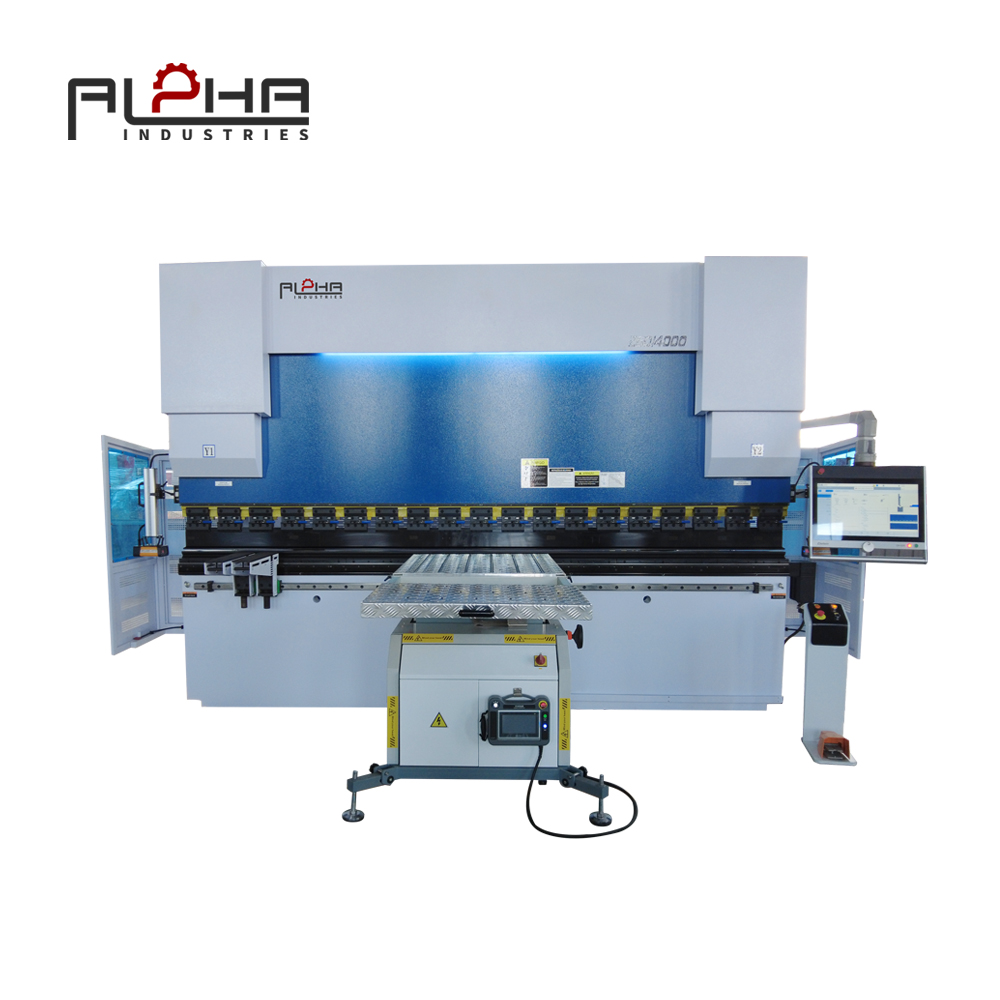

Press Brake Crowning System for High-Precision Sheet Metal Bending

In sheet metal fabrication, achieving consistent bending angles across the entire working length is one of the biggest technical challenges. As bending force increases, the press brake frame and ram naturally deflect, leading to angle deviation—especially in long workpieces. A press brake crowning system is the core solution to this problem.

At Alpha, we engineer press brakes with advanced crowning systems to guarantee stable, repeatable bending accuracy for demanding industrial applications.

What Is a Press Brake Crowning System?

A press brake crowning system is a precision compensation mechanism designed to offset machine deflection during bending. By applying controlled counter-deformation to the ram or table, the system ensures that bending force is evenly distributed along the full length of the tooling.

Without effective crowning, even a rigid press brake can produce inconsistent angles—tight in the center and open at the ends.

Why Deflection Compensation Is Critical in Press Brake Bending

During bending, the press brake frame behaves like a beam under load. As tonnage increases:

-

The ram bends downward in the center

-

The table deflects upward

-

Tool alignment changes microscopically

These small deformations can result in visible angle variation. A press brake deflection compensation system actively corrects this behavior in real time.

