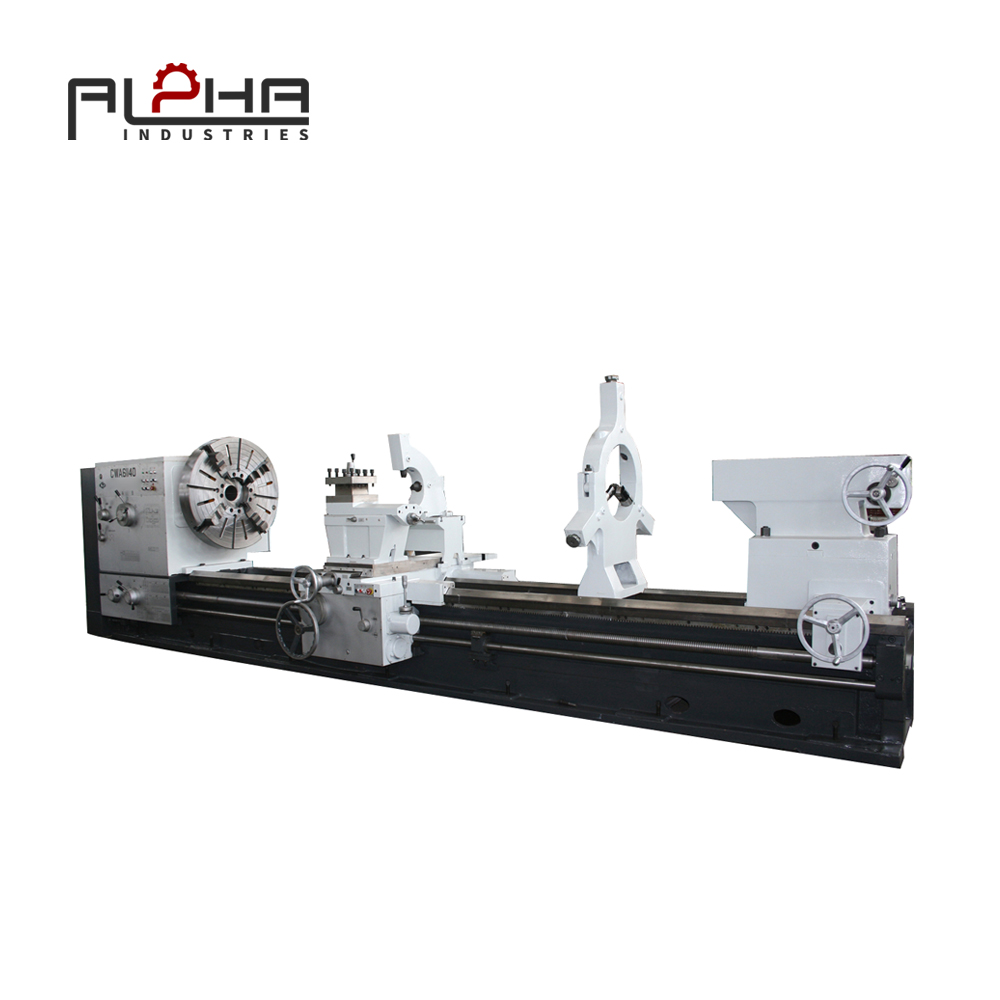

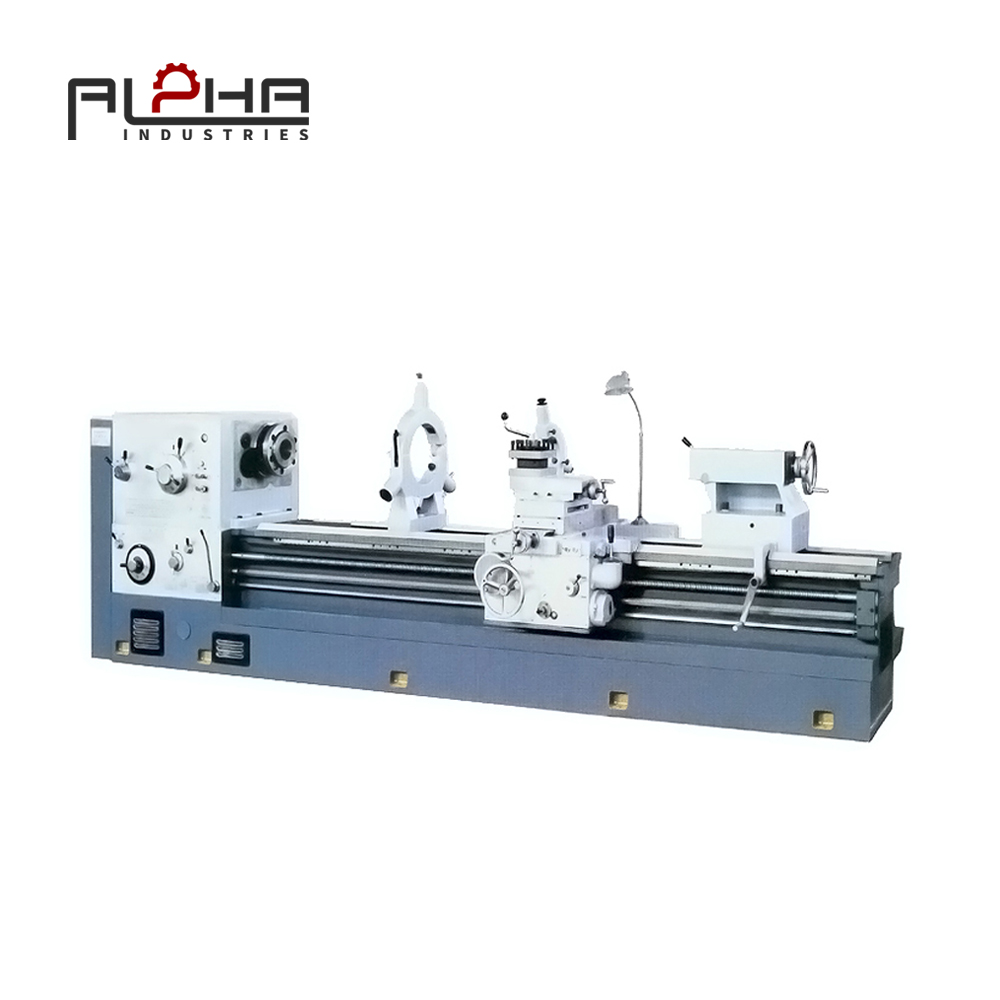

Lathe Machine Rigidity – The Foundation of Accurate Turning

In modern metal processing, the performance of a lathe machine is evaluated by more than just spindle power or control systems. The most fundamental element that determines machining results is machine rigidity.

Whether it is a conventional lathe or a CNC lathe, rigidity directly influences dimensional accuracy, surface finish, tool life, cutting stability, and long-term reliability.

At Alpha, we focus on designing and manufacturing high-rigidity lathe machines that deliver consistent turning performance for global industrial users.

Why Rigidity Matters in Lathe Machining

During turning operations, the cutting tool applies continuous force to the workpiece. This force generates vibration, deformation, and thermal effects. If the lathe structure lacks sufficient rigidity, several problems occur:

-

Unstable cutting

-

Dimensional deviation

-

Poor surface roughness

-

Chatter marks

-

Reduced tool lifespan

Rigidity is therefore not an optional feature—it is the core engineering principle of any professional lathe machine.

Key Structural Factors That Influence Lathe Rigidity

Machine Bed Design

The bed is the backbone of the lathe machine. A high-quality lathe bed must have heavy-duty cast iron structure, reinforced ribbing design, stress-relief treatment, and precision grinding.

Alpha lathe machines adopt high-strength Meehanite cast iron beds, providing excellent vibration damping and deformation resistance.

Headstock Stability

The headstock houses the spindle system. Any weakness here directly affects machining accuracy.

Critical elements include rigid spindle box design, high-precision bearings, balanced rotating components, and thermal stability. A stable headstock ensures that the spindle maintains concentric rotation even under heavy cutting loads.

Carriage and Slideway Strength

The carriage and slideways guide the movement of cutting tools. Insufficient rigidity in this area causes tool deflection, positioning errors, and inconsistent cutting depth.

Alpha lathe machines utilize hardened and precision-ground guideways to maintain long-term geometric accuracy.

Tailstock and Workpiece Support

For long shaft turning, the tailstock provides essential support. A weak tailstock system leads to bending deformation, taper errors, and poor surface finish. Proper rigidity in the tailstock structure is crucial for high-precision turning.

The Relationship Between Rigidity and Machining Accuracy

High rigidity in a lathe machine directly results in more stable dimensional tolerance, smoother surface finish, significantly reduced cutting vibration, extended tool life, and improved production efficiency.

In real production environments, rigidity is the difference between acceptable parts and truly precise parts.

