Introduction to Horizontal Machining Centers

When it comes to industrial machining, the **horizontal machining center** is an essential piece of equipment for precise and efficient production. These advanced tools are designed to meet the rigorous demands of various industries, ensuring top-notch performance and delivering high-quality outputs. In this article, we will explore the benefits of CNC horizontal machining, its applications, and why investing in a precision machining center like the HMC-50 is a smart choice.

What Makes CNC Horizontal Machining Revolutionary?

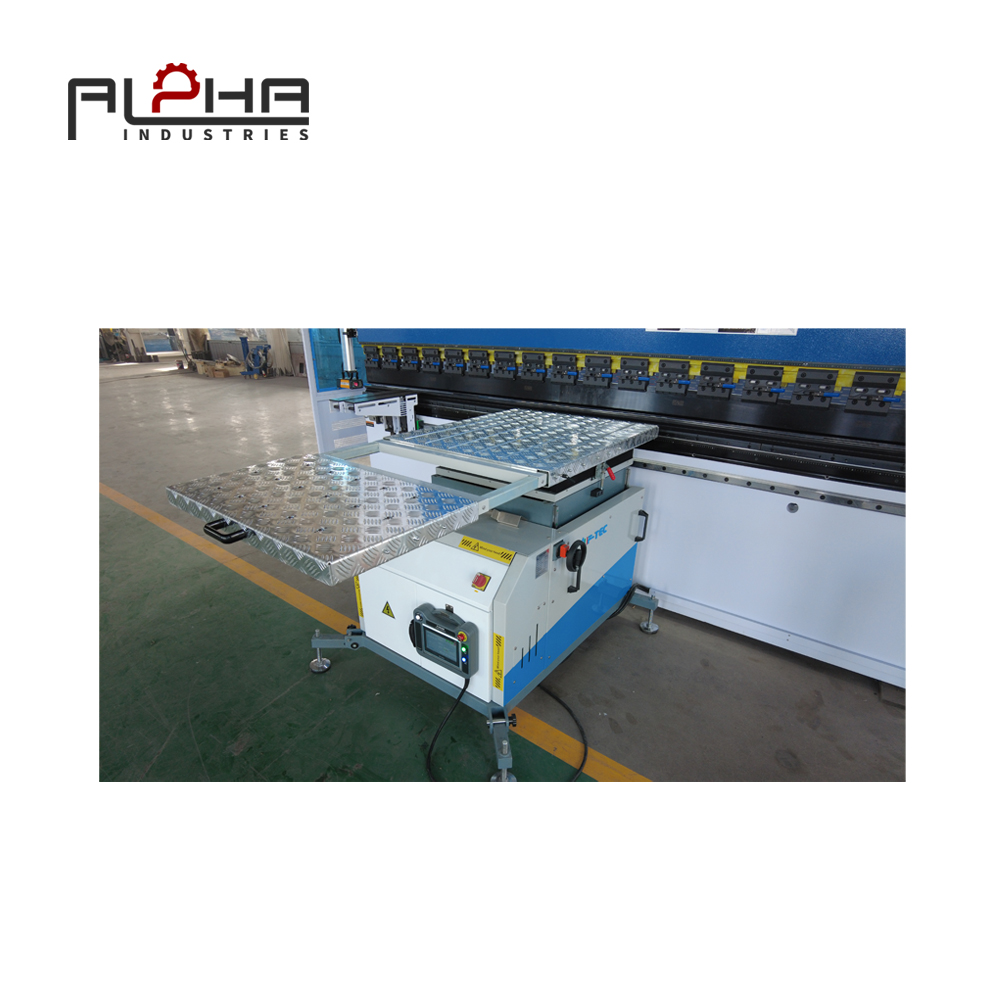

CNC horizontal machining is changing the face of modern manufacturing. By automating and streamlining complex machining tasks, these centers bring unparalleled accuracy and efficiency to the production floor. The **Alpha HMC-50 Smart Horizontal Machining Center** exemplifies this innovation by offering advanced controls, compact design, heavy-duty performance, and future-ready features. Manufacturers can tackle materials like aluminum and steel effortlessly while ensuring consistency for even the most intricate designs. Plus, its integrated features like automated chip conveyors and dynamic cooling systems make operations smoother and more cost-effective.

Applications and Benefits of Precision Machining Centers

Precision machining centers are widely used across industries, including automotive, aerospace, and heavy machinery manufacturing. The versatility of these centers, especially when equipped with tooling options compatible with a range of drills and mills, ensures they can adapt to various production needs. Investing in a product like the HMC-50 allows companies to produce complex geometries with extreme accuracy, reducing errors and boosting productivity. Furthermore, their reliable performance under high-capacity workloads is vital for businesses aiming to meet tight schedules.

Why Choose Horizontal Machining Center Manufacturers like Nanjing Alpha CNC Co., Ltd?

When selecting a machining center, partnering with an experienced manufacturer is crucial. **Nanjing Alpha CNC Co., Ltd** stands out by providing solutions that go beyond machinery sales. Their world-class R&D team ensures every machine, like the HMC-50, aligns with cutting-edge technologies and industry standards. From single units to complete production lines, their prompt customer support and safe shipments make them a trusted choice globally. Moreover, their ability to integrate machines into smart manufacturing ecosystems ensures future-proof solutions for businesses.

Custom Horizontal Machining Solutions for Your Business

Customization is key in today’s competitive manufacturing landscape, and Alpha offers tailored solutions to meet unique business requirements. The HMC-50, designed with minimalistic yet robust aesthetics and powerful functionality, reflects this commitment. Its user-friendly touchscreen interface allows operators to manage operations with ease, adapting to project demands in real time. This versatility, combined with Alphas’ dedication to customer satisfaction, makes their machines reliable tools for any production environment.

Conclusion: Elevate Your Production with the HMC-50

The **Alpha HMC-50 Smart Horizontal Machining Center** is not just a machine; it’s a transformative solution for precision manufacturing. Combining advanced features, efficiency, and heavy-duty performance, it stands as a testament to Alpha Industries’ expertise and innovation. Whether you are a small workshop or a global manufacturing facility, a horizontal machining center like the HMC-50 is indispensable for staying ahead in the competitive market.

Investing in world-class equipment from trusted manufacturers like Alpha ensures consistent quality, customer support, and enhanced productivity. Discover the possibilities today and let the HMC-50 redefine your production capabilities.