Types of Press Brake Crowning Systems

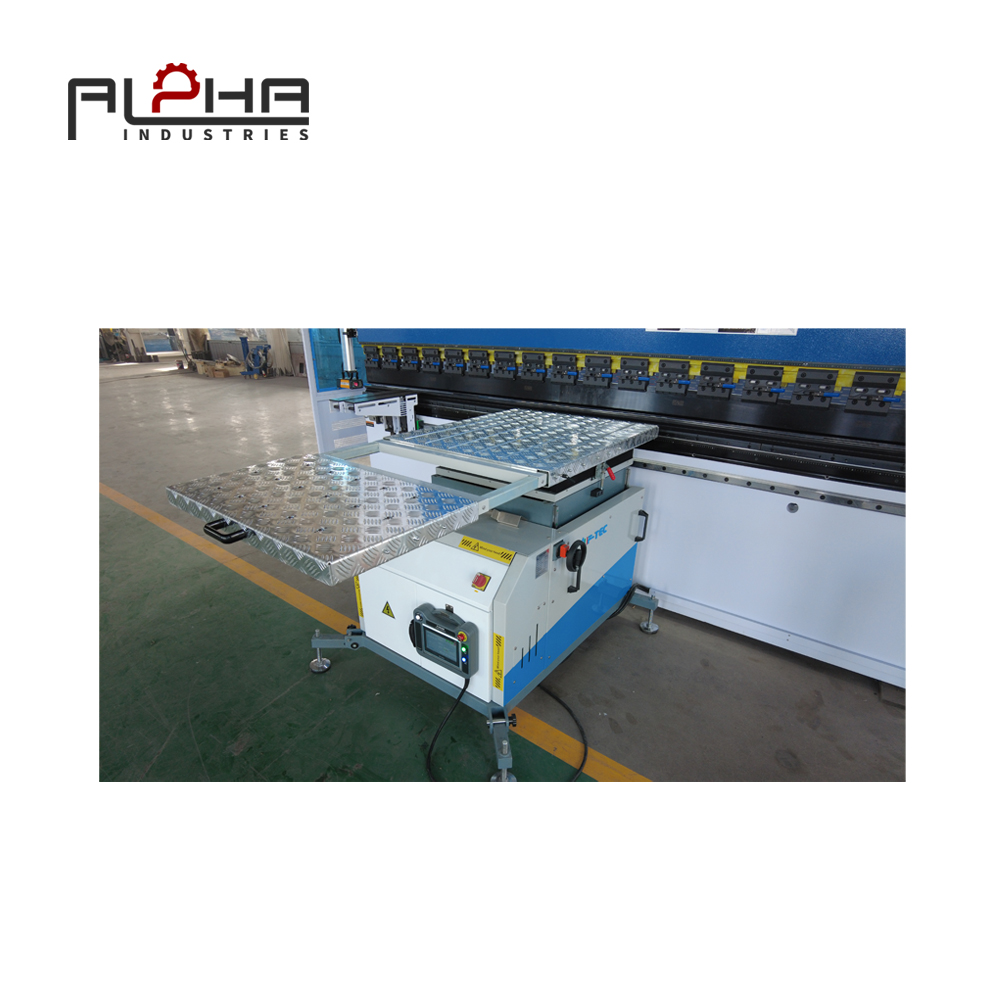

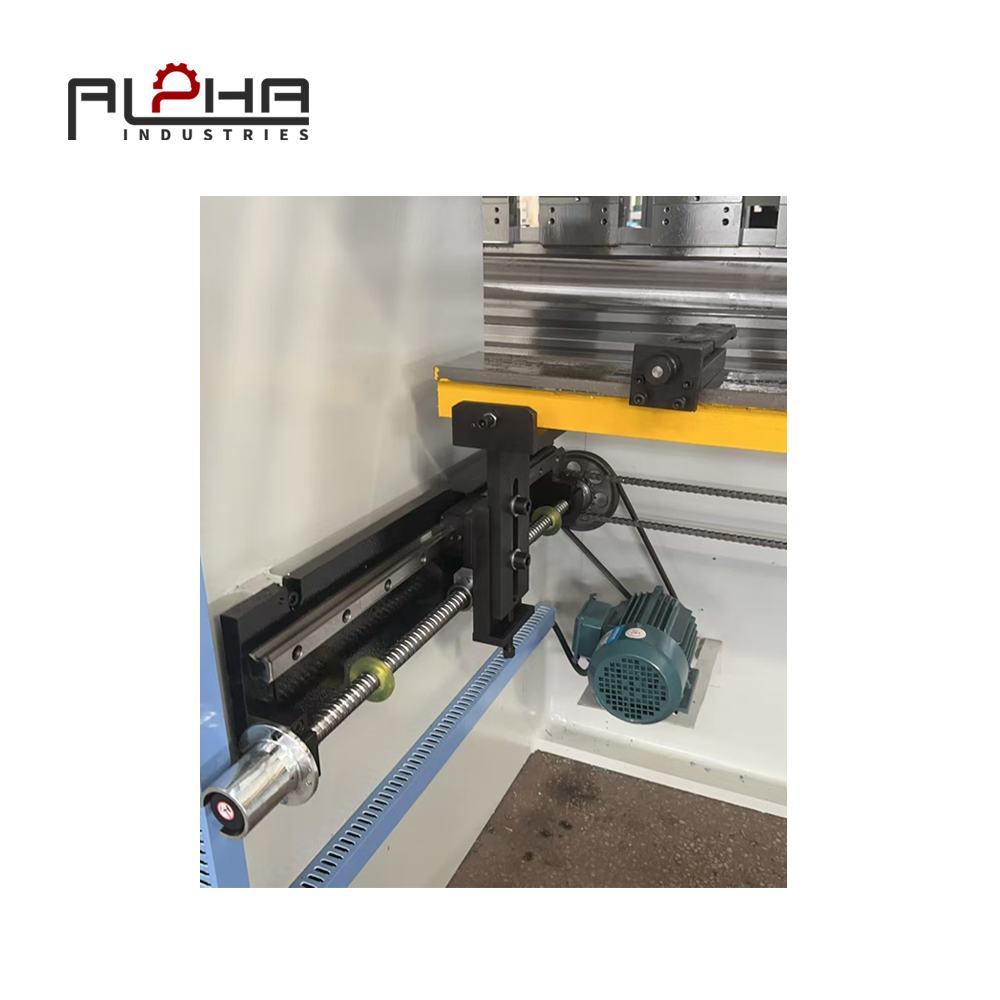

Mechanical Crowning System

Mechanical crowning uses wedges or adjustable bars installed beneath the lower die. Manual or motorized adjustments create a predefined crowning curve. This solution is stable and cost-effective for standard production.

Hydraulic Crowning System

A hydraulic crowning press brake uses multiple hydraulic cylinders distributed along the table. Pressure is precisely controlled to match bending force, providing dynamic and highly accurate compensation.

Hydraulic crowning is ideal for:

-

Long bending lengths

-

Variable material thickness

-

High-precision production environments

Technical Advantages of Alpha Press Brake Crowning Solutions

Alpha integrates crowning systems as a core structural design, not as an afterthought.

Key technical benefits include:

-

High-resolution compensation accuracy

-

Seamless CNC synchronization

-

Automatic adjustment based on material and length

-

Long-term stability under heavy load

Our systems are designed to maintain bending accuracy even after years of continuous operation.

How Crowning Improves Bending Quality and Productivity

With a properly configured press brake crowning system:

-

First-bend accuracy is significantly improved

-

Fewer test bends are required

-

Scrap rate is reduced

-

Tool wear becomes more uniform

