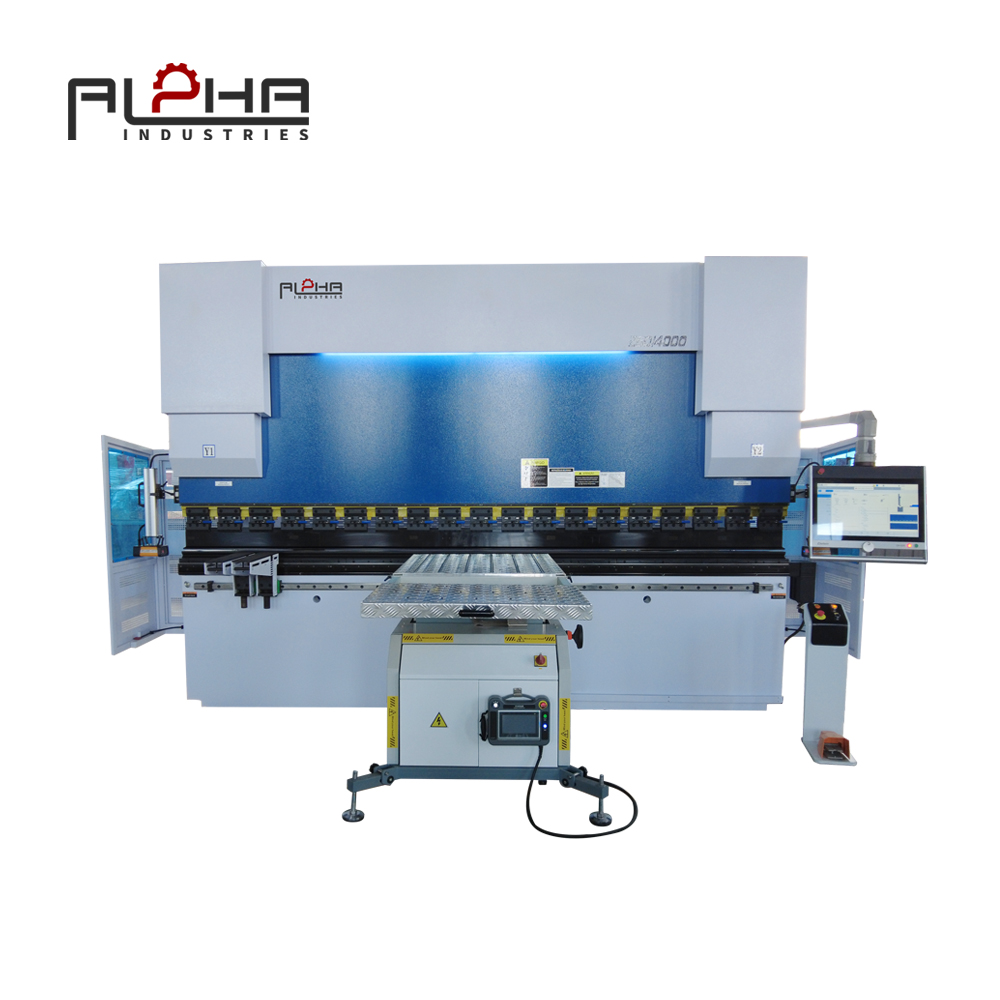

Press Brake Hydraulic System Stability for Precision Sheet Metal Bending

In press brake operation, bending accuracy is not determined by mechanics alone. The hydraulic system plays a decisive role in controlling force, speed, and repeatability. Any instability in hydraulic pressure or flow directly affects bending angle consistency, surface quality, and machine lifespan. Therefore, press brake hydraulic system stability is the foundation of reliable sheet metal forming.

At Alpha, hydraulic system design is treated as a core engineering discipline rather than a simple power source.

What Defines Hydraulic System Stability in a Press Brake?

Hydraulic stability refers to the ability of the system to maintain constant pressure, synchronized cylinder movement, and predictable response under varying loads.

A stable press brake hydraulic system ensures:

-

Smooth ram movement without vibration

-

Consistent bending force across repeated cycles

-

Accurate response to CNC commands

Without stability, even a rigid press brake frame cannot achieve precise bending results.

Key Factors Affecting Press Brake Hydraulic Stability

Hydraulic Circuit Design

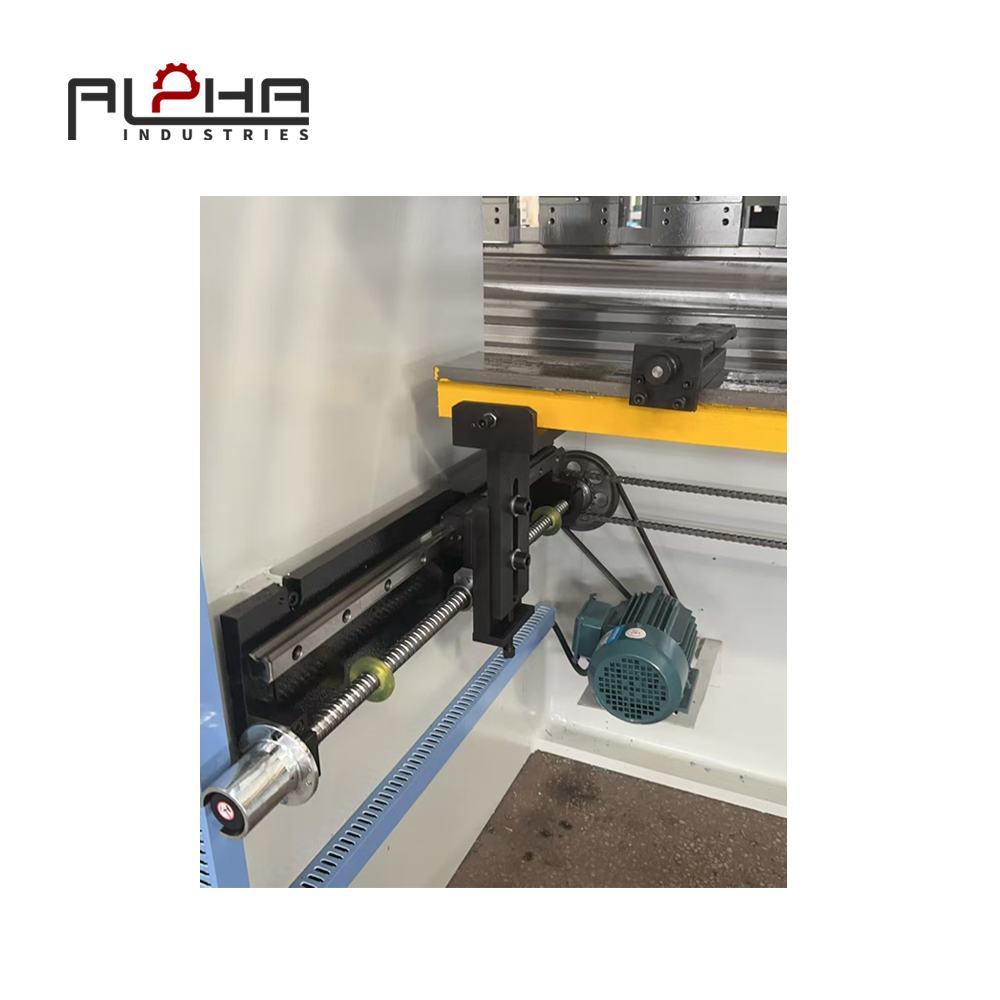

Balanced circuit layouts minimize pressure loss and ensure equal oil distribution to both cylinders. Poor circuit design can cause ram tilting and uneven bending force.

Oil Pressure and Flow Control

Stable pressure regulation valves and proportional flow control are essential for maintaining constant bending force throughout the stroke.

Temperature Control and Oil Quality

Hydraulic oil viscosity changes with temperature. Effective cooling systems and filtration maintain stable oil performance and reduce component wear.

Synchronized Cylinder Control and Its Impact on Accuracy

Modern press brakes rely on dual hydraulic cylinders. Precise synchronization between left and right cylinders is critical to prevent angular deviation.

Alpha press brakes use advanced hydraulic balancing combined with CNC monitoring to ensure:

-

Parallel ram movement

-

Uniform force distribution

-

Long-term positioning accuracy

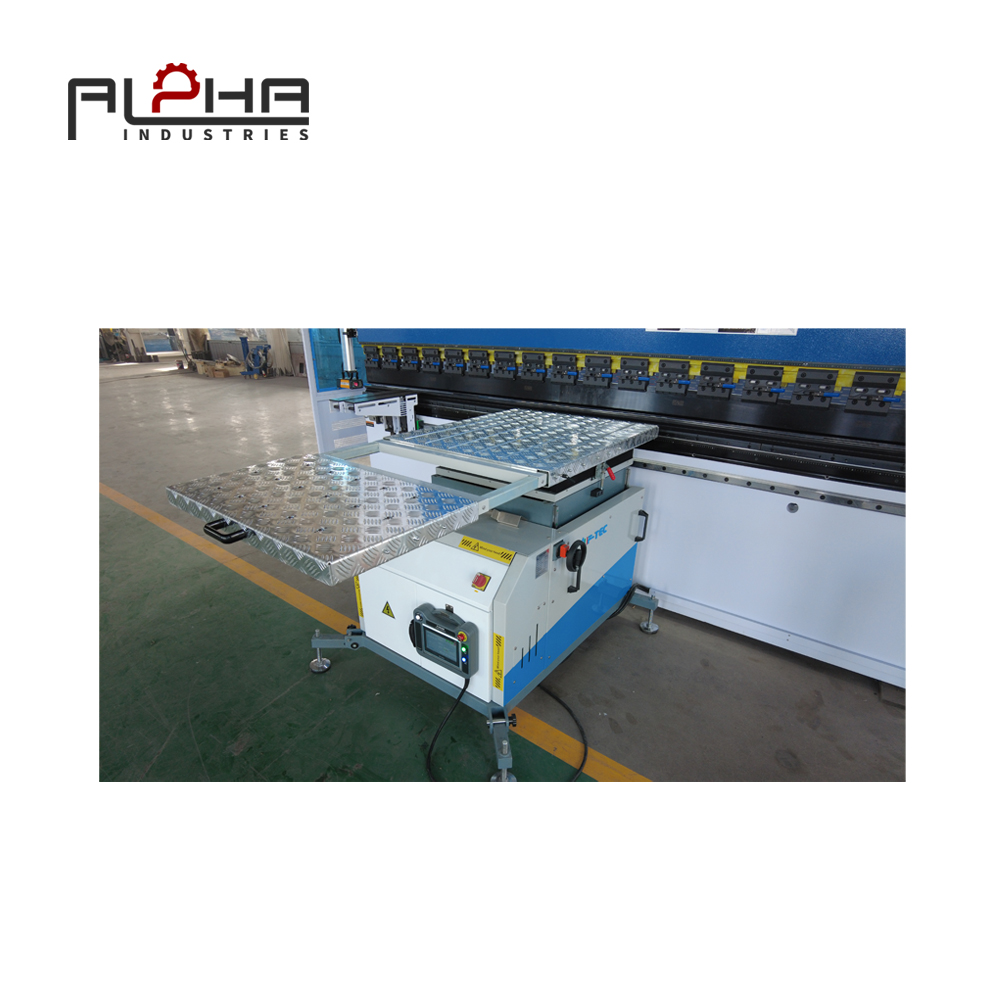

This synergy directly improves bending consistency for long and thick workpieces.

Technical Advantages of Alpha Hydraulic System Design

Alpha integrates hydraulic stability into every stage of press brake engineering.

Key advantages include:

-

High-response proportional hydraulic valves

-

Closed-loop pressure feedback systems

-

Optimized oil flow paths to reduce turbulence

-

Industrial-grade sealing components for long service life

These features ensure stable performance even under continuous high-load operation.

How Hydraulic Stability Improves Productivity and Machine Life

A stable press brake hydraulic system delivers tangible production benefits:

-

Fewer angle corrections and test bends

-

Reduced mechanical stress on frame and tooling

-

Lower maintenance frequency

-

Consistent quality across long production runs

This stability directly lowers total cost of ownership for manufacturers.

Application Scenarios Requiring High Hydraulic Stability

Hydraulic stability is especially critical in:

-

High-tonnage bending applications

-

Thick plate forming

-

Long workpiece production

-

Precision components with tight angle tolerances

For these scenarios, hydraulic instability is not acceptable—it becomes a production risk.

FAQ

How does hydraulic instability affect bending accuracy?

Unstable pressure or unsynchronized cylinders can cause angle variation, surface defects, and inconsistent part quality.

Can CNC control compensate for poor hydraulic stability?

CNC systems rely on stable hydraulic response. Without hydraulic stability, CNC compensation becomes unreliable.

How can hydraulic system life be extended?

Proper filtration, temperature control, and high-quality components significantly extend hydraulic system lifespan.

Why Choose Alpha Press Brakes With Stable Hydraulic Systems?

Alpha designs press brake hydraulic systems with a focus on long-term stability, precise control, and industrial reliability. Our approach ensures that hydraulic performance supports—not limits—bending accuracy.

Choosing Alpha means:

-

Stable bending force

-

Reliable long-term operation

-

Reduced downtime and maintenance

-

Predictable production quality

Learn more about Alpha press brake solutions:

For technical consultation or quotations, please visit: