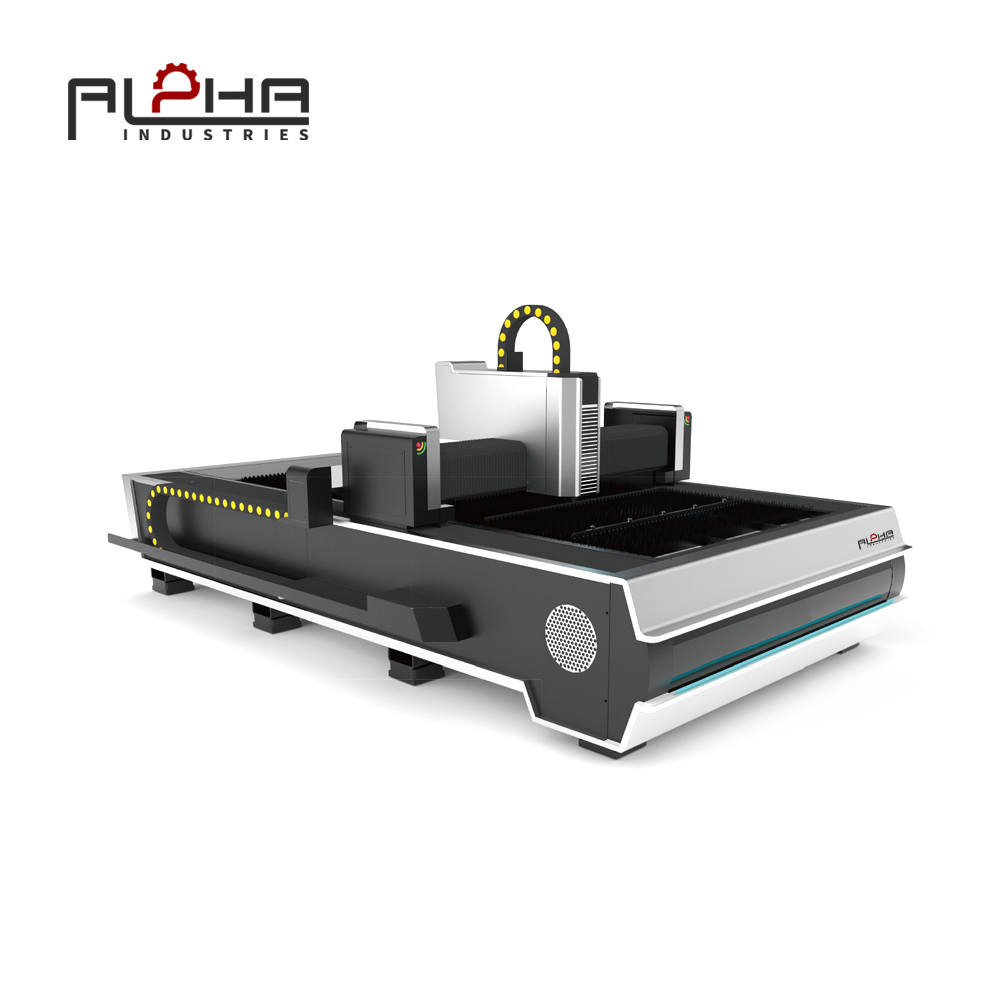

High-Precision Laser Cutting Technology for Industrial Sheet Metal

Laser cutting has become the foundation of modern metal fabrication, offering unmatched precision, efficiency, and versatility. At ALPHA, our industrial laser cutting systems are designed to meet the highest standards of dimensional accuracy and productivity — enabling manufacturers to achieve clean edges, complex geometries, and minimal material waste across all types of sheet metal.

Working Principle of Laser Cutting

Laser cutting operates through the high-energy beam concentration of a fiber laser source, which melts, burns, or vaporizes the targeted area with micron-level control. The focused laser beam — combined with assist gases such as oxygen or nitrogen — ensures thermal stability and smooth edge formation.

At ALPHA, our systems utilize:

-

Fiber Laser Generators for energy efficiency and beam consistency

-

High-Speed Servo Drives to synchronize cutting motion

-

Dynamic Focus Control to maintain beam precision during complex contours

-

CNC Smart Control Systems for real-time cutting optimization

This integration of optical, mechanical, and digital technologies ensures high-speed processing without compromising quality.