This directly translates into higher productivity and lower overall production cost.

Application Scenarios for Press Brake Crowning Systems

Crowning systems are essential in industries such as:

-

Electrical cabinet and enclosure manufacturing

-

Elevator and construction components

-

Automotive structural parts

-

Long sheet metal profiles and panels

For manufacturers producing long or thick parts, crowning is not optional—it is fundamental.

FAQ

Does every press brake need a crowning system?

For short bending lengths and thin materials, crowning impact may be minimal. However, for industrial production involving long parts or high tonnage, a crowning system is strongly recommended.

Is hydraulic crowning more accurate than mechanical crowning?

Yes. Hydraulic crowning provides real-time, adaptive compensation and higher precision, especially for variable bending conditions.

Can crowning systems be automatically controlled by CNC?

Modern press brakes, including Alpha machines, allow CNC-controlled crowning that adjusts automatically according to bending parameters.

Why Choose Alpha Press Brakes With Advanced Crowning Systems?

Alpha focuses on precision engineering, structural rigidity, and intelligent control. Our press brake crowning systems are designed to work in harmony with the machine frame, CNC system, and tooling.

By choosing Alpha, customers gain:

-

Consistent bending accuracy

-

Reduced setup time

-

Higher production efficiency

-

Long-term equipment reliability