Milling Machine Spindle Accuracy – The Core of High-Quality Machining

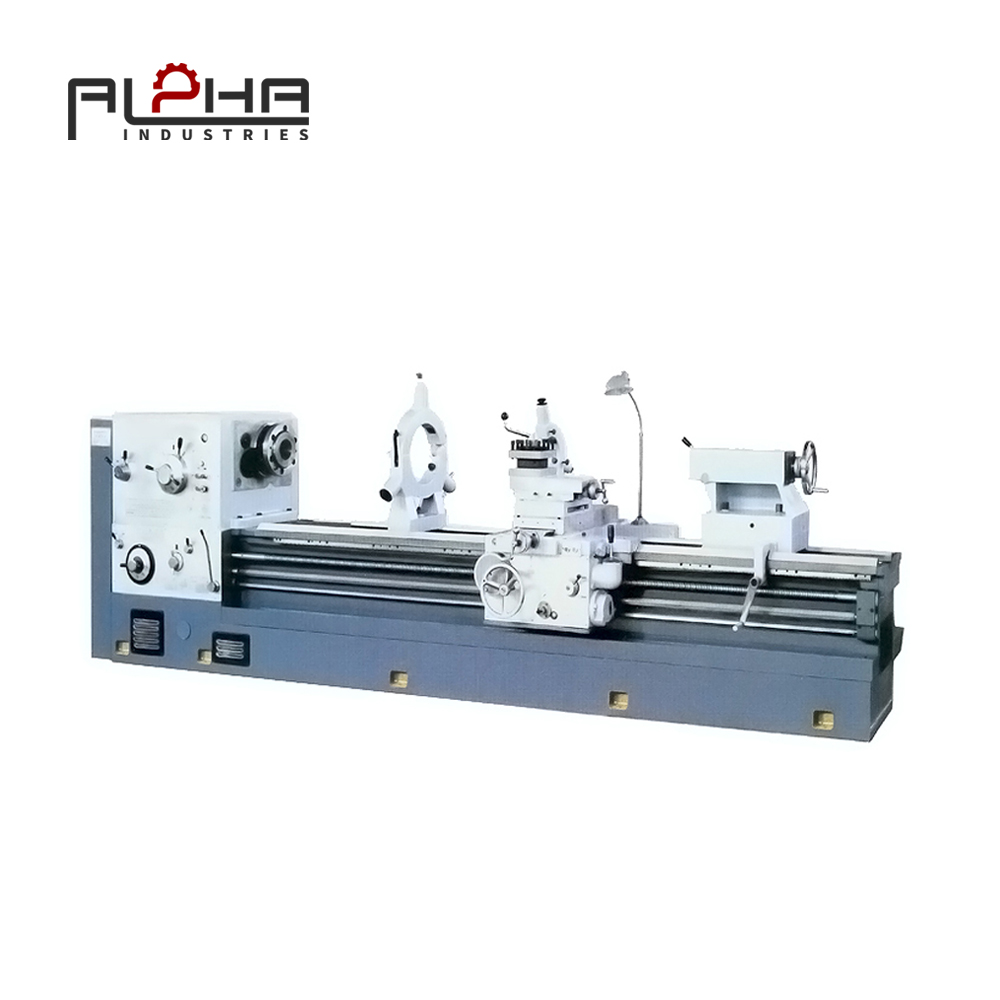

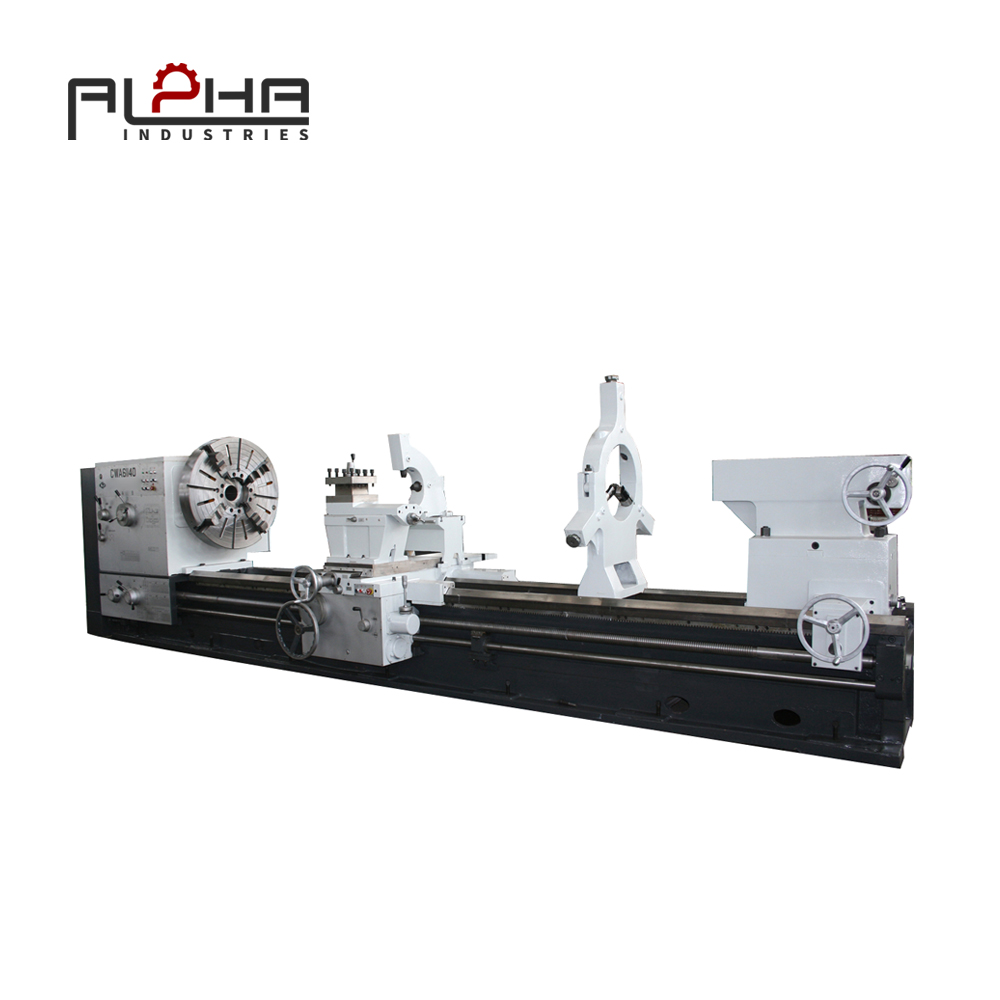

In modern metalworking industries, the milling machine is one of the most fundamental and versatile production tools. From aerospace components to automotive parts and mold manufacturing, almost every precision part is produced or finished on a milling platform.

However, when users evaluate a milling machine, they often focus on power, travel size, or control system, while ignoring one critical element — spindle accuracy. In reality, spindle precision is the true heart of any milling machine and directly determines machining quality, efficiency, and long-term stability.

At Alpha, we believe that improving spindle accuracy is the most effective way to enhance overall machining performance.

Why Spindle Accuracy Matters in a Milling Machine

The spindle is the core rotating component of a milling machine. All cutting tools are mounted on the spindle, and every cutting force is transmitted through it. Even the most advanced CNC system cannot compensate for poor spindle precision.

Spindle accuracy mainly affects:

-

Machining dimensional tolerance

-

Surface roughness

-

Tool vibration

-

Tool life

-

Repeatability

-

Long-term machine stability

If the spindle has excessive runout or poor rigidity, the milling machine will produce inaccurate parts, regardless of program quality or operator skill.

Understanding Spindle Runout

One of the most important indicators of spindle accuracy is spindle runout.

Spindle runout refers to the amount of deviation from the ideal rotational axis when the spindle rotates. In a high-quality milling machine, this value should be extremely small — usually within microns.

Typical problems caused by excessive spindle runout include:

-

Irregular cutting marks

-

Poor surface finish

-

Unstable cutting noise

-

Rapid tool wear

-

Difficulty holding tight tolerances

For precision industries, even a small runout error can lead to scrapped parts and increased production costs.

Key Factors Influencing Milling Machine Spindle Accuracy

Spindle accuracy is not determined by a single component. It is the result of multiple engineering factors working together.

(1) Bearing Quality

High-grade angular contact bearings are essential for maintaining stable rotation at high speed. Inferior bearings quickly lose precision.

(2) Spindle Material and Heat Treatment

Thermal deformation is one of the biggest enemies of precision. A properly heat-treated spindle shaft resists distortion and maintains alignment.

(3) Assembly Process

Even the best components will fail without professional assembly. Precision fitting, balancing, and alignment are critical.

(4) Cooling and Lubrication System

Temperature rise directly affects spindle expansion. A well-designed cooling system ensures long-term accuracy.

(5) Machine Structure Rigidity

The overall rigidity of the milling machine body supports spindle performance. Weak structures amplify vibration and reduce accuracy.

At Alpha, all these elements are strictly controlled to guarantee stable and reliable spindle performance.

How Alpha Ensures High Spindle Precision

As a professional machinery manufacturer, Alpha designs milling machines with accuracy as the first priority.

Our technical advantages include:

-

Precision-class spindle bearings

-

Dynamic balancing testing for every spindle

-

Advanced thermal compensation design

-

Rigid machine frame structure

-

Strict quality inspection procedures

-

Professional installation and calibration

Every Alpha milling machine is tested before delivery to ensure spindle runout is within strict tolerance standards.

The Relationship Between Spindle Accuracy and Surface Quality

Surface finish is often the first visible sign of spindle performance.

With high spindle precision:

-

Cutting marks are uniform

-

Surface roughness is significantly reduced

-

Micro-vibration is minimized

-

Post-processing requirements decrease

This not only improves product quality but also reduces the need for secondary grinding or polishing operations.

Extending Tool Life Through Better Spindle Accuracy

Another major benefit of precise spindle performance is longer tool life.

When spindle runout is minimal:

-

Cutting forces are evenly distributed

-

Tool edges experience less impact

-

Heat generation is reduced

-

Tools maintain sharpness longer

For manufacturers running large-volume production, this directly translates into major cost savings.

Maintenance Tips to Protect Spindle Accuracy

Even the best milling machine requires proper maintenance to maintain spindle precision.

Recommended practices include:

-

Regular spindle runout inspection

-

Proper lubrication management

-

Avoiding overload cutting

-

Keeping coolant clean

-

Monitoring temperature changes

-

Periodic professional calibration

These steps help ensure your milling machine delivers stable performance for years.

Applications Requiring High Spindle Precision

Industries that rely heavily on spindle accuracy include:

-

Aerospace machining

-

Medical equipment

-

Precision molds

-

Automotive components

-

Electronic parts

-

High-precision fixtures

In these fields, a high-quality milling machine is not optional — it is essential.

Frequently Asked Questions

Q1: What is spindle accuracy in a milling machine?

Spindle accuracy refers to how precisely the spindle rotates around its central axis, usually measured as runout in microns.

Q2: How does spindle runout affect machining?

Excessive runout leads to vibration, poor surface finish, inaccurate dimensions, and faster tool wear.

Q3: What is a good spindle runout value?

For precision milling machines, spindle runout should generally be within 0.002–0.005 mm.

Q4: Can spindle accuracy be improved after purchase?

Yes, through professional adjustment, bearing replacement, and proper maintenance.

Q5: Why choose Alpha milling machines?

Alpha milling machines are engineered with high-precision spindles, rigid structures, and strict quality control for reliable performance.

Conclusion

When selecting a milling machine, many technical parameters are important, but spindle accuracy is the true foundation of machining quality.

A machine with high power but poor spindle precision will never produce stable, high-quality results. That is why Alpha focuses on engineering every milling machine around a reliable, accurate, and durable spindle system.

If you are looking for a professional milling machine solution to improve production accuracy and efficiency, Alpha is ready to support your business.

Explore our full product range: Alpha Industrial Machinery

Need technical support or a quotation? Contact Us