Belt Sander Machine – The Core of Efficient Metal Surface Finishing

In modern metal fabrication, machining processes such as cutting, welding, and forming are only the first steps in creating high-quality products. After these operations, most metal parts require further treatment to achieve smooth surfaces, uniform textures, and precise dimensions. This is where the belt sander machine becomes indispensable.

Among all surface finishing technologies, belt sanding is recognized as one of the most efficient, flexible, and cost-effective methods. For manufacturers seeking higher productivity and better product appearance, investing in a professional belt sander machine is a critical decision.

At Alpha, we focus on delivering high-performance belt sanding solutions that help industries optimize their finishing processes and achieve superior results.

What Is a Belt Sander Machine?

A belt sander machine is an industrial grinding and polishing system that uses a continuous abrasive belt to process the surface of metal parts.

Unlike traditional grinding wheels, abrasive belts provide:

-

Larger contact area

-

More uniform finishing

-

Faster material removal

-

Lower heat generation

-

Better surface consistency

This makes belt sanders ideal for applications such as:

-

Surface deburring

-

Edge rounding

-

Weld seam grinding

-

Surface polishing

-

Oxide layer removal

For sheet metal, tubes, profiles, and structural parts, the belt sander machine is often the most practical finishing solution.

Why Belt Sander Machines Are Essential in Metalworking

Many manufacturers underestimate the importance of surface finishing. However, poor surface quality can directly affect:

-

Product appearance

-

Coating adhesion

-

Assembly precision

-

Corrosion resistance

-

Customer satisfaction

A properly selected belt sander machine solves these problems by providing stable and repeatable finishing performance.

Key benefits include:

-

Improved product aesthetics

-

Reduced manual labor

-

Faster production cycles

-

Higher consistency

-

Lower rework rates

For companies focused on efficiency and quality, belt sanding is not optional—it is a core production process.

How Belt Sanding Technology Works

The working principle of a belt sander machine is relatively simple but highly effective.

An abrasive belt rotates at high speed over contact wheels and tension rollers. When a metal part is pressed against the belt, material is gradually removed in a controlled manner.

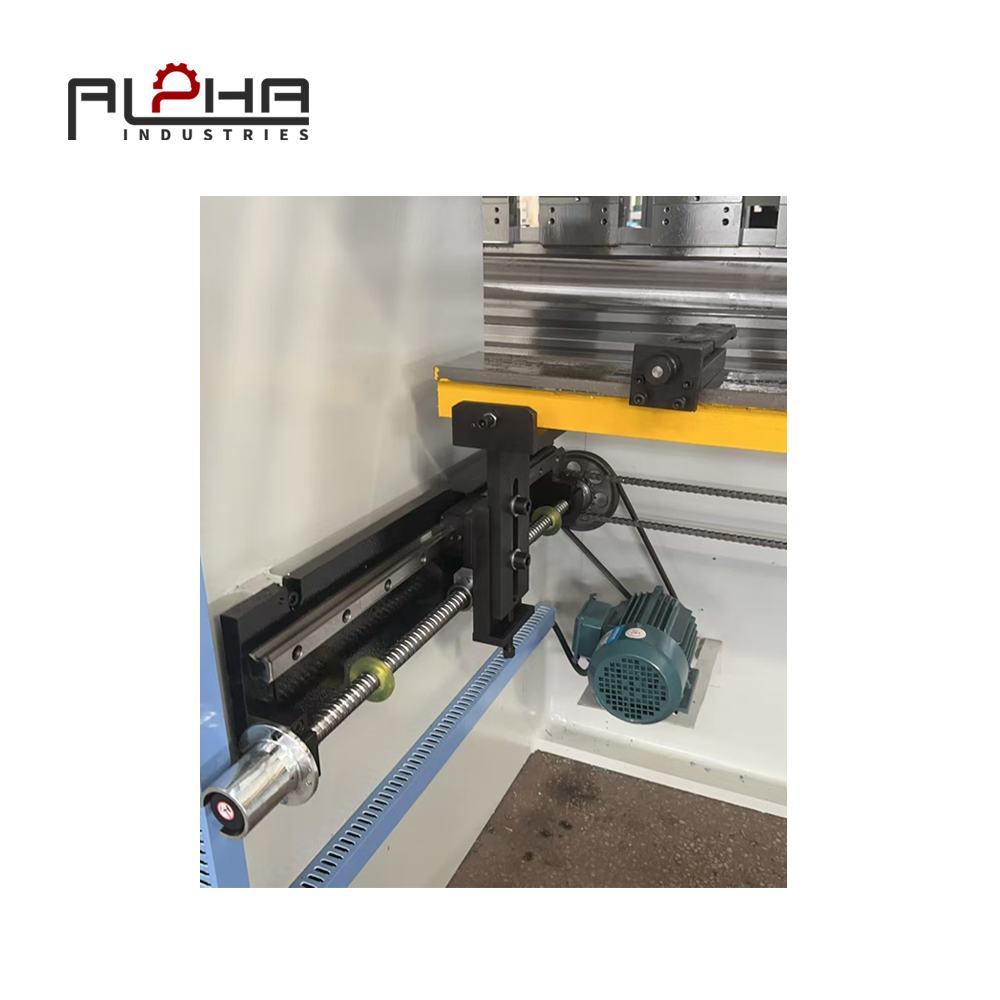

Main components include:

-

Abrasive belt

-

Drive motor

-

Contact wheel

-

Conveyor system

-

Pressure control unit

-

Dust extraction system

By adjusting belt grit, speed, and pressure, operators can achieve different surface results ranging from rough grinding to fine polishing.

Key Factors That Determine Belt Sanding Quality

To achieve optimal results, several technical factors must be carefully controlled:

(1) Abrasive Belt Selection

Different materials require different abrasive types and grit sizes.

(2) Belt Speed

Higher speed improves efficiency but must match material hardness.

(3) Contact Pressure

Excessive pressure may deform parts; insufficient pressure reduces effect.

(4) Machine Stability

Rigid machine structure ensures uniform surface finish.

(5) Dust Extraction

Effective dust removal protects both operators and machine components.

At Alpha, all these elements are optimized in our belt sander designs.

Applications of Belt Sander Machines

Belt sanders are widely used in multiple industries:

-

Sheet metal fabrication

-

Stainless steel processing

-

Automotive parts

-

Construction hardware

-

Furniture manufacturing

-

Elevator components

-

Kitchen equipment

-

Aerospace parts

Wherever metal surfaces require professional finishing, belt sanding technology plays a vital role.

Manual Grinding vs. Belt Sander Machine

Many workshops still rely on manual grinding. However, compared with a professional belt sander machine, manual processing has clear disadvantages:

| Factor | Manual Grinding | Belt Sander Machine |

|---|---|---|

| Efficiency | Low | High |

| Consistency | Poor | Excellent |

| Labor cost | High | Low |

| Surface quality | Unstable | Uniform |

| Safety | Risky | Safer |

For growing manufacturers, upgrading to automated belt sanding is a necessary step toward modernization.

How Alpha Belt Sander Machines Improve Productivity

Alpha designs belt sanding machines specifically for industrial users with demanding requirements.

Our advantages include:

-

Heavy-duty machine frame

-

Adjustable processing parameters

-

High-quality drive systems

-

Stable belt tracking

-

Easy maintenance

-

Long service life

With Alpha belt sander machines, customers can achieve:

-

Faster finishing speed

-

Lower production cost

-

More stable quality

-

Cleaner working environment

Choosing the Right Belt Sander Machine

Selecting the correct machine depends on several factors:

-

Part material

-

Part size

-

Required surface roughness

-

Production volume

-

Available workspace

Alpha provides professional consultation to help customers choose the most suitable belt sanding solution.

