Radial Drilling Machine Precision Control – The Core of Efficient Hole Processing

In modern metalworking workshops, the radial drilling machine plays a vital role in hole machining. From heavy machinery parts to structural steel components, accurate drilling directly determines the quality of the final product. Among many performance indicators of a radial drilling machine, processing precision is the most critical factor.

This article focuses on one core topic:

How to effectively control and improve the machining precision of a radial drilling machine

Why Precision Is So Important in Radial Drilling Machine Operations

The radial drilling machine is widely used for drilling, reaming, tapping, and boring operations. Unlike small bench drills, it is designed for large and heavy workpieces. Therefore, even a slight deviation can cause:

-

Misalignment of holes

-

Assembly difficulties

-

Excessive vibration

-

Tool wear

-

Rework or scrap

For industries such as automotive, construction machinery, mold making, and shipbuilding, drilling accuracy is directly related to product reliability. That is why choosing a high-quality radial drilling machine and using it correctly is essential.

Key Structural Factors Affecting Drilling Precision

A radial drilling machine mainly consists of:

-

Base

-

Column

-

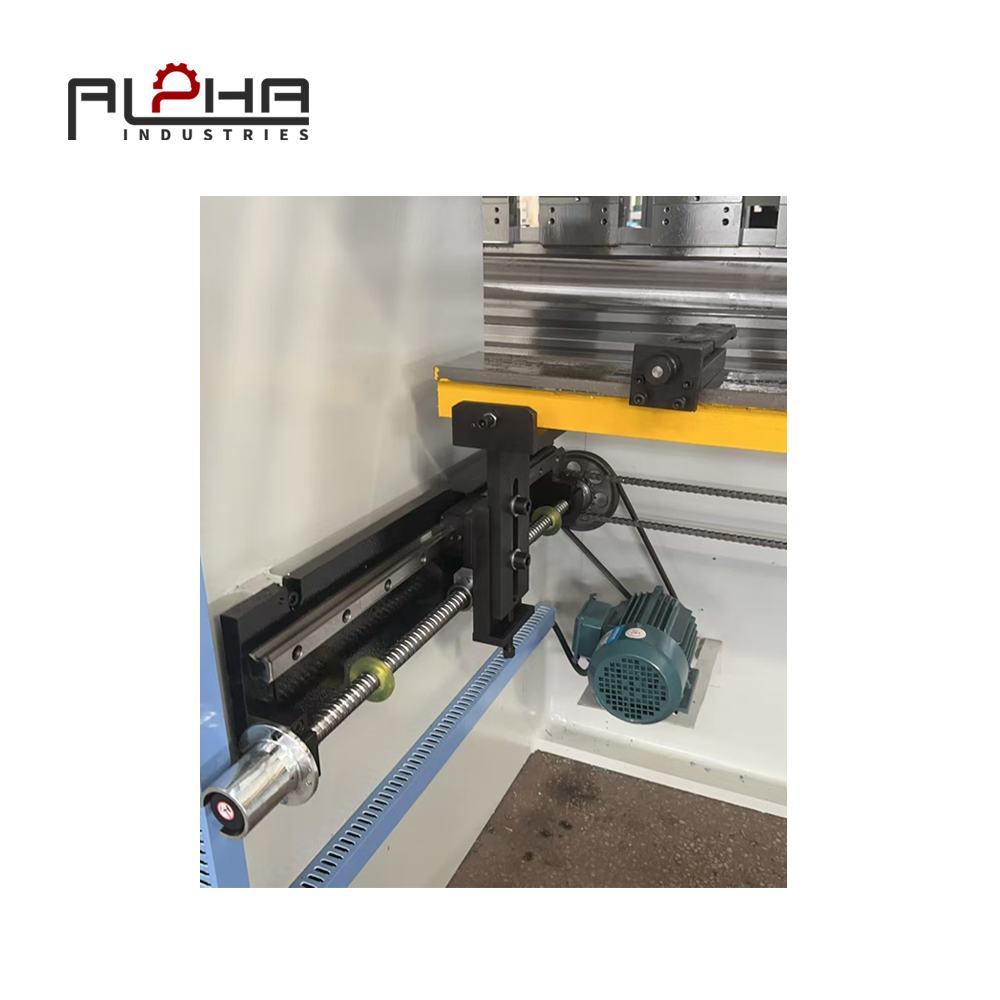

Radial arm

-

Spindle box

-

Spindle system

-

Feed system

Each component has a direct impact on machining accuracy.

Spindle System Stability

The spindle is the heart of the radial drilling machine. Its rigidity and rotational stability determine:

-

Hole roundness

-

Surface finish

-

Positional accuracy

High-quality spindle bearings, precise assembly, and effective lubrication are the foundation of stable performance.

Rigidity of Radial Arm and Column

During heavy drilling, the radial arm must remain completely stable. Any deformation or vibration will cause:

-

Hole deviation

-

Tool chatter

-

Inconsistent depth

A well-designed radial drilling machine uses reinforced cast iron structure to ensure long-term rigidity.

Clamping Mechanism Accuracy

The locking systems of:

-

Radial arm

-

Spindle box

-

Column

must provide firm and repeatable positioning. Weak clamping force is one of the most common reasons for poor precision in old or poorly maintained machines.

Operational Factors Influencing Drilling Accuracy

Even the best radial drilling machine cannot guarantee high precision without correct operation.

Proper Tool Selection

Different materials require different tools:

-

HSS drills

-

Carbide drills

-

Coated drills

Selecting the right drill bit diameter, material, and geometry is the first step toward accurate hole processing.

Correct Speed and Feed Rate

Excessive speed may cause:

-

Overheating

-

Tool wear

-

Poor surface quality

Too slow feed can lead to:

-

Work hardening

-

Low efficiency

Operators must adjust spindle speed and feed rate according to material and hole size.

Workpiece Fixing

A radial drilling machine often processes large workpieces. Improper fixing will result in:

-

Vibration

-

Hole offset

-

Safety risks

Using professional clamps and fixtures is essential to maintain precision.

Maintenance – The Hidden Key to Long-Term Precision

Many users focus only on machine price and ignore daily maintenance. In fact, precision loss is mostly caused by:

-

Lack of lubrication

-

Loose components

-

Worn bearings

-

Dust and chip accumulation

Daily Maintenance Checklist

-

Clean chips after every shift

-

Lubricate spindle and guideways

-

Check clamping mechanism

-

Inspect electrical system

-

Verify spindle runout periodically

A well-maintained radial drilling machine can maintain its original accuracy for many years.

How ALPHA Ensures Precision in Every Radial Drilling Machine

As a professional machinery manufacturer, ALPHA designs every radial drilling machine with precision as the first priority:

-

High-rigidity casting structure

-

Precision-ground spindle system

-

Reliable hydraulic clamping

-

Stable feed transmission

-

Strict quality inspection before delivery

These features ensure that our machines deliver:

-

Higher drilling accuracy

-

Longer service life

-

Lower maintenance cost

-

Better return on investment

Industries That Benefit Most from High-Precision Radial Drilling Machines

ALPHA radial drilling machines are widely used in:

-

Mechanical processing

-

Steel structure fabrication

-

Energy equipment

-

Mining machinery

-

Automotive components

-

Heavy equipment manufacturing

Wherever large and accurate hole processing is required, the radial drilling machine is an irreplaceable solution.

Frequently Asked Questions

Q1: What is a radial drilling machine used for?

A: It is mainly used for drilling, reaming, tapping, and boring large or heavy workpieces that cannot be easily moved.

Q2: How to improve drilling accuracy on a radial drilling machine?

A: Accuracy can be improved by stable clamping, correct speed/feed settings, high-quality tools, and regular machine maintenance.

Q3: What materials can be processed by a radial drilling machine?

A: It can process steel, cast iron, aluminum, copper, and various alloy materials.

Q4: How often should a radial drilling machine be maintained?

A: Daily cleaning and lubrication are recommended, with comprehensive inspection every 3–6 months.

Q5: Why does hole deviation occur during drilling?

A: Common reasons include poor workpiece fixing, spindle wear, incorrect tool selection, or excessive vibration.

Conclusion

The radial drilling machine is one of the most practical and powerful machines in metalworking workshops. However, only when structural stability, correct operation, and regular maintenance are combined can its real precision be fully utilized.

Focusing on machining accuracy is not just about producing better holes – it is about improving overall product quality and reducing manufacturing costs.

At ALPHA, we are committed to providing high-performance radial drilling machines that help customers achieve reliable and precise drilling results in every application.

If you need professional radial drilling solutions or technical support, feel free to contact us for more information.