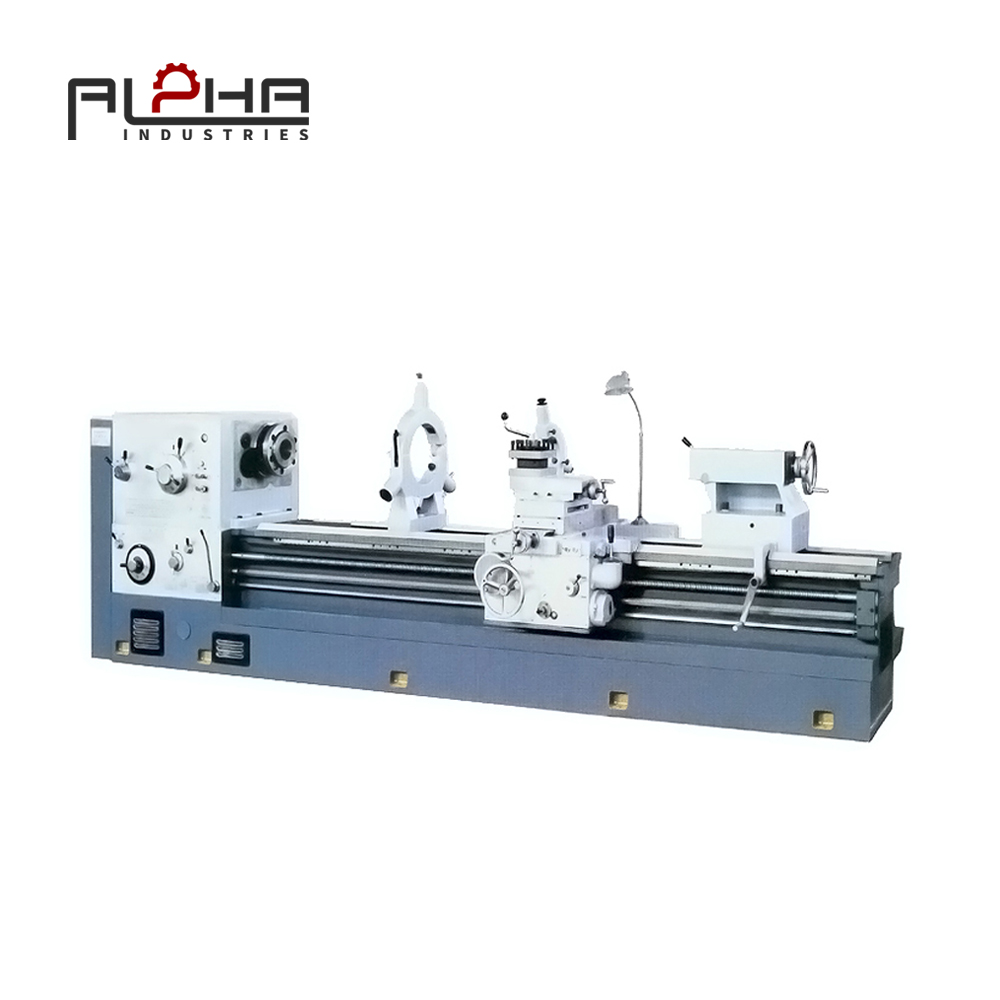

Lathe Spindle Accuracy – The Core of Precision Machining

In the field of metal processing, a lathe machine is one of the most widely used pieces of equipment. Among all technical parameters of a lathe, there is one element that directly determines machining results more than any other: spindle accuracy.

No matter how advanced the control system is, or how powerful the motor becomes, the final machining quality of a lathe machine ultimately depends on how precise and stable the spindle performs.

At Alpha, spindle accuracy is treated as the heart of every lathe machine we design and manufacture.

What Is Lathe Spindle Accuracy

Spindle accuracy refers to the rotational precision of the main spindle during operation. It is normally evaluated through:

-

Radial runout

-

Axial runout

-

Bearing precision

-

Rotational stability

-

Thermal deformation control

These factors together determine whether a lathe can produce truly accurate parts or only approximate results.

A high-accuracy spindle ensures that the cutting tool follows a perfectly stable path relative to the workpiece. Even a tiny deviation at the spindle will be magnified on the final machined component.

Why Spindle Accuracy Is So Important

In real production environments, spindle accuracy directly affects several critical aspects:

-

Dimensional tolerance of parts

-

Surface roughness quality

-

Roundness and cylindricity

-

Tool life

-

Cutting vibration

-

Scrap rate

For industries such as aerospace, automotive, medical devices, and precision instruments, even a few microns of error can lead to part rejection.

That is why professional users always evaluate a lathe machine primarily by its spindle performance rather than by appearance or optional functions.

Key Factors That Determine Spindle Accuracy

Spindle Bearing Quality

The bearing system is the foundation of spindle precision. High-grade angular contact bearings or roller bearings ensure:

-

Smooth rotation

-

Minimal clearance

-

High load capacity

-

Long-term stability

Alpha lathe machines adopt world-class precision spindle bearings to guarantee consistent machining accuracy.

Spindle Manufacturing Process

Even with good bearings, poor spindle manufacturing will still cause inaccuracy.

High spindle accuracy requires:

-

Precision grinding

-

Dynamic balancing

-

Strict tolerance control

-

Professional assembly process

At Alpha, every spindle goes through multi-stage inspection before installation.

Thermal Stability

During long hours of machining, heat generation can cause spindle expansion and deformation. This thermal effect is one of the main enemies of accuracy.

Professional lathe machines must include:

-

Optimized lubrication systems

-

Heat dissipation design

-

Temperature control mechanisms

Alpha lathe machines are engineered to minimize thermal influence and maintain stable accuracy even in continuous production.

Assembly and Alignment

Even the best components cannot perform well without proper assembly.

Spindle accuracy depends heavily on:

-

Precise installation

-

Professional alignment

-

Strict quality inspection

This is why Alpha applies rigorous assembly standards to every lathe machine before delivery.

How Spindle Accuracy Improves Machining Performance

When a lathe machine has excellent spindle accuracy, manufacturers can achieve:

-

Higher dimensional precision

-

Better surface finish

-

Reduced vibration

-

Longer tool life

-

Faster cutting speeds

-

More stable batch production

In short, spindle accuracy is directly connected to productivity and profitability.

Typical Problems Caused by Poor Spindle Accuracy

If spindle accuracy is not sufficient, users will often experience:

-

Oval or tapered parts

-

Rough surface texture

-

Unstable cutting noise

-

Rapid tool wear

-

Inconsistent product quality

These issues increase production cost and reduce customer satisfaction. Choosing a lathe with high spindle precision is therefore a long-term investment decision.

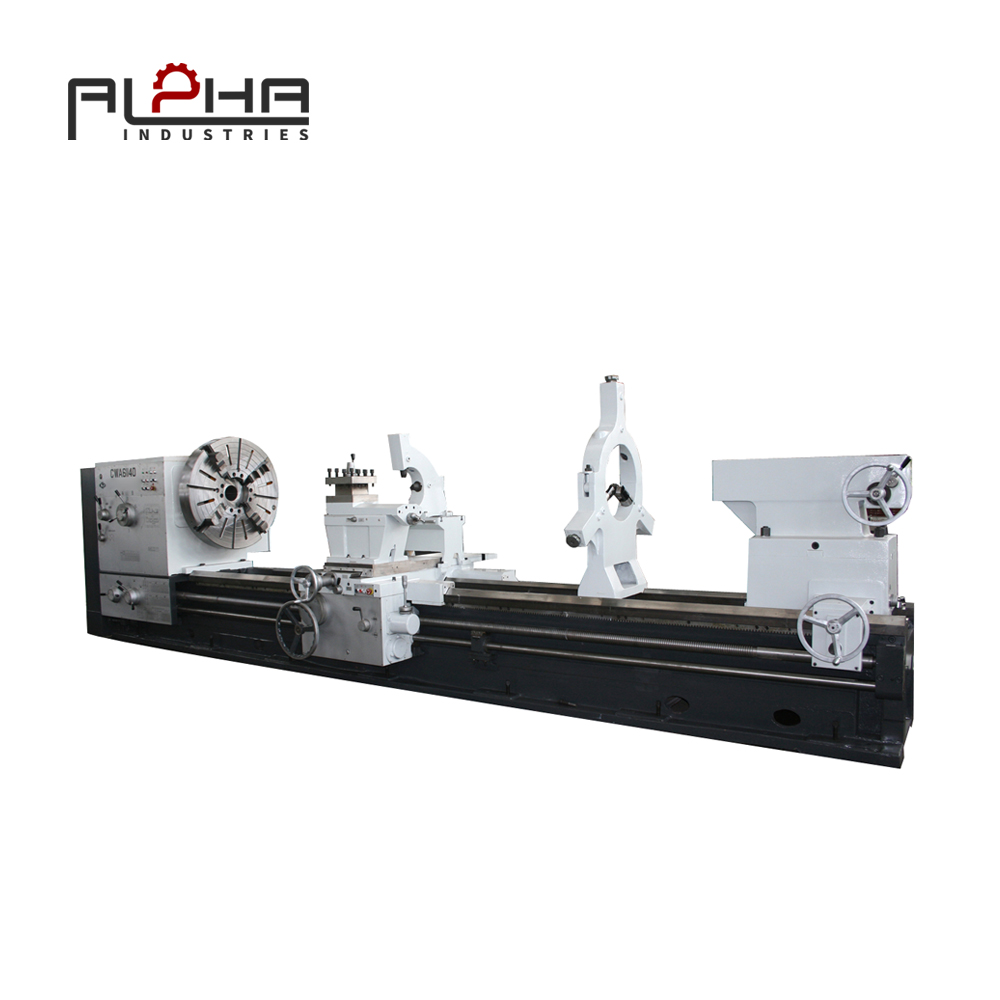

Alpha Lathe Machines – Built for Precision

Alpha places spindle accuracy at the center of lathe machine development.

Our technical advantages include:

-

High-precision spindle manufacturing

-

Premium grade bearings

-

Dynamic balancing technology

-

Professional assembly standards

-

Strict quality control system

Every Alpha lathe machine is tested for runout, vibration, and stability before leaving the factory, ensuring that customers receive equipment capable of real precision turning.

Industries That Rely on High Spindle Accuracy

High spindle accuracy is especially critical for:

-

Aerospace components

-

Automotive shafts and gears

-

Hydraulic and pneumatic parts

-

Mold and die manufacturing

-

Precision mechanical engineering

-

Medical equipment components

For these applications, an accurate and reliable spindle is not a luxury – it is a necessity.

How to Choose a Lathe with High Spindle Precision

When selecting a lathe machine, professional buyers should evaluate:

-

Spindle runout data

-

Bearing brand and grade

-

Assembly process

-

Machine testing reports

-

Real machining samples

Price alone should never be the main criterion. A cheaper lathe with low spindle accuracy will ultimately cost far more in production losses.

Alpha provides full technical consultation to help customers choose the most suitable lathe machine according to their precision requirements.

FAQ

What is spindle accuracy in a lathe machine?

Spindle accuracy refers to the rotational precision and stability of the spindle, usually measured by radial and axial runout.

Why does spindle accuracy affect machining quality?

Because any error in spindle rotation is directly transferred to the workpiece, influencing dimension, roundness, and surface finish.

How is spindle accuracy measured?

It is tested using precision instruments to measure runout, vibration, and thermal stability under working conditions.

Can spindle accuracy decrease over time?

Yes. Poor maintenance, bearing wear, or overheating can reduce accuracy. Regular maintenance is essential.

Are Alpha lathe machines suitable for high-precision machining?

Yes. Alpha lathe machines are designed with high-precision spindles specifically for demanding industrial applications.

Conclusion – Spindle Accuracy Defines Lathe Value

Among all technical indicators of a lathe machine, spindle accuracy is the true foundation of precision turning.

A lathe with superior spindle performance provides:

-

Reliable machining accuracy

-

Excellent surface quality

-

Higher efficiency

-

Lower scrap rate

-

Long-term stability

This is why Alpha continuously invests in spindle technology and precision manufacturing processes.

If you are searching for a professional lathe machine capable of real high-precision turning, Alpha is ready to support your production goals.

Explore our complete product range: Lathe Machines – Alpha

Get expert consultation and quotation: Contact Us – Alpha