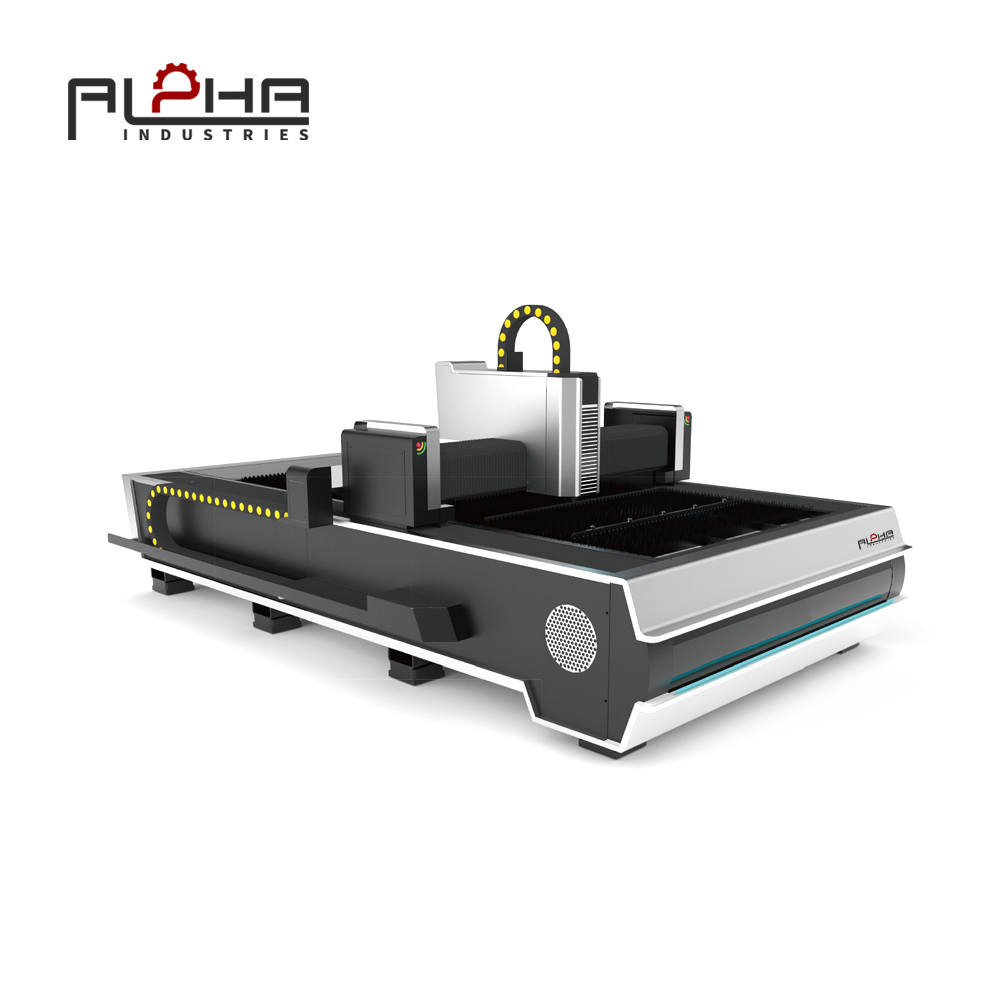

Precision Meets Efficiency

Laser cutting is a non-contact, high-precision cutting technology that uses a focused high-energy laser beam to melt, vaporize, or burn away material, enabling complex shapes with minimal waste. Alpha laser cutting machines are engineered for high precision and high efficiency, capable of cutting stainless steel, carbon steel, aluminum, copper, and titanium, widely applied in automotive, electronics, machinery, aerospace, and architectural industries.

Key advantages over traditional mechanical cutting:

-

Ultra-high cutting precision (±0.05 mm)

-

Smooth edges with minimal secondary finishing

-

Complex contours and small hole cutting

-

High-volume production efficiency

The Core Challenge: Balancing Speed and Accuracy

The main challenge in industrial laser cutting is maintaining precision while increasing cutting speed. High-speed cutting can cause:

-

Larger heat-affected zones (HAZ)

-

Edge micro-cracks or burrs

-

Slight angle deviations

Alpha laser cutting machines solve this with beam power modulation, precision CNC control, and a high-rigidity frame, ensuring consistent dimensions and smooth edges at high throughput.

Fiber Laser Technology: Efficiency Driver

Alpha uses fiber laser sources for:

-

High beam quality: minimal focus diameter, maximum precision

-

High energy efficiency: up to 30% power conversion efficiency

-

Low maintenance: minimal optical component replacement

-

Material versatility: suitable for thin and medium-thick metals

Fiber laser technology achieves high-speed production while maintaining micrometer-level accuracy.

CNC Integration and Automation

Equipped with high-precision CNC control, Alpha machines enable:

-

Automated cutting path optimization

-

Multi-axis motion for complex parts

-

Digital production monitoring, reducing human error

-

MES/ERP integration for smart manufacturing

CNC automation allows unattended continuous operation, dramatically improving production efficiency.

Heat Management & Quality Control

Alpha laser cutting machines manage thermal effects through:

-

Fast cutting head movement to reduce local heat accumulation

-

Assist gas for cooling and molten material removal

-

Real-time beam power adjustment according to sheet thickness

Resulting in smooth edges, high dimensional accuracy, and minimal HAZ.

Applications of High-Precision Laser Cutting

Alpha laser cutting machines are widely used in:

-

Automotive: body panels, exhaust components

-

Electronics & Electrical: control panels, precision connectors

-

Aerospace: titanium and light-alloy components

-

Architectural & Decorative: stainless steel engraving, metal panels

-

Mechanical Parts: gears, housings, precision components

They enable complex shape cutting and high-volume production simultaneously.

Advantages Over Traditional Cutting

| Feature | Laser Cutting | Mechanical Cutting |

|---|---|---|

| Contact | Non-contact | Contact cutting |

| Edge Quality | Smooth, no burr | Rough, may require secondary finishing |

| Accuracy | ±0.05 mm | ±0.2 mm or worse |

| Material Waste | Minimal | Higher |

| Complexity | Complex shapes easily | Limited by tooling |

Alpha laser cutting machines reduce production costs while improving consistency and flexibility.

Alpha Quality Control & Testing

Each Alpha laser cutting machine undergoes:

-

Laser beam power uniformity tests

-

CNC path accuracy verification

-

Heat-affected zone minimization

-

Long-duration continuous cutting test

-

Assist gas system calibration

Ensuring industrial-grade precision immediately on delivery.

FAQ

Q1: What metals can the laser cutting machine cut?

Stainless steel, carbon steel, aluminum, copper, titanium, and alloy materials.

Q2: How does laser cutting differ from traditional cutting?

Laser cutting is non-contact, produces smooth edges, high precision, requires no secondary finishing, and is more efficient.

Q3: How is cutting thick vs thin material different?

Thin sheets allow high-speed cutting; thick sheets require careful power and speed adjustment to maintain accuracy.

Q4: How does the machine achieve high precision?

Through fiber laser sources, high-rigidity frame, CNC path control, and assist gas cooling.

Q5: Can it run fully automated for batch production?

Yes, it supports MES/ERP integration for unattended continuous operation.

If your production requires high-precision, high-efficiency metal cutting with automation, Alpha laser cutting machines are your ideal solution.

👉 Explore Alpha Metal Processing Equipment:

-

CNC Lathe Slant – High-precision turning solution

-

Vertical Machining Center – Multi-axis milling system

-

Press Brake Machine – Long-sheet precision bending

-

Drilling & Milling Machine – Dual-function machining

-

Surface Grinder – Ultra-fine finishing accuracy