Future Trends of Belt Sanding Technology

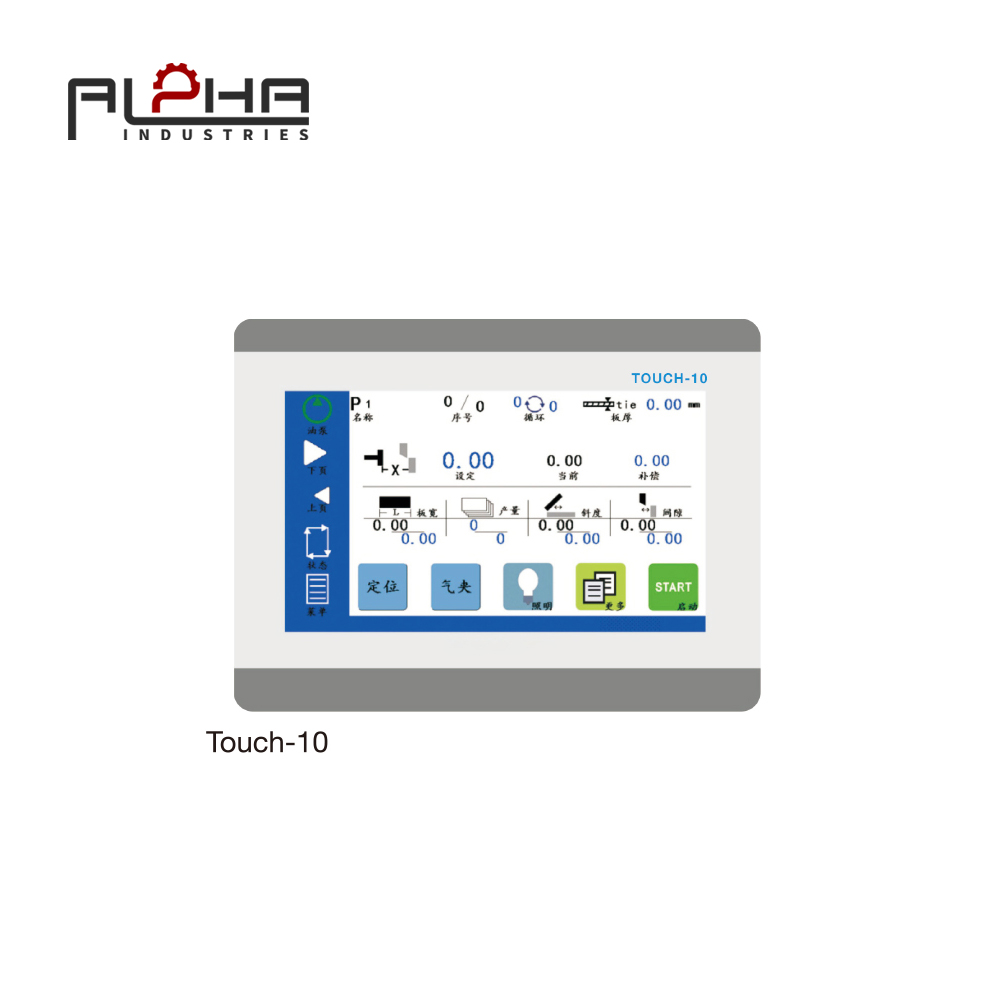

With Industry 4.0 and smart manufacturing development, belt sander machines are evolving toward:

-

Automated production lines

-

Robotic loading systems

-

Intelligent pressure control

-

Digital parameter storage

-

Higher energy efficiency

Alpha continues to innovate to ensure our customers stay competitive in modern manufacturing.

Frequently Asked Questions

Q1: What is a belt sander machine used for?

A belt sander machine is used for grinding, polishing, deburring, and finishing metal surfaces to achieve smooth and uniform results.

Q2: Why choose belt sanding instead of grinding wheels?

Belt sanding offers larger contact area, more consistent finishing, lower heat, and higher efficiency than traditional grinding wheels.

Q3: Can a belt sander machine process different metals?

Yes. With the correct abrasive belt, it can process steel, stainless steel, aluminum, and many other materials.

Q4: Is belt sanding suitable for mass production?

Absolutely. Belt sander machines are ideal for continuous, high-volume industrial production.

Q5: How to select the right belt grit?

Coarse grit is used for heavy material removal, while fine grit is used for polishing and final finishing.

Conclusion

In metal fabrication, product quality is not only determined by cutting or forming accuracy but also by surface finishing results. The belt sander machine is one of the most effective tools to achieve:

-

High-efficiency grinding

-

Uniform surface texture

-

Stable processing quality

-

Lower labor dependency

-

Better final product value

For manufacturers aiming to upgrade their finishing processes, a professional belt sander machine is a powerful investment.

At Alpha, we are committed to providing reliable, durable, and high-performance belt sanding equipment to help global customers improve productivity and competitiveness.

Explore More Solutions

Learn more about our industrial machinery:

👉 Alpha Industrial Machinery