How Alpha Ensures Superior Lathe Machine Rigidity

At Alpha, rigidity is built into every stage of lathe machine manufacturing:

-

Finite element structural analysis

-

Optimized casting design

-

Multi-stage heat treatment

-

Precision assembly process

-

Strict quality inspection

This systematic approach allows our lathe machines to deliver stable heavy cutting, high-precision turning, long-term durability, and minimal maintenance requirements.

Applications That Require High-Rigidity Lathe Machines

Industries that particularly benefit from rigid lathe machines include aerospace components, automotive parts, mold and die manufacturing, hydraulic cylinders, heavy machinery shafts, and precision mechanical parts.

In these fields, even microns of error can cause major quality problems. That is why rigidity is essential.

Choosing the Right Lathe Machine for Precision Turning

When selecting a lathe machine, buyers often focus on price, control system, or motor power. However, the most important evaluation criterion should always be structural rigidity.

A lathe with strong rigidity will consistently outperform a higher-spec machine with a weak structure. Alpha provides professional guidance to help customers select the most suitable lathe solution for their actual machining tasks.

FAQ

Why is rigidity important in a lathe machine?

Rigidity prevents vibration and deformation during cutting, ensuring better machining accuracy and surface quality.

What affects the rigidity of a lathe machine?

Main factors include the machine bed structure, spindle system, slideways, carriage design, and overall assembly precision.

Can poor rigidity damage machining quality?

Yes. Low rigidity leads to chatter, dimensional errors, poor surface finish, and shortened tool life.

How can I identify a high-rigidity lathe?

Look for heavy cast iron construction, reinforced bed design, precision guideways, and stable spindle bearings.

Are Alpha lathe machines suitable for heavy-duty turning?

Yes. Alpha lathe machines are engineered with high-rigidity structures specifically for stable heavy cutting.

Conclusion – Rigidity Defines Lathe Performance

In lathe machining, true performance is not only about speed or automation. It is fundamentally about how rigid and stable the machine structure is.

A rigid lathe machine delivers higher accuracy, better surface quality, greater efficiency, and longer service life. That is why Alpha always places structural rigidity at the center of lathe machine design and manufacturing.

If you are looking for a professional, high-rigidity lathe machine for reliable precision turning, Alpha is your trusted partner.

View full product categories: Lathe Machines – Alpha

Get expert support and quotation: Contact Us – Alpha

👉 Contact us for customized lathe machine solutions:

https://alpha-cnc.com/contact-us