Technical Advantages of ALPHA Laser Cutting Systems

Superior Cutting Accuracy

ALPHA’s machines achieve tolerances within ±0.02mm, ensuring repeatable results across mass production runs. The laser head’s automatic focus adjustment adapts instantly to material thickness changes, improving productivity.

High-Speed Production Efficiency

Our fiber laser cutters deliver cutting speeds up to 140m/min, significantly outperforming conventional plasma or mechanical cutting systems. This makes them ideal for high-volume industrial environments.

Clean Edge Quality

By eliminating mechanical stress and tool wear, laser cutting produces burr-free edges, reducing post-processing time and improving overall surface finish.

Versatility for Multiple Metals

The ALPHA laser cutting machine supports a wide range of materials:

-

Carbon steel up to 25mm

-

Stainless steel up to 20mm

-

Aluminum alloy up to 16mm

-

Copper and brass up to 10mm

This adaptability makes it suitable for industries like automotive manufacturing, aerospace, electrical enclosures, and precision machinery.

Smart Integration and Digital Monitoring

ALPHA integrates smart machining technology for real-time performance tracking and preventive maintenance. Our IoT-enabled platform monitors:

-

Cutting parameters and gas consumption

-

Laser head temperature and optical alignment

-

Predictive alerts for component wear

Through Industry 4.0 connectivity, users gain full visibility into production performance and cost efficiency, ensuring maximum uptime and consistency.

Energy Efficiency and Environmental Benefits

Unlike traditional mechanical cutting, fiber laser systems consume less power while minimizing waste. ALPHA’s systems feature:

-

Energy-efficient laser sources reducing power use by 30–40%

-

Closed-loop cooling systems for optimal thermal management

-

Smoke extraction and filtration units ensuring a cleaner workspace

These sustainability-driven innovations help manufacturers comply with global green manufacturing standards.

Applications of Laser Cutting in Modern Manufacturing

Laser cutting plays a vital role in sectors that demand precision and flexibility:

-

Automotive Components – precise cutting of car body panels and exhaust parts

-

Aerospace Structures – thin-wall aluminum and titanium components

-

Industrial Equipment – customized enclosures and sheet metal casings

-

Architectural Metalwork – intricate decorative panels and signage

Each application benefits from ALPHA’s customizable cutting systems, engineered for stability and continuous operation.

Why Choose ALPHA Laser Cutting Machines

-

Precision Engineered: Built with rigid structures to eliminate vibration.

-

Global Standards: Certified to CE and ISO quality regulations.

-

Service Support: Comprehensive training, installation, and lifetime technical assistance.

-

Customizable Design: Tailored configurations for various materials and power levels (1kW–20kW).

At ALPHA, we are dedicated to helping clients achieve production excellence through innovation, automation, and precision cutting solutions.

Frequently Asked Questions

Q1: What materials can be cut with ALPHA’s laser cutting machine?

ALPHA laser cutters can handle carbon steel, stainless steel, aluminum, brass, and copper with precision, supporting various industrial needs.

Q2: What is the difference between fiber laser and CO₂ laser cutting?

Fiber lasers provide higher energy efficiency, lower maintenance, and faster cutting speeds compared to CO₂ lasers, making them ideal for modern metal processing.

Q3: How does laser cutting improve production quality?

Laser cutting ensures smooth, burr-free edges and consistent dimensional accuracy, minimizing rework and improving overall product quality.

Q4: What power level should I choose for my production?

Power levels depend on material thickness and productivity goals. ALPHA experts help select the most cost-effective laser source between 1kW and 20kW.

Q5: Does ALPHA provide after-sales technical support?

Yes, ALPHA offers full installation guidance, operator training, remote diagnostics, and lifetime maintenance services.

Conclusion

Laser cutting represents the future of metal fabrication, combining speed, precision, and sustainability.

At ALPHA, we deliver advanced laser solutions engineered for industrial-grade reliability and productivity.

Explore more of our high-performance machinery: