of one critical feature: variable rake angle (VR) control.

While many users focus only on cutting capacity or blade material, the real key to high-quality shearing lies in how accurately the machine can control the cutting angle.

At Alpha, we specialize in manufacturing advanced Hydraulic VR Guillotine Shears designed to deliver precise, efficient, and deformation-free cutting performance.

What Is Cutting Angle in a Guillotine Shear

The cutting angle, also called the rake angle, refers to the angle formed between the upper blade and the lower blade during the shearing process.

This angle directly influences:

-

Cutting force

-

Material deformation

-

Cutting quality

-

Noise level

-

Energy consumption

Traditional guillotine shears usually work with a fixed rake angle. However, different materials and thicknesses require different optimal angles. That is why the variable rake angle system in a Hydraulic VR Guillotine Shear is so important.

Why Cutting Angle Control Is Critical

During sheet metal cutting, the blade presses and separates the material. If the cutting angle is not suitable, several problems may occur:

-

Twisting of the sheet

-

Excessive burrs

-

Uneven cutting edges

-

Increased blade wear

-

Higher cutting resistance

With proper angle control, the machine can adapt to different materials such as:

-

Mild steel

-

Stainless steel

-

Aluminum

-

Copper

-

Galvanized sheets

This adaptability is exactly what makes the Hydraulic VR Guillotine Shear a superior solution for modern workshops.

How Variable Rake Angle Technology Works

A Hydraulic VR Guillotine Shear uses a hydraulic adjustment system to automatically change the cutting angle according to material thickness.

The working principle is simple but powerful:

-

Thin materials require a small cutting angle

-

Thick plates require a larger cutting angle

-

Softer materials need less angle

-

Harder materials need more angle

By optimizing the angle for every job, the machine achieves:

-

Lower cutting force

-

Better edge quality

-

Less distortion

-

Longer blade life

This intelligent adjustment is a major advantage compared with conventional fixed-angle shears.

Technical Benefits of Hydraulic VR Guillotine Shear

Improved Cutting Precision

Accurate angle control allows the blades to penetrate the material more smoothly, resulting in:

-

Straighter cuts

-

Cleaner edges

-

Higher dimensional accuracy

This is especially important for industries that require high-quality finished parts.

Reduced Sheet Deformation

One of the biggest problems in shearing is material distortion after cutting.

The VR system minimizes:

-

Twisting

-

Bending

-

Warping

As a result, parts can often be used directly without secondary straightening processes.

Lower Cutting Force and Energy Saving

When the angle is optimized, the required cutting force becomes significantly lower. This leads to:

-

Reduced hydraulic load

-

Lower power consumption

-

Quieter operation

-

More stable performance

For long-term production, this means real cost savings.

Extended Blade Lifetime

Incorrect cutting angles cause excessive blade friction and impact. With VR technology, blades work under optimal conditions, which provides:

-

Less wear

-

Fewer blade changes

-

Lower maintenance cost

Alpha Hydraulic VR Guillotine Shears are designed to maximize blade efficiency and service life.

Industries That Benefit from VR Guillotine Shears

The cutting angle control function is especially valuable in:

-

Metal fabrication workshops

-

HVAC duct manufacturing

-

Automotive parts production

-

Electrical cabinet making

-

Construction machinery

-

General sheet metal processing

Any industry that handles multiple material types and thicknesses will gain significant advantages from a Hydraulic VR Guillotine Shear.

Alpha Hydraulic VR Guillotine Shear – Professional Design

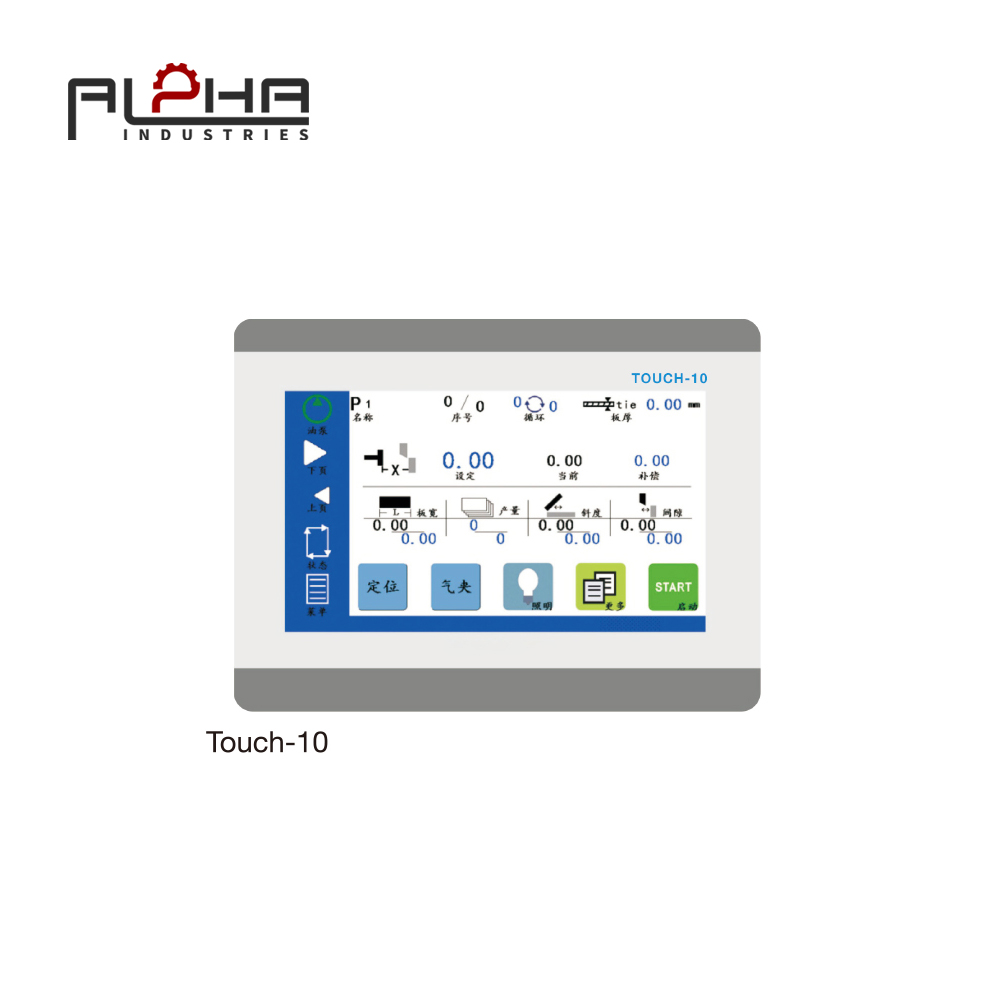

Alpha integrates advanced technology into every Hydraulic VR Guillotine Shear, including:

-

High-precision hydraulic angle adjustment

-

Strong welded frame structure

-

CNC-controlled back gauge

-

Premium quality blades

-

Reliable hydraulic components

-

User-friendly control systems

These features ensure that every Alpha shear machine delivers consistent, professional cutting results.

How to Choose the Right Guillotine Shear

When selecting a shearing machine, many buyers only look at:

-

Maximum cutting thickness

-

Motor power

-

Price

However, the most important factor should be:

👉 Whether the machine has reliable cutting angle control

A Hydraulic VR Guillotine Shear with adjustable rake angle will always outperform a standard fixed-angle shear in terms of quality, efficiency, and versatility.

Alpha provides professional consultation to help customers choose the most suitable model according to their actual production needs.

FAQ

What is a Hydraulic VR Guillotine Shear?

It is a hydraulic guillotine shearing machine equipped with variable rake angle control for optimized cutting performance.

Why is cutting angle important in shearing?

Because the cutting angle directly affects cutting force, edge quality, deformation, and blade life.

What materials can a VR Guillotine Shear cut?

It can cut carbon steel, stainless steel, aluminum, copper, and many other sheet metals.

Does variable angle control improve cutting quality?

Yes. Proper angle adjustment reduces distortion and produces cleaner, straighter cuts.

Are Alpha Hydraulic VR Guillotine Shears suitable for heavy-duty work?

Yes. Alpha machines are engineered for industrial-grade, continuous production environments.

Conclusion – Cutting Angle Determines Shearing Quality

In sheet metal cutting, the true performance of a guillotine shear is not only about tonnage or blade length. The decisive factor is how intelligently the machine controls the cutting angle.

A Hydraulic VR Guillotine Shear with accurate rake angle adjustment provides:

-

Higher cutting precision

-

Better edge quality

-

Lower deformation

-

Reduced energy consumption

-

Longer blade life

That is why Alpha focuses on advanced VR technology to deliver professional and reliable shearing solutions for global customers.

If you are looking for a high-performance Hydraulic VR Guillotine Shear for precise and efficient sheet metal cutting, Alpha is your ideal partner.

Get expert support and quotation: Contact Us – Alpha